Professional Documents

Culture Documents

PhuBia-WPS-AWS D1.1-8-6-2011

PhuBia-WPS-AWS D1.1-8-6-2011

Uploaded by

poulmackOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PhuBia-WPS-AWS D1.1-8-6-2011

PhuBia-WPS-AWS D1.1-8-6-2011

Uploaded by

poulmackCopyright:

Available Formats

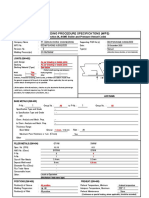

WELDING PROCEDURE SPECIFICATION (WPS) Yes

PREQUALIFIED_______QUALIFIED BY TESTING_______

or PROCEDURE QUALIFICATION RECORDS(PQR) Yes

AWS D1.1/D1.1M:2008 ANNEX N

Identifcation # WPS No.MEI-023/FCAW

Company Name M E I Egineering and Construction Co.,Ltd. Revision 0 Date 5/6/2011 By K.Chaiwan

Welding Process(es) FCAW Type Manual Semiautomatic

Supporting PQR No.(s) N/A Machine Automatic

JOINT DESIGN USED POSITION

Type: B-L2c-S, Single-V-Groove, Butt Joint Position of Groove: Vertical Fillet N/A

Single Doubie Weld Vertcal Progression: Up Down

Backing: Yes. No.

Backing Material: Weld metal ELECTRICAL CHARACTERISTICS

Root Opening 0-3 mm Root Face Dimension 0-3 mm Transfer Mode (GMAW) Short-Circuiting

Groove Anagle: 60'-70' Radius (J-U) N/A Globular Spray

Back Gouging Yes. No. Method Griding or CAC/A

Current: AC DCEP DCEN PLUSE

BASE METALS Other N/A

Material Spec. JISG3101 to JISG3101 Tungsten Electrode (GTAW)

Type or Grade SS400 to SS400 size: N/A

Thickness: Groove 3mm-Unlim Fillet N/A Type: N/A

Diameter (Pipe) All(BG or Backing)

FILLER METALS TECHNIQUE

AWS Specification A5.20 Stringer or Weave Bead: String

AWS Classification E71T-1 Multi-pass or Single Pass (per side) Multiple/Single

Number of Electrodes Single

Electrode Spacing Longitudinal N/A

SHIELDING Lateral N/A

Flux N/A Gas CO2 Angle N/A

Composition 100% Contact Tube to Work Distance 10-25mm

Electrode-flux(Class) Flow Rate 20-25Lpm Peening N/A

N/A Gas Cup Size 16mm Interpass Cleaning: Grinding,Brushing

PREHEAT POSTWELD HEAT TREATMENT

PREHEAT Temp. See Table Temp. N/A

Interpass Temp., Min. See Table Max. See Table Temp. N/A

WELDING PROCEDURE

Pass or Filler Metals Current Travel Joint Details

Weld Process Diam. Type & Amps Wire Feed Speed Volts Speed

Layer(s) Class (mm) Polarity (cm/min) (cm/min) a = 60'-70'

t=unlimited

Root FCAW E71T-1 1.2 DCEP 120~260 60~125 21~30 15~30 N

Hot FCAW E71T-1 1.2 DCEP 120~260 60~125 21~30 15~30 1 f = 0~16mm

Cover FCAW E71T-1 1.2 DCEP 120~260 60~125 21~30 15~30

R = 0~2mm

MINIMUM PREHEAT AND INTERPASS TEMPERATURE

Up to 20mm(3/4") Over 20-38mm3/4"-1.1/2") Over 38-65mm(1.1/2"-2.1/2") Over 65mm(2.1/2")

Ambient Ambient 65 'C 110 'C

Note

1 . Joint surface shall be cleaned by chipping,grinding or brushing prior to welding

2 . Procedure conforms to AWS D1.1:2008, See Project Specification and /or AWS D1.1 for additional requirement.

3 . Tack welding shall be made using SMAW process and shall be cleaned thoroughly.

Prepared by Reviewed by/Approved by

(Mr. Chamnien Chanheaw) (Mr. Chaiwan Kaewruamvong)

QA/QA SECTION AWS-CWI No.11061571

Reviewed by/Approved by Client

( .)

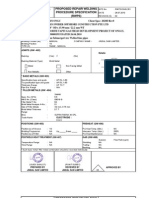

WELDING PROCEDURE SPECIFICATION (WPS) Yes

PREQUALIFIED_______QUALIFIED BY TESTING_______

or PROCEDURE QUALIFICATION RECORDS(PQR) Yes

AWS D1.1/D1.1M:2008 ANNEX N

Identifcation # WPS No.MEI-022/SAW

Company Name M E I Egineering and Construction Co.,Ltd. Revision 0 Date 5/6/2011 By K.Chaiwan

Welding Process(es) SAW Type Manual Semiautomatic

Supporting PQR No.(s) N/A Machine Automatic

JOINT DESIGN USED POSITION

Type: B-L2c-S, Single-V-Groove, Butt Joint Position of Groove: FLAT Fillet N/A

Single Doubie Weld Vertcal Progression: Up Down

Backing: Yes. No. N/A

Backing Material: Weld metal ELECTRICAL CHARACTERISTICS

Root Opening 0-2 mm Root Face Dimension 0-16 mm Transfer Mode (GMAW) Short-Circuiting

Groove Anagle: 60'-70' Radius (J-U) N/A Globular Spray

Back Gouging Yes. No. Method Griding or CAC/A

Current: AC DCEP DCEN PLUSE

BASE METALS Other N/A

Material Spec. JISG3101 to JISG3101 Tungsten Electrode (GTAW)

Type or Grade SS400 to SS400 size: N/A

Thickness: Groove 12-50 mm Fillet N/A Type: N/A

Diameter (Pipe) All(BG or Backing)

FILLER METALS TECHNIQUE

AWS Specification A5.17 Stringer or Weave Bead: String

AWS Classification EM12K Multi-pass or Single Pass (per side) Multiple/Single

Number of Electrodes Single

Electrode Spacing Longitudinal N/A

SHIELDING Lateral N/A

Flux F6A2-EL12 Gas N/A Angle N/A

Composition N/A Contact Tube to Work Distance 25-35mm

Electrode-flux(Class) Flow Rate N/A Peening N/A

F7A0-EM12K Gas Cup Size N/A Interpass Cleaning: Grinding,Brushing

PREHEAT POSTWELD HEAT TREATMENT

PREHEAT Temp. See Table Temp. N/A

Interpass Temp., Min. See Table Max. See Table Temp. N/A

WELDING PROCEDURE

Pass or Filler Metals Current Travel Joint Details

Weld Process Diam. Type & Amps Wire Feed Speed Volts Speed

Layer(s) Class (mm) Polarity (cm/min) (cm/min) a = 60'-70'

t=50 Max

1 to N SAW EM-12K 3.2 DCEP 550 145.00 34 58.00 N

+15% +10% +7% +10% 1 f = 0~16mm

-15% -10% -7% -10%

R = 0~2mm

MINIMUM PREHEAT AND INTERPASS TEMPERATURE

Up to 20mm(3/4") Over 20-38mm3/4"-1.1/2") Over 38-65mm(1.1/2"-2.1/2") Over 65mm(2.1/2")

Ambient Ambient 65 'C 110 'C

Note

1 . Joint surface shall be cleaned by chipping,grinding or brushing prior to welding

2 . Procedure conforms to AWS D1.1:2008, See Project Specification and /or AWS D1.1 for additional requirement.

3 . Tack welding shall be made using SMAW process and shall be cleaned thoroughly.

Prepared by Reviewed by/Approved by

(Mr. Chamnien Chanheaw) (Mr. Chaiwan Kaewruamvong)

QA/QA SECTION AWS-CWI No.11061571

Reviewed by/Approved by Client

( .)

You might also like

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- Aws B2.1 (2000)Document249 pagesAws B2.1 (2000)poulmack100% (2)

- Astm A767-09Document5 pagesAstm A767-09poulmackNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- WPS Format For AWS D1.1 - PQR - SMAWDocument3 pagesWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Samplesamer_saif8456100% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Document2 pagesRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- RT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Document20 pagesRT Acceptance Criteria For Welder Test According To ASME Sec IX (QW 191 1.2)Oscar Iván Duque Diaz100% (1)

- MPI Report FormatDocument4 pagesMPI Report Formatpankaj ranaNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- A 36 WPSDocument2 pagesA 36 WPSNaqqash Sajid100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- PWPS Fillet WeldDocument2 pagesPWPS Fillet WeldUgonnaNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- PWHT PROCEDURE (11) Rev 0Document14 pagesPWHT PROCEDURE (11) Rev 0AbdulNeyasNo ratings yet

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- 1993 Ley CanacietDocument4 pages1993 Ley CanacietpoulmackNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Aws A5.15 PDFDocument18 pagesAws A5.15 PDFpoulmackNo ratings yet