Professional Documents

Culture Documents

Sustainable Production of Biofuel Bioethanol From Shellfish Waste

Sustainable Production of Biofuel Bioethanol From Shellfish Waste

Uploaded by

Subkhan11Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustainable Production of Biofuel Bioethanol From Shellfish Waste

Sustainable Production of Biofuel Bioethanol From Shellfish Waste

Uploaded by

Subkhan11Copyright:

Available Formats

Sustainable production of biofuel

(bioethanol) from shellfish waste

Sustainable production of biofuel (bioethanol) from shellfish

waste.

SUMMARY

The research group of Plant Pathology at the University of Alicante has

developed a new process by using fungi to produce biofuel (bioethanol) and

fungal biomass for agrobiotech use from shellfish waste. It is a sustainable

alternative to agroforestry crops currently used. The current technology stands

out because it uses chitosan as the sole source of nutrients, and produces

bioethanol in profitable, sustainable and environmentally friendly manner. The

research group is looking for companies or investors partners interested in

acquiring this technology for commercial exploitation.

INTRODUCTION

The decline in oil reserves is raising interest in biofuels as alternative to fossil

fuels. Liquid or gas biofuels are obtained from biomass. Biodiesel and

bioethanol are the only biofuels currently produced and used on a large scale

worldwide. Bioethanol is the most widely used biofuel. In fact, data on

Bioethanol production is increasing with a total production in the United States

in 2011 of 52,617 million liters, a 4.5 % increase versus 2010.

Current biofuel production is mainly carried out by yeast fermentation (eg.

Saccharomyces cerevisiae) of plant raw material with high sugar content.

Yeasts have high growth potential under fermentative conditions since they

tolerate high concentrations of substrate and they are highly resistant to the

ethanol than they themselves produce. However , the use of plant raw

materials for biofuels poses serious economic, social and environmental

problems due to the necessary increase in the cultivated area for this purpose.

In this sense, the high demand for agricultural biofuels would be a huge effort to

produce sufficient raw material, which would in turn adversely affect food price

and availability.

To solve these problems, it is advisable to use alternative substrates to crops

that would allow high biofuel production at competitive costs. Agroforestry,

industrial or fish waste are potential raw materials for biofuel production.

However, most of these residues require pre-treatments (for example, chemical

or enzymatic pre-digestions) prior to yeast fermentation that complicate

production and increasing costs.

In the other hand, chitin is one of the most abundant biopolymers on Earth. It is

a key component of the exoskeleton of many invertebrates (insects,

SGITT-OTRI (University of Alicante) 2

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

crustaceans, molluscs, nematodes), and of the cell wall of true fungi. Shellfish

waste (especially marine crustaceans) is an abundant and readily available (a

fishing industry by-product) source of chitin. Since it is nitrogen rich its disposal

has a negative environmental impact, mainly due to ammonia toxicity.

Chitosan is a chitin derivative with high antimicrobial activity spectrum

(bactericidal and fungicidal), useful both in medicine and agriculture. However,

chitosan has not been used as biofuel raw material, since traditional fermenting

organisms (eg. Saccharomyces cerevisiae), are sensitive to chitosan and

therefore unable to use it. Consequently, new strategies to use chitin waste

which would reduce its negative environmental impact are needed.

TECHNICAL DESCRIPTION

We have developed a novel process for producing biofuel (bioethanol) and

fungal biomass for sustainable crop pest management as by-product. This

novel process can use waste from the shellfish industry (or other sources of

chitin or chitosan), as an alternative raw material to the use of crops or

agroforestry residues. Our process is a sustainable way to eliminate the

pollution caused by shellfish waste. We use nematophagous and

entomopathogenic fungi which are able to grow efficiently in anaerobiosis,

producing ethanol from the reducing sugars obtained from chitosan, chitin or

their derivatives (produced as a result of the degradation of the shellfish

industry waste). These nematophagous and entomopathogenic fungi are:

• Pochonia chlamydosporia.

• Beauveria bassiana.

• Metarhizium anisopliae.

Fungi (as conidia and chlamydospores) are at given concentrations that allow

rapid and abundant growth without producing self-inhibition.

SGITT-OTRI (University of Alicante) 3

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

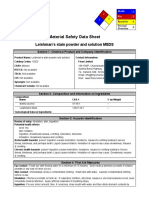

Appearance of 15 day-old colonies of Pochonia chlamydosporia growing with chitosan

under aerobic and anaerobic conditions . The dark halo around the colonies of the

fungus corresponds to the degradation of chitosan.

ADVANTAGES OF THE TECHNOLOGY

• Fungi can grow under high chitosan concentrations (more than 2

mg/ml), which are toxic to other microorganisms conditions, thus

reducing culture contamination.

• Fungi use chitosan as a sole source of nutrients.

• Fungi produce a large amount of reducing sugars which are fermented

into ethanol.

• Fungi can grow under anaerobic conditions.

• Fungi are able to tolerate the amount of ethanol that they themselves

produce in the culture medium (no self-inhibition occurs).

• Fungi encode in their genomes zinc-dependent alcohol

dehydrogenases and pyruvate decarboxylases that are required to

produce ethanol.

SGITT-OTRI (University of Alicante) 4

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

• Fungi produce ethanol and fungal biomass from chitosan rich

residues of the shellfish industry, thus reducing pollution they cause.

• The process is sustainable and environmentally friendly.

• It is profitable process.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

We have developed a new procedure for producing biofuel (ethanol) using

shellfish industry waste and nematophagous or entomopathogenic fungi. It is

a sustainable non-food alternative to crops or agroforestry waste

processed, instead of the traditional fermentation processes.

CURRENT STATE OF THE TECHNOLOGY

We have obtained under laboratory conditions up to 2% ethanol by growing

aerobic and anaerobically nematophagous and entomopathogenic fungi

(Pochonia chlamydosporia, Beauveria bassiana, Metarhizium anisopliae) with

chitosan as only nutrient source.

The research group has the know-how to scale-up and improve their results to

pre-industrial level to show their full potential and profitability.

INTELLECTUAL PROPERTY RIGHTS

The present invention is protected through 3 patent applications:

Patent 1:

• Tittle: “Procedimiento para la producción de bioetanol a partir de

quitosano mediante el uso del hongo nematófago Pochonia

chlamydosporia”.

• Application number: P201530552.

• Application date: 27th April 2015.

SGITT-OTRI (University of Alicante) 5

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

Patent 2:

• Tittle: “Procedimiento para la producción de bioetanol a partir de

quitosano mediante el uso del hongo entomopatógeno Metarhizium

anisopliae”.

• Application number: P201530894.

• Date of Application: 27th April 2015.

Patent 3:

• Tittle: “Procedimiento para la producción de bioetanol a partir de

quitosano mediante el uso del hongo entomopatógeno Beauveria

bassiana”.

• Application number: P201530895.

• Date of Application: 27th April 2015.

APPLICATION SECTORS

This technology is part of the field of Biotechnology . It is a novel process for

ethanol and fungal biomass production as by-product using entomopathogenic

and nematophagous fungi and a source of chitosan.

Applications:

• Biofuel production (bioethanol) as an alternative to ethanol produced

by fermentation processes (using yeast) from plant as raw material.

• Production of fungal biomass for sustainable crop protection.

• Biodegradation and decontamination of shellfish industry waste (the

high nitrogen content of this waste leads eutrophication, so that its

uncontrolled disposal has serious environmental problems).

COLLABORATION SOUGHT

Companies or investors partners interested in acquiring this technology for

commercial exploitation through:

• License agreement of the patents.

• Search for funding opportunities to develop new applications adapted to

the specific needs of the company.

SGITT-OTRI (University of Alicante) 6

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

• Technology and knowledge transfer agreements.

• Technical reports and scientific advice services.

• Standardization, calibration, development of national and international

technical standards.

• Provide technical support in those techniques that require highly skilled

personnel or sophisticated instruments that are not available for the

applicant.

• Staff exchange for defined time periods (eg. for learning a technique).

• Rental own equipment to customers who wish to conduct their own tests

(through own infrastructure of the Department of Marine Sciences and

Applied Biology or Common Research Facilities (SSTTI) at the University

of Alicante).

KEYWORDS

Biofuel, bioethanol, chitin, chitosan, shellfish waste, Pochonia chlamydosporia,

Beauveria bassiana, Metarhizium anisopliae.

OTHER DATA OF INTEREST

The research group of Plant Pathology at the University of Alicante was created

in 1990 (http://www.fungalinteractions.org/). Research in the group aims at

understanding the mode of action (at molecular, cell and ecological levels) and

practical development of biocontrol fungi. The group also works on the

endophytic behaviour of nematophagous (especially the nematode egg-

parasite Pochonia chlamydosporia) and entomopathogenic fungi

(mainly Beauveria bassiana), and their implications in biocontrol and plant

growth promotion. The research group also worked on the role of fungal root

endophytes in natural vegetation under stress and their applications. The group

is currently researching about chitosan (a seafood waste product) as a fungicide

for human pathogenic fungi and yeast, and its compatibility with biocontrol fungi.

After the genome sequencing of Pochonia chlamydosporia the lab is currently

developing the fungus as a cell factory for antimicrobial, enzyme and biofuel

applications (as this technological offer). These results have been published in

more than 100 papers (and book chapters), most of them with high impact in

SGITT-OTRI (University of Alicante) 7

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

the scientific and technological communities. The laboratory has requested

more than 10 patents about the development of fungi (production, formulation)

for biotechnological applications. The research group has also developed and

patented the interactions of fungi with chitosan applicable to control fungal

pathogens or to enhace biocontrol fungi. It has been also patented the

application of biocontrol fungi in plant growth/development promotion. The plant

pathology group actively collaborates with Spanish and international research

groups (Germany, Central America, Australia, Brasil, Canada, Finland, Holland,

Italy, United Kingdom, Russia and the USA), as well as with prestigious

companies.

CONTACT

Víctor Manuel Pérez Lozano

SGITT-OTRI (Universidad de Alicante)

Phone: +34 96 590 9959

Fax: +34 96 590 3803

E-Mail: areaempresas@ua.es

URL: http://sgitt-otri.ua.es/es/empresa/ofertas-tecnologicas.html

SGITT-OTRI (University of Alicante) 8

Phone: +34965909959 Fax: +34965903803 E-mail: areaempresas@ua.es

You might also like

- Table Conversion TOEFLDocument1 pageTable Conversion TOEFLOvila Nanci Septiawan100% (2)

- Mercruiser 525 EfiDocument126 pagesMercruiser 525 EfiNicky Jans100% (1)

- Methamphetamine ManufactureDocument31 pagesMethamphetamine ManufactureNafis NizamNo ratings yet

- CAPE CHEMISTRY UNIT 2-Comparing AciditiesDocument22 pagesCAPE CHEMISTRY UNIT 2-Comparing AciditiesRikkiNo ratings yet

- Yellow Blue Colorful Illustrated Education Presentation 169Document14 pagesYellow Blue Colorful Illustrated Education Presentation 169Mike Clinton BilogNo ratings yet

- Lecture 1 Introduction To Biotechnology Ramadan YahiaDocument28 pagesLecture 1 Introduction To Biotechnology Ramadan YahiaRamez JasonNo ratings yet

- Industrial MicrobiologyDocument18 pagesIndustrial MicrobiologyRajini hc100% (2)

- Namitha M R 2015664502 M.Tech. in Land and Water Management Engineering AEC & RI, Kumulur TnauDocument56 pagesNamitha M R 2015664502 M.Tech. in Land and Water Management Engineering AEC & RI, Kumulur TnauLakshay BatraNo ratings yet

- 1243 - Industrial Micro OverviewDocument18 pages1243 - Industrial Micro OverviewGounder KirthikaNo ratings yet

- White Biotechnology Final PDFDocument4 pagesWhite Biotechnology Final PDFMayank SharmaNo ratings yet

- Colors of BiotechnologyDocument66 pagesColors of Biotechnologyasdfgh0% (1)

- Biotech Lec 1 Introd PDFDocument5 pagesBiotech Lec 1 Introd PDFnareman hassanNo ratings yet

- Biotech Lec 1 IntrodDocument5 pagesBiotech Lec 1 Introdnareman hassanNo ratings yet

- Presentation On The Topic of Industrial Microbiology by MariyaDocument13 pagesPresentation On The Topic of Industrial Microbiology by MariyaShubham MishraNo ratings yet

- Microbial Biotechnology and Industrial ApplicationDocument13 pagesMicrobial Biotechnology and Industrial ApplicationinnocentNo ratings yet

- Biotechnology q4Document6 pagesBiotechnology q4viendalisay27No ratings yet

- Industrial BiotechnologyDocument9 pagesIndustrial BiotechnologyRohailNo ratings yet

- Group 8 - Biodiversity FinalDocument15 pagesGroup 8 - Biodiversity FinalmanlanothammillanNo ratings yet

- BIO FLOC TECHNOLOGY For Sustainable AquacultureDocument19 pagesBIO FLOC TECHNOLOGY For Sustainable AquacultureRabia HaiderNo ratings yet

- Q4 - Week 5 - IndustryDocument10 pagesQ4 - Week 5 - Industrynormalguy34kNo ratings yet

- Report On BiotechnologyDocument10 pagesReport On BiotechnologyPrayash SinghNo ratings yet

- BioTech TextilesDocument11 pagesBioTech TextilesSaket UpadhyayNo ratings yet

- Bioresource Technology: ReviewDocument11 pagesBioresource Technology: ReviewDaniela FonsecaNo ratings yet

- Biochemical EngineeringDocument17 pagesBiochemical EngineeringÅrñäb RøyNo ratings yet

- Plant BiotechnologyDocument3 pagesPlant BiotechnologyLittleagleNo ratings yet

- Mbio313 Assignment 2Document8 pagesMbio313 Assignment 2Razia UrmiNo ratings yet

- Bioethanol Production From Pineapple (AnanasDocument6 pagesBioethanol Production From Pineapple (Ananasdauda usmanNo ratings yet

- Techno-Economic Assessment of Microbial Limonene PDocument8 pagesTechno-Economic Assessment of Microbial Limonene Ppaula martinezNo ratings yet

- Industrial Applications of Crustacean By-Products (Chitin, Chitosan, and Chitooligosaccharides) : A ReviewDocument12 pagesIndustrial Applications of Crustacean By-Products (Chitin, Chitosan, and Chitooligosaccharides) : A ReviewNatalia PadillaNo ratings yet

- BiotechnologyDocument27 pagesBiotechnologySunil PillaiNo ratings yet

- Teri MicorisaDocument7 pagesTeri MicorisabiodieselnetNo ratings yet

- What Is Bioprocess?Document28 pagesWhat Is Bioprocess?sanyukta sinhaNo ratings yet

- Plant Biotechnology: A Resource Guide For Biotechnology Club SponsorsDocument30 pagesPlant Biotechnology: A Resource Guide For Biotechnology Club SponsorsmondereyNo ratings yet

- BIOTECHNOLOGYDocument8 pagesBIOTECHNOLOGYvijaysecondmailNo ratings yet

- Biochemical Power Point Chapter OneDocument22 pagesBiochemical Power Point Chapter OneEstifa negashNo ratings yet

- Introduction To BiotechnologyDocument13 pagesIntroduction To BiotechnologyManar ElropiNo ratings yet

- To DefenseDocument121 pagesTo DefenseLeslie Jean ObradorNo ratings yet

- Biotechnology and IndustryDocument7 pagesBiotechnology and IndustryDionne Carel Paliwanan-RonquilloNo ratings yet

- 160 PresentationDocument46 pages160 PresentationRuben MarquezNo ratings yet

- ICBA 2019 - SDG Brochure - FinalDocument44 pagesICBA 2019 - SDG Brochure - FinalDeepto G. MorshedNo ratings yet

- Enzyme and Ethanol Production Using Water Hyacinth BiomassDocument22 pagesEnzyme and Ethanol Production Using Water Hyacinth BiomassRajeev SukumaranNo ratings yet

- Feed Mill Sanitation: Institute of Animal Health & Veterinary BiologicalDocument7 pagesFeed Mill Sanitation: Institute of Animal Health & Veterinary Biologicaljose seguraNo ratings yet

- A Not On Biochemical EngineeringDocument81 pagesA Not On Biochemical EngineeringSuleiman TaofeeqNo ratings yet

- Introduction and Definition BiotecDocument4 pagesIntroduction and Definition BiotecworknehbethanyNo ratings yet

- Egypt Agricultural Biotechnology Annual 2018 Egypt Needs A Biosafety Framework For Agricultural BiotechnologyDocument13 pagesEgypt Agricultural Biotechnology Annual 2018 Egypt Needs A Biosafety Framework For Agricultural BiotechnologyÖjiNo ratings yet

- Biotechnology and Its ApplicationsDocument11 pagesBiotechnology and Its ApplicationsrealdarkbladeNo ratings yet

- Assignment BiotechnologyDocument2 pagesAssignment Biotechnologypalconganhenry15No ratings yet

- Types of Biotechnology BrochureDocument2 pagesTypes of Biotechnology Brochure여자마비100% (1)

- Nguyen Thi Kim Hue Et Al. 2020 Potential of Garlic Oil To Control Biological Contamination of Chlamydomonas Cultures by The Ciliate OxytrichaDocument7 pagesNguyen Thi Kim Hue Et Al. 2020 Potential of Garlic Oil To Control Biological Contamination of Chlamydomonas Cultures by The Ciliate OxytrichaHue NguyenNo ratings yet

- 1 Introduction To BiotechnologyDocument2 pages1 Introduction To BiotechnologyxNo ratings yet

- Biotechnology and Its ApplicationsDocument11 pagesBiotechnology and Its ApplicationsArchana shuklaNo ratings yet

- Lecture 2 SMDocument25 pagesLecture 2 SMRohan MatreNo ratings yet

- BiotechnologyDocument27 pagesBiotechnologyreethudavidson2002No ratings yet

- 3 PDFDocument9 pages3 PDFRiana HzNo ratings yet

- Genetically Modified Organisms (Gmos) and EnvironmentDocument41 pagesGenetically Modified Organisms (Gmos) and EnvironmentManish KumarNo ratings yet

- Theme 7 KBBE Biowaste 4SPDocument42 pagesTheme 7 KBBE Biowaste 4SPMarlon AbdullahNo ratings yet

- Biorefinery of Microalgae For Food and Fuel - WageningenDocument8 pagesBiorefinery of Microalgae For Food and Fuel - WageningenCarlosNo ratings yet

- Applications in Environmental BiotechDocument13 pagesApplications in Environmental BiotechabhithkrNo ratings yet

- Biotechnology Basic TermsDocument3 pagesBiotechnology Basic TermsSoumen PaulNo ratings yet

- Looking at Edible Insects from a Food Safety Perspective: Challenges and Opportunities for the SectorFrom EverandLooking at Edible Insects from a Food Safety Perspective: Challenges and Opportunities for the SectorNo ratings yet

- Microbial Biocontrol Agents: Developing Effective BiopesticidesFrom EverandMicrobial Biocontrol Agents: Developing Effective BiopesticidesGerardo PuopoloNo ratings yet

- Pertemuan 5Document23 pagesPertemuan 5Subkhan11No ratings yet

- Docslide - Us Table Conversion TOEFLDocument2 pagesDocslide - Us Table Conversion TOEFLSubkhan11No ratings yet

- Choosing The Right Scholarship Type For Your Otago Master'S DegreeDocument1 pageChoosing The Right Scholarship Type For Your Otago Master'S DegreeSubkhan11No ratings yet

- Cold Start Emissions of An SI Engine Using Ethanol-Gasoline Blended FuelDocument5 pagesCold Start Emissions of An SI Engine Using Ethanol-Gasoline Blended FuelDarel DalmassoNo ratings yet

- A Surprising New Medium For Specimen Preservation and DisplayDocument2 pagesA Surprising New Medium For Specimen Preservation and DisplayMarienNo ratings yet

- 19 Documents HiraDocument6 pages19 Documents HiraDeblina AroraNo ratings yet

- Application of Magnetic Stirrer For Influencing Extraction Method OnDocument4 pagesApplication of Magnetic Stirrer For Influencing Extraction Method OnCarla MetarNo ratings yet

- Chemical Guide Caen Ipex PVCDocument14 pagesChemical Guide Caen Ipex PVCZulfequar KhanNo ratings yet

- Material Safety Data Sheet: Leishman's Stain Powder and Solution MSDSDocument5 pagesMaterial Safety Data Sheet: Leishman's Stain Powder and Solution MSDSmaha muhammedNo ratings yet

- Carew and CoDocument34 pagesCarew and CoMd Loby MahmudNo ratings yet

- Haloalkanes & HaloarenesDocument28 pagesHaloalkanes & HaloarenesFam IlyNo ratings yet

- WO2010069028A1Document26 pagesWO2010069028A1NnaLupizNo ratings yet

- Beer Wine CompositionDocument29 pagesBeer Wine CompositionDougMooreNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument20 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary EducationHaider AliNo ratings yet

- 6 SikloheksenaDocument13 pages6 SikloheksenaHasrilia BeskaraNo ratings yet

- Chemistry Lab Report 25.04.2024Document11 pagesChemistry Lab Report 25.04.2024ryuutoranekoNo ratings yet

- CH 01Document31 pagesCH 01loverNo ratings yet

- Ozo Hand Sanitizer Spec Sheet Rev.5Document1 pageOzo Hand Sanitizer Spec Sheet Rev.5bernardo vergaraNo ratings yet

- Oxidation of Aromatic Aldehydes Using Oxone: Green ChemistryDocument3 pagesOxidation of Aromatic Aldehydes Using Oxone: Green ChemistryArish AhmedNo ratings yet

- Characterization of Antimicrobial Polylactic Acid Based FilmsDocument9 pagesCharacterization of Antimicrobial Polylactic Acid Based FilmsMuhammad Mushtaq AliNo ratings yet

- DNA Extraction PDFDocument6 pagesDNA Extraction PDFSteve StevensonNo ratings yet

- Manual - High Capacity Tank With Collapsible Structure (EN) (PDF, 495.94 KB)Document8 pagesManual - High Capacity Tank With Collapsible Structure (EN) (PDF, 495.94 KB)Forum PompieriiNo ratings yet

- US4472593 - Paten FixDocument4 pagesUS4472593 - Paten FixDaradjati HendroNo ratings yet

- Physical Properties TableDocument12 pagesPhysical Properties TableALIF SYAKIR SATARNo ratings yet

- Synthesis of New Aryliden Derivative of 3-AminorhodanineDocument3 pagesSynthesis of New Aryliden Derivative of 3-AminorhodanineNgô Thị Mộng TuyềnNo ratings yet

- Our Product and Price List On 6 Jul 2015Document2 pagesOur Product and Price List On 6 Jul 2015DrShailesh SawaleNo ratings yet

- Alcohols, Organic ChemistryDocument32 pagesAlcohols, Organic Chemistryclassy43390% (1)

- Review Poison N ToxicologyDocument10 pagesReview Poison N ToxicologyAceAsabu100% (1)

- 2.5 (2.5) .Separating MixturesDocument24 pages2.5 (2.5) .Separating MixturesNicaliaNo ratings yet

- Research DesignDocument14 pagesResearch DesignNicoleNo ratings yet