Professional Documents

Culture Documents

Nps 4 D

Nps 4 D

Uploaded by

nukkeCopyright:

Available Formats

You might also like

- Z Material CatalogueDocument46 pagesZ Material CatalogueNoel P. RamosNo ratings yet

- Police Log July 4, 2016Document12 pagesPolice Log July 4, 2016MansfieldMAPoliceNo ratings yet

- #14 Batch - Delivery Note - 15.02.2020 PDFDocument1 page#14 Batch - Delivery Note - 15.02.2020 PDFShiva RajNo ratings yet

- Hamada:, Rtnhjt-O-A R.R. View WaterDocument10 pagesHamada:, Rtnhjt-O-A R.R. View WaterXaqani AxmedovNo ratings yet

- Floor Wall PaintDocument6 pagesFloor Wall PaintdenisNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- PK 15307BMDocument1 pagePK 15307BMrubenacvNo ratings yet

- Office Building G+iii-Sheet 2-R3Document1 pageOffice Building G+iii-Sheet 2-R3saurav bhaktaNo ratings yet

- DSA-T Acoustical Louver: Materials Surface Finish Screen FeaturesDocument3 pagesDSA-T Acoustical Louver: Materials Surface Finish Screen FeaturesHoangDung LeNo ratings yet

- R-KEX II Ficha Tecnica ENDocument9 pagesR-KEX II Ficha Tecnica ENHFNo ratings yet

- Siemens MotorDocument1 pageSiemens MotorFarshad MahmoudiNo ratings yet

- STM Pitch and PulleyDocument17 pagesSTM Pitch and PulleyAli Diab100% (1)

- PROSKIT Tool-KitsDocument45 pagesPROSKIT Tool-KitsHaider FiberNo ratings yet

- Restaurant+ +04 16 20Document30 pagesRestaurant+ +04 16 20Santiago MenesesNo ratings yet

- Onsrud CatalogDocument104 pagesOnsrud CatalogDaniel AustinNo ratings yet

- 120mm KE W A1 APFSDS T 2023 10Document2 pages120mm KE W A1 APFSDS T 2023 101834295709No ratings yet

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- Dyn O Strut LitSheetDocument2 pagesDyn O Strut LitSheetprinceNo ratings yet

- KHRA/KHLVA/KHA Series: U U U U U UDocument2 pagesKHRA/KHLVA/KHA Series: U U U U U UWinston TanNo ratings yet

- Greenlam Toilet CubicleDocument6 pagesGreenlam Toilet CubicleArjunraj SinghNo ratings yet

- Rodillos Ryobi ItekDocument11 pagesRodillos Ryobi Itekjuanluis201277No ratings yet

- R-KER With Threaded Rods: Bonded AnchorsDocument8 pagesR-KER With Threaded Rods: Bonded AnchorsLouis BirNo ratings yet

- Separator 1 (1)Document2 pagesSeparator 1 (1)DhameemAnsariNo ratings yet

- Roof Beam Det 3Document1 pageRoof Beam Det 3Anonymous fQLEF2tQpqNo ratings yet

- Finish Standard Plastic MaterialDocument1 pageFinish Standard Plastic Materialsalvatore.bassoNo ratings yet

- CT Nut Forged GGCDocument32 pagesCT Nut Forged GGCanderson_bicudoNo ratings yet

- Code Inner Code Material HTDocument3 pagesCode Inner Code Material HTBahadır HarmancıNo ratings yet

- Ironmongery NewDocument178 pagesIronmongery NewSENG ZHeng CHIEWNo ratings yet

- R-Kex Ii - StudsDocument20 pagesR-Kex Ii - StudsMarvinNo ratings yet

- 2) Everyday Paint Indent & Status DetailsDocument61 pages2) Everyday Paint Indent & Status DetailsStructures ProductionNo ratings yet

- Tabela Equivalencia NCSDocument5 pagesTabela Equivalencia NCSGil OjedaNo ratings yet

- Batch Mixer Skid Details 001280 - Rev1Document1 pageBatch Mixer Skid Details 001280 - Rev1kiranvar13No ratings yet

- SXLSXHDocument11 pagesSXLSXHJuan carlos 200797No ratings yet

- Att: Drilling Site Manager: The Above Mentioned Materials Were Received in Good Order and Condition byDocument3 pagesAtt: Drilling Site Manager: The Above Mentioned Materials Were Received in Good Order and Condition byKhairatul Nada BurhanuddinNo ratings yet

- Premier General Catalogue PDFDocument48 pagesPremier General Catalogue PDFSanthosh SandyNo ratings yet

- Myers HubsDocument1 pageMyers HubsJeffrey MyersNo ratings yet

- Project: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017Document1 pageProject: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017JeanmuelEstolonioNo ratings yet

- Access SummaryDocument4 pagesAccess SummaryG.Yebes SahaiNo ratings yet

- 033 PDFDocument1 page033 PDFjugaad bazi rahul kumarNo ratings yet

- 3Document1 page3Mani CadNo ratings yet

- 2015 - Catalog - ABB Cable Accessories 52-420 KV - English - ToolsDocument2 pages2015 - Catalog - ABB Cable Accessories 52-420 KV - English - ToolsSamir DandawateNo ratings yet

- 03 - Storz Couplings - Catalog - Rakord 100 S.RDocument2 pages03 - Storz Couplings - Catalog - Rakord 100 S.RSopon SrirattanapiboonNo ratings yet

- H21 1.2581 SKD5 Round BarDocument2 pagesH21 1.2581 SKD5 Round BarMANJEET KUMARNo ratings yet

- Acc Logistik April 22Document6 pagesAcc Logistik April 22yohanes hariyantoNo ratings yet

- Bulk Cement Silo Dia 3000 (005) (Mombasa Cement)Document1 pageBulk Cement Silo Dia 3000 (005) (Mombasa Cement)p.tooconstructionltdNo ratings yet

- Samtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueDocument1 pageSamtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueJohn AllenNo ratings yet

- MD004 8 Pressure Vessel List R1Document2 pagesMD004 8 Pressure Vessel List R1ibrahimNo ratings yet

- Acbrakedatseries PDFDocument1 pageAcbrakedatseries PDFR JAGADEESANNo ratings yet

- T SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationDocument1 pageT SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationFábioNo ratings yet

- St-Viv - 02Document1 pageSt-Viv - 02A8304008005No ratings yet

- INSP626061 R2 ACC System Corrosion Protection ColouringDocument3 pagesINSP626061 R2 ACC System Corrosion Protection ColouringRoberto Garcia Das NevesNo ratings yet

- 60 TR 80Document3 pages60 TR 80Marcos LunaNo ratings yet

- Plant and MachineryDocument3 pagesPlant and MachinerySM AreaNo ratings yet

- HM CC - 5.0.1 00 enDocument9 pagesHM CC - 5.0.1 00 enjanNo ratings yet

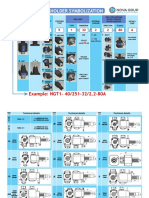

- Toolholder CodificationDocument5 pagesToolholder CodificationMarius NiculaNo ratings yet

- BRIDGESTONE VREP-quarryDocument2 pagesBRIDGESTONE VREP-quarryMORTEMNo ratings yet

- ER89-187-2 CL 9002 VacDocument1 pageER89-187-2 CL 9002 VacGabriel VejarNo ratings yet

- PPG Engineering New Bulletin C-ESB-22-05a Eldorado Products WithdrawalDocument2 pagesPPG Engineering New Bulletin C-ESB-22-05a Eldorado Products WithdrawalManuel Antonio Oñate CarvajalNo ratings yet

- SGT Shear GagesDocument3 pagesSGT Shear GagesSamuel PaulNo ratings yet

- 107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsDocument10 pages107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsLouis BirNo ratings yet

- GAO 12-Step Estimating ProcessDocument3 pagesGAO 12-Step Estimating ProcessnukkeNo ratings yet

- VOL01AOTDocument154 pagesVOL01AOTnukkeNo ratings yet

- Maintenance Programs For Nuclear Power Plants: Regulatory StandardDocument24 pagesMaintenance Programs For Nuclear Power Plants: Regulatory StandardnukkeNo ratings yet

- 16 20 Despre IrodDocument346 pages16 20 Despre IrodDubei VioricaNo ratings yet

- Poppet Valves For Crane Power PackDocument4 pagesPoppet Valves For Crane Power PacknukkeNo ratings yet

- Nuclear Decommissioning Capability StatementDocument20 pagesNuclear Decommissioning Capability StatementnukkeNo ratings yet

- Warrant: Catherine Lynn JarveyDocument4 pagesWarrant: Catherine Lynn JarveyLeigh EganNo ratings yet

- Clean RoomDocument9 pagesClean Roomxyzscribd1988No ratings yet

- Creative Beading Vol3 N6Document86 pagesCreative Beading Vol3 N6Rosalba Jg56% (9)

- Portuguese Market Outlook Up To 2040: A Report To APRENDocument48 pagesPortuguese Market Outlook Up To 2040: A Report To APRENMiguel Chã AlmeidaNo ratings yet

- Potassium AcetateDocument1 pagePotassium Acetaterushikesh pandyaNo ratings yet

- Arrow Metal Brochure - Perforated MetalDocument12 pagesArrow Metal Brochure - Perforated MetalSterlingNo ratings yet

- 26 Spruit DragonairDocument2 pages26 Spruit DragonairW.J. ZondagNo ratings yet

- Antenna DKK 8 PortDocument2 pagesAntenna DKK 8 PortvohoangphuNo ratings yet

- Energy Challenges in SomaliaDocument14 pagesEnergy Challenges in SomaliaLiban Abdullahi AliNo ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Concha y Toro Company AnalysisDocument23 pagesConcha y Toro Company AnalysisflyawaywiththeseaNo ratings yet

- Why Jesus Is Worthy of WorshipDocument7 pagesWhy Jesus Is Worthy of Worshiprukmani27No ratings yet

- Assignment 2 Inorganic ChemistryDocument2 pagesAssignment 2 Inorganic Chemistryinam ullahNo ratings yet

- MMSE Journal Vol.7 2016Document114 pagesMMSE Journal Vol.7 2016Leonardo MonteiroNo ratings yet

- CordaDocument7 pagesCordaAlone InNo ratings yet

- Questionnaire Socio-Economic Structure of Small-Scale Coastal Fishermen at Barangay Bonawon, Siaton, Negros OrientalDocument6 pagesQuestionnaire Socio-Economic Structure of Small-Scale Coastal Fishermen at Barangay Bonawon, Siaton, Negros OrientalGuilbert AtilloNo ratings yet

- God and The WorldDocument5 pagesGod and The WorldSivasonNo ratings yet

- Floor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Document30 pagesFloor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Sony Kasujaya100% (1)

- Plant Service Maret 2023Document82 pagesPlant Service Maret 2023Teguh WibowoNo ratings yet

- Instrumentation Cables: Product CatalogueDocument44 pagesInstrumentation Cables: Product Cataloguexinying liuNo ratings yet

- Westermo Ds Ddw-x42-Series 2204 en RevfDocument5 pagesWestermo Ds Ddw-x42-Series 2204 en RevfAnanthan GunasaharanNo ratings yet

- Project Proposal - BSMA 1202 byDocument19 pagesProject Proposal - BSMA 1202 byFabbi FababairNo ratings yet

- TXP® BTC: GeometryDocument2 pagesTXP® BTC: GeometryLeonardo BarriosNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- 2010 Reclamation Criteria For Wellsites and Associated Facilities For Forested LandsDocument95 pages2010 Reclamation Criteria For Wellsites and Associated Facilities For Forested Landskartikeyab111No ratings yet

- WiproDocument21 pagesWiproAnu TanjaNo ratings yet

- 168 ProjectDocument2 pages168 Projectfrederique.retailNo ratings yet

- New Material Seals Better On HVOF CoatingsDocument2 pagesNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Extra NumericalsDocument2 pagesExtra NumericalsDeep KambleNo ratings yet

Nps 4 D

Nps 4 D

Uploaded by

nukkeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nps 4 D

Nps 4 D

Uploaded by

nukkeCopyright:

Available Formats

ST SERIES

ST SERIES

ST-10

WORK

Shredding system

for low volume liquid

AT

& solids separation.

S H R E D -T E C H DUAL SHAFT INDUSTRIAL SHREDDERS

ST-25 ST-50

D U A L S H A F T Shredder c/w tote Shredder destroying

tipper for confidential off spec. consumer

document destruction. products.

ST-75 ST-100

Shredder for high Shredder and feed

volume mixed office conveyor processing

paper and confidential spent military

document destruction. munitions.

ST-150 ST-200

Shredder for baled Shredder for

plastic film reduction. high volume soil

processing.

H i g h e s t k n i f e t i p f o rc e i n t h e i n d u s t r y.

ST-500 ST-1200

Shredder reducing Severe duty shredder

heavy commercial for metals reduction.

electronic waste

components.

SHRED-TECH

W O R L D L E A D E R I N R E D U C T I O N E N G I N E E R I N G A N D M A N U FA C T U R I N G ST SERIES

w www.shred-tech.com e shred@shred-tech.com

t 1 800 465 3214 or 1 519 621 3560 f 1 519 621 4288

service hotline 1 877 566 2345

SHRED-TECH world leaders. world leaders.

All Shred-Tech Shredders are available under US Federal Supply Contract. ® All rights reserved.

Shred-Tech and Shred-Tech logo are registered trade-marks of Shred-Tech.

ST SERIES

CARDBOARD CLOTHING ELECTRONICS METALS PET BOTTLES HARD PLASTICS WOOD PAPER RUBBER TIRES

Shred-Tech’s ST Series, Dual Shaft, High Torque, Shear Shred-Tech’s hex shaft drive system, superior bearing

Shredders have long been recognized as the industry's and seal protection and proprietary torque setting

"Flagship" line of shredding equipment. Ranging in size mechanism, help to ensure low operating costs, reduced

from 7 1/2 hp (5.5 kW) up to 1,200 hp (900 kW), Shred-Tech downtime and maximize shredding efficiency.

Dual Shaft Shredders are in operation worldwide reducing,

destroying and recycling everything from tires to teabags. Shred-Tech’s team of experienced Technical Sales

Representatives are trained to advise on the exact equip-

Available with electric or hydraulic drive configurations, ment specifications needed to meet all application

either stationary or mobile, Shred-Tech shredders have requirements. Complete testing facilities, with modern

the highest knife tip force in the industry. video and digital imaging hardware are also available to

ensure Shred-Tech’s equipment recommendations are

based on factual data and available for the customers to

review.

F E AT U R E S BENEFITS F E AT U R E S BENEFITS

Modular construction allows for off-the-shelf wear part replacement. Heavy-duty torsion tube body construction ensures robust trouble-free

operation.

Abrasion resistant wear components help to decrease operating costs.

Auto-reversing feature protects systems from over-loading by re-orienting

Bearings and seals are mounted outboard of the cutting chamber to material to ensure consistent feeding.

avoid contamination.

You might also like

- Z Material CatalogueDocument46 pagesZ Material CatalogueNoel P. RamosNo ratings yet

- Police Log July 4, 2016Document12 pagesPolice Log July 4, 2016MansfieldMAPoliceNo ratings yet

- #14 Batch - Delivery Note - 15.02.2020 PDFDocument1 page#14 Batch - Delivery Note - 15.02.2020 PDFShiva RajNo ratings yet

- Hamada:, Rtnhjt-O-A R.R. View WaterDocument10 pagesHamada:, Rtnhjt-O-A R.R. View WaterXaqani AxmedovNo ratings yet

- Floor Wall PaintDocument6 pagesFloor Wall PaintdenisNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- PK 15307BMDocument1 pagePK 15307BMrubenacvNo ratings yet

- Office Building G+iii-Sheet 2-R3Document1 pageOffice Building G+iii-Sheet 2-R3saurav bhaktaNo ratings yet

- DSA-T Acoustical Louver: Materials Surface Finish Screen FeaturesDocument3 pagesDSA-T Acoustical Louver: Materials Surface Finish Screen FeaturesHoangDung LeNo ratings yet

- R-KEX II Ficha Tecnica ENDocument9 pagesR-KEX II Ficha Tecnica ENHFNo ratings yet

- Siemens MotorDocument1 pageSiemens MotorFarshad MahmoudiNo ratings yet

- STM Pitch and PulleyDocument17 pagesSTM Pitch and PulleyAli Diab100% (1)

- PROSKIT Tool-KitsDocument45 pagesPROSKIT Tool-KitsHaider FiberNo ratings yet

- Restaurant+ +04 16 20Document30 pagesRestaurant+ +04 16 20Santiago MenesesNo ratings yet

- Onsrud CatalogDocument104 pagesOnsrud CatalogDaniel AustinNo ratings yet

- 120mm KE W A1 APFSDS T 2023 10Document2 pages120mm KE W A1 APFSDS T 2023 101834295709No ratings yet

- Rawlplug en R Kex II Pure Epoxy Resin Threaded RodsDocument9 pagesRawlplug en R Kex II Pure Epoxy Resin Threaded RodsgumuskapiNo ratings yet

- Dyn O Strut LitSheetDocument2 pagesDyn O Strut LitSheetprinceNo ratings yet

- KHRA/KHLVA/KHA Series: U U U U U UDocument2 pagesKHRA/KHLVA/KHA Series: U U U U U UWinston TanNo ratings yet

- Greenlam Toilet CubicleDocument6 pagesGreenlam Toilet CubicleArjunraj SinghNo ratings yet

- Rodillos Ryobi ItekDocument11 pagesRodillos Ryobi Itekjuanluis201277No ratings yet

- R-KER With Threaded Rods: Bonded AnchorsDocument8 pagesR-KER With Threaded Rods: Bonded AnchorsLouis BirNo ratings yet

- Separator 1 (1)Document2 pagesSeparator 1 (1)DhameemAnsariNo ratings yet

- Roof Beam Det 3Document1 pageRoof Beam Det 3Anonymous fQLEF2tQpqNo ratings yet

- Finish Standard Plastic MaterialDocument1 pageFinish Standard Plastic Materialsalvatore.bassoNo ratings yet

- CT Nut Forged GGCDocument32 pagesCT Nut Forged GGCanderson_bicudoNo ratings yet

- Code Inner Code Material HTDocument3 pagesCode Inner Code Material HTBahadır HarmancıNo ratings yet

- Ironmongery NewDocument178 pagesIronmongery NewSENG ZHeng CHIEWNo ratings yet

- R-Kex Ii - StudsDocument20 pagesR-Kex Ii - StudsMarvinNo ratings yet

- 2) Everyday Paint Indent & Status DetailsDocument61 pages2) Everyday Paint Indent & Status DetailsStructures ProductionNo ratings yet

- Tabela Equivalencia NCSDocument5 pagesTabela Equivalencia NCSGil OjedaNo ratings yet

- Batch Mixer Skid Details 001280 - Rev1Document1 pageBatch Mixer Skid Details 001280 - Rev1kiranvar13No ratings yet

- SXLSXHDocument11 pagesSXLSXHJuan carlos 200797No ratings yet

- Att: Drilling Site Manager: The Above Mentioned Materials Were Received in Good Order and Condition byDocument3 pagesAtt: Drilling Site Manager: The Above Mentioned Materials Were Received in Good Order and Condition byKhairatul Nada BurhanuddinNo ratings yet

- Premier General Catalogue PDFDocument48 pagesPremier General Catalogue PDFSanthosh SandyNo ratings yet

- Myers HubsDocument1 pageMyers HubsJeffrey MyersNo ratings yet

- Project: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017Document1 pageProject: Single Storey Commercial Bldg. (Kalayaan Ave.) Subject: Shelves Materials For Fabrication Date: April / 21 / 2017JeanmuelEstolonioNo ratings yet

- Access SummaryDocument4 pagesAccess SummaryG.Yebes SahaiNo ratings yet

- 033 PDFDocument1 page033 PDFjugaad bazi rahul kumarNo ratings yet

- 3Document1 page3Mani CadNo ratings yet

- 2015 - Catalog - ABB Cable Accessories 52-420 KV - English - ToolsDocument2 pages2015 - Catalog - ABB Cable Accessories 52-420 KV - English - ToolsSamir DandawateNo ratings yet

- 03 - Storz Couplings - Catalog - Rakord 100 S.RDocument2 pages03 - Storz Couplings - Catalog - Rakord 100 S.RSopon SrirattanapiboonNo ratings yet

- H21 1.2581 SKD5 Round BarDocument2 pagesH21 1.2581 SKD5 Round BarMANJEET KUMARNo ratings yet

- Acc Logistik April 22Document6 pagesAcc Logistik April 22yohanes hariyantoNo ratings yet

- Bulk Cement Silo Dia 3000 (005) (Mombasa Cement)Document1 pageBulk Cement Silo Dia 3000 (005) (Mombasa Cement)p.tooconstructionltdNo ratings yet

- Samtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueDocument1 pageSamtech - Discrete Wire Housing ISDF & TSDF Series - CatalogueJohn AllenNo ratings yet

- MD004 8 Pressure Vessel List R1Document2 pagesMD004 8 Pressure Vessel List R1ibrahimNo ratings yet

- Acbrakedatseries PDFDocument1 pageAcbrakedatseries PDFR JAGADEESANNo ratings yet

- T SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationDocument1 pageT SR ARMET SIMRIT I II Tape Silicone Rubber Freudenberg NOK Equivalent Electrical InsulationFábioNo ratings yet

- St-Viv - 02Document1 pageSt-Viv - 02A8304008005No ratings yet

- INSP626061 R2 ACC System Corrosion Protection ColouringDocument3 pagesINSP626061 R2 ACC System Corrosion Protection ColouringRoberto Garcia Das NevesNo ratings yet

- 60 TR 80Document3 pages60 TR 80Marcos LunaNo ratings yet

- Plant and MachineryDocument3 pagesPlant and MachinerySM AreaNo ratings yet

- HM CC - 5.0.1 00 enDocument9 pagesHM CC - 5.0.1 00 enjanNo ratings yet

- Toolholder CodificationDocument5 pagesToolholder CodificationMarius NiculaNo ratings yet

- BRIDGESTONE VREP-quarryDocument2 pagesBRIDGESTONE VREP-quarryMORTEMNo ratings yet

- ER89-187-2 CL 9002 VacDocument1 pageER89-187-2 CL 9002 VacGabriel VejarNo ratings yet

- PPG Engineering New Bulletin C-ESB-22-05a Eldorado Products WithdrawalDocument2 pagesPPG Engineering New Bulletin C-ESB-22-05a Eldorado Products WithdrawalManuel Antonio Oñate CarvajalNo ratings yet

- SGT Shear GagesDocument3 pagesSGT Shear GagesSamuel PaulNo ratings yet

- 107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsDocument10 pages107857.rawlplug - En.r-Ker-Ii Hybrid Resin Threaded RodsLouis BirNo ratings yet

- GAO 12-Step Estimating ProcessDocument3 pagesGAO 12-Step Estimating ProcessnukkeNo ratings yet

- VOL01AOTDocument154 pagesVOL01AOTnukkeNo ratings yet

- Maintenance Programs For Nuclear Power Plants: Regulatory StandardDocument24 pagesMaintenance Programs For Nuclear Power Plants: Regulatory StandardnukkeNo ratings yet

- 16 20 Despre IrodDocument346 pages16 20 Despre IrodDubei VioricaNo ratings yet

- Poppet Valves For Crane Power PackDocument4 pagesPoppet Valves For Crane Power PacknukkeNo ratings yet

- Nuclear Decommissioning Capability StatementDocument20 pagesNuclear Decommissioning Capability StatementnukkeNo ratings yet

- Warrant: Catherine Lynn JarveyDocument4 pagesWarrant: Catherine Lynn JarveyLeigh EganNo ratings yet

- Clean RoomDocument9 pagesClean Roomxyzscribd1988No ratings yet

- Creative Beading Vol3 N6Document86 pagesCreative Beading Vol3 N6Rosalba Jg56% (9)

- Portuguese Market Outlook Up To 2040: A Report To APRENDocument48 pagesPortuguese Market Outlook Up To 2040: A Report To APRENMiguel Chã AlmeidaNo ratings yet

- Potassium AcetateDocument1 pagePotassium Acetaterushikesh pandyaNo ratings yet

- Arrow Metal Brochure - Perforated MetalDocument12 pagesArrow Metal Brochure - Perforated MetalSterlingNo ratings yet

- 26 Spruit DragonairDocument2 pages26 Spruit DragonairW.J. ZondagNo ratings yet

- Antenna DKK 8 PortDocument2 pagesAntenna DKK 8 PortvohoangphuNo ratings yet

- Energy Challenges in SomaliaDocument14 pagesEnergy Challenges in SomaliaLiban Abdullahi AliNo ratings yet

- KW 18KWH Canada Interim Letters - KWUSDocument2 pagesKW 18KWH Canada Interim Letters - KWUSMecano PadNo ratings yet

- Concha y Toro Company AnalysisDocument23 pagesConcha y Toro Company AnalysisflyawaywiththeseaNo ratings yet

- Why Jesus Is Worthy of WorshipDocument7 pagesWhy Jesus Is Worthy of Worshiprukmani27No ratings yet

- Assignment 2 Inorganic ChemistryDocument2 pagesAssignment 2 Inorganic Chemistryinam ullahNo ratings yet

- MMSE Journal Vol.7 2016Document114 pagesMMSE Journal Vol.7 2016Leonardo MonteiroNo ratings yet

- CordaDocument7 pagesCordaAlone InNo ratings yet

- Questionnaire Socio-Economic Structure of Small-Scale Coastal Fishermen at Barangay Bonawon, Siaton, Negros OrientalDocument6 pagesQuestionnaire Socio-Economic Structure of Small-Scale Coastal Fishermen at Barangay Bonawon, Siaton, Negros OrientalGuilbert AtilloNo ratings yet

- God and The WorldDocument5 pagesGod and The WorldSivasonNo ratings yet

- Floor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Document30 pagesFloor 76: Sword Art Online: Infinity Moment - Guide (Uncompleted)Sony Kasujaya100% (1)

- Plant Service Maret 2023Document82 pagesPlant Service Maret 2023Teguh WibowoNo ratings yet

- Instrumentation Cables: Product CatalogueDocument44 pagesInstrumentation Cables: Product Cataloguexinying liuNo ratings yet

- Westermo Ds Ddw-x42-Series 2204 en RevfDocument5 pagesWestermo Ds Ddw-x42-Series 2204 en RevfAnanthan GunasaharanNo ratings yet

- Project Proposal - BSMA 1202 byDocument19 pagesProject Proposal - BSMA 1202 byFabbi FababairNo ratings yet

- TXP® BTC: GeometryDocument2 pagesTXP® BTC: GeometryLeonardo BarriosNo ratings yet

- 'RAUP IOM-Aug06Document35 pages'RAUP IOM-Aug06Ngô Khắc ToảnNo ratings yet

- 2010 Reclamation Criteria For Wellsites and Associated Facilities For Forested LandsDocument95 pages2010 Reclamation Criteria For Wellsites and Associated Facilities For Forested Landskartikeyab111No ratings yet

- WiproDocument21 pagesWiproAnu TanjaNo ratings yet

- 168 ProjectDocument2 pages168 Projectfrederique.retailNo ratings yet

- New Material Seals Better On HVOF CoatingsDocument2 pagesNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Extra NumericalsDocument2 pagesExtra NumericalsDeep KambleNo ratings yet