Professional Documents

Culture Documents

Design of Piercing and Punching

Design of Piercing and Punching

Uploaded by

jacky hansdah0 ratings0% found this document useful (0 votes)

210 views41 pagesThis document discusses various types of dies used in punching and blanking operations, including conventional dies, inverted dies, compound dies, progressive dies, and combination dies. It also covers design considerations for punches, such as plain punches, pedestal punches, and punches with shedders. Additional components discussed are knockouts, pilots, strippers, and stock stops.

Original Description:

type of dies

Original Title

design of piercing and punching

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses various types of dies used in punching and blanking operations, including conventional dies, inverted dies, compound dies, progressive dies, and combination dies. It also covers design considerations for punches, such as plain punches, pedestal punches, and punches with shedders. Additional components discussed are knockouts, pilots, strippers, and stock stops.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

210 views41 pagesDesign of Piercing and Punching

Design of Piercing and Punching

Uploaded by

jacky hansdahThis document discusses various types of dies used in punching and blanking operations, including conventional dies, inverted dies, compound dies, progressive dies, and combination dies. It also covers design considerations for punches, such as plain punches, pedestal punches, and punches with shedders. Additional components discussed are knockouts, pilots, strippers, and stock stops.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 41

TYPES OF DIES

AND

DESIGN OF PIERCING AND

BLANKING PUNCHES AND DIES

TYPES OF DIES

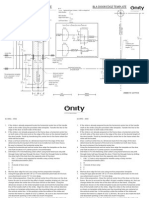

CONVENTIONAL DIES:

• Punch holder fastened to the ram of the press

• Die shoe fastened to the bolster plate

• Punch is fastened to the punch holder and

aligned with the opening in the die block using

guide pins

• Stripper holds the scrap strip so that the punch

may pull out of the hole

CONVENTIONAL POSITION

OF THE DIE SET

INVERTED DIES

• Punch and die positions are interchanged

• Reason: The opening in the bolster plate is too

small to permit the finished part to pass through

bolster opening

• Die block fastened to the punch holder and

punch fastened to the die shoe

• As the ram descends the blank is sheared from

the strip

INVERTED DIES

• The punch is forced through the scarp strip and

a spring attached to the stripper is compressed

and loaded

• On the upstroke of the ram the shedder pushes

the blank out of the die opening

• Stripper forces the scrap strip off the punch

INVERTED DIES

COMPOUND DIES

• Combine the principles of conventional and

inverted dies in one station

• Workpiece is pierced and blanked in one station

and in one operation

• The piercing punch is fastened in conventional

position to the punch holder

• Die opening for piercing is machined into the

blanking punch

COMPOUND DIES

• The blanking punch and blanking die opening

are mounted in an inverted position

• The blanking punch is fastened to the die shoe

• The blanking die opening is fastened to the

punch holder

COMPOUND DIES

PROGRESSIVE DIES

• These dies perform two or more operations at

different stages every time the ram descends

• The stock strip is advanced through a series of

stations that perform one or more distinct

operations on w.p

• The strip must move from first through each

successive station to produce a complete w.p

• The distance from one station to the next must

be same

PROGRESSIVE DIES

Each operation performs an operation on

the work piece, so that the work piece is

completed when the last operation has

been accomplished. For a four station die,

each successive stroke will produce a

finished part.

Operations that can perform are piercing,

blanking, forming, drawing etc

PROGRESSIVE DIES

COMBINATION DIES

• In these types of dies cutting operation is

combined with a non-cutting operation

• The cutting operations may include blanking,

piercing, trimming etc. and are combined with

non-cutting operations like bending, extruding,

forming etc.

PUNCH DESIGN

• The punch must withstand the maximum

blanking or piercing pressure

• They should not deflect during operation

• Deflection of punches may be avoided by

making the body diameter of punch larger than

cutting diameter

• Small punches may require punch support to

prevent breakage

PUNCH DESIGN

• Punch plates serve to hold, position and

strengthen the punch

• Piercing punches should not be smaller in

diameter than the thickness of the stock they are

to pierce

• Always avoid designing punches that would

have more than 4 in. of unguided length

PUNCH DESIGN

PUNCH DESIGN

PLAIN PUNCHES:

• They are simply a block of hardened tool steel

shaped to conform to the cutting contour

• Screws and dowels secure plain punches

• Plain punches must be large enough in area to

allow for screws and dowels

• Screw and dowel holes should be located at

least 1 ½ to 2 times the screw or dowel diameter

from the cutting edge

PUNCH DESIGN

PLAIN PUNCHES:

PUNCH DESIGN

PLAIN PUNCHES:

PUNCH DESIGN

PEDESTAL PUNCHES:

• Constructed by machining in such a manner that

leaves a flange around the base of the punch

• This punch always has a base area larger than

its cutting face area

• Its major advantage is stability caused by the

large base and solid construction

• Cutting forces are dispersed through the large

base, so used for heavy cutting loads

PUNCH DESIGN

PEDESTAL PUNCHES:

PUNCH DESIGN

PUNCH SHEDDERS:

• In piercing and blanking, sometimes, slug or blank

clings to the punch face called ‘slug pulling’

• Another factor of slug pulling is lubricant

• Heavy lubricants make slugs cling to punch face

• Slug pulling caused by heavy lubricants can be

reduced by using lower viscosity lubricant

• Another method is to use shedders

PUNCH DESIGN

PUNCH SHEDDERS:

• Spring-actuated shedder pins are located

in the center of the punch

• Air pressure may also be used to prevent

slug pulling

• This method is more complicated and also

tends to blow lubricant away from cutting

areas

PUNCH DESIGN

PUNCH SHEDDERS:

PUNCH DESIGN

The maximum allowable punch length:

Lm = πD/8 (E.D/fs.t)½

Where

D = Diameter of punched hole

fs = Shear stress

t = Material thickness

E = Modulus of elasticity of punch material

Where

D/t = 1.1 or higher

KNOCKOUTS

• In normal operations the slug clings to the die

wall because of spring back in the blank or slug

• Knockouts are used to remove workpieces that

adhere to the die opening

• The upper end of the knockout registers against

the knockout bar of the press which pushes the

shedder down so that the workpiece is pushed

back

KNOCKOUTS

PILOTS

• The function of the pilot is to position the work

piece or stock strip accurately

• In progressive dies to locate the work strip so

that the relationships between stations may be

maintained.

• Advantage is taken of these holes so that the

blank formed is exactly concentric to the pierced

hole

• This piloting is obtained with the help of pilots

secured to the blanking punches

PILOTS

Pilots are fitted to punches by the methods:

• Press fit pilot

• Threaded shank pilots

• Socket set screw pilots

• If the operation is slow the pilots may be press

fitted into a hole in the center of punch

• If there is any danger of pilot dropping out, it

should be fastened

PILOTS

STRIPPERS

• They are used to remove the stock from the

punch after a blanking or piercing operation

• Classified as fixed and spring-operated

• Fixed strippers are solidly attached to the die

block or die shoe

• Spring operated strippers travel up and down on

the shank of the punch

STRIPPERS

CHANNEL STRIPPERS:

• A type of fixed stripper

• Consists of a rectangular plate mounted on top

of die block

• A channel or groove is milled through which the

strip is passed

• The height of the channel should be 1 ½ times

the stock thickness

• The width must be equal to the strip width plus

some clearance to allow variation in strip width

STRIPPERS

CHANNEL STRIPPERS:

SPRING-OPERATED STRIPPERS

• Also called pressure pad strippers

• Employ springs to apply pressure to the stock

strip

• Suspended from punch holder with stripper bolts

and compression springs

• An advantage of this type is that it tends to hold

the strip flat during the press cycle

SPRING-OPERATED STRIPPERS

DIE STOPS (STOCK STOPS)

• Used to locate the stock in the die set when

hand feeding

• The simplest form of stock stop is dowel pin

• An edge of previously blanked opening is

pushed against this pin

• The stock is lifted above the pin on return stroke

to release the strip from pin

• Demands considerable skill on the part of

operator

STOCK STOPS

Dowel pin used as stop

STOCK STOPS

• ‘Trip stop’ is another type of stock stop

• The pawl rises on ratchet principle

• When the operator pulls the stock back, the pawl

drops and locates the stock

A ratchet is a device used to restrict motion in

one direction

STOCK STOPS

STOCK STOPS

• ‘Finger stops’ are used to start new strips in the

proper location in a die

• They are pushed into the stock channel until

they seat

• The press is tripped, the stop is released and

returns to its out position

• It is not used again until a new strip is started

• They are also called ‘primary’ stops

STOCK STOPS

Finger stop

You might also like

- Ksm5 Service ManualDocument42 pagesKsm5 Service ManualIo Sugay100% (3)

- Operation Instruction: THDP-3 Single Punch Tablet PressDocument7 pagesOperation Instruction: THDP-3 Single Punch Tablet Press8859357No ratings yet

- Tumble Jig: Presented by Bharat.k.manvi Reg No: 100926022Document29 pagesTumble Jig: Presented by Bharat.k.manvi Reg No: 100926022Bharat ManviNo ratings yet

- Progressive Die Design PDFDocument1 pageProgressive Die Design PDFSakthi VelNo ratings yet

- 13 Mig & Mag WeldingDocument24 pages13 Mig & Mag WeldingMohamed BencharifNo ratings yet

- 19d Impeller SpacingDocument9 pages19d Impeller Spacingbtgottlieb100% (1)

- Digital Die Design SystemDocument17 pagesDigital Die Design Systemjagas123455123No ratings yet

- 108 Metal Forming Systems PDFDocument3 pages108 Metal Forming Systems PDFNatarajan BalajiNo ratings yet

- Design of Single Point Cutting ToolDocument11 pagesDesign of Single Point Cutting ToolSiddharth DubeyNo ratings yet

- Blanking & Piercing (Handout)Document50 pagesBlanking & Piercing (Handout)banana100% (1)

- Jigs Fixtures MainDocument30 pagesJigs Fixtures MainPrashanth RamakrishnanNo ratings yet

- GERE Axum 8Document36 pagesGERE Axum 8Misge Chekole100% (1)

- Unit 3 Press and Press Tools: StructureDocument14 pagesUnit 3 Press and Press Tools: StructurePranav SharmaNo ratings yet

- Clamping Method in Jigs and FixtureDocument15 pagesClamping Method in Jigs and FixturenilamNo ratings yet

- Jigs and FixturesDocument20 pagesJigs and FixturesRenjith RajendraprasadNo ratings yet

- Jig and FixtureDocument24 pagesJig and FixtureprabhjotbhangalNo ratings yet

- Jigs FixuresDocument36 pagesJigs FixuresThulasi RamNo ratings yet

- Lab Session 1 & 2& 3Document24 pagesLab Session 1 & 2& 3Ali RazaNo ratings yet

- Advanced Tool Design PDFDocument4 pagesAdvanced Tool Design PDFgsudhanta1604No ratings yet

- Linear MeasurementDocument79 pagesLinear MeasurementRht BrdNo ratings yet

- FixturesDocument12 pagesFixturesakshay2761No ratings yet

- Abstract - Pneumatic Auto Feed Sheet Cutting MachineDocument4 pagesAbstract - Pneumatic Auto Feed Sheet Cutting MachineJagathVishnuNo ratings yet

- Jigs and Fixtures DesignDocument9 pagesJigs and Fixtures Designazizmaarof100% (4)

- Introduction To Jigs and FixturesDocument14 pagesIntroduction To Jigs and FixturesDhduNo ratings yet

- DFM CH 3Document44 pagesDFM CH 3Trâp A NâtïøñNo ratings yet

- ActuatorsDocument17 pagesActuatorsGururaj GadadNo ratings yet

- Die DesignDocument16 pagesDie DesignxzzNo ratings yet

- Methods of Mounting of Jobs and Cutting ToolsDocument19 pagesMethods of Mounting of Jobs and Cutting ToolsRaghav L NaikNo ratings yet

- Press Working TerminologyDocument16 pagesPress Working TerminologyAadrika UmashankarNo ratings yet

- Ch-23 Jig and FixturesDocument51 pagesCh-23 Jig and FixturesrajaNo ratings yet

- Press Tool TechDocument48 pagesPress Tool Technikhil sidNo ratings yet

- Generation Motions of Machine Tools, Requirements of Machine Tools, Fundamental of Machine Tool DesignDocument50 pagesGeneration Motions of Machine Tools, Requirements of Machine Tools, Fundamental of Machine Tool DesignDeepan RajNo ratings yet

- Geometric Dimensioning & Tolerancing TrainingDocument5 pagesGeometric Dimensioning & Tolerancing TrainingLokesh NarasimhaiahNo ratings yet

- CH 32-Mechanical AssemblyDocument65 pagesCH 32-Mechanical AssemblyNasir MaqsoodNo ratings yet

- BroachingDocument22 pagesBroachingvijchoudhary16No ratings yet

- Milling Tool DesignDocument18 pagesMilling Tool DesignSiddharth DubeyNo ratings yet

- Split Cavity and Side CoreDocument29 pagesSplit Cavity and Side CoreShubham ChoudhariNo ratings yet

- Unit IV 180208091907Document153 pagesUnit IV 180208091907tamilselvan nNo ratings yet

- Fitting (Bench Working) ShopDocument26 pagesFitting (Bench Working) ShopBhaskar KandpalNo ratings yet

- QB - ME5635-Design of Jigs, Fixtures and Press Tools-Jan-May.2014Document27 pagesQB - ME5635-Design of Jigs, Fixtures and Press Tools-Jan-May.2014Carlos WilliamsonNo ratings yet

- Jigs and FixturesDocument8 pagesJigs and FixturesHafizuddin NasirNo ratings yet

- Manufacturing Technology II - Notes PDFDocument17 pagesManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- Jigs and Fixtures: Guides Not GuidesDocument2 pagesJigs and Fixtures: Guides Not GuidesShichibukai WarlordNo ratings yet

- Development of Transition PiecesDocument37 pagesDevelopment of Transition PiecesElancheran RengaNo ratings yet

- Jigs&FixtureDocument14 pagesJigs&FixtureBikram MuduliNo ratings yet

- Inspection of Press Tools and MouldsDocument35 pagesInspection of Press Tools and MouldsPra VeeNo ratings yet

- CatalogDocument32 pagesCatalogsaravanan_c1No ratings yet

- Pneumatic Auto Feed Sheet Cutting MachineDocument5 pagesPneumatic Auto Feed Sheet Cutting MachineVigneshwaran Srinivasan100% (1)

- "Design For Manufacturing and Assembly": 1 DfmaDocument40 pages"Design For Manufacturing and Assembly": 1 DfmasaiNo ratings yet

- 15me835 PLCM Module 2Document17 pages15me835 PLCM Module 2prashanth prabhuNo ratings yet

- Flowforming or Metal Spinning (Spin Forming)Document2 pagesFlowforming or Metal Spinning (Spin Forming)ShivajiNo ratings yet

- Jigs and Fixtures: DR Arslan AhmedDocument18 pagesJigs and Fixtures: DR Arslan AhmedKNOWLEDGE WORLDNo ratings yet

- Metal Forming LabDocument57 pagesMetal Forming LabRohitGuptaNo ratings yet

- Broaching MachineDocument10 pagesBroaching MachineVinayakNerkarNo ratings yet

- For Wood Cutter MachineDocument19 pagesFor Wood Cutter MachineRahul Rajput100% (1)

- Safety in Shop Floor - Tools Equipments - Safety - Identification ...Document2 pagesSafety in Shop Floor - Tools Equipments - Safety - Identification ...Hamza NoumanNo ratings yet

- MD Design ConsiderationDocument18 pagesMD Design ConsiderationjhpatelNo ratings yet

- 01 Die Blocks PDFDocument26 pages01 Die Blocks PDFLibardo Cardenas PNo ratings yet

- Lathe and Drilling MachinesDocument48 pagesLathe and Drilling MachinesMisga BekeleNo ratings yet

- Toolchapter 1 Tool JigDocument66 pagesToolchapter 1 Tool JigTamirat NemomsaNo ratings yet

- Advanced Strength of Materials Prof. S. K. Maiti Department of Mechanical Engineering Indian Institute of Technology, Bombay Lecture - 15Document17 pagesAdvanced Strength of Materials Prof. S. K. Maiti Department of Mechanical Engineering Indian Institute of Technology, Bombay Lecture - 15jacky hansdahNo ratings yet

- Project Engg NotesDocument37 pagesProject Engg Notesjacky hansdahNo ratings yet

- New Doc 2018-11-26 15.53.39Document21 pagesNew Doc 2018-11-26 15.53.39jacky hansdahNo ratings yet

- Tutorial Sheet No 2 MA1201 MO16Document9 pagesTutorial Sheet No 2 MA1201 MO16jacky hansdahNo ratings yet

- Polymer Blends and CompositesDocument23 pagesPolymer Blends and Compositesjacky hansdahNo ratings yet

- Ergonomics 111024094525 Phpapp01Document24 pagesErgonomics 111024094525 Phpapp01jacky hansdahNo ratings yet

- Ergonomics: Ihsan Ali WassanDocument28 pagesErgonomics: Ihsan Ali Wassanjacky hansdahNo ratings yet

- Lecture 22 PDFDocument3 pagesLecture 22 PDFjacky hansdahNo ratings yet

- Tool Design Press Tool Design 1 x1Document86 pagesTool Design Press Tool Design 1 x1jacky hansdah100% (2)

- CNC MachineDocument70 pagesCNC Machinejacky hansdah100% (1)

- Slags From Steel ProductionDocument5 pagesSlags From Steel Productionjacky hansdahNo ratings yet

- Theory of WiredrawingDocument56 pagesTheory of Wiredrawingjacky hansdahNo ratings yet

- Fette Tablet Press Replacement Parts CatalogDocument84 pagesFette Tablet Press Replacement Parts Catalogedsonlevi100% (1)

- Mounting Methods of Punches and DiesDocument1 pageMounting Methods of Punches and DiesPeter Nomikos100% (1)

- Fire Control Pocket With A DRODocument7 pagesFire Control Pocket With A DROterrencebelles100% (1)

- Pg1078-1109 - Products DataDocument32 pagesPg1078-1109 - Products DataRANJANI RAGHUNATHANNo ratings yet

- ILS Magstripe - BLA TemplateDocument3 pagesILS Magstripe - BLA TemplatesubaquatecNo ratings yet

- HL 600 OmtDocument10 pagesHL 600 Omtonur tezmanNo ratings yet

- Exp-01-Study of Different Types of Hand Tools Used in WorkshopDocument9 pagesExp-01-Study of Different Types of Hand Tools Used in WorkshopNoyon Noyon60% (5)

- Desarmado y Armado de Transmision 950BDocument26 pagesDesarmado y Armado de Transmision 950Bedilberto chableNo ratings yet

- 7.3 ToolsDocument157 pages7.3 ToolskpilNo ratings yet

- Halloween Activity Book ColorDocument19 pagesHalloween Activity Book ColorLe NhungNo ratings yet

- How To Create Turret BoardsDocument28 pagesHow To Create Turret BoardsXefNed100% (1)

- Repairing Sheet MetalDocument5 pagesRepairing Sheet Metalماريانا مت رانيNo ratings yet

- Caterpillar Cat 326D2 L Excavator (Prefix REC) Service Repair Manual (REC00001 and Up)Document28 pagesCaterpillar Cat 326D2 L Excavator (Prefix REC) Service Repair Manual (REC00001 and Up)kfm8seuuduNo ratings yet

- Paper II With AnswersDocument275 pagesPaper II With AnswersAmit BibarNo ratings yet

- Lesson 3 Basic Hand Tools and 5S 2Document47 pagesLesson 3 Basic Hand Tools and 5S 2hiiamaj03No ratings yet

- Punch Price BookDocument28 pagesPunch Price Book4U6ogj8b9snylkslkn3nNo ratings yet

- 320C Assemble Final DriveDocument15 pages320C Assemble Final DriveLuis ValenzuelaNo ratings yet

- Cherrymax Process Manual: SPS Fastener Division, A CompanyDocument32 pagesCherrymax Process Manual: SPS Fastener Division, A CompanymeantendoNo ratings yet

- Diy RcabDocument32 pagesDiy RcabMatias Dacosta NeghmeNo ratings yet

- Fabrication ReportDocument14 pagesFabrication ReportFazliy RafiyNo ratings yet

- Set IDocument98 pagesSet IPritamjit RoutNo ratings yet

- Types of DiesDocument17 pagesTypes of DiesJayditya KumarNo ratings yet

- Lab Report ME2Document13 pagesLab Report ME2Hassan Iftekhar AhmedNo ratings yet

- Fabrication of Eccentric Hammer Cam Machanism For Industrial PurposeDocument38 pagesFabrication of Eccentric Hammer Cam Machanism For Industrial PurposeANAND KRISHNANNo ratings yet

- Osstem KIT Catalogue PDFDocument21 pagesOsstem KIT Catalogue PDFMeysha BiogreenNo ratings yet

- Servicebok586 588TBDocument16 pagesServicebok586 588TBLeandra RodriguesNo ratings yet

- 5330 New Carriage Drive Motor ReplacementDocument15 pages5330 New Carriage Drive Motor ReplacementBrenda ClayNo ratings yet