Professional Documents

Culture Documents

Key Steps in Production Execution: Discrete Production Is An Industry Where Produce Materials Change

Key Steps in Production Execution: Discrete Production Is An Industry Where Produce Materials Change

Uploaded by

Bruno martins0 ratings0% found this document useful (0 votes)

12 views2 pagesSAP Production Planning (PP) module handles planning processes like capacity and material planning, production order execution, bills of material, and goods movement. It keeps master data for bills of materials, work centers, and routings in a separate component. SAP PP submodules vary by industry type, such as discrete production, repetitive production, or other production industries. Discrete production involves changing materials for each lot while repetitive production uses consistent materials over long periods. Key steps in production execution include converting planned orders to production orders, issuing and confirming production orders, issuing goods, and receiving finished goods.

Original Description:

This article aproat an introduction about SAP PP

Original Title

SAP PP Introduction

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSAP Production Planning (PP) module handles planning processes like capacity and material planning, production order execution, bills of material, and goods movement. It keeps master data for bills of materials, work centers, and routings in a separate component. SAP PP submodules vary by industry type, such as discrete production, repetitive production, or other production industries. Discrete production involves changing materials for each lot while repetitive production uses consistent materials over long periods. Key steps in production execution include converting planned orders to production orders, issuing and confirming production orders, issuing goods, and receiving finished goods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

12 views2 pagesKey Steps in Production Execution: Discrete Production Is An Industry Where Produce Materials Change

Key Steps in Production Execution: Discrete Production Is An Industry Where Produce Materials Change

Uploaded by

Bruno martinsSAP Production Planning (PP) module handles planning processes like capacity and material planning, production order execution, bills of material, and goods movement. It keeps master data for bills of materials, work centers, and routings in a separate component. SAP PP submodules vary by industry type, such as discrete production, repetitive production, or other production industries. Discrete production involves changing materials for each lot while repetitive production uses consistent materials over long periods. Key steps in production execution include converting planned orders to production orders, issuing and confirming production orders, issuing goods, and receiving finished goods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

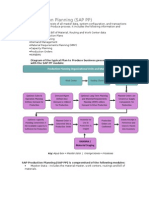

SAP Production Planning is one of the key modules in ERP and deals

with planning processes, such as capacity planning, material planning,

execution of production order, bill of material and goods movement.

SAP PP module handles the master data required for Bill of Materials

(BOMs) activity, work center and routing, and keeps it in a separate

component.

SAP PP submodules vary as per industry type like discrete production,

repetitive production, or production industries.

Discrete production is an industry where produce materials change

with each lot and costs are calculated as per orders and lots.

In repetitive production, the product is not changed for a long period

of time. Production takes place in total quantity and not in the form of

individual lots.

For most of the industry types, above-mentioned planning and

execution submodules are commonly used. Before the production

execution, many steps are performed as a part of the planning process

−

• Material Requirement Planning (MRP) run (More details later in this

tutorial).

• Bill of material and routing master data is entered in a planned order

automatically with MRP run.

• Planning quantities are maintained in the system.

Key Steps in Production Execution

Following are the key steps in executing a production order. It starts

with a planned order and ends with goods receipt against a Production

order.

Convert Planned Order to Production Order

The first step is to convert a planned order to production order. When

you create a production order, type is defined in SAP PP system.

Issue the Production Order

To start the production process, it is necessary to issue production

order. Till a production order is released, execution of the production

process cannot start.

Issue Goods for Production Order

To execute the production order, goods need to be issued. Once goods

are issued, the document number can be updated in the system.

Production Order Confirmation

All the sub processes are executed in accordance with the required

operations to confirm the production as per the production order.

Good Receipts w.r.t Production Order

Once the execution of production order is complete, goods produced

w.r.t production order are received and placed in the storage area.

You might also like

- The Influence of Digitilization On Real Estate Operations in NigeriaDocument27 pagesThe Influence of Digitilization On Real Estate Operations in NigeriaIbrahim Saliman ZainabNo ratings yet

- Joy Gabriel Last UpdateDocument8 pagesJoy Gabriel Last UpdateKetut GarjitaNo ratings yet

- Sap PPDocument34 pagesSap PPVamshisir40% (5)

- Odoo 10 ManufacturingDocument58 pagesOdoo 10 ManufacturingImenou Imen100% (4)

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyFrom EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyRating: 4 out of 5 stars4/5 (6)

- SAP Overview: Production PlanningDocument32 pagesSAP Overview: Production PlanningVamshisirNo ratings yet

- Production Planning Document - MainDocument3 pagesProduction Planning Document - MainSureshNo ratings yet

- SAP PP-Production Planning: Key Steps in Production ExecutionDocument7 pagesSAP PP-Production Planning: Key Steps in Production ExecutionAhmed IhsanNo ratings yet

- Sap Interview QuestionsDocument20 pagesSap Interview QuestionsNagarjuna ReddyNo ratings yet

- SAP PP Interview Questions: Converting Planned Order To Production OrderDocument8 pagesSAP PP Interview Questions: Converting Planned Order To Production OrderUday Shankar100% (1)

- Sap PP Tutorials - GuruDocument97 pagesSap PP Tutorials - GuruKishor Kolhe100% (1)

- SAP Production Planning (PP)Document17 pagesSAP Production Planning (PP)manasiNo ratings yet

- SAP PP FlowDocument13 pagesSAP PP FlowMayankNo ratings yet

- #1 Service Desk Software: What Is SAP Production PlanningDocument3 pages#1 Service Desk Software: What Is SAP Production PlanningAnonymous IpnRP293100% (1)

- SAP PP - IntroductionDocument8 pagesSAP PP - IntroductionKoustubha KhareNo ratings yet

- What Is Production PlanningDocument7 pagesWhat Is Production PlanningAr CahyadiNo ratings yet

- L6 Sap Production Planning ModuleDocument37 pagesL6 Sap Production Planning ModuleRajat Shetty100% (1)

- Learn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orDocument23 pagesLearn SAP PP in 1 Day: ALL RIGHTS RESERVED. No Part of This Publication May Be Reproduced orAmr ShararaNo ratings yet

- SAP Production Planning Overview For New SAP ConsultantsDocument31 pagesSAP Production Planning Overview For New SAP ConsultantsSri Harsha100% (1)

- Discrete Manufacturing - The Made To Order Cycle and Make TO Stock CycleDocument3 pagesDiscrete Manufacturing - The Made To Order Cycle and Make TO Stock Cyclealbertoca990No ratings yet

- Cost of Goods SoldDocument9 pagesCost of Goods SoldAmitava SahaNo ratings yet

- SAP PP Interview Questions - TutorialsPointDocument12 pagesSAP PP Interview Questions - TutorialsPointManickath Mani Nair100% (2)

- PPCONFIGDocument1 pagePPCONFIGRemove NameNo ratings yet

- HANA Plant Maintenance (PM) - OverviewDocument15 pagesHANA Plant Maintenance (PM) - OverviewpreetigopalNo ratings yet

- Configuration Is Backend SAP System Activity and Must Occur Only Once During An SAP Implementation ProjectDocument2 pagesConfiguration Is Backend SAP System Activity and Must Occur Only Once During An SAP Implementation ProjectRemove NameNo ratings yet

- BBP For PP Module ProcessDocument4 pagesBBP For PP Module ProcesspaiashokNo ratings yet

- SAP PP OverviewDocument215 pagesSAP PP Overviewmanju-aeNo ratings yet

- Production Planning OverviewDocument2 pagesProduction Planning Overviewarunkumar189613No ratings yet

- SAP PresentationDocument21 pagesSAP PresentationAdvait BawdekarNo ratings yet

- Interview Questions - SAP Production PlanningDocument33 pagesInterview Questions - SAP Production Planningrushikeshdeokar132No ratings yet

- SAP Production Planning Modules PresentationDocument42 pagesSAP Production Planning Modules Presentationmuhammad shahbaz yousafNo ratings yet

- PP NotesDocument33 pagesPP NotesRohail Tahir100% (1)

- Production Planning and ControlDocument14 pagesProduction Planning and ControlMuthuvel M100% (1)

- SAP PP Pointers To ReviewDocument18 pagesSAP PP Pointers To Reviewivan_robie9328100% (1)

- PP Basics UnderstandingDocument7 pagesPP Basics UnderstandingprashantsdpikiNo ratings yet

- 5 Master Data in PPDocument7 pages5 Master Data in PPprashantsdpikiNo ratings yet

- Sales and DistributionDocument32 pagesSales and Distributionraghunandan2293No ratings yet

- SAP PP Organization StructureDocument3 pagesSAP PP Organization StructuregopinathNo ratings yet

- 45 Important SAP PP Interview Questions Answers Set 1 - CareersLiteDocument34 pages45 Important SAP PP Interview Questions Answers Set 1 - CareersLiterushikeshdeokar155No ratings yet

- MTS & MtoDocument4 pagesMTS & MtokalidasmNo ratings yet

- SAP PP OverviewDocument45 pagesSAP PP OverviewNikhil Wani100% (1)

- Ranbaxy Case Study: Md. Moiz Ali PGFC1915Document3 pagesRanbaxy Case Study: Md. Moiz Ali PGFC1915Moiz AliNo ratings yet

- SAP PP Intrw QTNDocument8 pagesSAP PP Intrw QTN4ArunNo ratings yet

- SAP Production Planning Life CycleDocument3 pagesSAP Production Planning Life Cyclecreater127ab50% (2)

- SAP Note BookDocument8 pagesSAP Note Bookమనోహర్ రెడ్డిNo ratings yet

- ERP-Production Module: Presented To: Ms. Sudha SinghDocument41 pagesERP-Production Module: Presented To: Ms. Sudha SinghsanjibkrjanaNo ratings yet

- PI SheetDocument8 pagesPI SheetKumarNo ratings yet

- What Is MRPDocument15 pagesWhat Is MRPParag Narkhede100% (1)

- Planning of Production Logistics Systems - KOALM327 - Final ExamDocument19 pagesPlanning of Production Logistics Systems - KOALM327 - Final ExamAna Paula CarvalhoNo ratings yet

- Module 3 - Overview of ERP PackagesDocument16 pagesModule 3 - Overview of ERP PackagesGangadharNo ratings yet

- ERP Module 1Document16 pagesERP Module 1burn121212No ratings yet

- Production Planning Process FlowDocument3 pagesProduction Planning Process Flowrvnd_kkNo ratings yet

- Routing Is A Sequence of Operations Necessary To Be Performed inDocument2 pagesRouting Is A Sequence of Operations Necessary To Be Performed inSiva Sankar MohapatraNo ratings yet

- Sap Modules OverviewDocument4 pagesSap Modules Overviewajaydashora14No ratings yet

- CIM Presentation 1-5-2021Document23 pagesCIM Presentation 1-5-2021Sanket TitarmareNo ratings yet

- Srinidhi9 0Document3 pagesSrinidhi9 0Mangesh SNo ratings yet

- 0-Erp - Sap OverviewDocument99 pages0-Erp - Sap OverviewSABARI NATHANNo ratings yet

- SAP PP StepsDocument11 pagesSAP PP StepsAjay KumarNo ratings yet

- PP Training Presentation M&MDocument49 pagesPP Training Presentation M&MNikhil WaniNo ratings yet

- Mba 3rd Semester, Material ManagementDocument61 pagesMba 3rd Semester, Material ManagementVikash KumarNo ratings yet

- Practical Guide To Production Planning & Control [Revised Edition]From EverandPractical Guide To Production Planning & Control [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Big Data and BIDocument5 pagesBig Data and BIBruno martinsNo ratings yet

- Big DataDocument2 pagesBig DataBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Ssssssssssbig Data History and Current ConsiderationsDocument1 pageSsssssssssbig Data History and Current ConsiderationsBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Rrrrrrrrrrbig Data History and Current ConsiderationsDocument1 pageRrrrrrrrrrbig Data History and Current ConsiderationsBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Gdfcbig Data History and Current Considerations: Volume. Organizations Collect Data From A Variety of Sources, IncludingDocument1 pageGdfcbig Data History and Current Considerations: Volume. Organizations Collect Data From A Variety of Sources, IncludingBruno martinsNo ratings yet

- Ts223Big Data History and Current Considerations: Volume. Organizations Collect Data From A Variety of Sources, IncludingDocument1 pageTs223Big Data History and Current Considerations: Volume. Organizations Collect Data From A Variety of Sources, IncludingBruno martinsNo ratings yet

- Big DataDocument1 pageBig DataBruno martinsNo ratings yet

- Guardium v11 0 p270 Patch Release NotesDocument4 pagesGuardium v11 0 p270 Patch Release NotesChristian José Castillo ValarezoNo ratings yet

- Book 1Document6 pagesBook 1aditiNo ratings yet

- What Is The Difference Between Content Based Filtering and Collaborative Filtering - QuoraDocument5 pagesWhat Is The Difference Between Content Based Filtering and Collaborative Filtering - Quoraehsan.amimul3795No ratings yet

- Assignment 7 - Final Project v1Document14 pagesAssignment 7 - Final Project v1api-540028293No ratings yet

- Assignment 1Document3 pagesAssignment 1عطاف أبو هدةNo ratings yet

- How To Upload Image in Folder and Path in Database Using Servlet, JSP %Document4 pagesHow To Upload Image in Folder and Path in Database Using Servlet, JSP %Yanno Dwi Ananda50% (2)

- ArcGIS Tutorials PDFDocument3 pagesArcGIS Tutorials PDFVaneet GuptaNo ratings yet

- I. Create A Procube Database File (.Olp) Named Foodmart 2000 (This Does Not Represents TheDocument35 pagesI. Create A Procube Database File (.Olp) Named Foodmart 2000 (This Does Not Represents Theaasmita2007No ratings yet

- BCG Online Test Technical Instructions - 2024Document1 pageBCG Online Test Technical Instructions - 2024hantao199903300113No ratings yet

- Frontline Defense Against Network AttackDocument15 pagesFrontline Defense Against Network AttackRyan Roman CatogNo ratings yet

- Middle WaresDocument3 pagesMiddle WaresMay Ann Agcang SabelloNo ratings yet

- Tek Not Hon ReportDocument20 pagesTek Not Hon Reportpavan yadavNo ratings yet

- Midterm AE108 Practical 10-7-22Document2 pagesMidterm AE108 Practical 10-7-22cheesekuhNo ratings yet

- 2015 06 08 Voluntary Principles For Article Sharing On Scholarly Collaboration NetworksDocument2 pages2015 06 08 Voluntary Principles For Article Sharing On Scholarly Collaboration NetworksPavanNo ratings yet

- Difference Between Table Variable and Temporary TableDocument2 pagesDifference Between Table Variable and Temporary Tablesamsonawane09No ratings yet

- Waterfall vs. Agile: Must Know Differences: What Is Waterfall Methodology?Document5 pagesWaterfall vs. Agile: Must Know Differences: What Is Waterfall Methodology?SarojTimsinaNo ratings yet

- Amazon FulfillmentDocument11 pagesAmazon FulfillmentprajaktaNo ratings yet

- Lucille StartDocument3 pagesLucille Startram.petrychkoNo ratings yet

- Distributed Deep Learning With HorovodDocument42 pagesDistributed Deep Learning With HorovodKesava Reddy MNo ratings yet

- Case 4-3 - SIM-F-Klp-7Document5 pagesCase 4-3 - SIM-F-Klp-7Ilham DevaNo ratings yet

- Material EstudoDocument16 pagesMaterial EstudoEmerson FerreiraNo ratings yet

- Sunmi Cloud User Manual 20181105Document96 pagesSunmi Cloud User Manual 20181105Jeffrey LingNo ratings yet

- 1 KyuDocument1 page1 Kyus sNo ratings yet

- Training CCURE900 Ver 2.8-EngDocument57 pagesTraining CCURE900 Ver 2.8-EngMoisesManuelBravoLeonNo ratings yet

- Oracle E-Business InstallDocument162 pagesOracle E-Business InstallCarlos HernandezNo ratings yet

- Stop Updates 10 LogDocument3 pagesStop Updates 10 LogJohn Mark CelosaNo ratings yet

- RDR-XXXXX Test Report TempDocument5 pagesRDR-XXXXX Test Report TempMarianna GofmanNo ratings yet

- license to use this Student Guideฺ: Oracle Database 12c: Managing Multitenant ArchitectureDocument280 pageslicense to use this Student Guideฺ: Oracle Database 12c: Managing Multitenant ArchitectureManuel RafaelNo ratings yet

![Practical Guide To Production Planning & Control [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/235162742/149x198/2a816df8c8/1709920378?v=1)