Professional Documents

Culture Documents

DC Position Control System scl-106

DC Position Control System scl-106

Uploaded by

Atul MahajanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DC Position Control System scl-106

DC Position Control System scl-106

Uploaded by

Atul MahajanCopyright:

Available Formats

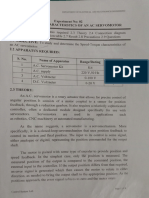

SCL 106

DC POSITION CONTROL SYSTEM

INTRODUCTION:

This set up is designed to study of dc motor

position control system called servo

mechanism and comes first in automatic

control systems. The prime advantage of this

set up is near perfection to the simulated sys-

tems. The set up comprises two parts a, the

motor unit and b, the control unit.

Features:

The motor unit : It consists a permanent Potentiometer

0

: Two 360 servo - potentiometers with

0

magnet armature controlled geared servo calibrated dials with 1 resolution for

reference and output position

motor. It has the technical specifications as DC motor : 12V/1A geared PM motor ( 50 / 60 RPM )

Tacho feedback : Positive/Negative tacho generator

Operating voltage : 12 Vdc, 5W.Rated shaft feedback with polarity reverse switch

Tacho constant : Calibrated tacho constant 0.2 to 1 in steps

speed : 50 RPM ( reduced by gear train,

Signal : Built in step signal for dynamic response

otherwise 2400 hence n= .02 )Torque : 3.5 Kg / Gain : Calibrated forward path gain 3 to 10 in

steps

cm at load shaft. The angular displacement is Motor unit : The motor unit is housed in a separate

cabinet with transparent cover for easy

sensed by a 3600 servo potentiometer. A viewing. Interconnection with the main unit

graduated disc is mounted upon the is through a standard 9-pin D-type

connector.

potentiometer to indicates angular position Display : 3½ digit LED is available on the panel for

the measurement of various signals

with 10resolution. A small dc motor is driven by Storage : Digital storage of transient response (step

the servo motor to generate the speed mode) through built in waveform capture /

display card for study dynamics in step

proportional voltage which are used as tacho mode

Power supply : Built in IC regulated power supplies

output for velocity feedback. A miniature toggle Cabinate : Housed in rigid MS powder coated with

moulded frame

switch is provided at rear side of the motor unit

Mains : 230V/50Hz AC

to change the polarity of these tacho voltages. Instruction manual : One

Dimension : 410x260x160mm ( approx)

EXPERIMENT COVERED

Operation of the position control system for different values of the forward

gain to angular position commands(effect of forward path gain in steady state error)

Step response studies for various values of forward gain(to analyze the transient)

Study of the effect of velocity feedback on the transient and steady state performance

of the system as well as its stability(Effect of velocity feedback upon transient response)

AUTH. DEALER

MANUFACTURED BY:

SATISH BROTHERS

#4309/20,Marble house,Punjabi Mohalla,

Ambala Cantt -133001(hry.)

Tel: 0171-2642617,4008617

E-mail: info@sibaindia.com

You might also like

- Section 2 SR Power Conversion System 004 PDFDocument76 pagesSection 2 SR Power Conversion System 004 PDFHarry Wart Wart100% (1)

- Cicind Part 2Document23 pagesCicind Part 2tommaso100% (2)

- Cecd, Edfp: Professional ExperienceDocument4 pagesCecd, Edfp: Professional ExperienceIsland Packet and Beaufort GazetteNo ratings yet

- Gramática AwáDocument422 pagesGramática AwáJaghu San100% (1)

- Binsfeld TTR ManualDocument32 pagesBinsfeld TTR ManualEd ArenasNo ratings yet

- CS Exp 5Document4 pagesCS Exp 5D StudiosNo ratings yet

- EPS AC Wire Guidance Itens 1.0-5.2Document8 pagesEPS AC Wire Guidance Itens 1.0-5.2Jose SantosNo ratings yet

- Electric Actuator RHD250 ABBDocument20 pagesElectric Actuator RHD250 ABBQuốc BảoNo ratings yet

- Digital - Control - For - A - Brush - DC - MotorDocument9 pagesDigital - Control - For - A - Brush - DC - MotorCarlos ReisNo ratings yet

- A Meh392aDocument32 pagesA Meh392agsNo ratings yet

- SMC006Document6 pagesSMC006Sreejith KumarNo ratings yet

- AN296285 BLDC Driver For Automotive Fuel PumpsDocument28 pagesAN296285 BLDC Driver For Automotive Fuel PumpslcisnydeksdtaujutlNo ratings yet

- Ed WP Automatic Commutation of Stepper MotorsDocument9 pagesEd WP Automatic Commutation of Stepper MotorsSelfiana UlfaNo ratings yet

- Controlador de Direccion 1Document6 pagesControlador de Direccion 1JOEL APONTE ORTIZNo ratings yet

- New Hybrid Fuzzy Controller For Direct Torque Control Induction Motor DrivesDocument9 pagesNew Hybrid Fuzzy Controller For Direct Torque Control Induction Motor DrivesBook4AllNo ratings yet

- Blog 3 - Position Control of DC MotorDocument2 pagesBlog 3 - Position Control of DC MotorShayan FarrukhNo ratings yet

- Motors - Stepper, BLDC, DCRDocument46 pagesMotors - Stepper, BLDC, DCRSaurabh Shukla100% (1)

- KSQ304E2: Automatic Co-Generation Management SystemDocument2 pagesKSQ304E2: Automatic Co-Generation Management SystemRN NNo ratings yet

- Fundamentals of DSP-Based Control For AC Machines: by Finbarr Moynihan, Embedded Control Systems GroupDocument4 pagesFundamentals of DSP-Based Control For AC Machines: by Finbarr Moynihan, Embedded Control Systems Groupveer110No ratings yet

- DC Motor Control Module: User ManualDocument26 pagesDC Motor Control Module: User ManualDavid de Almeida FiorilloNo ratings yet

- Sensorless Speed Controlled Brushless DC Drive Using The TMS320C242 DSP ControllerDocument17 pagesSensorless Speed Controlled Brushless DC Drive Using The TMS320C242 DSP ControllerVladv123No ratings yet

- An-8201 FCM8201 Three-Phase Sine-Wave BLDC Motor ControllerDocument25 pagesAn-8201 FCM8201 Three-Phase Sine-Wave BLDC Motor ControllerFelipePerezNo ratings yet

- Advanced Control System Lab PDFDocument15 pagesAdvanced Control System Lab PDFarpitg2208No ratings yet

- AN2227Document23 pagesAN2227Ahmed ShoeebNo ratings yet

- L Series Position ControllerDocument2 pagesL Series Position ControllerKaiser Iqbal100% (1)

- User Manual For Speed Control of BLDC Motor Using DspicDocument12 pagesUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcNo ratings yet

- Designofa 75 K WSwitched Reluctance Motor Drive SystemDocument6 pagesDesignofa 75 K WSwitched Reluctance Motor Drive Systempdseetharam009No ratings yet

- Sensorless Vector ControlDocument6 pagesSensorless Vector ControlDavid MartinNo ratings yet

- Position Tracking System With Brushless DC Motor: Keywords: BLDC Motor Hall Sensors PID ControllerDocument5 pagesPosition Tracking System With Brushless DC Motor: Keywords: BLDC Motor Hall Sensors PID ControllerMyat AungNo ratings yet

- Pub111 101 00 0720Document4 pagesPub111 101 00 0720vdphong2012No ratings yet

- P0903, P0915Document1 pageP0903, P0915Joanmanel Sola QuintanaNo ratings yet

- Absolute Encoder DataDocument66 pagesAbsolute Encoder DataShahiNo ratings yet

- Ramesh 2011Document6 pagesRamesh 2011Hoang Hoang LeNo ratings yet

- Real-Time BLDC Motor Control and Characterization Using TMS320F28069M With CCS and GUIDocument6 pagesReal-Time BLDC Motor Control and Characterization Using TMS320F28069M With CCS and GUIvinaykumaarNo ratings yet

- of BLDCDocument45 pagesof BLDCsmhbNo ratings yet

- Control LabDocument9 pagesControl Labdominique fortierNo ratings yet

- Speed Control of Permanent Magnet Brushless DC Motor Using Fuzzy Logic Controller-Hardware ImplementationDocument5 pagesSpeed Control of Permanent Magnet Brushless DC Motor Using Fuzzy Logic Controller-Hardware ImplementationSofyan AhmadiNo ratings yet

- DSE501 Data Sheet PDFDocument2 pagesDSE501 Data Sheet PDFChristopher100% (3)

- Application of DC/DC Buck Power Converter in DC Motor For Speed Controlling Using PI ControllerDocument5 pagesApplication of DC/DC Buck Power Converter in DC Motor For Speed Controlling Using PI ControllerShreeji ExportsNo ratings yet

- TMC5072 Datasheet Rev1.25Document106 pagesTMC5072 Datasheet Rev1.25Florian OuvrardNo ratings yet

- Permanent Magnet Brushless DC MotorDocument7 pagesPermanent Magnet Brushless DC MotoratultiwarihinduNo ratings yet

- Probo Step VXDocument3 pagesProbo Step VXkayproNo ratings yet

- Reverse Power (Current) RelayDocument3 pagesReverse Power (Current) RelayjaytamijNo ratings yet

- EEL 841 Solid State Controllers of DrivesDocument9 pagesEEL 841 Solid State Controllers of DrivesHimanshu GuptaNo ratings yet

- BLDCDocument45 pagesBLDCthulasi_krishna75% (4)

- Ijett V53P221Document6 pagesIjett V53P221Rifky WahyudaNo ratings yet

- ACDC Flyback Converter With A Single SwitchDocument6 pagesACDC Flyback Converter With A Single SwitchJAY S TANDELNo ratings yet

- SSDC Family Brochure EN20200320 A1Document36 pagesSSDC Family Brochure EN20200320 A1Công NguyễnNo ratings yet

- Stmicroelectronics cd00166530-1206032Document5 pagesStmicroelectronics cd00166530-1206032mikifit1No ratings yet

- ENGLISH - Operation Guide SD SeriesDocument85 pagesENGLISH - Operation Guide SD Seriescatur skakNo ratings yet

- Drives BasicsDocument37 pagesDrives BasicsNaveen NagarNo ratings yet

- TMC5160A Datasheet Rev1.17Document134 pagesTMC5160A Datasheet Rev1.17Florian OuvrardNo ratings yet

- Drive Technologies: Brushless Motor DrivesDocument2 pagesDrive Technologies: Brushless Motor Drivesparsa mahvisNo ratings yet

- Excitation System of Synchronous GeneratorDocument7 pagesExcitation System of Synchronous GeneratorMOHSIN_IIUINo ratings yet

- Variador Yanwa AcerosDocument9 pagesVariador Yanwa Acerosjuan Carlos GonzalezNo ratings yet

- GE Power Electronics BrochureDocument48 pagesGE Power Electronics BrochureDaniel CamosNo ratings yet

- Servo Controlled Automatic Voltage Stabilizer With Automatic High & Low Cut-Off ProvisionDocument5 pagesServo Controlled Automatic Voltage Stabilizer With Automatic High & Low Cut-Off ProvisionRANAIVOARILALA FanomezantsoaNo ratings yet

- Amfandmains Parallel Controller Deepseaelectronics: DescriptionDocument2 pagesAmfandmains Parallel Controller Deepseaelectronics: DescriptionpikaNo ratings yet

- Electronic Governor CatalogDocument26 pagesElectronic Governor CatalogAung Mh100% (1)

- Manual Regulador de Velocidade Gac Esd 5111 PDFDocument2 pagesManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- EC Council Career Path 2015Document1 pageEC Council Career Path 2015Atul MahajanNo ratings yet

- Synchro Transmitter-Receiver SCL 110ADocument1 pageSynchro Transmitter-Receiver SCL 110AAtul MahajanNo ratings yet

- EVOLUTION of HumanDocument8 pagesEVOLUTION of HumanAtul MahajanNo ratings yet

- PEL 131 Finalised WorkbookDocument99 pagesPEL 131 Finalised WorkbookAtul MahajanNo ratings yet

- 4.3 - Maintenance Processing V2.0Document14 pages4.3 - Maintenance Processing V2.0ఈశ్వర్ భరణి100% (1)

- Application of IntegralsDocument14 pagesApplication of IntegralsSanjayNo ratings yet

- 2.1 Theory of Metal Cutting Q&A For StudentDocument8 pages2.1 Theory of Metal Cutting Q&A For Studentnikhilbatham0% (1)

- Political Cycle - Alberto AlesinaDocument3 pagesPolitical Cycle - Alberto AlesinayumicintaNo ratings yet

- Bearings - Boston GearDocument7 pagesBearings - Boston GearJames GreenNo ratings yet

- 13IPST068 Fabian PerezDocument7 pages13IPST068 Fabian Perezquisi123No ratings yet

- Semprof SweetinaDocument20 pagesSemprof SweetinaSweetina MerkusiNo ratings yet

- Replication and Disaster Recovery Administration Guide: Hitachi Unified NAS Module Hitachi NAS Platform Release 12.7Document97 pagesReplication and Disaster Recovery Administration Guide: Hitachi Unified NAS Module Hitachi NAS Platform Release 12.7PrasadValluraNo ratings yet

- Diaphragm and Lung Ultrasound To Predict Weaning Outcome: Systematic Review and Meta-AnalysisDocument11 pagesDiaphragm and Lung Ultrasound To Predict Weaning Outcome: Systematic Review and Meta-AnalysisPablo IgnacioNo ratings yet

- Celebrity's Self-Disclosure On Twitter and Parasocial Relationships (Mediating Soc Presence)Document8 pagesCelebrity's Self-Disclosure On Twitter and Parasocial Relationships (Mediating Soc Presence)RIZKINo ratings yet

- Hydrogeophysical Investigation Using Electrical Resistivity Method Within Lead City University Ibadan, Oyo State, NigeriaDocument1 pageHydrogeophysical Investigation Using Electrical Resistivity Method Within Lead City University Ibadan, Oyo State, NigeriaAdebo BabatundeNo ratings yet

- Methaforming - 6: Processing Unit For Up To 6 000 Tpa (150 BPD) of Hydrocarbon FeedDocument16 pagesMethaforming - 6: Processing Unit For Up To 6 000 Tpa (150 BPD) of Hydrocarbon FeedramatajamaNo ratings yet

- Excel Formulas ManualDocument8 pagesExcel Formulas ManualVidya NeemuNo ratings yet

- Vineeta Singh (Final)Document3 pagesVineeta Singh (Final)9304768839No ratings yet

- PDBA Operations Course OutlineDocument12 pagesPDBA Operations Course OutlineQasim AbrahamsNo ratings yet

- Replace Left Hand Wheel Speed Sensor (Fittings Rear Axle 1)Document6 pagesReplace Left Hand Wheel Speed Sensor (Fittings Rear Axle 1)Ovidijus JankauskasNo ratings yet

- Gagne VS BrunerDocument5 pagesGagne VS Bruner86mmc100% (1)

- Bar Charts in ResearchDocument5 pagesBar Charts in ResearchPraise NehumambiNo ratings yet

- SolidCAM 2015 IMachining FAQDocument55 pagesSolidCAM 2015 IMachining FAQhed_panNo ratings yet

- Ford 970Document4 pagesFord 970amanNo ratings yet

- World Population From 1800 To 2100Document19 pagesWorld Population From 1800 To 2100bharatNo ratings yet

- An Information Silo: Management System Information System InformationDocument5 pagesAn Information Silo: Management System Information System InformationGeetanjaliNo ratings yet

- The Hubbard Energy Transformer by Gaston Burridge, Fate Magazine 1956Document24 pagesThe Hubbard Energy Transformer by Gaston Burridge, Fate Magazine 1956pplowe2305tedNo ratings yet

- Multi-Threading Processes: The ConceptDocument5 pagesMulti-Threading Processes: The ConceptNenad KiticNo ratings yet

- Bus FestoDocument82 pagesBus FestoraphvalonNo ratings yet

- Pulmonary ThromboembolismDocument61 pagesPulmonary ThromboembolismsanjivdasNo ratings yet

- 2f Making Frequency Distribution Graph RStudioDocument7 pages2f Making Frequency Distribution Graph RStudioGordon FreemanNo ratings yet