Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

7 viewsFor Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

For Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

Uploaded by

Alexander Albuja TorresThis document is a supplier first article data sheet used to collect measurement data on key dimensions of a part. It requests the supplier name, part number, description, target dimension specifications, measurement details, and a table to record 30 measurements of the dimension with calculated capability indices. Any measurements outside specifications or with a Cpk below 1 would require a description and corrective action. The purpose is to verify the dimension is manufactured correctly before full production.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You might also like

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- ASV 2800 2810 Posi Track Loader Parts Manual DownloadDocument61 pagesASV 2800 2810 Posi Track Loader Parts Manual DownloadShiv Kumar0% (1)

- AutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionFrom EverandAutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionRating: 3 out of 5 stars3/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Good Medical PracticeDocument22 pagesGood Medical PracticeRanjita BainsNo ratings yet

- Historinha Clima G5Document28 pagesHistorinha Clima G5Miss HelenNo ratings yet

- R-30iA Cimplicity Operator Manual (B-82604EN 01)Document90 pagesR-30iA Cimplicity Operator Manual (B-82604EN 01)YoganandhK100% (1)

- HiPath Xpressions Compact V3.0 Installation Administration GuideDocument194 pagesHiPath Xpressions Compact V3.0 Installation Administration GuideenjoythedocsNo ratings yet

- Взвешивающая Система Top Master - engDocument33 pagesВзвешивающая Система Top Master - enggluykNo ratings yet

- Mini Project: A Simple Xerox Machine Controller: 23 JAN 2021 SECR1013 Digital LogicDocument19 pagesMini Project: A Simple Xerox Machine Controller: 23 JAN 2021 SECR1013 Digital LogicIsmail LifeNo ratings yet

- Capabilidade 501220 - (Doosan5024)Document6 pagesCapabilidade 501220 - (Doosan5024)Marcos PoffoNo ratings yet

- Introduction To PSpiceDocument15 pagesIntroduction To PSpiceUmera Anjum100% (1)

- Staad Model Report 6dec21Document25 pagesStaad Model Report 6dec21Anwar Issa MatarnehNo ratings yet

- Mincoef Maxcoef Range: DSP Scaling, A Pid Example: Difference Equations Must Be Scaled ToDocument9 pagesMincoef Maxcoef Range: DSP Scaling, A Pid Example: Difference Equations Must Be Scaled ToVIJAYPUTRANo ratings yet

- Universal Measuring Device: Brief Instructions See Last PageDocument32 pagesUniversal Measuring Device: Brief Instructions See Last PagealeksandarlaskovNo ratings yet

- Lab No2 To Find Unknown Branch Current in A Circuit Containing Dependent SourceDocument3 pagesLab No2 To Find Unknown Branch Current in A Circuit Containing Dependent SourcedaudNo ratings yet

- Membuat One Line Diagram (SLD)Document5 pagesMembuat One Line Diagram (SLD)Muhammad Harris MunandarNo ratings yet

- Instruction: Do Not Edit/alterDocument68 pagesInstruction: Do Not Edit/alterRenee LaagNo ratings yet

- MB - Cdiasworks - Manual Práctico Operaciones SolidworksDocument26 pagesMB - Cdiasworks - Manual Práctico Operaciones SolidworksGabrielSorianoNo ratings yet

- KKKL2151 - Lab 0 - Recovery Simulation - V2Document8 pagesKKKL2151 - Lab 0 - Recovery Simulation - V2Chang YongNo ratings yet

- Especificaciones BandejaDocument9 pagesEspecificaciones BandejaJulianNo ratings yet

- Protel DXP TutorialDocument123 pagesProtel DXP TutorialMarkNo ratings yet

- Module 3 AE4 Linear Programming The Simplex MethodDocument73 pagesModule 3 AE4 Linear Programming The Simplex MethodEleyna AlcatrazNo ratings yet

- Lab 2 (I) 2Document3 pagesLab 2 (I) 2SchaieraNo ratings yet

- Chapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFDocument18 pagesChapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFLuis Felipe Blanco CatalánNo ratings yet

- Metrology Lab Fair Record FormatDocument140 pagesMetrology Lab Fair Record FormatnNo ratings yet

- MB - CDIASWORKS - Manual Práctico CHAPA METÁLICA SolidWorksDocument26 pagesMB - CDIASWORKS - Manual Práctico CHAPA METÁLICA SolidWorksGabrielSorianoNo ratings yet

- Electric Machine Design ANSYS Maxwell ToolkitTuToDocument310 pagesElectric Machine Design ANSYS Maxwell ToolkitTuToYsid Bello C67% (3)

- FlowCAD AN PSpice Etable SubcktDocument9 pagesFlowCAD AN PSpice Etable SubcktMaherNo ratings yet

- 00002447a PDFDocument24 pages00002447a PDFlumix345-web1802No ratings yet

- Gascalc 5.0: Calculation ReferenceDocument12 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Microcontroller Cores ForDocument8 pagesMicrocontroller Cores ForGoran MiljkovicNo ratings yet

- 12-MGDP-L-9005-0 (Tagging Procedure)Document34 pages12-MGDP-L-9005-0 (Tagging Procedure)Aly ShahNo ratings yet

- How To Calculate Basic Pitch TimeDocument3 pagesHow To Calculate Basic Pitch TimealaminNo ratings yet

- R-L TransientDocument4 pagesR-L Transientsalmansalem3002No ratings yet

- Electric Circuit Analysis LabDocument6 pagesElectric Circuit Analysis Labms2sl4No ratings yet

- A Freeware-Based Antenna Simulation Exercise: L. Brent JenkinsDocument8 pagesA Freeware-Based Antenna Simulation Exercise: L. Brent JenkinsnoubernouNo ratings yet

- Catalogue Vaccum Recloser 3AD enDocument50 pagesCatalogue Vaccum Recloser 3AD enVannak TAINGNo ratings yet

- J&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationDocument16 pagesJ&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationEnrico BishopNo ratings yet

- UICAFE12815-ENG-CAL-XXXX Rev ADocument23 pagesUICAFE12815-ENG-CAL-XXXX Rev AElias EliasNo ratings yet

- Total Manpower Costs: 1,000.00 2,000.00Document3 pagesTotal Manpower Costs: 1,000.00 2,000.00reninbabaskiNo ratings yet

- Phycore - A5D2X: Hardware ManualDocument36 pagesPhycore - A5D2X: Hardware ManualNelaparthy BenhurNo ratings yet

- Pareto Charts: Xbar ChartDocument12 pagesPareto Charts: Xbar ChartYahya AljarokNo ratings yet

- Appendix G - OrCAD 10.5 TutorialDocument20 pagesAppendix G - OrCAD 10.5 TutorialcrazycheekboyNo ratings yet

- ENGN2912E Cadence FirstCMOSDesignDocument5 pagesENGN2912E Cadence FirstCMOSDesignsanssansshilthNo ratings yet

- DINACELL CÉLULA DE CARGA 1262-04 (En - Web)Document33 pagesDINACELL CÉLULA DE CARGA 1262-04 (En - Web)Ton marquesNo ratings yet

- AN0254Document14 pagesAN0254muthukumar_eee3659No ratings yet

- How To Use Dependent Source in pSPICEDocument27 pagesHow To Use Dependent Source in pSPICEMyunghwan Ryu0% (1)

- Not Required: Verification of Equipment (Weekly)Document3 pagesNot Required: Verification of Equipment (Weekly)asdasdasdasdNo ratings yet

- Lab 2 (Ii) ValveDocument3 pagesLab 2 (Ii) ValveSchaieraNo ratings yet

- Measurement System AnalysisDocument21 pagesMeasurement System AnalysisArijitMalakarNo ratings yet

- NG3S238 CFD Assingment Cover Sheet 2020-21Document5 pagesNG3S238 CFD Assingment Cover Sheet 2020-21Ahmed Al SayedNo ratings yet

- Control Charts and Bench Sheets Manuals and Procedures For Accredited LaboratoriesDocument18 pagesControl Charts and Bench Sheets Manuals and Procedures For Accredited LaboratoriesDiana RuizNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument15 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- Family Hydro - A Propeller Type Micro TurbineDocument4 pagesFamily Hydro - A Propeller Type Micro TurbineFathur RahmanNo ratings yet

- PCB Design: Exercise 2Document6 pagesPCB Design: Exercise 2juenkkoNo ratings yet

- Eoc 2Document7 pagesEoc 2Iman AthirahNo ratings yet

- OSMRE BIVDEP DocumentationDocument22 pagesOSMRE BIVDEP DocumentationrodrigoNo ratings yet

- PSPICE (Orcad Family Release 9.2 Lite Edition) Installation InstructionsDocument3 pagesPSPICE (Orcad Family Release 9.2 Lite Edition) Installation InstructionsDipal JaniNo ratings yet

- Bi Metal, Liquid in Glass, Remote Reading ThermosDocument16 pagesBi Metal, Liquid in Glass, Remote Reading ThermosMatthew ShawNo ratings yet

- Navair 17-20aq-347Document23 pagesNavair 17-20aq-347ampinto1No ratings yet

- LAB #01 To Determine Unknown Voltage and Current in A DC Network ObjectiveDocument8 pagesLAB #01 To Determine Unknown Voltage and Current in A DC Network ObjectiveImaad KhanNo ratings yet

- PSpice16 6 TutorialDocument20 pagesPSpice16 6 TutorialAmbili MuraliNo ratings yet

- Contoh Form TTDocument1 pageContoh Form TTgerry rutmNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Ford Half ShaftDocument10 pagesFord Half Shaftsuysuy00No ratings yet

- Academic Calendar 2023 Undergraduate OdlDocument1 pageAcademic Calendar 2023 Undergraduate Odlbroken swordNo ratings yet

- ThermoFisherScientific 10K 20130227Document157 pagesThermoFisherScientific 10K 20130227siddk0312No ratings yet

- Fracture ToughnessDocument3 pagesFracture ToughnessMinu.j.j100% (1)

- Personal Information: Single / Male / Indonesia / Purwakarta Passport / - / C2940195Document5 pagesPersonal Information: Single / Male / Indonesia / Purwakarta Passport / - / C2940195Muhammad RaihanNo ratings yet

- Eposter For Art & Science of Patient PreparationDocument50 pagesEposter For Art & Science of Patient PreparationdrsmritiNo ratings yet

- Dual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RDocument4 pagesDual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RManojit SahaNo ratings yet

- Basic Data Kar Part 4Document11 pagesBasic Data Kar Part 4vpmohammedNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Interpretation of Vane Shear Tests For Geotechnical Stability CalculationsDocument9 pagesInterpretation of Vane Shear Tests For Geotechnical Stability CalculationsiliavaNo ratings yet

- ApomixisDocument3 pagesApomixisAnonymous yKjxyeLNo ratings yet

- HRC - Forms - Employee Application - Rev2019 NewDocument3 pagesHRC - Forms - Employee Application - Rev2019 NewGanang CucuNo ratings yet

- Analysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)Document9 pagesAnalysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)IJRASETPublicationsNo ratings yet

- G6PD Deficiency - Favism FINAL Oct2018Document3 pagesG6PD Deficiency - Favism FINAL Oct2018Hana'a GhalibNo ratings yet

- Passive Cooling 1Document15 pagesPassive Cooling 11SI17AT024 MOHAMMED AASIM ATIQNo ratings yet

- Solar Generator (LB-P500-A) : Product DetailsDocument2 pagesSolar Generator (LB-P500-A) : Product Detailsbogdan danescuNo ratings yet

- Connectors of Addition and ContrastDocument3 pagesConnectors of Addition and ContrastAnamaria OnițaNo ratings yet

- Correlational Relationship of Nursing Professional Subjects and Board Exam Performance of Isabela State University-Echague November 2022 Nursing Licensure Examination TakersDocument20 pagesCorrelational Relationship of Nursing Professional Subjects and Board Exam Performance of Isabela State University-Echague November 2022 Nursing Licensure Examination TakersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CS 507 Mid TermDocument10 pagesCS 507 Mid TermMuddsir AmanNo ratings yet

- Fresh VisionDocument2 pagesFresh VisionTerry DehartNo ratings yet

- 4058 - Bunnings Store Map - Canberra Airport ACT 4058 - PFO - WebDocument2 pages4058 - Bunnings Store Map - Canberra Airport ACT 4058 - PFO - WebplaywellmusicNo ratings yet

- Manage Prescribed Load List (PLL) AR0008 C: InstructionsDocument5 pagesManage Prescribed Load List (PLL) AR0008 C: InstructionsAmazinmets07No ratings yet

- Applying IGBTs - 5SYA 2053-04 PDFDocument22 pagesApplying IGBTs - 5SYA 2053-04 PDFbacuoc.nguyen356No ratings yet

For Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

For Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

Uploaded by

Alexander Albuja Torres0 ratings0% found this document useful (0 votes)

7 views7 pagesThis document is a supplier first article data sheet used to collect measurement data on key dimensions of a part. It requests the supplier name, part number, description, target dimension specifications, measurement details, and a table to record 30 measurements of the dimension with calculated capability indices. Any measurements outside specifications or with a Cpk below 1 would require a description and corrective action. The purpose is to verify the dimension is manufactured correctly before full production.

Original Description:

Calculo del Cp y Cpk para control estadístico de procesos

Original Title

pr000665 (1)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a supplier first article data sheet used to collect measurement data on key dimensions of a part. It requests the supplier name, part number, description, target dimension specifications, measurement details, and a table to record 30 measurements of the dimension with calculated capability indices. Any measurements outside specifications or with a Cpk below 1 would require a description and corrective action. The purpose is to verify the dimension is manufactured correctly before full production.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

7 views7 pagesFor Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

For Key Performance Characteristic Dimensions: Viasat Supplier First Article Data Sheet

Uploaded by

Alexander Albuja TorresThis document is a supplier first article data sheet used to collect measurement data on key dimensions of a part. It requests the supplier name, part number, description, target dimension specifications, measurement details, and a table to record 30 measurements of the dimension with calculated capability indices. Any measurements outside specifications or with a Cpk below 1 would require a description and corrective action. The purpose is to verify the dimension is manufactured correctly before full production.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 7

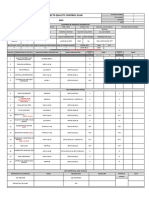

only overwrite yellow!

ViaSat Supplier First Article Data Sheet Date:

for Key Performance Characteristic Dimensions

Supplier: NAME LOCATION

ViaSat Part Number (also name worksheet tab): P/N Part Rev.: A

ViaSat Part Description:

Target dimension

Must enter upper and lower spec limits LSL>>>> <<<<USL

Dimension location on drawing: ZONE PAGE

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects:

Measuring equipment used:

Measuring precision:

Attach pictures of measuring tool showing fixtured part:

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: NAME

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 21

2 22 % OHL #DIV/0!

3 23 % ULL #DIV/0!

4 24 % NC #DIV/0!

5 25

6 26

7 27 Cp = #DIV/0!

8 28

9 29 Cpk,u = #DIV/0!

10 30 Cpk,l = #DIV/0!

11

12 Cpk = #DIV/0!

13

14

15 Cpm= #DIV/0!

16 Above is the "Taguchi

17 Capability Index,"

18 a "2nd generation" index

19 that is aligned with the

20 "Taguchi Cost Function"

average #DIV/0!

std dev #DIV/0! Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

PR000665 Rev 001 (1/11/08)

only overwrite yellow! ViaSat Supplier First Article Data Sheet Date:

for Key Performance Characteristic Dimensions

Supplier: NAME LOCATION

ViaSat Part Number (also name worksheet tab): P/N Part Rev.: A

ViaSat Part Description:

Target dimension

Must enter upper and lower spec limits LSL>>>> <<<<USL

Dimension location on drawing: ZONE PAGE

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects:

Measuring equipment used:

Measuring precision:

Attach pictures of measuring tool showing fixtured part:

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: NAME

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 21

2 22 % OHL #DIV/0!

3 23 % ULL #DIV/0!

4 24 % NC #DIV/0!

5 25

6 26

7 27 Cp = #DIV/0!

8 28

9 29 Cpk,u = #DIV/0!

10 30 Cpk,l = #DIV/0!

11

12 Cpk = #DIV/0!

13

14

15 Cpm= #DIV/0!

16 Above is the "Taguchi

17 Capability Index,"

18 a "2nd generation" index

19 that is aligned with the

20 "Taguchi Cost Function"

average #DIV/0!

std dev #DIV/0! Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

PR000665 Rev 001 (1/11/08)

only overwrite yellow! ViaSat Supplier First Article Data Sheet Date:

for Key Performance Characteristic Dimensions

Supplier: NAME LOCATION

ViaSat Part Number (also name worksheet tab): P/N Part Rev.: A

ViaSat Part Description:

Target dimension

Must enter upper and lower spec limits LSL>>>> <<<<USL

Dimension location on drawing: ZONE PAGE

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects:

Measuring equipment used:

Measuring precision:

Attach pictures of measuring tool showing fixtured part:

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: NAME

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 21

2 22 % OHL #DIV/0!

3 23 % ULL #DIV/0!

4 24 % NC #DIV/0!

5 25

6 26

7 27 Cp = #DIV/0!

8 28

9 29 Cpk,u = #DIV/0!

10 30 Cpk,l = #DIV/0!

11

12 Cpk = #DIV/0!

13

14

15 Cpm= #DIV/0!

16 Above is the "Taguchi

17 Capability Index,"

18 a "2nd generation" index

19 that is aligned with the

20 "Taguchi Cost Function"

average #DIV/0!

std dev #DIV/0! Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

PR000665 Rev 001 (1/11/08)

only overwrite yellow! ViaSat Supplier First Article Data Sheet Date:

for Key Performance Characteristic Dimensions

Supplier: NAME LOCATION

ViaSat Part Number (also name worksheet tab): P/N Part Rev.: A

ViaSat Part Description:

Target dimension

Must enter upper and lower spec limits LSL>>>> <<<<USL

Dimension location on drawing: ZONE PAGE

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects:

Measuring equipment used:

Measuring precision:

Attach pictures of measuring tool showing fixtured part:

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: NAME

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 21

2 22 % OHL #DIV/0!

3 23 % ULL #DIV/0!

4 24 % NC #DIV/0!

5 25

6 26

7 27 Cp = #DIV/0!

8 28

9 29 Cpk,u = #DIV/0!

10 30 Cpk,l = #DIV/0!

11

12 Cpk = #DIV/0!

13

14

15 Cpm= #DIV/0!

16 Above is the "Taguchi

17 Capability Index,"

18 a "2nd generation" index

19 that is aligned with the

20 "Taguchi Cost Function"

average #DIV/0!

std dev #DIV/0! Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

PR000665 Rev 001 (1/11/08)

only overwrite yellow! ViaSat Supplier First Article Data Sheet Date:

for Key Performance Characteristic Dimensions

Supplier: NAME LOCATION

ViaSat Part Number (also name worksheet tab): P/N Part Rev.: A

ViaSat Part Description:

Target dimension

Must enter upper and lower spec limits LSL>>>> <<<<USL

Dimension location on drawing: ZONE PAGE

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects:

Measuring equipment used:

Measuring precision:

Attach pictures of measuring tool showing fixtured part:

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: NAME

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 21

2 22 % OHL #DIV/0!

3 23 % ULL #DIV/0!

4 24 % NC #DIV/0!

5 25

6 26

7 27 Cp = #DIV/0!

8 28

9 29 Cpk,u = #DIV/0!

10 30 Cpk,l = #DIV/0!

11

12 Cpk = #DIV/0!

13

14

15 Cpm= #DIV/0!

16 Above is the "Taguchi

17 Capability Index,"

18 a "2nd generation" index

19 that is aligned with the

20 "Taguchi Cost Function"

average #DIV/0!

std dev #DIV/0! Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

PR000665 Rev 001 (1/11/08)

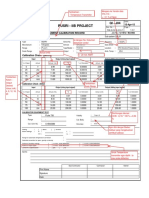

only overwrite yellow! ViaSat Supplier First Article Data Sheet Date: 1/1/2008

for Key Performance Characteristic Dimensions

Supplier: XYZ SAN DIEGO, CA

ViaSat Part Number (also name worksheet tab): 1039960 Part Rev.: A

ViaSat Part Description: LAP SHEAR

Target dimension 2200

Must enter upper and lower spec limits LSL>>>> 1600 4500 <<<<USL

Dimension location on drawing: ZONE C5 PAGE 1

Supplier recommended tolerance for this dimension: OPTIONAL

Attach recommended tolerancing handbook, if available: OPTIONAL

Primary fabrication method used effecting this dimension:

Function dimension effects: BONDLINE COMPLETED EXAM

Measuring equipment used:

Measuring precision:

SHEAR FRAME

-25

FOR ILLUSTRAT

Attach pictures of measuring tool showing fixtured part: PUPOSES ONL

OPTIONAL

(use: insert - object - create from file - icon)

Attach any gage R&R study done on this tool:

Measurement tool operator name: OCM TEST LAB

Fill-in Table

use new spreadsheet tab for each (30 measurements preferred,

partnumber Part ID: Measurement Part ID: Measurement 20 minimum)

1 2980.000 21 3950.000

2 2260.000 22 4300.000 % OHL 9.952%

3 4280.000 23 4080.000 % ULL 3.010%

4 3540.000 24 3910.000 % NC 12.962%

5 2380.000 25 3810.000

6 2292.000 26 3820.000

7 2950.000 27 Cp = 0.527

8 1783.000 28

9 2499.000 29 Cpk,u = 0.428

10 1904.000 30 Cpk,l = 0.626

11 2646.000

12 2834.000 Cpk = 0.428

13 4095.000

14 2886.000

15 2882.000 Cpm= 0.333

16 2495.000 Above is the "Taguchi

17 4895.000 Capability Index,"

18 5034.000 a "2nd generation" index

19 3519.000 that is aligned with the

20 4367.000 "Taguchi Cost Function"

average 3322.7308

std dev 916.6680777 Best if all Cp's > 1

If any measurements are not within spec range, or Cpk<1.0, describe reason & corrective action:

801.4 MADE LAP SHEAR FIXT. TO HOLD .008 BONDLINE ON LAP SHER SPECIMENS TEST #

261720 ELIMNATING .OO8 WIRE IN BOND ADHESIVE

PR000665 Rev 001 (1/11/08)

D EXAMPLE

STRATIVE

ES ONLY

PR000665 Rev 001 (1/11/08)

You might also like

- Risk Assessment of Fire Hose Reel InstallationDocument9 pagesRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- ASV 2800 2810 Posi Track Loader Parts Manual DownloadDocument61 pagesASV 2800 2810 Posi Track Loader Parts Manual DownloadShiv Kumar0% (1)

- AutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionFrom EverandAutoCAD Electrical 2017 for Electrical Control Designers, 8th EditionRating: 3 out of 5 stars3/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceFrom EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNo ratings yet

- Good Medical PracticeDocument22 pagesGood Medical PracticeRanjita BainsNo ratings yet

- Historinha Clima G5Document28 pagesHistorinha Clima G5Miss HelenNo ratings yet

- R-30iA Cimplicity Operator Manual (B-82604EN 01)Document90 pagesR-30iA Cimplicity Operator Manual (B-82604EN 01)YoganandhK100% (1)

- HiPath Xpressions Compact V3.0 Installation Administration GuideDocument194 pagesHiPath Xpressions Compact V3.0 Installation Administration GuideenjoythedocsNo ratings yet

- Взвешивающая Система Top Master - engDocument33 pagesВзвешивающая Система Top Master - enggluykNo ratings yet

- Mini Project: A Simple Xerox Machine Controller: 23 JAN 2021 SECR1013 Digital LogicDocument19 pagesMini Project: A Simple Xerox Machine Controller: 23 JAN 2021 SECR1013 Digital LogicIsmail LifeNo ratings yet

- Capabilidade 501220 - (Doosan5024)Document6 pagesCapabilidade 501220 - (Doosan5024)Marcos PoffoNo ratings yet

- Introduction To PSpiceDocument15 pagesIntroduction To PSpiceUmera Anjum100% (1)

- Staad Model Report 6dec21Document25 pagesStaad Model Report 6dec21Anwar Issa MatarnehNo ratings yet

- Mincoef Maxcoef Range: DSP Scaling, A Pid Example: Difference Equations Must Be Scaled ToDocument9 pagesMincoef Maxcoef Range: DSP Scaling, A Pid Example: Difference Equations Must Be Scaled ToVIJAYPUTRANo ratings yet

- Universal Measuring Device: Brief Instructions See Last PageDocument32 pagesUniversal Measuring Device: Brief Instructions See Last PagealeksandarlaskovNo ratings yet

- Lab No2 To Find Unknown Branch Current in A Circuit Containing Dependent SourceDocument3 pagesLab No2 To Find Unknown Branch Current in A Circuit Containing Dependent SourcedaudNo ratings yet

- Membuat One Line Diagram (SLD)Document5 pagesMembuat One Line Diagram (SLD)Muhammad Harris MunandarNo ratings yet

- Instruction: Do Not Edit/alterDocument68 pagesInstruction: Do Not Edit/alterRenee LaagNo ratings yet

- MB - Cdiasworks - Manual Práctico Operaciones SolidworksDocument26 pagesMB - Cdiasworks - Manual Práctico Operaciones SolidworksGabrielSorianoNo ratings yet

- KKKL2151 - Lab 0 - Recovery Simulation - V2Document8 pagesKKKL2151 - Lab 0 - Recovery Simulation - V2Chang YongNo ratings yet

- Especificaciones BandejaDocument9 pagesEspecificaciones BandejaJulianNo ratings yet

- Protel DXP TutorialDocument123 pagesProtel DXP TutorialMarkNo ratings yet

- Module 3 AE4 Linear Programming The Simplex MethodDocument73 pagesModule 3 AE4 Linear Programming The Simplex MethodEleyna AlcatrazNo ratings yet

- Lab 2 (I) 2Document3 pagesLab 2 (I) 2SchaieraNo ratings yet

- Chapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFDocument18 pagesChapter 2 - DC Bias Point - 2018 - Analog Design and Simulation Using OrCAD Cap PDFLuis Felipe Blanco CatalánNo ratings yet

- Metrology Lab Fair Record FormatDocument140 pagesMetrology Lab Fair Record FormatnNo ratings yet

- MB - CDIASWORKS - Manual Práctico CHAPA METÁLICA SolidWorksDocument26 pagesMB - CDIASWORKS - Manual Práctico CHAPA METÁLICA SolidWorksGabrielSorianoNo ratings yet

- Electric Machine Design ANSYS Maxwell ToolkitTuToDocument310 pagesElectric Machine Design ANSYS Maxwell ToolkitTuToYsid Bello C67% (3)

- FlowCAD AN PSpice Etable SubcktDocument9 pagesFlowCAD AN PSpice Etable SubcktMaherNo ratings yet

- 00002447a PDFDocument24 pages00002447a PDFlumix345-web1802No ratings yet

- Gascalc 5.0: Calculation ReferenceDocument12 pagesGascalc 5.0: Calculation Referencekarioke mohaNo ratings yet

- Microcontroller Cores ForDocument8 pagesMicrocontroller Cores ForGoran MiljkovicNo ratings yet

- 12-MGDP-L-9005-0 (Tagging Procedure)Document34 pages12-MGDP-L-9005-0 (Tagging Procedure)Aly ShahNo ratings yet

- How To Calculate Basic Pitch TimeDocument3 pagesHow To Calculate Basic Pitch TimealaminNo ratings yet

- R-L TransientDocument4 pagesR-L Transientsalmansalem3002No ratings yet

- Electric Circuit Analysis LabDocument6 pagesElectric Circuit Analysis Labms2sl4No ratings yet

- A Freeware-Based Antenna Simulation Exercise: L. Brent JenkinsDocument8 pagesA Freeware-Based Antenna Simulation Exercise: L. Brent JenkinsnoubernouNo ratings yet

- Catalogue Vaccum Recloser 3AD enDocument50 pagesCatalogue Vaccum Recloser 3AD enVannak TAINGNo ratings yet

- J&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationDocument16 pagesJ&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationEnrico BishopNo ratings yet

- UICAFE12815-ENG-CAL-XXXX Rev ADocument23 pagesUICAFE12815-ENG-CAL-XXXX Rev AElias EliasNo ratings yet

- Total Manpower Costs: 1,000.00 2,000.00Document3 pagesTotal Manpower Costs: 1,000.00 2,000.00reninbabaskiNo ratings yet

- Phycore - A5D2X: Hardware ManualDocument36 pagesPhycore - A5D2X: Hardware ManualNelaparthy BenhurNo ratings yet

- Pareto Charts: Xbar ChartDocument12 pagesPareto Charts: Xbar ChartYahya AljarokNo ratings yet

- Appendix G - OrCAD 10.5 TutorialDocument20 pagesAppendix G - OrCAD 10.5 TutorialcrazycheekboyNo ratings yet

- ENGN2912E Cadence FirstCMOSDesignDocument5 pagesENGN2912E Cadence FirstCMOSDesignsanssansshilthNo ratings yet

- DINACELL CÉLULA DE CARGA 1262-04 (En - Web)Document33 pagesDINACELL CÉLULA DE CARGA 1262-04 (En - Web)Ton marquesNo ratings yet

- AN0254Document14 pagesAN0254muthukumar_eee3659No ratings yet

- How To Use Dependent Source in pSPICEDocument27 pagesHow To Use Dependent Source in pSPICEMyunghwan Ryu0% (1)

- Not Required: Verification of Equipment (Weekly)Document3 pagesNot Required: Verification of Equipment (Weekly)asdasdasdasdNo ratings yet

- Lab 2 (Ii) ValveDocument3 pagesLab 2 (Ii) ValveSchaieraNo ratings yet

- Measurement System AnalysisDocument21 pagesMeasurement System AnalysisArijitMalakarNo ratings yet

- NG3S238 CFD Assingment Cover Sheet 2020-21Document5 pagesNG3S238 CFD Assingment Cover Sheet 2020-21Ahmed Al SayedNo ratings yet

- Control Charts and Bench Sheets Manuals and Procedures For Accredited LaboratoriesDocument18 pagesControl Charts and Bench Sheets Manuals and Procedures For Accredited LaboratoriesDiana RuizNo ratings yet

- Gascalc 5.0: Calculation ReferenceDocument15 pagesGascalc 5.0: Calculation ReferenceApril TrevinoNo ratings yet

- Family Hydro - A Propeller Type Micro TurbineDocument4 pagesFamily Hydro - A Propeller Type Micro TurbineFathur RahmanNo ratings yet

- PCB Design: Exercise 2Document6 pagesPCB Design: Exercise 2juenkkoNo ratings yet

- Eoc 2Document7 pagesEoc 2Iman AthirahNo ratings yet

- OSMRE BIVDEP DocumentationDocument22 pagesOSMRE BIVDEP DocumentationrodrigoNo ratings yet

- PSPICE (Orcad Family Release 9.2 Lite Edition) Installation InstructionsDocument3 pagesPSPICE (Orcad Family Release 9.2 Lite Edition) Installation InstructionsDipal JaniNo ratings yet

- Bi Metal, Liquid in Glass, Remote Reading ThermosDocument16 pagesBi Metal, Liquid in Glass, Remote Reading ThermosMatthew ShawNo ratings yet

- Navair 17-20aq-347Document23 pagesNavair 17-20aq-347ampinto1No ratings yet

- LAB #01 To Determine Unknown Voltage and Current in A DC Network ObjectiveDocument8 pagesLAB #01 To Determine Unknown Voltage and Current in A DC Network ObjectiveImaad KhanNo ratings yet

- PSpice16 6 TutorialDocument20 pagesPSpice16 6 TutorialAmbili MuraliNo ratings yet

- Contoh Form TTDocument1 pageContoh Form TTgerry rutmNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Ford Half ShaftDocument10 pagesFord Half Shaftsuysuy00No ratings yet

- Academic Calendar 2023 Undergraduate OdlDocument1 pageAcademic Calendar 2023 Undergraduate Odlbroken swordNo ratings yet

- ThermoFisherScientific 10K 20130227Document157 pagesThermoFisherScientific 10K 20130227siddk0312No ratings yet

- Fracture ToughnessDocument3 pagesFracture ToughnessMinu.j.j100% (1)

- Personal Information: Single / Male / Indonesia / Purwakarta Passport / - / C2940195Document5 pagesPersonal Information: Single / Male / Indonesia / Purwakarta Passport / - / C2940195Muhammad RaihanNo ratings yet

- Eposter For Art & Science of Patient PreparationDocument50 pagesEposter For Art & Science of Patient PreparationdrsmritiNo ratings yet

- Dual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RDocument4 pagesDual Stack 10G Ethernet Routing Fiber Switch: AP6500E-16X-4XG-RManojit SahaNo ratings yet

- Basic Data Kar Part 4Document11 pagesBasic Data Kar Part 4vpmohammedNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Interpretation of Vane Shear Tests For Geotechnical Stability CalculationsDocument9 pagesInterpretation of Vane Shear Tests For Geotechnical Stability CalculationsiliavaNo ratings yet

- ApomixisDocument3 pagesApomixisAnonymous yKjxyeLNo ratings yet

- HRC - Forms - Employee Application - Rev2019 NewDocument3 pagesHRC - Forms - Employee Application - Rev2019 NewGanang CucuNo ratings yet

- Analysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)Document9 pagesAnalysis of Behaviour of Multistorey RCC Structure With Different Types of Bracing System (By Using Software)IJRASETPublicationsNo ratings yet

- G6PD Deficiency - Favism FINAL Oct2018Document3 pagesG6PD Deficiency - Favism FINAL Oct2018Hana'a GhalibNo ratings yet

- Passive Cooling 1Document15 pagesPassive Cooling 11SI17AT024 MOHAMMED AASIM ATIQNo ratings yet

- Solar Generator (LB-P500-A) : Product DetailsDocument2 pagesSolar Generator (LB-P500-A) : Product Detailsbogdan danescuNo ratings yet

- Connectors of Addition and ContrastDocument3 pagesConnectors of Addition and ContrastAnamaria OnițaNo ratings yet

- Correlational Relationship of Nursing Professional Subjects and Board Exam Performance of Isabela State University-Echague November 2022 Nursing Licensure Examination TakersDocument20 pagesCorrelational Relationship of Nursing Professional Subjects and Board Exam Performance of Isabela State University-Echague November 2022 Nursing Licensure Examination TakersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CS 507 Mid TermDocument10 pagesCS 507 Mid TermMuddsir AmanNo ratings yet

- Fresh VisionDocument2 pagesFresh VisionTerry DehartNo ratings yet

- 4058 - Bunnings Store Map - Canberra Airport ACT 4058 - PFO - WebDocument2 pages4058 - Bunnings Store Map - Canberra Airport ACT 4058 - PFO - WebplaywellmusicNo ratings yet

- Manage Prescribed Load List (PLL) AR0008 C: InstructionsDocument5 pagesManage Prescribed Load List (PLL) AR0008 C: InstructionsAmazinmets07No ratings yet

- Applying IGBTs - 5SYA 2053-04 PDFDocument22 pagesApplying IGBTs - 5SYA 2053-04 PDFbacuoc.nguyen356No ratings yet