Professional Documents

Culture Documents

Air-Torque Dimensions PT200

Air-Torque Dimensions PT200

Uploaded by

Lailatul MufidaCopyright:

Available Formats

You might also like

- Audi A6 C6 Basic Equipment Wiring Diagrams 09.2008Document34 pagesAudi A6 C6 Basic Equipment Wiring Diagrams 09.2008Вадим Пушкарский100% (2)

- Air TorqueDocument1 pageAir TorqueJagannathNo ratings yet

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDocument5 pagesPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Air-Torque Dimensions PT300Document1 pageAir-Torque Dimensions PT300adil_farooq_6No ratings yet

- TME-20 CouplingDocument1 pageTME-20 Couplingdebashis ghosemohapatraNo ratings yet

- Stefano-Planta TechoDocument1 pageStefano-Planta Techoyosebajartangas2005No ratings yet

- DC30a5P, 12V DC, 10rpm, 300.1 Ratio, OJ Shaft (A30CD2N5P30BOJR00)Document1 pageDC30a5P, 12V DC, 10rpm, 300.1 Ratio, OJ Shaft (A30CD2N5P30BOJR00)sampada.khopadeNo ratings yet

- PALET ADJ-HK Rev 1Document1 pagePALET ADJ-HK Rev 1AgungNo ratings yet

- Medidas CimientoDocument1 pageMedidas Cimientoing.yael.castilloNo ratings yet

- Punch Trimming 307Document1 pagePunch Trimming 307Sasa MonicaNo ratings yet

- 8 A1 No Angle: Created ApprovedDocument8 pages8 A1 No Angle: Created ApprovedwaleednazarNo ratings yet

- 1.5 X 45° CH TYP: Isometric ViewDocument1 page1.5 X 45° CH TYP: Isometric ViewChandru ChristurajNo ratings yet

- PJ 2000213601Document1 pagePJ 2000213601karan singh solankiNo ratings yet

- Interior Lighting Range Rover 2006Document3 pagesInterior Lighting Range Rover 2006Febina MisriyaNo ratings yet

- Depropanizer Debutanizer: LPG Unit 12.1,2,3 Pressure & TempDocument3 pagesDepropanizer Debutanizer: LPG Unit 12.1,2,3 Pressure & Tempbeshoy naseefNo ratings yet

- Ntroduction: +D FjahDocument16 pagesNtroduction: +D FjahFiroj AlamNo ratings yet

- L.O.W L.O.W: For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-015Document1 pageL.O.W L.O.W: For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-015naveenNo ratings yet

- N Noz Zzle MM Mannhoole: IT TEM D9503Document17 pagesN Noz Zzle MM Mannhoole: IT TEM D9503giovanni perozziNo ratings yet

- Pipe Sleeper-Ps2Document1 pagePipe Sleeper-Ps2dennyherdanathaNo ratings yet

- Semiconductor KRC241S KRC246S: Technical DataDocument5 pagesSemiconductor KRC241S KRC246S: Technical DataAron OrtencioNo ratings yet

- Ilovepdf MergedDocument12 pagesIlovepdf MergedSeptianNo ratings yet

- Estructuras 1Document1 pageEstructuras 1Coinpi Constructora e InmboliariaNo ratings yet

- A0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - LeftDocument2 pagesA0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - Leftjavahz74No ratings yet

- Penthouse Floor Area PF1 ISO .PDF 06.10.2020Document1 pagePenthouse Floor Area PF1 ISO .PDF 06.10.2020Fed ValdezNo ratings yet

- Axe CameDocument1 pageAxe CameChokri AtefNo ratings yet

- FT-MPD-177-2024 - Rev - Fabricação API Blind FlangeDocument6 pagesFT-MPD-177-2024 - Rev - Fabricação API Blind FlangeLuan OliveiraNo ratings yet

- Planta 1da EvalDocument1 pagePlanta 1da Evalyair.angeles134No ratings yet

- Conector BurdnyDocument1 pageConector BurdnyjoseNo ratings yet

- Af AgDocument1 pageAf Agphamvantienqn1234No ratings yet

- Draw 2Document1 pageDraw 2dinoardianto2526No ratings yet

- Uf - Gia: CV-CV (1:1.5)Document1 pageUf - Gia: CV-CV (1:1.5)Eduardo RodriguezNo ratings yet

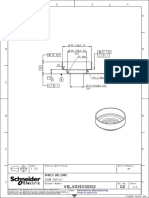

- VSLVG14030102 02Document1 pageVSLVG14030102 02Baljeet SinghNo ratings yet

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDocument1 pageSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNo ratings yet

- Dibujo PlotDocument1 pageDibujo PlotUriel J CrNo ratings yet

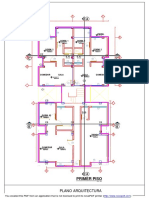

- Plano Arq Piso 1Document1 pagePlano Arq Piso 1Said Kalef Paucar CuriNo ratings yet

- Model: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanDocument2 pagesModel: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanJoseph DavidNo ratings yet

- Honda K20A Conrod PDFDocument1 pageHonda K20A Conrod PDFJohnJulienGraymondNo ratings yet

- Stump MeasurementDocument1 pageStump MeasurementSyida KamaruddinNo ratings yet

- General Information Cavity: Type Series: ALDocument2 pagesGeneral Information Cavity: Type Series: ALarabiangulf.limitedNo ratings yet

- Wheel Pop-1Document1 pageWheel Pop-1joeuneloveNo ratings yet

- Tctl-U (RLLB) Terminales de Compresión IDocument1 pageTctl-U (RLLB) Terminales de Compresión Ijavier SuarezNo ratings yet

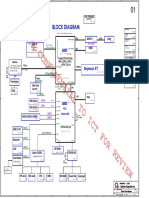

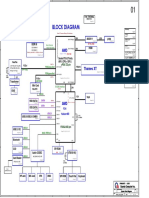

- Block Diagram: DDR IiiDocument51 pagesBlock Diagram: DDR Iiijoe wiillsonNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- PJ 2000171591Document1 pagePJ 2000171591karan singh solankiNo ratings yet

- 34.sun Tracking Solar PanelDocument1 page34.sun Tracking Solar PanelMahi JoshNo ratings yet

- Tuerca 1-1-1 2HDocument1 pageTuerca 1-1-1 2Hcomercial 3No ratings yet

- PLANTADocument1 pagePLANTAing.yael.castilloNo ratings yet

- Mass Scale Part NoDocument1 pageMass Scale Part Nopoochselvam57No ratings yet

- 02 - Renforcement PoutreDocument1 page02 - Renforcement PoutreZakaria KchiriNo ratings yet

- Instalacion P.BDocument1 pageInstalacion P.BhernandezmunozlisandroNo ratings yet

- Gearmotor Key 10x8Document1 pageGearmotor Key 10x8Sek PyroNo ratings yet

- Quanta LZ3C Rev 2a - Lenovo Ideapad z585Document51 pagesQuanta LZ3C Rev 2a - Lenovo Ideapad z585Raj kishorNo ratings yet

- Flow Systems and SolutionsDocument3 pagesFlow Systems and SolutionsAndres JaramilloNo ratings yet

- Niv 01 PDFDocument1 pageNiv 01 PDFJF YanhyNo ratings yet

- KRC104S-RTK PDocument6 pagesKRC104S-RTK PGlam BarberiaNo ratings yet

- Engr. Jehan Y. Luces Engr. Angie Rose B. Gico: Typical Plan ViewDocument1 pageEngr. Jehan Y. Luces Engr. Angie Rose B. Gico: Typical Plan ViewShiela Jane MananquilNo ratings yet

- PLANO METRADOS ModelDocument1 pagePLANO METRADOS ModelMinos QuitaNo ratings yet

- Techint Ingeniería Y Construcción: Tc13-PendareDocument7 pagesTechint Ingeniería Y Construcción: Tc13-PendareJeisson RozoNo ratings yet

- PLANTA BAJA Esc:1/75 PLANTA ALTA Esc:1/75: Jardin Lavanderia Dormitorio 02 BalconDocument1 pagePLANTA BAJA Esc:1/75 PLANTA ALTA Esc:1/75: Jardin Lavanderia Dormitorio 02 BalconchristianNo ratings yet

- Mazak Robot Interface EIPDocument3 pagesMazak Robot Interface EIPTensaigaNo ratings yet

- PaintsDocument14 pagesPaintsBarshat KhakurelNo ratings yet

- QR 0109 Fire Pumps Sensing LinesDocument1 pageQR 0109 Fire Pumps Sensing LinesStory LoveNo ratings yet

- Civil Engineering Department, NITK, SurathkalDocument6 pagesCivil Engineering Department, NITK, SurathkalPremanand ShenoyNo ratings yet

- Airpollution Unit 1Document11 pagesAirpollution Unit 1Tabrez AhmedNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Ces ManualsDocument8 pagesCes Manualslosmoscasbr-1No ratings yet

- Valvula Mariposa 705 VictaulicDocument7 pagesValvula Mariposa 705 Victaulicrvalentino2012No ratings yet

- Overview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplDocument6 pagesOverview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplSami SyedNo ratings yet

- Sensors PDFDocument192 pagesSensors PDFAsith SavindaNo ratings yet

- Compressed Air Purification ProductsDocument28 pagesCompressed Air Purification Productsherysyam1980No ratings yet

- Waste Water Management April 2019Document4 pagesWaste Water Management April 2019Narendra maddulurNo ratings yet

- Guia de Proveedores de PinturasDocument28 pagesGuia de Proveedores de PinturasEDGrog100% (1)

- 2pf OptibendDocument1 page2pf OptibendElaine JohnsonNo ratings yet

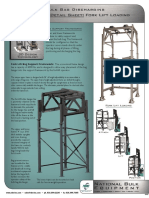

- Fork Lift LoadingDocument1 pageFork Lift LoadingkaliNo ratings yet

- Part Xi-Electrical EquipmentDocument123 pagesPart Xi-Electrical EquipmenttonyNo ratings yet

- Industrial Synthesis of Formic AcidDocument15 pagesIndustrial Synthesis of Formic Acidworlds tour100% (2)

- Ceramic Tile InstallationDocument4 pagesCeramic Tile InstallationAjit Singh RathoreNo ratings yet

- IFFCO Report.Document43 pagesIFFCO Report.Harsh DesaiNo ratings yet

- 393 Thermal Performance of TransformersDocument105 pages393 Thermal Performance of Transformersepri100% (2)

- Material Safety Data Sheet Surfa Activator D (Long)Document3 pagesMaterial Safety Data Sheet Surfa Activator D (Long)Fabrication PMCNo ratings yet

- Manual Masina de Spalat Rufe Beko 8 KGDocument71 pagesManual Masina de Spalat Rufe Beko 8 KGPerfectreviewNo ratings yet

- Investigation of The Mechanical Properties of Thermal Bonded Nonwoven Composite Produced of Blends With Sustainable FibersDocument6 pagesInvestigation of The Mechanical Properties of Thermal Bonded Nonwoven Composite Produced of Blends With Sustainable FibersHea TherNo ratings yet

- TuringMachine Expanders 1.1Document14 pagesTuringMachine Expanders 1.1Nico PinealNo ratings yet

- Dyeing or Finishing DefectsDocument1 pageDyeing or Finishing DefectsMianAbrarAnjumNo ratings yet

- Reciprocating Compressor PDFDocument16 pagesReciprocating Compressor PDFshan4600No ratings yet

- Standard DWG For Box Cell CulvertDocument623 pagesStandard DWG For Box Cell CulvertKothapalliGuruManiKantaNo ratings yet

- 2-Lubricants CharacteristcsDocument30 pages2-Lubricants CharacteristcsHariajahNo ratings yet

- Types of BathtubDocument2 pagesTypes of BathtubNudrat FatimaNo ratings yet

- AlphaFlo® - Warman Slurry Pump Parts List InterchangeableDocument39 pagesAlphaFlo® - Warman Slurry Pump Parts List InterchangeableAlphaFlo0% (1)

Air-Torque Dimensions PT200

Air-Torque Dimensions PT200

Uploaded by

Lailatul MufidaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air-Torque Dimensions PT200

Air-Torque Dimensions PT200

Uploaded by

Lailatul MufidaCopyright:

Available Formats

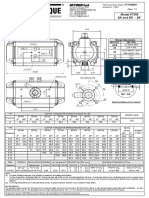

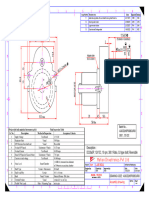

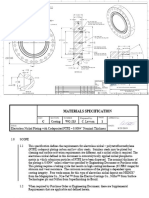

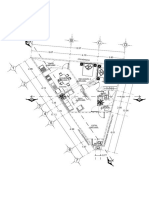

AIR TORQUE S.p.A.

S.p.A Technical Data Sheet n° PT200DU

via Alla Campagna, N°1 Issued on: 12/04

24060 Costa di Mezzate (Bg) Italy Page: 1/1

Tel.: +39 035 682299

Fax: +39 035 687791

E-mail: info@airtorque.it Model PT200

DA and SR - 90°

Dimensions in inch

Flange Dimensions

ISO 5211 F05 + F07

d2 f8 1,38 (Only F05)

d3 1,97 + 2,76

1/4-20UNC x 0,35

d4

5/16-18UNC x 0,47

H 1,38

Ch 0,55

I min. 0,63

h min. 0,06

h1 0,08

Pressure connection N1

Ancillary Attachment AA 1

F05+ F07

Spigot available only on request

TYPE OUTPUT TORQUE FOR DOUBLE ACTING IN FT-LBS

WEIGHT (LBS)

40 Psi 50 Psi 60 Psi 70 Psi 80 Psi 90 Psi 100 Psi 116 Psi

Pressure

0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90°

6,53

D 23,7 29,6 35,5 41,4 47,3 53,3 59,2 68,6

TYPE OUTPUT TORQUE FOR SPRING RETURN IN FT-LBS Spring

40 Psi 50 Psi 60 Psi 70 Psi 80 Psi 90 Psi 100 Psi 116 Psi stroke WEIGHT

Pressure 90° 0° ( LBS )

0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90° 0° 90°

Start End

S 05 15,5 10,9 21,4 16,8 27,4 22,7 33,3 28,7 39,2 34,6 45,1 40,5 51,0 46,4 60,5 55,9 12,8 8,2 6,90

S 06 13,9 8,4 19,8 14,3 25,7 20,2 31,6 26,1 37,6 32 43,5 37,9 49,4 43,9 58,9 53,3 15,3 9,8 6,98

S 07 12,3 5,8 18,2 11,7 24,1 17,6 30 23,6 35,9 29,5 41,8 35,4 47,8 41,3 57,2 50,8 17,9 11,4 7,05

S 08 16,5 9,2 22,5 15,1 28,4 21 34,3 26,9 40,2 32,8 46,1 38,7 55,6 48,2 20,4 13 7,13

S 09 14,9 6,6 20,8 12,5 26,7 18,4 32,7 24,4 38,6 30,3 44,5 36,2 54 45,7 23 14,7 7,20

S 10 19,2 10 25,1 15,9 31 21,8 37 27,7 42,9 33,6 52,3 43,1 25,5 16,3 7,28

S 11 17,6 7,4 23,5 13,3 29,4 19,3 35,3 25,2 41,2 31,1 50,7 40,6 28,1 17,9 7,35

S 12 21,9 10,8 27,8 16,7 33,7 22,6 39,6 28,5 49,1 38 30,6 19,6 7,43

3

Max. Rotation Screw stroke Chamber Air Volume (in ) Moving Time (Sec.) ( A ) Operating Temperature (°F) ( B )

Pressure Adjustment φ (inch) Opening Closing Opening Closing STD (standard) HT (high temperature) LT (low temperature)

90° ±4° For 1° adj. D 0,30 D 0,35 NBR "O" ring FPM "O" ring Silicone "O" ring

116 Psi at 0° and 90° need 1/6 Turn 2,95 18,9 29,9 S 0,40 S 0,50 - 4 to + 176 + 5 to + 300 - 40 to + 176

Notes:

(A) The above indicated moving time of the actuator, are obtained in the following test conditions:

(1) Room Temperature, (2) Actuator Stroke 90°, (3) Solenoid Valve with Orifice Of 4 mm and a flow capacity Qn 400 L/min., (4) Inside pipe diameter 8 mm, (5) Medium clean air, (6) Air supply pressure

5,5 bar (79,75 Psi), (7) Actuator without external resistance load. Cautions: obviously on the field applications when one or more of the above parameter are different, the moving time will be

different.

(B) For HT (high temperature) and LT (low temperature) services, a special Lubricant is requested. Please contact Air Torque factory.

Operating Medium:

The operating medium must be free of dust and oil. The maximum particle size must not exceed 30µm (ISO 8573 Part1, Class5). In order to prevent water condensation and/or solidification – ice, when

actuator work below 0°C (32°F) – the operating medium must have a dew point equal to –20°C (– 4°F) or, at least 10°C below the ambient temperature (ISO 8573 Part1, Class3).

This drawing is property of AIR TORQUE S.p.A. Costa di Mezzate - Italy and all rights of use and reproduction are reserved.

This data sheet is general in nature and manufacturer reserves the right to alter materials or to make other improvements from time to time

You might also like

- Audi A6 C6 Basic Equipment Wiring Diagrams 09.2008Document34 pagesAudi A6 C6 Basic Equipment Wiring Diagrams 09.2008Вадим Пушкарский100% (2)

- Air TorqueDocument1 pageAir TorqueJagannathNo ratings yet

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDocument5 pagesPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Air-Torque Dimensions PT300Document1 pageAir-Torque Dimensions PT300adil_farooq_6No ratings yet

- TME-20 CouplingDocument1 pageTME-20 Couplingdebashis ghosemohapatraNo ratings yet

- Stefano-Planta TechoDocument1 pageStefano-Planta Techoyosebajartangas2005No ratings yet

- DC30a5P, 12V DC, 10rpm, 300.1 Ratio, OJ Shaft (A30CD2N5P30BOJR00)Document1 pageDC30a5P, 12V DC, 10rpm, 300.1 Ratio, OJ Shaft (A30CD2N5P30BOJR00)sampada.khopadeNo ratings yet

- PALET ADJ-HK Rev 1Document1 pagePALET ADJ-HK Rev 1AgungNo ratings yet

- Medidas CimientoDocument1 pageMedidas Cimientoing.yael.castilloNo ratings yet

- Punch Trimming 307Document1 pagePunch Trimming 307Sasa MonicaNo ratings yet

- 8 A1 No Angle: Created ApprovedDocument8 pages8 A1 No Angle: Created ApprovedwaleednazarNo ratings yet

- 1.5 X 45° CH TYP: Isometric ViewDocument1 page1.5 X 45° CH TYP: Isometric ViewChandru ChristurajNo ratings yet

- PJ 2000213601Document1 pagePJ 2000213601karan singh solankiNo ratings yet

- Interior Lighting Range Rover 2006Document3 pagesInterior Lighting Range Rover 2006Febina MisriyaNo ratings yet

- Depropanizer Debutanizer: LPG Unit 12.1,2,3 Pressure & TempDocument3 pagesDepropanizer Debutanizer: LPG Unit 12.1,2,3 Pressure & Tempbeshoy naseefNo ratings yet

- Ntroduction: +D FjahDocument16 pagesNtroduction: +D FjahFiroj AlamNo ratings yet

- L.O.W L.O.W: For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-015Document1 pageL.O.W L.O.W: For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-015naveenNo ratings yet

- N Noz Zzle MM Mannhoole: IT TEM D9503Document17 pagesN Noz Zzle MM Mannhoole: IT TEM D9503giovanni perozziNo ratings yet

- Pipe Sleeper-Ps2Document1 pagePipe Sleeper-Ps2dennyherdanathaNo ratings yet

- Semiconductor KRC241S KRC246S: Technical DataDocument5 pagesSemiconductor KRC241S KRC246S: Technical DataAron OrtencioNo ratings yet

- Ilovepdf MergedDocument12 pagesIlovepdf MergedSeptianNo ratings yet

- Estructuras 1Document1 pageEstructuras 1Coinpi Constructora e InmboliariaNo ratings yet

- A0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - LeftDocument2 pagesA0431-01-02 - Bio-Sea - Uv - Reactor - (Flange) - Leftjavahz74No ratings yet

- Penthouse Floor Area PF1 ISO .PDF 06.10.2020Document1 pagePenthouse Floor Area PF1 ISO .PDF 06.10.2020Fed ValdezNo ratings yet

- Axe CameDocument1 pageAxe CameChokri AtefNo ratings yet

- FT-MPD-177-2024 - Rev - Fabricação API Blind FlangeDocument6 pagesFT-MPD-177-2024 - Rev - Fabricação API Blind FlangeLuan OliveiraNo ratings yet

- Planta 1da EvalDocument1 pagePlanta 1da Evalyair.angeles134No ratings yet

- Conector BurdnyDocument1 pageConector BurdnyjoseNo ratings yet

- Af AgDocument1 pageAf Agphamvantienqn1234No ratings yet

- Draw 2Document1 pageDraw 2dinoardianto2526No ratings yet

- Uf - Gia: CV-CV (1:1.5)Document1 pageUf - Gia: CV-CV (1:1.5)Eduardo RodriguezNo ratings yet

- VSLVG14030102 02Document1 pageVSLVG14030102 02Baljeet SinghNo ratings yet

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDocument1 pageSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNo ratings yet

- Dibujo PlotDocument1 pageDibujo PlotUriel J CrNo ratings yet

- Plano Arq Piso 1Document1 pagePlano Arq Piso 1Said Kalef Paucar CuriNo ratings yet

- Model: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanDocument2 pagesModel: G-070-VG: Direct Drive Centrifugal Roof Exhaust FanJoseph DavidNo ratings yet

- Honda K20A Conrod PDFDocument1 pageHonda K20A Conrod PDFJohnJulienGraymondNo ratings yet

- Stump MeasurementDocument1 pageStump MeasurementSyida KamaruddinNo ratings yet

- General Information Cavity: Type Series: ALDocument2 pagesGeneral Information Cavity: Type Series: ALarabiangulf.limitedNo ratings yet

- Wheel Pop-1Document1 pageWheel Pop-1joeuneloveNo ratings yet

- Tctl-U (RLLB) Terminales de Compresión IDocument1 pageTctl-U (RLLB) Terminales de Compresión Ijavier SuarezNo ratings yet

- Block Diagram: DDR IiiDocument51 pagesBlock Diagram: DDR Iiijoe wiillsonNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- PJ 2000171591Document1 pagePJ 2000171591karan singh solankiNo ratings yet

- 34.sun Tracking Solar PanelDocument1 page34.sun Tracking Solar PanelMahi JoshNo ratings yet

- Tuerca 1-1-1 2HDocument1 pageTuerca 1-1-1 2Hcomercial 3No ratings yet

- PLANTADocument1 pagePLANTAing.yael.castilloNo ratings yet

- Mass Scale Part NoDocument1 pageMass Scale Part Nopoochselvam57No ratings yet

- 02 - Renforcement PoutreDocument1 page02 - Renforcement PoutreZakaria KchiriNo ratings yet

- Instalacion P.BDocument1 pageInstalacion P.BhernandezmunozlisandroNo ratings yet

- Gearmotor Key 10x8Document1 pageGearmotor Key 10x8Sek PyroNo ratings yet

- Quanta LZ3C Rev 2a - Lenovo Ideapad z585Document51 pagesQuanta LZ3C Rev 2a - Lenovo Ideapad z585Raj kishorNo ratings yet

- Flow Systems and SolutionsDocument3 pagesFlow Systems and SolutionsAndres JaramilloNo ratings yet

- Niv 01 PDFDocument1 pageNiv 01 PDFJF YanhyNo ratings yet

- KRC104S-RTK PDocument6 pagesKRC104S-RTK PGlam BarberiaNo ratings yet

- Engr. Jehan Y. Luces Engr. Angie Rose B. Gico: Typical Plan ViewDocument1 pageEngr. Jehan Y. Luces Engr. Angie Rose B. Gico: Typical Plan ViewShiela Jane MananquilNo ratings yet

- PLANO METRADOS ModelDocument1 pagePLANO METRADOS ModelMinos QuitaNo ratings yet

- Techint Ingeniería Y Construcción: Tc13-PendareDocument7 pagesTechint Ingeniería Y Construcción: Tc13-PendareJeisson RozoNo ratings yet

- PLANTA BAJA Esc:1/75 PLANTA ALTA Esc:1/75: Jardin Lavanderia Dormitorio 02 BalconDocument1 pagePLANTA BAJA Esc:1/75 PLANTA ALTA Esc:1/75: Jardin Lavanderia Dormitorio 02 BalconchristianNo ratings yet

- Mazak Robot Interface EIPDocument3 pagesMazak Robot Interface EIPTensaigaNo ratings yet

- PaintsDocument14 pagesPaintsBarshat KhakurelNo ratings yet

- QR 0109 Fire Pumps Sensing LinesDocument1 pageQR 0109 Fire Pumps Sensing LinesStory LoveNo ratings yet

- Civil Engineering Department, NITK, SurathkalDocument6 pagesCivil Engineering Department, NITK, SurathkalPremanand ShenoyNo ratings yet

- Airpollution Unit 1Document11 pagesAirpollution Unit 1Tabrez AhmedNo ratings yet

- 4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsDocument1 page4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi MetalsidontlikeebooksNo ratings yet

- Ces ManualsDocument8 pagesCes Manualslosmoscasbr-1No ratings yet

- Valvula Mariposa 705 VictaulicDocument7 pagesValvula Mariposa 705 Victaulicrvalentino2012No ratings yet

- Overview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplDocument6 pagesOverview: Behavior of Adhesive Bonded Anchors: Ronald A. Cook Rolf Eligehausen Jörg J. ApplSami SyedNo ratings yet

- Sensors PDFDocument192 pagesSensors PDFAsith SavindaNo ratings yet

- Compressed Air Purification ProductsDocument28 pagesCompressed Air Purification Productsherysyam1980No ratings yet

- Waste Water Management April 2019Document4 pagesWaste Water Management April 2019Narendra maddulurNo ratings yet

- Guia de Proveedores de PinturasDocument28 pagesGuia de Proveedores de PinturasEDGrog100% (1)

- 2pf OptibendDocument1 page2pf OptibendElaine JohnsonNo ratings yet

- Fork Lift LoadingDocument1 pageFork Lift LoadingkaliNo ratings yet

- Part Xi-Electrical EquipmentDocument123 pagesPart Xi-Electrical EquipmenttonyNo ratings yet

- Industrial Synthesis of Formic AcidDocument15 pagesIndustrial Synthesis of Formic Acidworlds tour100% (2)

- Ceramic Tile InstallationDocument4 pagesCeramic Tile InstallationAjit Singh RathoreNo ratings yet

- IFFCO Report.Document43 pagesIFFCO Report.Harsh DesaiNo ratings yet

- 393 Thermal Performance of TransformersDocument105 pages393 Thermal Performance of Transformersepri100% (2)

- Material Safety Data Sheet Surfa Activator D (Long)Document3 pagesMaterial Safety Data Sheet Surfa Activator D (Long)Fabrication PMCNo ratings yet

- Manual Masina de Spalat Rufe Beko 8 KGDocument71 pagesManual Masina de Spalat Rufe Beko 8 KGPerfectreviewNo ratings yet

- Investigation of The Mechanical Properties of Thermal Bonded Nonwoven Composite Produced of Blends With Sustainable FibersDocument6 pagesInvestigation of The Mechanical Properties of Thermal Bonded Nonwoven Composite Produced of Blends With Sustainable FibersHea TherNo ratings yet

- TuringMachine Expanders 1.1Document14 pagesTuringMachine Expanders 1.1Nico PinealNo ratings yet

- Dyeing or Finishing DefectsDocument1 pageDyeing or Finishing DefectsMianAbrarAnjumNo ratings yet

- Reciprocating Compressor PDFDocument16 pagesReciprocating Compressor PDFshan4600No ratings yet

- Standard DWG For Box Cell CulvertDocument623 pagesStandard DWG For Box Cell CulvertKothapalliGuruManiKantaNo ratings yet

- 2-Lubricants CharacteristcsDocument30 pages2-Lubricants CharacteristcsHariajahNo ratings yet

- Types of BathtubDocument2 pagesTypes of BathtubNudrat FatimaNo ratings yet

- AlphaFlo® - Warman Slurry Pump Parts List InterchangeableDocument39 pagesAlphaFlo® - Warman Slurry Pump Parts List InterchangeableAlphaFlo0% (1)