Professional Documents

Culture Documents

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Uploaded by

Raul AlexCopyright:

Available Formats

You might also like

- Assetto Corsa Touge Setup GuideDocument4 pagesAssetto Corsa Touge Setup Guideethanjoyce68100% (1)

- Great Plains Parts Manual 1200, 1210, 1220, 1500, 1510, 1520, 2000, 2010 & 2020Document218 pagesGreat Plains Parts Manual 1200, 1210, 1220, 1500, 1510, 1520, 2000, 2010 & 2020a04205No ratings yet

- Dau Terminal AnalysisDocument49 pagesDau Terminal AnalysisMila Zulueta100% (2)

- LPT 709 Parts ListDocument289 pagesLPT 709 Parts ListvipulNo ratings yet

- Samjungtech Parking PDFDocument14 pagesSamjungtech Parking PDFwillyNo ratings yet

- A Semi-Automated Parallel Parking System For Passenger Cars: J PohlDocument13 pagesA Semi-Automated Parallel Parking System For Passenger Cars: J PohlAlexandru IlincaNo ratings yet

- DSP-EL PresentationDocument19 pagesDSP-EL PresentationAditi BardhanNo ratings yet

- SR No Reseach Work Conclusion Name of Author Year of PublicationDocument2 pagesSR No Reseach Work Conclusion Name of Author Year of PublicationtomyNo ratings yet

- Autonomous Self-Parking RobotDocument10 pagesAutonomous Self-Parking RobotTsion NegussieNo ratings yet

- Robot FireDocument5 pagesRobot FireAmirulFarisNo ratings yet

- Automatic Multilevel Car Parking & Controlling System Using PLCDocument3 pagesAutomatic Multilevel Car Parking & Controlling System Using PLCAnonymous kw8Yrp0R5r0% (1)

- An Introduction To Plug-and-Play Motion SubsystemsDocument5 pagesAn Introduction To Plug-and-Play Motion SubsystemsIlija BozovicNo ratings yet

- Vertical Car ParkingDocument5 pagesVertical Car ParkingTanvi Khurana0% (1)

- Sara Van An 2009Document3 pagesSara Van An 2009Arjun JayaprakasNo ratings yet

- 0 ReviewDocument10 pages0 ReviewKural ArasanNo ratings yet

- Presentation IoTDocument21 pagesPresentation IoTMuhammad HamzihNo ratings yet

- Car Parking Space CounterDocument5 pagesCar Parking Space CounterAjith Kumar M100% (1)

- ICSE2018 Rethink EE Architecture in Automotive To Facilitate Automation Connectivity and Electro Mobility 5Document11 pagesICSE2018 Rethink EE Architecture in Automotive To Facilitate Automation Connectivity and Electro Mobility 5Shivaji Bhausaheb ThoratNo ratings yet

- Automatic Headlamp Steering System: Rajesh.GDocument5 pagesAutomatic Headlamp Steering System: Rajesh.GAbhyudayNo ratings yet

- UntitledhdusisDocument15 pagesUntitledhdusisSlim AgentNo ratings yet

- Autonomous Driving Developed With An FPGA DesignDocument4 pagesAutonomous Driving Developed With An FPGA Designrahul rNo ratings yet

- Robotics Challenge Proposal - TEAM NITRO_7, REVA University - IISc ARTPARKDocument10 pagesRobotics Challenge Proposal - TEAM NITRO_7, REVA University - IISc ARTPARKamarkaratagi.sfalNo ratings yet

- Android Based Advanced Car Lifting System Using Bluetooth: August 2017Document6 pagesAndroid Based Advanced Car Lifting System Using Bluetooth: August 2017Just4 FuntechNo ratings yet

- Multi Parking System Fional Project ReportDocument54 pagesMulti Parking System Fional Project ReportVinay MuleyNo ratings yet

- Microcontroller Based Automatic Parking SystemDocument5 pagesMicrocontroller Based Automatic Parking SystemOLivSitanggangNo ratings yet

- B.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARDocument11 pagesB.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARMohammad Tarique Mumtaz100% (1)

- Drive by WireDocument4 pagesDrive by WireanishmohantcrNo ratings yet

- Automated Guided Vehicle With Scissor Lifting Mechanism Using Arduino INO ProgramDocument3 pagesAutomated Guided Vehicle With Scissor Lifting Mechanism Using Arduino INO ProgramInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- IJSTEV2I10004Document6 pagesIJSTEV2I10004Bitthal ParidaNo ratings yet

- Electric Vehicle Wireless Charging Technology On The GoDocument4 pagesElectric Vehicle Wireless Charging Technology On The GoSourav DuttaNo ratings yet

- Robust Yaw Stability Controller Design and Hardware-in-the-Loop Testing For A Road VehicleDocument17 pagesRobust Yaw Stability Controller Design and Hardware-in-the-Loop Testing For A Road Vehiclekishor sahuNo ratings yet

- As Systemmappe Servolectric E Lowres 20150513Document18 pagesAs Systemmappe Servolectric E Lowres 20150513Ahmed SamNo ratings yet

- Co-Simulation of Energy Management Strategy For Hybrid Electric Vehicle in Avl InmotionDocument6 pagesCo-Simulation of Energy Management Strategy For Hybrid Electric Vehicle in Avl InmotionConfidential SinghNo ratings yet

- BoglitchDocument19 pagesBoglitchAgnidipta BasuNo ratings yet

- Line Following RobotDocument5 pagesLine Following RobotsathishNo ratings yet

- Autonomous Car Using Embedded SystemDocument12 pagesAutonomous Car Using Embedded Systemkiran vemulaNo ratings yet

- Pick and Place Robotic Arm: Guided By: Prof. J. N. PathanDocument15 pagesPick and Place Robotic Arm: Guided By: Prof. J. N. PathanPraveen MathiasNo ratings yet

- Servo MotorDocument8 pagesServo MotorEng.Theyazen Al-dubibiNo ratings yet

- RACE Vault Product BrochureDocument17 pagesRACE Vault Product BrochureAbhilashBetanamudiNo ratings yet

- Design and Fabrication of Automobile Reverse Locking Differential MechanismDocument83 pagesDesign and Fabrication of Automobile Reverse Locking Differential MechanismPraveen MathiasNo ratings yet

- ZigbeeDocument37 pagesZigbeeSana AdreesNo ratings yet

- Design and Analysis of Multi Story (G+4) Parking Using Staad-Pro SoftwareDocument5 pagesDesign and Analysis of Multi Story (G+4) Parking Using Staad-Pro SoftwareRishika DixitNo ratings yet

- Universal Power Automatic JackDocument4 pagesUniversal Power Automatic JackSenthilraj Sarangapani100% (1)

- 4 Ujf J&pages 1&min SRC Count 5Document1 page4 Ujf J&pages 1&min SRC Count 5Siyyadula Chandra SekharNo ratings yet

- A Seminar Report ON: Sensor Based Automated CarDocument12 pagesA Seminar Report ON: Sensor Based Automated CarWARRIOR GamingNo ratings yet

- Assad - Dissertation Final PDFDocument20 pagesAssad - Dissertation Final PDFamal roshanNo ratings yet

- Design and Development of Automated Parking Slot: March 2014Document3 pagesDesign and Development of Automated Parking Slot: March 2014Zahara175No ratings yet

- Ai For AutomotivesDocument18 pagesAi For AutomotivesAbhishek SoundaleNo ratings yet

- ABE - EV Chargers - POCO ModelDocument14 pagesABE - EV Chargers - POCO ModelOm ChavanNo ratings yet

- Autonomous Scale Vehicles FOR Road Tracking AND Obstacle AvoidanceDocument8 pagesAutonomous Scale Vehicles FOR Road Tracking AND Obstacle AvoidanceCHAMBITANo ratings yet

- Car Parking With 90° RotationDocument10 pagesCar Parking With 90° RotationIJRASETPublicationsNo ratings yet

- Wada 2013Document4 pagesWada 2013ezhilarasi ezhilarsiNo ratings yet

- Simulation and Real Time Implementation of Motor Controller For 3ph Induction Motor Using MATLAB and dSPACEDocument11 pagesSimulation and Real Time Implementation of Motor Controller For 3ph Induction Motor Using MATLAB and dSPACEShubham PatilNo ratings yet

- A Seminar Report ON: Sensor Based Automated CarDocument12 pagesA Seminar Report ON: Sensor Based Automated CarWARRIOR GamingNo ratings yet

- RACE Vault Product BrochureDocument16 pagesRACE Vault Product BrochureShitanshuNo ratings yet

- Adaptive Head Lamp SystemDocument22 pagesAdaptive Head Lamp SystemAkshay bypNo ratings yet

- PLC Based Multilevel Automatic Car Parking System: Ijireeice IjireeiceDocument3 pagesPLC Based Multilevel Automatic Car Parking System: Ijireeice IjireeiceAliNo ratings yet

- Intelligent Car Parking SystemDocument8 pagesIntelligent Car Parking SystemLeo BoyNo ratings yet

- AbstractDocument2 pagesAbstractchdev007No ratings yet

- Using Exit Time Predictions To Optimize Self Automated Parking LotsDocument6 pagesUsing Exit Time Predictions To Optimize Self Automated Parking LotsOtrebor ZenchasNo ratings yet

- LDRDocument19 pagesLDRAnonymous qh5UUGTNo ratings yet

- Smart Adaptive Vehicle Lighting System: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-8, 2017Document7 pagesSmart Adaptive Vehicle Lighting System: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-8, 2017Mohan RNo ratings yet

- Design and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakeDocument4 pagesDesign and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakePreeti BhamreNo ratings yet

- 6 Carburator Si Kituri de ReparatieDocument5 pages6 Carburator Si Kituri de ReparatieSerban NicolaeNo ratings yet

- Manual Q8Document320 pagesManual Q8Кирилл ИлюшинNo ratings yet

- Entry LIST Speed Test 2 LEBANONDocument2 pagesEntry LIST Speed Test 2 LEBANONnicolashindiNo ratings yet

- Boq No. Particulars Unit BOQ QTY Basic Rate Basic AmountDocument18 pagesBoq No. Particulars Unit BOQ QTY Basic Rate Basic AmountmanojNo ratings yet

- Owner's Handbook Peugeot 505Document97 pagesOwner's Handbook Peugeot 505luki yuspitaNo ratings yet

- A4af A4bfDocument23 pagesA4af A4bfjuan valderramaNo ratings yet

- SSP - 464 The Amarok - Powertrain and Drive ConceptDocument60 pagesSSP - 464 The Amarok - Powertrain and Drive ConceptwurtukukNo ratings yet

- Motor Graders: Engine 120K2 140K2Document6 pagesMotor Graders: Engine 120K2 140K2Akhilesh SinghNo ratings yet

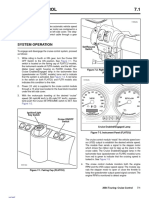

- Cruise Control 7.1: GeneralDocument22 pagesCruise Control 7.1: Generaljose fermin carrozaNo ratings yet

- 1.1 The Project Proponent: EIA GSJ at Pont Fer / Jumbo / Dowlut Roundabouts May 2017 M191/GSJ/3.1Document6 pages1.1 The Project Proponent: EIA GSJ at Pont Fer / Jumbo / Dowlut Roundabouts May 2017 M191/GSJ/3.1Hrithik IGNo ratings yet

- Dok Bike Bed 16 3213412 en Om Sen Aepi v1Document198 pagesDok Bike Bed 16 3213412 en Om Sen Aepi v1lantapanNo ratings yet

- Cylinder Head Part Numbers - ASET™ EnginesDocument2 pagesCylinder Head Part Numbers - ASET™ EnginesHamilton MirandaNo ratings yet

- Mort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementDocument6 pagesMort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementAkshay PendurkarNo ratings yet

- 2017 Renault Clio 104255Document260 pages2017 Renault Clio 104255IngvaldNilsen-NygaardNo ratings yet

- 1 Engine: Error Codes Engine, DescritionDocument12 pages1 Engine: Error Codes Engine, DescritionHAINo ratings yet

- Rear Axle: (Cu1 2 3 TON Series)Document44 pagesRear Axle: (Cu1 2 3 TON Series)Brayan NohNo ratings yet

- FS (O) 10309 Es (O) 1X409 AngDocument2 pagesFS (O) 10309 Es (O) 1X409 AngAnGel AmayaNo ratings yet

- Stadler Kiss DD SBBDocument2 pagesStadler Kiss DD SBBRodrigo Sampaio100% (1)

- Re Spare PartsDocument81 pagesRe Spare Partssubham jaiswalNo ratings yet

- Prices Effective Dated December 01 2013Document41 pagesPrices Effective Dated December 01 2013Ayyaz ShadNo ratings yet

- Railway Budget 2010Document8 pagesRailway Budget 2010jubin654No ratings yet

- Otani 2022Document10 pagesOtani 2022Humbie EspejoNo ratings yet

- Vehicles in The Town TravellingDocument3 pagesVehicles in The Town TravellingD GNo ratings yet

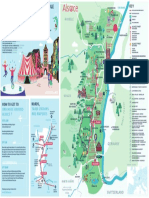

- Touristic Map Alsace Carte Touristique 2018Document1 pageTouristic Map Alsace Carte Touristique 2018Randy GongNo ratings yet

- Study On Platform Gap Fillers For Indian RailwaysDocument3 pagesStudy On Platform Gap Fillers For Indian Railwaysshubham bisaneNo ratings yet

- Suzuki SJ413a PDFDocument4 pagesSuzuki SJ413a PDFRahadi IskandarNo ratings yet

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Uploaded by

Raul AlexOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Intelligent Parallel Parking and Obstacle Avoidance System: Spring 2011 Senior Design Project

Uploaded by

Raul AlexCopyright:

Available Formats

Intelligent Parallel Parking and Obstacle Avoidance System

Spring 2011 Senior Design Project

Abhishek Yadav

Department of Electrical Engineering

University of New Orleans

New Orleans, LA USA

ayadav1@uno.edu

Abstract— The objective of this project is to design and enough for parallel parking and perform the necessary parking

build the Intelligent Parallel Parking and Obstacle Avoidance maneuver into the parking spot. IPPOAS will provide the user

System. The system is comprised of mechanical, navigation, with the ability to drop off the vehicle in the traffic lane and be

microprocessing and power systems installed on a model car. The ensured that the vehicle will park independently without any

system measures an available parking space, checks whether the incidents.

space is large enough for parking, aligns the car correctly in the

traffic lane and then performs the necessary parallel parking IPPOAS is a response to the need for an intelligent parallel

maneuvers into the parking spot. In addition to parallel parking, parking system that can be installed in any four-wheeled

the system can detect static obstacles, like road blocks and vehicle regardless of its make and model.

dynamic obstacles, like pedestrians, in the vehicle’s path. If Curb

dynamic obstacles are detected, the vehicle stops until the

obstacle moves out of the way. If static obstacles are detected, the

vehicle maneuvers around the obstacle ensuring a collision free

trajectory. The project entailed many tasks like mechanical

design and assembly, strategic sensor placement and interfacing,

power regulation and programming. This paper focuses on my

personal contributions to the system design in addition to various Ending

contributions my teammates. Position

Keywords-autonomous vehicle; intelligent parallel parking;

sensors; motor control; dc motor; servo motor; stepper motor

Starting

Position

I. INTRODUCTION

With the development in artificial intelligent industry,

more car manufactures are upgrading their product by adding Figure 1 – Parallel Parking Maneuver

smart technology. One of the important additions to four-

wheeled vehicles is the function of autonomous parallel IPPOAS focuses on robust engineering design, advanced

parking. Manufactures like Toyota, Ford and BMW are adding sensor systems, strategic placement of sensor arrays, efficient

this feature. Due to the need of precisely calculated parallel programming techniques and multiple testing scenarios. Design

parking maneuvers, even experienced drivers find it very requirements for this project are the knowledge of available

difficult to parallel park. Therefore, autonomous parallel sensor technologies, knowledge of the vehicle steering

parking feature is very convenient for drivers. function, knowledge of available microprocessing solutions

and design of parallel parking and obstacle avoidance

The parking system of manufactures like Ford only algorithms.

performs the steering maneuvers and requires the driver

to manually operate the gas pedal. Also, in the presence of an Our goal is to provide intelligent and independent parallel

obstacle, the driver is required to hit the brake manually as seen parking solution. Also, we seek to incorporate obstacle

in [1]. Therefore, there is a need for a parallel parking system detection and obstacle avoidance maneuvers in the traffic lane,

that will completely replace the driver for the purpose of therefore, leading to an increase in the use of autonomous

parallel parking. features in vehicle navigation.

Intelligent Parallel Parking and Obstacle Avoidance System Figure 1 shows the maneuver executed by IPPOAS to

(IPPOAS) is flexible enough to be installed in any four- perform parallel parking. Figure 2 shows the maneuver

wheeled vehicle. IPPOAS can detect obstacles in the traffic performed by IPPOAS in presence of a static obstacle. Also,

lane, maneuver around static obstacles like road blocks, stop the vehicle stops in presence of dynamic obstacle as seen in the

for dynamic obstacles like pedestrians crossing the traffic lane, bottom part of Figure 2.

detect parking space, check whether the parking space is large

introduced a few modifications from our initial design. First of

all, the DC motor provided with the chassis required high

current and power which didn’t meet our design specification.

It required a high current of 2.5 A as seen in [2]; whereas, the

Static Obstacle H-bridge providing the forward and backward drive logic to the

DC motor could not handle current over 1 A as seen in [3].

Also, the speed of the original DC motor was too high for the

purpose of parallel parking. Therefore, we used the back-up

DC motor which was ordered separately. As the back-up DC

motor was considerably smaller in size, we had to design a new

Ending Starting motor mount to secure the new DC motor onto the DC motor

Position Position casing designed for a larger motor. To solve this problem, we

used a plastic housing that would hold the small DC motor into

the larger space. It was fastened to the housing using screws

and washers to eliminate any unwanted wobbling of the motor

body.

Dynamic Next, we finalized the design of the steering motor. While

Obstacle testing the steering motor, we realized that using a servo motor

instead of a stepper motor would suffice for our project. The

stepper motor, as the name suggests, can move in precise steps

and operate in an open loop system as seen in [4]. However, the

stepper motor was too bulky to be used for steering; therefore,

we replaced it with a servo motor bought from a local hobby

Stopping for a

pedestrian store.

After, the completion of the final design, we were ready to

Figure 2 – Obstacle Avoidance assemble these parts and interface them with each other. Figure

3 shows the configuration of individual parts mounted on the

IPPOAS will impart a positive societal impact chassis.

by incorporating innovative, clean and smart technologies to

improve the quality of life of drivers. One major societal

impact of the project is to decrease the frequency of parking

1 8 8 2

accidents and increase the safety and comfort of drivers.

13 7

II. MECHANICAL DESIGN 5

6

A. Initial Design

The tentative design of our project was sketched 3 12 10 11

9

during our Senior Design I class. Since we were focusing less 4

6

on the mechanical system and more on the navigation and

microprocessing system, we decided to purchase a built-in 13 7

chassis that would come with the motor and gear system

already installed. Each task leader prepared a rough draft of his 1 2

system design and these designs were discussed in the team

meeting for approval. After a couple of weeks, the initial design

S. No Components

was completed. Following the initial design, we decided to use 1 Front Wheels

a DC motor to drive the back wheel, a stepper motor to steer 2 Real Wheels

the vehicle, four infrared sensors for obstacle detection (two on 3 Servo Steering Motor

the front and two on the rear), two ultrasonic sensors for 4 DC Motor for Rear-Wheel Drive

5 Gear Box

distance measurement (attached to the right hand side of the 6 Cross-tanked Front IR Sensors

chassis), a microprocessor with at least 6 analog pins, a 7-8 V 7 Cross-tanked Back IR Sensors

battery to power the dc motor and a 5 V USB battery to power 8 Distance sensors

all other components. Based on these criteria we ordered the 9 Microcontroller

10 7.2 V Ni-Cd Battery

parts, and started to build our product. 11 5 V USB Battery

12 Breadboard with H-bridge

B. Final Design 13 Steering Rods

Once we received these parts, we started to test them

individually and finalize our design. The final design phase

Figure 3 – Final Design

Department of Electrical Engineering, The University of New Orleans

III. MECHANICAL ASSEMBLY plastic casing, and attached our motor into the casing using

As the design of our system was finalized, we started to screws. Next, we attached the gear wheel to the motor head,

assemble the individual components. The Tamiya chassis used and tested the motor for the preferred speed.

as the base of the IPPOAS came in separate pieces along with After making sure that the motor was moving at the desired

the instruction manual. Using the manual, and making minor speed, we attached the gear head of the motor to the gear head

modifications, we assembled the pieces together to build the of the gear box. After proper alignment and fitting of the gear

chassis. Next, we mounted the DC motor onto the DC motor heads, we secured the DC motor mount to the chassis using a

housing of the chassis. single long screw.

After mounting the DC motor, we attached the servo motor

on the chassis. The servo motor was then connected to the

adjustable steering rods which connected to the right and left

front tires. The tires were properly aligned such that our vehicle

moved in a straight path by adjusting the length of steering

rods. An important aspect of assembling was to mount the

infrared sensors in a suitable configuration, such that their line

of sight could be adjusted. For mounts, we cut up aluminum

plates into the desired shapes, and mounted them onto strategic

locations on the chassis. The sensors could then be attached

onto these mounts. The ultrasonic sensors were mounted on the

right hand side of the chassis at the center of the vehicle length

using custom made aluminum plate mounts and double tape. Figure 4 – DC Motor Mount

A breadboard and the microprocessor were then attached on

the top of the chassis using double tape. The H-bridge and Figure 5 shows the completed DC motor mount. The

other circuitry were then placed on the breadboard. The circuits picture on the left shows the back of the DC mount with the

for the DC motor, the infrared sensors and the ultrasonic motor attached inside the casing. The picture on the right

sensors were obtained from their datasheets. The servo motor shows the two gear heads fitting together.

and the distance sensors were connected directly to the

microprocessor’s analog pin. Individual sensors and motors

C. Servo Motor and Steering Rods

were provided with an operating voltage of 5V using the USB

battery powering the microprocessor. After finishing the work on the DC motor mount, we

decided to attach the servo motor to the steering rods which

A. Chassis Assembly would control the angle of the front wheels.

The Chassis was assembled by following the directions in

the manual provided by the chassis manufacturer, Tamiya Servo Motor

Racing. Next, the wheels were attached to the chassis. After the

completion of chassis assembly, we moved on to attaching the

DC motor to the gear box of the chassis, which moved the rear

wheels of the vehicle. Figure 4 shows the assembled chassis.

Figure 6 – Servo Motor

We used double sided tape to fix the servo motor on the

space on the chassis provided for a steering motor. Then, the

steering rods were attached to the servo motor. The steering

Figure 4 – Assembled Chassis

rods were adjustable, meaning that, we could alter the length of

B. DC Motor Mount the rods by screwing or unscrewing the plastic head of the

As the DC motor that came with the chassis was not steering rods. This allowed us to properly align the front

suitable for our project, we had to build our own DC motor wheels, making sure that the vehicle would travel in a straight

mount to attach the suitable Polulu dc motor to the gear system line.

which attached to the back wheels. We started with an empty

Figure 6 shows the top view of the servo motor attached to Similarly, the ultrasonic distance sensors were attached to

the steering rods and the front wheels. Figure 7 shows the the right hand side of the chassis using an L-shaped and a

bottom view of the adjustable steering rods attached to the front square-shaped sensor mount made out of aluminum cut-outs.

wheels, using the screw caps.

Steering Rod

Figure 7 – Adjustable Steering Rods

Figure 10 – Ultrasonic Sensor Mounts

D. Sensor Mounts

After completing the assembly of the servo motor and the Figure 10 shows the ultrasonic sensors attached to the

steering rods, we moved on to assemble the sensors onto the sensor mounts, which were attached to the chassis using

chassis. To attach the sensors, we had to design sensor mounts. double sided tape.

We knew we were going to configure the sensors in a cross E. Other Components

tank; therefore, we had to ensure that the sensors would not

After the work on sensor mounts were completed, major

interfere with each other’s line of sight. We chose to cut out

work on assembling the chassis was finished. Next, we

aluminum sheets in a T-shape to make the front sensor mounts. attached various other components like the microprocessor, the

Also, the stem of one sensor mount was made smaller than the breadboard and the batteries to the chassis as appropriate.

other, such that, they would not interfere with each other’s line

of sight. Figure 8 shows the front infrared sensors attached to The microprocessor and the breadboard were placed next to

the sensor mounts, which were attached to the chassis. each other on the middle section of the chassis and attached to

the chassis using a piece of aluminum plate and double sided-

tape. Figure 11 shows the mounted microprocessor and the

breadboard.

Figure 8 – Front Infrared Sensor Mounts Microprocessor

.

Similarly, the sensor mounts for the rear infrared sensors

were cut out in an I-shape. Figure 9 shows one of the two rear

infrared sensors attached to the sensor mount, which was

attached to the chassis.

Breadboard

Figure 9 - Rear Infrared Sensor Mount

Figure 11 – Microprocessor and Breadboard Mount

Next, we placed the 7.2 V Ni-Cd battery, which powered ACKNOWLEDGMENT

the DC motor, in the provided battery housing at the base of the I would like to thank Dr. Parviz Rastgoufard for his

chassis. We placed a cover on the battery, to ensure that the unwavering guidance, motivation, and feedback which were

battery would not be exposed to the outside environment using crucial to project management and completion. Also, I would

the battery cover that came with the chassis. like to thank Dr. Jeffrey Frank Gray for getting my team started

with the project, which gave us a head start with the design

phase. Next, I would like to thank the Department of Electrical

Engineering at The University of New Orleans for partially

funding our project.

I would like to thank Anil Pandey for the design of the

power system. I would like to thank Ajit Gauli for his expertise

Battery Casing with the sensor system. I would like to thank Nischal Basnet

for the long hours spent coding the parallel parking algorithms.

Without the collaboration and hard work of the group

members, this project would never be successful.

Last but not the least, I would like to extend my gratitude to

all my friends and family members, whose interest in the

Battery project provided me the moral support to keep working

consistently on the project.

Figure 12 – Battery Housing REFERENCES

Figure 12 shows the base of the chassis with the battery [1] Ford Motor Company. http://media.ford.com/article_display.cfm?

housing and the battery cover. article_id=29625 [Online]

[2] Mabuchi Motor.

Next, we decided to mount the 5 V USB battery, which http://www.mabuchi-motor.co.jp/en_US/cat_files/rs_540rhsh.pdf

powered all other electronic components, beneath the tail of the [Online]

vehicle. Finally, we attached the vehicle cover on the chassis [3] Texas Instruments. http://focus.ti.com/lit/ds/symlink/sn754410.pdf

using a single screw, which completed the assembly of the [Online]

mechanical system. [4] Solarbotics. http://www.solarbotics.net/library/pdflib/pdf/motorbas.pdf

[Online]

Figure 13 shows the completed mechanical design. It must

be noted that the final mechanical assembly was completed as The template will number citations consecutively within

various components were interfaced with each other and we brackets [1]. The sentence punctuation follows the bracket [2].

had a completely working design. Refer simply to the reference number, as in [3]—do not use

“Ref. [3]” or “reference [3]” except at the beginning of a

sentence: “Reference [3] was the first . . .”

The template will number citations consecutively within

brackets [1]. The sentence punctuation follows the bracket [2].

Refer simply to the reference number, as in [3]—do not use

“Ref. [3]” or “reference [3]” except at the beginning of a

sentence: “Reference [3] was the first . . .”

The template will number citations consecutively within

brackets [1]. The sentence punctuation follows the bracket [2].

Refer simply to the reference number, as in [3]—do not use

“Ref. [3]” or “reference [3]” except at the beginning of a

sentence: “Reference [3] was the first reference [3]” except at

the beginning of a sentence: “Reference [3] was the first . . .”

The template will number citations consecutively within

brackets [1]. The sentence punctuation follows the bracket [2].

Refer simply to the reference number, as in [3]—do not use

Figure 13 – Final Assembled Product “Ref. [3]” or “reference [3]” except at the beginning of a

sentence: “Reference [3] was the first . . .”

You might also like

- Assetto Corsa Touge Setup GuideDocument4 pagesAssetto Corsa Touge Setup Guideethanjoyce68100% (1)

- Great Plains Parts Manual 1200, 1210, 1220, 1500, 1510, 1520, 2000, 2010 & 2020Document218 pagesGreat Plains Parts Manual 1200, 1210, 1220, 1500, 1510, 1520, 2000, 2010 & 2020a04205No ratings yet

- Dau Terminal AnalysisDocument49 pagesDau Terminal AnalysisMila Zulueta100% (2)

- LPT 709 Parts ListDocument289 pagesLPT 709 Parts ListvipulNo ratings yet

- Samjungtech Parking PDFDocument14 pagesSamjungtech Parking PDFwillyNo ratings yet

- A Semi-Automated Parallel Parking System For Passenger Cars: J PohlDocument13 pagesA Semi-Automated Parallel Parking System For Passenger Cars: J PohlAlexandru IlincaNo ratings yet

- DSP-EL PresentationDocument19 pagesDSP-EL PresentationAditi BardhanNo ratings yet

- SR No Reseach Work Conclusion Name of Author Year of PublicationDocument2 pagesSR No Reseach Work Conclusion Name of Author Year of PublicationtomyNo ratings yet

- Autonomous Self-Parking RobotDocument10 pagesAutonomous Self-Parking RobotTsion NegussieNo ratings yet

- Robot FireDocument5 pagesRobot FireAmirulFarisNo ratings yet

- Automatic Multilevel Car Parking & Controlling System Using PLCDocument3 pagesAutomatic Multilevel Car Parking & Controlling System Using PLCAnonymous kw8Yrp0R5r0% (1)

- An Introduction To Plug-and-Play Motion SubsystemsDocument5 pagesAn Introduction To Plug-and-Play Motion SubsystemsIlija BozovicNo ratings yet

- Vertical Car ParkingDocument5 pagesVertical Car ParkingTanvi Khurana0% (1)

- Sara Van An 2009Document3 pagesSara Van An 2009Arjun JayaprakasNo ratings yet

- 0 ReviewDocument10 pages0 ReviewKural ArasanNo ratings yet

- Presentation IoTDocument21 pagesPresentation IoTMuhammad HamzihNo ratings yet

- Car Parking Space CounterDocument5 pagesCar Parking Space CounterAjith Kumar M100% (1)

- ICSE2018 Rethink EE Architecture in Automotive To Facilitate Automation Connectivity and Electro Mobility 5Document11 pagesICSE2018 Rethink EE Architecture in Automotive To Facilitate Automation Connectivity and Electro Mobility 5Shivaji Bhausaheb ThoratNo ratings yet

- Automatic Headlamp Steering System: Rajesh.GDocument5 pagesAutomatic Headlamp Steering System: Rajesh.GAbhyudayNo ratings yet

- UntitledhdusisDocument15 pagesUntitledhdusisSlim AgentNo ratings yet

- Autonomous Driving Developed With An FPGA DesignDocument4 pagesAutonomous Driving Developed With An FPGA Designrahul rNo ratings yet

- Robotics Challenge Proposal - TEAM NITRO_7, REVA University - IISc ARTPARKDocument10 pagesRobotics Challenge Proposal - TEAM NITRO_7, REVA University - IISc ARTPARKamarkaratagi.sfalNo ratings yet

- Android Based Advanced Car Lifting System Using Bluetooth: August 2017Document6 pagesAndroid Based Advanced Car Lifting System Using Bluetooth: August 2017Just4 FuntechNo ratings yet

- Multi Parking System Fional Project ReportDocument54 pagesMulti Parking System Fional Project ReportVinay MuleyNo ratings yet

- Microcontroller Based Automatic Parking SystemDocument5 pagesMicrocontroller Based Automatic Parking SystemOLivSitanggangNo ratings yet

- B.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARDocument11 pagesB.Tech Final Year Project On AUTONOMOUS PARALLEL PARKING RC CARMohammad Tarique Mumtaz100% (1)

- Drive by WireDocument4 pagesDrive by WireanishmohantcrNo ratings yet

- Automated Guided Vehicle With Scissor Lifting Mechanism Using Arduino INO ProgramDocument3 pagesAutomated Guided Vehicle With Scissor Lifting Mechanism Using Arduino INO ProgramInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- IJSTEV2I10004Document6 pagesIJSTEV2I10004Bitthal ParidaNo ratings yet

- Electric Vehicle Wireless Charging Technology On The GoDocument4 pagesElectric Vehicle Wireless Charging Technology On The GoSourav DuttaNo ratings yet

- Robust Yaw Stability Controller Design and Hardware-in-the-Loop Testing For A Road VehicleDocument17 pagesRobust Yaw Stability Controller Design and Hardware-in-the-Loop Testing For A Road Vehiclekishor sahuNo ratings yet

- As Systemmappe Servolectric E Lowres 20150513Document18 pagesAs Systemmappe Servolectric E Lowres 20150513Ahmed SamNo ratings yet

- Co-Simulation of Energy Management Strategy For Hybrid Electric Vehicle in Avl InmotionDocument6 pagesCo-Simulation of Energy Management Strategy For Hybrid Electric Vehicle in Avl InmotionConfidential SinghNo ratings yet

- BoglitchDocument19 pagesBoglitchAgnidipta BasuNo ratings yet

- Line Following RobotDocument5 pagesLine Following RobotsathishNo ratings yet

- Autonomous Car Using Embedded SystemDocument12 pagesAutonomous Car Using Embedded Systemkiran vemulaNo ratings yet

- Pick and Place Robotic Arm: Guided By: Prof. J. N. PathanDocument15 pagesPick and Place Robotic Arm: Guided By: Prof. J. N. PathanPraveen MathiasNo ratings yet

- Servo MotorDocument8 pagesServo MotorEng.Theyazen Al-dubibiNo ratings yet

- RACE Vault Product BrochureDocument17 pagesRACE Vault Product BrochureAbhilashBetanamudiNo ratings yet

- Design and Fabrication of Automobile Reverse Locking Differential MechanismDocument83 pagesDesign and Fabrication of Automobile Reverse Locking Differential MechanismPraveen MathiasNo ratings yet

- ZigbeeDocument37 pagesZigbeeSana AdreesNo ratings yet

- Design and Analysis of Multi Story (G+4) Parking Using Staad-Pro SoftwareDocument5 pagesDesign and Analysis of Multi Story (G+4) Parking Using Staad-Pro SoftwareRishika DixitNo ratings yet

- Universal Power Automatic JackDocument4 pagesUniversal Power Automatic JackSenthilraj Sarangapani100% (1)

- 4 Ujf J&pages 1&min SRC Count 5Document1 page4 Ujf J&pages 1&min SRC Count 5Siyyadula Chandra SekharNo ratings yet

- A Seminar Report ON: Sensor Based Automated CarDocument12 pagesA Seminar Report ON: Sensor Based Automated CarWARRIOR GamingNo ratings yet

- Assad - Dissertation Final PDFDocument20 pagesAssad - Dissertation Final PDFamal roshanNo ratings yet

- Design and Development of Automated Parking Slot: March 2014Document3 pagesDesign and Development of Automated Parking Slot: March 2014Zahara175No ratings yet

- Ai For AutomotivesDocument18 pagesAi For AutomotivesAbhishek SoundaleNo ratings yet

- ABE - EV Chargers - POCO ModelDocument14 pagesABE - EV Chargers - POCO ModelOm ChavanNo ratings yet

- Autonomous Scale Vehicles FOR Road Tracking AND Obstacle AvoidanceDocument8 pagesAutonomous Scale Vehicles FOR Road Tracking AND Obstacle AvoidanceCHAMBITANo ratings yet

- Car Parking With 90° RotationDocument10 pagesCar Parking With 90° RotationIJRASETPublicationsNo ratings yet

- Wada 2013Document4 pagesWada 2013ezhilarasi ezhilarsiNo ratings yet

- Simulation and Real Time Implementation of Motor Controller For 3ph Induction Motor Using MATLAB and dSPACEDocument11 pagesSimulation and Real Time Implementation of Motor Controller For 3ph Induction Motor Using MATLAB and dSPACEShubham PatilNo ratings yet

- A Seminar Report ON: Sensor Based Automated CarDocument12 pagesA Seminar Report ON: Sensor Based Automated CarWARRIOR GamingNo ratings yet

- RACE Vault Product BrochureDocument16 pagesRACE Vault Product BrochureShitanshuNo ratings yet

- Adaptive Head Lamp SystemDocument22 pagesAdaptive Head Lamp SystemAkshay bypNo ratings yet

- PLC Based Multilevel Automatic Car Parking System: Ijireeice IjireeiceDocument3 pagesPLC Based Multilevel Automatic Car Parking System: Ijireeice IjireeiceAliNo ratings yet

- Intelligent Car Parking SystemDocument8 pagesIntelligent Car Parking SystemLeo BoyNo ratings yet

- AbstractDocument2 pagesAbstractchdev007No ratings yet

- Using Exit Time Predictions To Optimize Self Automated Parking LotsDocument6 pagesUsing Exit Time Predictions To Optimize Self Automated Parking LotsOtrebor ZenchasNo ratings yet

- LDRDocument19 pagesLDRAnonymous qh5UUGTNo ratings yet

- Smart Adaptive Vehicle Lighting System: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-8, 2017Document7 pagesSmart Adaptive Vehicle Lighting System: ISSN (PRINT) : 2393-8374, (ONLINE) : 2394-0697, VOLUME-4, ISSUE-8, 2017Mohan RNo ratings yet

- Design and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakeDocument4 pagesDesign and Development of Anti-Roll Back Mechanism: V. D. Kolate, R. R. Kurup, A. M. LatakePreeti BhamreNo ratings yet

- 6 Carburator Si Kituri de ReparatieDocument5 pages6 Carburator Si Kituri de ReparatieSerban NicolaeNo ratings yet

- Manual Q8Document320 pagesManual Q8Кирилл ИлюшинNo ratings yet

- Entry LIST Speed Test 2 LEBANONDocument2 pagesEntry LIST Speed Test 2 LEBANONnicolashindiNo ratings yet

- Boq No. Particulars Unit BOQ QTY Basic Rate Basic AmountDocument18 pagesBoq No. Particulars Unit BOQ QTY Basic Rate Basic AmountmanojNo ratings yet

- Owner's Handbook Peugeot 505Document97 pagesOwner's Handbook Peugeot 505luki yuspitaNo ratings yet

- A4af A4bfDocument23 pagesA4af A4bfjuan valderramaNo ratings yet

- SSP - 464 The Amarok - Powertrain and Drive ConceptDocument60 pagesSSP - 464 The Amarok - Powertrain and Drive ConceptwurtukukNo ratings yet

- Motor Graders: Engine 120K2 140K2Document6 pagesMotor Graders: Engine 120K2 140K2Akhilesh SinghNo ratings yet

- Cruise Control 7.1: GeneralDocument22 pagesCruise Control 7.1: Generaljose fermin carrozaNo ratings yet

- 1.1 The Project Proponent: EIA GSJ at Pont Fer / Jumbo / Dowlut Roundabouts May 2017 M191/GSJ/3.1Document6 pages1.1 The Project Proponent: EIA GSJ at Pont Fer / Jumbo / Dowlut Roundabouts May 2017 M191/GSJ/3.1Hrithik IGNo ratings yet

- Dok Bike Bed 16 3213412 en Om Sen Aepi v1Document198 pagesDok Bike Bed 16 3213412 en Om Sen Aepi v1lantapanNo ratings yet

- Cylinder Head Part Numbers - ASET™ EnginesDocument2 pagesCylinder Head Part Numbers - ASET™ EnginesHamilton MirandaNo ratings yet

- Mort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementDocument6 pagesMort&H, MSRDC, Mumbai, Maharashtra Schedules To AgreementAkshay PendurkarNo ratings yet

- 2017 Renault Clio 104255Document260 pages2017 Renault Clio 104255IngvaldNilsen-NygaardNo ratings yet

- 1 Engine: Error Codes Engine, DescritionDocument12 pages1 Engine: Error Codes Engine, DescritionHAINo ratings yet

- Rear Axle: (Cu1 2 3 TON Series)Document44 pagesRear Axle: (Cu1 2 3 TON Series)Brayan NohNo ratings yet

- FS (O) 10309 Es (O) 1X409 AngDocument2 pagesFS (O) 10309 Es (O) 1X409 AngAnGel AmayaNo ratings yet

- Stadler Kiss DD SBBDocument2 pagesStadler Kiss DD SBBRodrigo Sampaio100% (1)

- Re Spare PartsDocument81 pagesRe Spare Partssubham jaiswalNo ratings yet

- Prices Effective Dated December 01 2013Document41 pagesPrices Effective Dated December 01 2013Ayyaz ShadNo ratings yet

- Railway Budget 2010Document8 pagesRailway Budget 2010jubin654No ratings yet

- Otani 2022Document10 pagesOtani 2022Humbie EspejoNo ratings yet

- Vehicles in The Town TravellingDocument3 pagesVehicles in The Town TravellingD GNo ratings yet

- Touristic Map Alsace Carte Touristique 2018Document1 pageTouristic Map Alsace Carte Touristique 2018Randy GongNo ratings yet

- Study On Platform Gap Fillers For Indian RailwaysDocument3 pagesStudy On Platform Gap Fillers For Indian Railwaysshubham bisaneNo ratings yet

- Suzuki SJ413a PDFDocument4 pagesSuzuki SJ413a PDFRahadi IskandarNo ratings yet