Professional Documents

Culture Documents

Syabas Guidelines PDF

Syabas Guidelines PDF

Uploaded by

zaidizarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Syabas Guidelines PDF

Syabas Guidelines PDF

Uploaded by

zaidizarCopyright:

Available Formats

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR b. Pipe Laying Requirements

c. Valves and Utilities

WATER SUPPLY SYSTEM

3.4.2 Reservoirs and Tanks

a. Storage Capacity

b. Hydraulic Requirements

Table of Contents c. Boundary Setback

d. Materials and Measures

e. Pipeworks Inside Reservoirs and Tanks

FOREWORD

f. Control Valves

g. Pipe Strainers

ABBREVIATIONS h. Miscellaneous

3.4.3 Pumping Stations

1.0 GENERAL a. General

1.1 Scope b. Pump Plinths

1.2 Definitions 3.4.4 Geotechnical Considerations

a. Reservoir, Tank and Pumping Station Buffer Zones for Slopes

1.3 Standards and Specifications

b. Slope Stability Analysis

1.4 Interpretation of Guidelines

c. Drainage Provisions

d. Slope Surface Protection

e. Reservoir, Tank and Pumping Station Foundation

2.0 PLANNING FOR WATER SUPPLY 3.6 Materials

2.1 General 3.7 Checklist

2.2 Development Proposals

2.2.1 General

2.2.2 Reservoirs and Tanks 4.0 INTERNAL PLUMBING SYSTEM

2.2.3 Site Dimensions for Reservoirs and Tanks 4.1 Plans

4.2 Technical Requirements

4.2.1 General

3.0 EXTERNAL WATER SUPPLY SYSTEM 4.2.2 Pipes and Valves

3.1 Application for Source of Water Supply 4.2.3 Water Tanks within Consumer Premises

3.2 Concept Design Submissions a. Capacity

3.3 Detailed Design Submissions b. Pipeworks and Materials

c. Safety and Security

3.3.1 Civil Works

4.2.4 Pumping Systems

3.3.2 Mechanical and Electrical Works

4.2.5 Hot Water Systems

3.3.3 Geotechnical Works

4.2.6 Swimming Pools

3.4 Design Guidelines

4.3 Water Conservation

3.4.1 Water Pipes

4.3.1 General

a. Hydraulic Requirements

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers i

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

4.3.2 Water Conservation Measures 7.0 MECHANICAL SYSTEM

4.4 Checklist 7.1 General

7.2 Detailed Design Submissions

7.2.1 First Stage (Design Stage before Tender Award)

5.0 METERING 7.2.2 Second Stage (After Tender Award during Approval Stage of Equipment)

5.1 General 7.3 Planned Water Quantity and Number of Pump Units

5.2 Locations of Meters 7.4 Pumpsets

5.3 Sizes of Meters 7.4.1 Duties and Selection

5.4 Automatic Meter Reading System (AMR) 7.4.2 Horizontal Split Casing Pumps

7.4.3 End Suction Pumps

5.5 Meter stands

7.4.4 Pump Casing, Rotating Element, Driving Coupling, Gland Sealing and Other Pump

5.5.1 General

Accessories

5.5.2 Markings for Meter stands

7.5 Pressure Gauges

7.6 Suction and Delivery Pipes

6.0 ELECTRICAL SYSTEM 7.7 Pipeworks

6.1 Standards, Code of Practice, Rules and Regulations 7.8 Valves

6.2 Detailed Design Submissions 7.8.1 Sluice Valves

7.8.2 Butterfly Valves

6.3 Power Supply Requirements

7.8.3 Non-slam Type Check Valves and Surge Calculation

6.4 HT Installations

7.8.4 Altitude Valves

6.5 LV Installations

7.9 Surge Suppression Systems

6.6 Essential Power Supply

7.10 Mechanical Handling Equipment

6.7 Motor Starter Panels

7.11 Mechanical Spare Parts

6.8 Electric Motors

7.12 Variable Speed Drive (VSD) Pumping System

6.9 Internal Lighting and Power

7.13 Checklist

6.10 External Lighting Installations

6.11 Lighting and Surge Protection Systems

6.12 Earthing Systems

8.0 SCADA/ TELEMETRY SYSTEM

6.13 Electrical Spare Parts

8.1 General

6.14 Electrical As-Built Fitted Drawings

8.2 Hardware Requirements

6.15 Testing and Commissioning

8.2.1 General

6.16 Variable Speed Drive (VSD) Pumping System 8.2.2 Outstations

6.17 Checklist 8.2.3 Remote Terminal Units

8.2.4 GPRS/ GSM Modem

8.2.5 Video Cameras

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers ii

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

8.3 Communication Systems FOREWORD

8.4 Operation Requirements on SCADA System

8.4.1 Introduction

8.4.2 Suction Reservoirs and Suction Tanks Syarikat Bekalan Air Selangor Sdn. Bhd. (SYABAS) is responsible for the water supply services in the

8.4.3 Pumping stations State of Selangor and the Federal Territories of Kuala Lumpur and Putrajaya. Qualified consulting

8.4.4 Reservoirs and Tanks engineers, planners and architects or other agents of the Developers are required to submit their design

8.4.5 Telemetry Systems for Gravity Fed Reservoirs and Tanks proposals for water supply works to SYABAS in order to ensure that the water supply systems meet the

planning, design, operation and maintenance requirements of SYABAS.

8.5 Spare Parts

8.6 Checklist

This document is a statement of general policies and design standards expected of new water supply

works for external water supply system as well as internal plumbing system in the State of Selangor and

the Federal Territories of Kuala Lumpur and Putrajaya.

9.0 CAPITAL COST CONTRIBUTION (SKP)

9.1 Definitions

The document has been adapted and revised from the document “GARIS PANDUAN PENGEMUKAAN –

9.2 Charge Rates Sistem Bekalan Air Di Negeri Selangor, Wilayah Persekutuan Kuala Lumpur dan Putrajaya”, which was

9.3 Exemption from Capital Cost Contribution previously published by Perbadanan Urus Air Selangor Berhad (PUAS).

9.4 Effective Date

The standards and parameters set out in this document may be subject to revision. Nothing herein shall

be construed as relieving the responsibilities of any person or entity responsible for the design, execution

10.0 SERVICE CHARGES and completion of the works. The consulting engineers, planners and architects shall be expected to

10.1 Charges for Connection to Public Mains exercise professional judgement and sound engineering practices in developing the design proposals.

10.2 Charges for Disconnection and Reconnection

10.3 Charges for Meter Tests

10.4 Charges for Swimming Bath Tests

10.5 Charges for Licenses to Carry Out Work

10.6 Charges for Pressure Test on Mains

10.7 Agency Fees

10.8 Charges for New Installation without Tapping or Tee-Connection

10.9 Supervision Charges for Connection

APPENDICES

A Standard Forms

B Standard Drawings

C Design Checklists

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers iii

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

ABBREVIATIONS DOL - Direct On-line

Elev. - Elevation

ELR - Earth Leakage Relay

NAMES etc - et cetera

ANSI - American National Standards Institute FRP - Fibre Reinforced Polyester

ASME - American Society of Mechanical Engineers FS - Factor of Safety

BOMBA - Jabatan Bomba dan Penyelamat (Fire and Rescue Department) fsd - Full-scale Deflection

BSI - British Standards Institution G.I. - Galvanised Iron

DCA - Department of Civil Aviation GPRS - General Packet Radio Service

DOE - Department of Environment GRP - Glass Reinforced Plastic

DOSH - Department of Occupancy Safety and Health of Malaysia GSM - Global System for Mobile Communications

EN - European Committee of Standardization HDPE - High Density Polyethylene

IEC - International Electrotechnical Commission HGL - Hydraulic Grade Line

IEEE - Institute of Electrical and Electronics Engineers HL - Head Loss

IES - Illuminating Engineering Society HSL - Highest Supply Level

ISO - International Organization for Standardization HT - High Tension

JKAS - Jabatan Kawalselia Air Selangor HWC - Hazen-William Coefficient

JKR - Jabatan Kerja Raya ID - Internal Diameter

MASMA - Manual Saliran Mesra Alam Malaysia IDMT - Inverse Definite Minimum Time

MWA - Malaysian Water Association IP - Ingress Protection

PUAS - Perbadanan Urus Air Selangor Berhad LED - Light Emitting Diode

SIRIM - Standards and Industrial Research Institution of Malaysia LPU - Lightning Protection Unit

ST - Energy Commission (Suruhanjaya Tenaga) LV - Low Voltage

SYABAS - Syarikat Bekalan Air Selangor Sdn. Bhd. M&E - Mechanical and Electrical

TM - Telekom Malaysia Berhad MCB - Miniature Circuit breaker

TNB - Tenaga Nasional Berhad MCCB - Moulded Case Circuit Breaker

MMI - Man-Machine Interface

MS - Malaysian Standards

NPSH - Net Positive Suction Head

TERMS NRW - Non Revenue Water

ABS - Acrylonitrile Butadiene Styrene O&M - Operation and Maintenance

ACB - Air Circuit Breaker ODL - Ordnance Datum Level

AMR - Automatic Meter Reading p.a - Per annum

ARI - Average Recurrence Interval PC - Personal Computer

AutoCAD - Automation Computer Aided Design PE - Polyethylene

BS - British Standard PID - Proportional, Integral, Derivative

BWL - Bottom Water Level PKNS - Perbadanan Kemajuan Negeri Selangor

CD - Compact Disc PLC - Programmable Logic Controller

CEMEP-EU - European Committee of Manufacturers of Electrical Machines and PN (16) - Pressure Number of 16 bars

Power Electronics and European Commission

POB - Polyolefine Blend

CT - Current Transformer

PP-R - Polypropylene Random Copolymer

DB - Distribution Board

PT - Power Transformer

Dia. - Diameter

PTFE - Polyetrafluoroethylene

DMZ - District Meter Zone

PVC - Polyvinyl Chloride

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers iv

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

RBE - Report-by-exception mg/l - Milligram per litre

RC - Reinforced Concrete Ml - Million Litres

RCD - Residual Current Device Mld, Ml/d - Million Litres per day

RL - Reduced level mm - Millimetre

RTU - Remote Terminal Unit mm2 - Square Millimetre

SCADA - Supervisory Control and Data Acquisition Mohm - Mega Ohm

Sdn. Bhd. - Sendirian Berhad No. - Number

SKP - Sumbangan Kos Pembangunan (Capital Cost Contribution rpm - Revolution per minute

SMS - Short Message Service V - Volt

SPT - Standard Penetration Test Var - Volt-ampere reactive

SWA - Steel Wire Armoured W - Watt

SWG - Standard Wire Gauge Yr - Year

TEFC - Totally Enclosed, Fan Cooled

TWL - Top Water Level

uPVC - Unplasticised Polyvinyl Chloride

v:h - Vertical Height : Horizontal Length

VSD - Variable Speed Drive

WC - Water Closet

WTP - Water Treatment Plant

XLPE - Crosslinked Polyethylene

UNITS

% - Percent

A - Ampere

d - Day

deg. C - degree Celsius

deg. F - degree Fahrenheit

ft2 - Square Foot

ha - Hectare

hr - Hour

kA - Kilo Ampere

kg - Kilogram

km - Kilometre

kW - Kilowatt

l/d - Litre per day

l/s - Litre per second

lcd - Litre per capita per day

m - Metre

m/s - Metre per second

m3 - Cubic Metre

m3/hr - Cubic Metre per hour

m3/month - Cubic Metre per month

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers v

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

1.0 GENERAL d. Consumer

A person who is supplied with water from the pubic main or a person who is

1.1 SCOPE otherwise liable for the payment of charges for the supply of water and includes an

occupier.

These guidelines deal with the planning and design for water supply systems in the State e. Licensed Plumber

of Selangor and the Federal Territories of Kuala Lumpur and Putrajaya. It covers external

A plumber who is registered with JKAS to implement water plumbing works.

water supply systems as well as internal plumbing systems for individual premises. It does

not cover all aspects of water supplies for fire fighting.

f. Meter

The guidelines are prepared to provide guidance to engineers, architects, developers, Any appliance, equipment or device used for the purpose of measuring,

contractors and licensed plumbers, and should be of interest also to water consumers. ascertaining, regulating or estimating the amount of water consumed, supplied or

used.

1.2 DEFINITIONS g. Meter stand

The position where a meter is installed.

For the purpose of these guidelines unless the context otherwise requires, the following

definitions shall apply:- h. Premises

Any building, land and any tent or structure.

a. Approved Standard

Standard or specification or code of practice issued by Standards and Industrial i. Plumbing system

Research Institution of Malaysia (SIRIM) or if such is non-existent, by the British

All pipes, tanks, valves and fittings from the public main to and within the premises

Standards Institution (BSI) as amended or revised from time to time, or such other

of the owner or occupier.

standards as approved by SYABAS.

j. Sub-meter

b. Bulk Meter

Any meter which measures water which has already metered since leaving the

A meter measuring water all or part of which is subsequently measured by one or

public main.

more sub-meters.

k. Water fittings

c. Consulting Engineer

Pipes (other than the public mains), taps, cocks, valves, ferrules, meters, cisterns,

A professional engineer who is registered with the Board of Engineers, Malaysia

baths, water closets, water heaters, telemetering system and other apparatus or

and whose registration is still valid when making any submission.

appliance used in connection for the supply or use of water.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 1-1

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

1.3 STANDARDS AND SPECIFICATIONS

All materials and water fittings used in the construction of any of the works described in

these guidelines shall comply with the requirements specified in the latest edition of any

applicable approved standard and the specification issued by SYABAS.

In case there is any discrepancy between the approved standard and specification of

SYABAS the latter should take precedence.

1.4 INTERPRETATION OF GUIDELINES

Every design proposal shall meet the underlying objectives of these guidelines of:-

• Reliability

• Ease of Maintenance

• Quality of Work

• Energy Efficient

In this guidelines, the term “shall” is used in reference to standardized design parameters

or requirements where departures from which are not normally permitted.

The term “should” is used in reference to suggested design parameters or requirements

and the consulting engineer is expected to exercise sound professional judgment in

deciding whether to depart from the suggested parameters. The consulting engineer would

be expected to justify such departures in terms of cost and improved engineering

performance.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 1-2

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

2.0 PLANNING FOR WATER SUPPLY 2.2.2 Reservoirs and Tanks

2.1 GENERAL a. The water reservoir and tank sites shall be placed at:-

i. The highest ground area in the proposed development.

In the planning for the water supply for any development, the following factors shall be ii. Level grounds and not on slopes.

considered:- iii. Rectangular site area.

a. The requirement of SYABAS.

b. Dedicated access (entrance/ exit) shall be provided to reservoir/ tank and pumping

b. The estimated daily demand and the maximum flow rate.

station.

c. The location of the available supply.

c. All slopes shall be constructed within the reservoir/ tank and pumping station

d. The quantity and pressure of the available supply.

reserves for ease of maintenance. Fencing shall cover all slopes with sufficient

e. The water storage capacity if required.

setback for drainage.

f. The pumping system if required.

d. All land on which waterworks are built shall be surrendered to SYABAS, who will

g. No temporary water supply will be granted by SYABAS. SYABAS will only provide

then hand over to the State Government. The land shall include access road, main

water supply for construction purposes.

infrastructure, slopes etc.

h. The planning and design of water supply systems shall seek to optimize available

e. Should the water pressure from the connection point to the highest development

energy/ water pressure.

area be insufficient, one or more suction reservoir/ tank and pumping station sites

shall be provided whether inside or outside the proposed development area at the

expense of the developer. The pumping head shall not exceed 75 m for each

2.2 DEVELOPMENT PROPOSALS

pumping stage.

f. The difference between the highest and lowest Finished Platform Level within the

2.2.1 General

development area shall not exceed 30 m. If it exceeds 30 m, the concept of low level

and high level service reservoirs/ tanks shall be considered.

Development proposals shall comply with the following requirements:-

g. The developer shall be responsible to carry out any landscaping works and

a. Proposals shall be prepared and submitted by the consulting engineers/ town architectural design if required by the local authorities.

planners.

b. Types and numbers of development units and the total development area shall be

shown clearly. 2.2.3 Site Dimensions for Reservoirs and Tanks

c. Contour lines shall be shown clearly on the plan at 5 m intervals.

d. Key plan and location plan shall be shown on the layout plan. For any development, the minimum site dimensions for suction reservoir/ tank and

e. Levels shall be based on Ordnance Datum Level (ODL). pumping station, service reservoir/ tank and the combination of the aforementioned are

f. Coordinates and bearings of boundary shall be stated. shown in Table 2.1, Table 2.2 and Table 2.3 respectively.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers

2-1

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

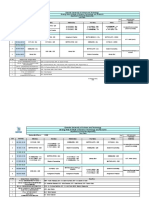

Table 2.1 : Minimum site dimensions for suction reservoir/ tank and pumping station Table 2.2 : Minimum site dimensions for service reservoir/ tank

Site Dimensions (Minimum)

Water Demand (l/d) Site Dimensions (Minimum) Reservoir/ Tank

Capacity

Ground Reservoir/ Tank Elevated Reservoir/ Tank

≤ 45,000 20 m x 25 m

≤ 45,000 20 m x 20 m

45,001 – 227,000 20 m x 25 m

45,001 – 227,000 20 m x 20 m

227,001 – 454,000 25 m x 30 m

227,001 – 454,000 25 m x 25 m

454,001 – 680,000 25 m x 30 m

454,001 – 680,000 30 m x 30 m

680,001 – 900,000 30 m x 35 m

680,001 – 900,000 30 m x 30 m

900,001 – 1,135,000 35 m x 40 m

900,001 – 1,135,000 35 m x 35 m

1,135,001 – 2,270,000 30 m x 45 m

1,135,001 – 2,270,000 40 m x 40 m

2,270,001 – 3,405,000 45 m x 55 m

2,270,001 – 3,405,000 45 m x 45 m

3,405,001 – 6,810,000 60 m x 65 m

3,405,001 – 6,810,000 60 m x 60 m 50 m x 95 m

6,810,001 – 13,620,000 75 m x 80 m

6,810,001 – 13,620,000 75 m x 75 m 55 m x 125 m

To be approved by SYABAS but

> 13,620,000

subject to a minimum of 90 m x 95 m To be approved by To be approved by

> 13,620,000 SYABAS but subject to a SYABAS but subject to a

minimum of 90 m x 90 m minimum of 80 m x 130 m

Note: Dimensions in the above table are excluding the areas of office, storeroom,

toilet and quarter. Please refer Clause 3.4.3.a for details. Note: Dimensions in the above table are excluding the areas of office, storeroom, toilet

and quarter. Please refer Clause 3.4.3.a for details.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers

2-2

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Table 2.3 : Minimum site dimensions for the combination of suction reservoir/ tank,

pumping station and service reservoir/ tank

Water Demand (l/d) Site Dimensions (Minimum)

≤ 45,000 25 m x 50 m

45,001 – 227,000 25 m x 60 m

227,001 – 454,000 30 m x 65 m

454,001 – 680,000 35 m x 70 m

680,001 – 900,000 35 m x 70 m

900,001 – 1,135,000 35 m x 75 m

1,135,001 – 2,270,000 40 m x 90 m

2,270,001 – 3,405,000 45 m x 100 m

3,405,001 – 6,810,000 50 m x 115 m

6,810,001 – 13,620,000 55 m x 145 m

To be approved by SYABAS but

> 13,620,000

subject to a minimum of 55 m x 260 m

Note: Dimensions in the above table are excluding the areas of office, storeroom,

toilet and quarter. Please refer Clause 3.4.3.a for details.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers

2-3

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

3.0 EXTERNAL WATER SUPPLY SYSTEM v. Hydraulic calculations for main pipes for peak flow condition from supply source to

storage reservoir/ tank, incoming main, size and level of suction reservoir/ tank,

3.1 APPLICATION FOR SOURCE OF WATER SUPPLY pumping main, size and level of storage reservoir/ tank and residual pressure in the

pipes for the particular supply zone.

a. The owner or developer shall apply to SYABAS through their consulting engineer together vi. General brief and schematic plan of the overall water supply system showing nodal

with the following:- and pipe data. Flow and pressure readings for nodes and pipes shall be indicated.

i. Appointment letter to the consulting engineer from the owner or developer, and the c. All plans/ drawings submitted shall be of A1 size.

consulting engineer’s registration letter with the BEM.

ii. Calculation of water demand according to SYABAS requirements as shown in

Table 3.1. 3.3 DETAILED DESIGN SUBMISSIONS

iii. Approval letter and plans from the local authority.

iv. Three (3) sets of Key Plan and Location Plan. a. The detailed design shall be in accordance with the requirements of the development

v. Three (3) sets of Site Plan, with a minimum scale of 1:500 showing the phases.

existing and proposed layout of reticulation mains, lot numbers, adjacent lot b. A copy of SYABAS Standard Specifications shall be included.

nos., house numbers and landmarks. c. Two (2) sets of Detailed Design Report shall be submitted by the consulting engineer.

vi. Three (3) sets of Layout Plan complete with contour lines and proposed land d. Three (3) set of drawings of A1 size shall be submitted for approval.

development levels (in metre ODL). e. The submission shall be accompanied with one (1) no. CD containing the soft copy of all

vii. All plans/ drawings submitted shall be of A1 size. drawings relating to the water supply system, in AutoCAD format and the calculation

data. There shall cover the following:-

b. Application with water demand of more than 50,000 litres per day shall be made directly to

the Development Department, SYABAS Headquarters. i. Reticulation system layout plan.

c. Application with water demand of less than 50,000 litres per day shall be made directly to ii. Symbols used shall be those as shown in the SYABAS’ Standard Drawings

the respective SYABAS District Office. attached.

iii. Reservoir/ tank and pumping station layout plan.

iv. Details of reservoir/ tank and pumping station.

3.2 CONCEPT DESIGN SUBMISSIONS v. Plan and profile of incoming main pipe.

vi. Standard drawings.

a. For development with water demands exceeding 4.5 million litres per day and to be vii. Hydraulic calculation data for reticulation system.

developed in phases or where pumping station is required, the Concept Design Report for

f. Drawings, calculations and works specifications shall be endorsed by a consulting

the entire development shall be submitted to SYABAS.

engineer appointed by the owner or developer.

b. Two (2) sets of Concept Design Report shall consist of the following:-

i. General description about the project.

ii. Water demand table according to the type of development for the entire project.

iii. Water demand computation table according to phase and type of development

including the years for each development phases.

iv. Supply zones for the development phases from service reservoirs/ tanks.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-4

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

3.3.1 Civil Works Pipe Details

Pipe From To Length Dia. HL Velocity

HWC HL/1000

Each design proposal shall consist of the following:- No. Node Node (m) (mm) (m) (m/s)

a. Brief description for that particular phase.

b. Water demand table showing the types of development, calculations of reticulation pipe Node Details

design for the cases of peak flow, fire flow and average flow, calculations for levels and Node Flow Elev HGL HSL Residual

size of reservoir/ tank and pumping system calculations. No. (l/s) (m.ODL) (m.ODL) (m.ODL) Pressure (m)

c. Detailed calculations showing that the pipes are able to withstand the expected

design traffic load with a minimum of 1.0 m depth of cover, well compacted with

suitable backfill materials.

Where:-

d. Calculation and sizing of scour pipe for the reservoir/ tank.

HWC = Hazen William Coefficient

e. Storm drainage system design calculation.

HL = Head Loss

f. Detailed layout plan showing the main reticulation pipe system, that are coloured

HGL = Hydraulic Grade Line

according to:-

HSL = Highest Supply Level

i. Types and sizes of pipes.

ii. Location, type, size and BWL/ TWL for reservoir/ tank.

iii. Pumping station, including drainage. 3.3.2 Mechanical and Electrical Works

g. Detailed layout plan of reservoir/ tank showing location, side views, top and sectional

The submission of detailed design and installation for mechanical and electrical works shall be as

views, details of levels, incoming water pipe, outgoing water pipe, overflow and scour

per Clause 7.2 and 6.2 respectively. It shall be submitted to SYABAS within four (4) weeks from

pipes, valves locations, level indicator, ventilation system and ladders for reservoirs/ tank

the approval date of the detailed design of the civil works. The mechanical and electrical system

and security fencing.

design considerations shall be as required in Chapters 6.0 and 7.0. The design and calculation

h. Floor plan, side and sectional views of pumping station showing the pump locations,

report shall be prepared and endorsed by consulting engineer. Approval from SYABAS shall be

arrangement of pumping system including suction pipe from suction reservoir/ tank to

obtained before any work may commence at site.

pumps, pumping mains, pipe fittings, pipe trenches, motor, switchboard surge suppression

system and details of levels.

i. Detailed drawing showing the supports, foundation arrangements with base plate

3.3.3 Geotechnical Works

dimensions and the positions of all foundation bolts and pipe connection, chequered plate

and all necessary information for the complete design.

Each design proposal shall consist of the following:-

j. Structural design including the design calculations and design criteria for pumping station

and reservoir/ tank endorsed by a consulting civil engineer.

a. Soil Investigation Report

k. The hydraulic calculations for reticulation system shall include the following information:-

b. Geotechnical Interpretation Report

c. Geotechnical Design Report which shall include the following:-

i. Subsoil conditions of the project site.

ii. Design soil parameters.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-5

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

iii. Selection of foundation type. to development where the source of water is drawn directly from SYABAS

iv. Design calculations for foundation of reservoir/ tank and pumping station main.

including calculations for long term settlement and short term settlement. • Each node shall have a minimum residual pressure not less than 4.5 m

v. Detailed drawings for foundation of reservoir/ tank and pumping station. above the highest supply level during peak flow condition. This is applicable

to development where the source of water is drawn from the developer’s

d. When slopes are encountered adjacent to the reservoir/ tank or pumping station, the

storage reservoir/ tank with the hydraulic calculations based on the BWL.

followings shall be included in the Geotechnical Design Report:-

• Each node shall have a minimum residual pressure not less than 7.5 m

i. Detailed drawings for earthwork which shall show the cross sections of above the platform level, for combined average flow and fire flow condition.

critical slopes and cut/ fill sections within the reservoir/ tank or pumping • Each node shall have a maximum residual pressure not exceeding 30 m for

station reserve and including areas 100 m beyond the site boundary. the two flow conditions analysed. Pressure Reducing Valve shall be

ii. Selection of slope surface protection and erosion control. provided where the residual pressure exceeds 30 m.

iii. Slope stability analysis except for slopes that fall under Clause 3.4.4.b.vii.

vi. Fire flow requirement, location and type of hydrants shall be recommended by

iv. Selection of slope stabilization method, if relevant, and detailed drawings and

BOMBA.

design calculations of all slope stabilization measures.

vii. Reticulation pipe size shall be subject to the hydraulic design for peak flow

e. Geotechnical design considerations as required in Clause 3.4.4. requirements and for pipe system with hydrant, the pipe size shall be

determined by the hydraulic requirements and minimum pressure required

for fire fighting and average flow condition. For pipes with hydrant, a

3.4 DESIGN GUIDELINES minimum pipe size of 100 mm diameter shall be applied except the last 91 m

before pipe end. Hydrant shall be installed at least 91 m before any pipe end.

3.4.1 Water Pipes

a. Hydraulic Requirements b. Pipe Laying Requirements

i. The reticulation system shall be designed as per the following flow i. All pipes shall be laid at locations which are easy for maintenance works and

conditions:- the cost of repair and rehabilitation works shall be considered.

ii. Twin pipes shall be installed on both sides of road shoulder should there be more

• Peak flow

than ten (10) units of houses/ shops in a row for that particular road. The main

• Combination of average and fire flow

pipe shall be subject to the hydraulic and fire fighting requirements.

• Summary of both flow conditions above

iii. The types of pipes used shall comply with Table 3.3 and 3.4.

ii. Hazen-William Coefficient C shall be as per Table 3.2. iv. Pipe dead ends shall be installed with isolating valve or hydrant.

iii. Head loss gradient shall be less than 2/1000 during peak flow condition. v. The pipes shall be buried in sufficient depth, well compacted with suitable

iv. Peak factor of average flow for incoming flow to reservoir and reticulation system backfill materials and able to withstand the expected design traffic load

shall be 1.2 and 2.5 respectively. according to the standard pipe bedding details in the attached SYABAS

v. The following residual pressures shall be achieved:- Standard Drawings.

vi. Under all circumstances, water pipes shall be laid above sewers with a

• Each node shall have a minimum residual pressure not less than 7.5 m

minimum vertical clearance of 1 m.

above the highest supply level during peak flow condition. This is applicable

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-6

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

vii. Hydrant pipeline shall be installed separately from the domestic pipeline in any • For pipe size 600 mm - 800 mm dia. - 100 mm double orifice type

area with apartment/ condominium, factory, complex, office, commercial complex, with double flanged isolating

institution and school, where the water demand does not exceed 2.0 million litres valve

per day except for low-cost flats built by the Government. Water meter shall • For pipe size 850 mm - 1200mm dia. - 150 mm double orifice type with

be provided for both of the hydrant and domestic pipelines. flange ended isolating valve

• For pipe size 1300 mm dia. and above - 200 mm double orifice type

with flange ended isolating

c. Valves and Utilities valve

viii. Sampling box with pressure gauge shall be provided as per Table 3.5.

i. All valves shall comply with prevailing SYABAS requirements.

ix. Water usage for a NRW zone shall be limited to 1,000,000 litres per day.

ii. All isolating/ regulating and scour valves shall be of flange ended sluice type for

x. District Meter Zone (DMZ) chamber shall be provided as per Table 3.6 within

pipe diameter up to 400 mm and of flange ended butterfly type for pipe diameter

each hydraulic zone.

450 mm and above. The in-line valves shall be installed at a maximum of

xi. Constant flow valve shall be installed on the incoming pipe to the suction reservoir/

every 2000 m interval of incoming main.

tank of condominium, apartment and office to limit the flow rate at 20 hours per day

iii. The size of isolating valve shall be at least the size of the pipeline. However

whenever the residual head at the inlet of the reservoir/ tank exceed 15 m.

for pipe diameter of 900 mm and above, the isolating valve can be one size

The developer shall submit the characteristic curve/ chart of the constant

smaller than the pipe size.

flow valve to SYABAS for approval.

iv. Scour locations and sizes shall be designed such that the pipelines can be

scoured within three (3) hours.

v. Full bore scour point shall be provided not greater than 5 km apart at low

3.4.2 Reservoirs and Tanks

points near river/ big drain. A self cleansing velocity of greater than 0.6 m/s

shall be achieved.

a. Storage Capacity

vi. Scour valve sizes shall be as follows:-

• For pipe size 150 mm - 400 mm dia. - 100mm flange ended i. The storage capacity requirements for reservoirs/ tanks shall be as per Table 3.7

• For pipe size 450 mm - 550 mm dia. - 150mm flange ended ii. The preferable volumetric ratio of suction reservoir/ tank : elevated storage

• For pipe size 600 mm - 750 mm dia. - 200mm flange ended reservoir/ tank shall be 1:2. However, a proportion between 1:1 and 1:2 may be

• For pipe size 800 mm - 1000 mm dia. - 250mm flange ended considered.

• For pipe size 1050 mm - 1200 mm dia. - 300mm flange ended

• For pipe size 1300 mm dia. and above - 450mm flange ended

b. Hydraulic Requirements

vii. Air valve sizes shall be as follows:-

i. For hilly development, the concept of high, medium and low hydraulic zone shall be

• For pipe size 150 mm - 300 mm dia. - 50 mm double orifice type

adopted where viable.

• For pipe size 350 mm - 550 mm dia. - 80 mm double orifice type with

ii. Design of reticulation system supplied from reservoir/ tank shall be based on the

flange ended isolating valve

reservoir’s BWL and the minimum residual pressure shall be 4.5 m above HSL.

iii. The following residual pressure requirements shall be satisfied:-

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-7

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

• Minimum residual pressure at reservoir/ tank’s TWL shall not be less than e. Pipeworks Inside Reservoirs and Tanks

4.5 m, where the connection source of incoming main has no connection to

any other reticulation main. i. All pipes in reservoir/ tank shall be of stainless steel, ductile iron painted with

• Minimum residual pressure at reservoir/ tank’s TWL shall not be less than suitable anti-corrosion paint system or other materials as approved by SYABAS.

7.5 m where the incoming main has direct connection to reticulation pipe. ii. All vertical pipes shall be anchored and supported with stainless steel

• Maximum residual pressures above HSL at any case shall not exceed brackets, steel bolt and nut bolted into the wall of the reservoir.

15 m for gravity fed reservoirs/ tanks and 5 m for pumping fed iii. Overflow pipes shall be at least one size larger than the inlet pipe diameter

reservoirs/ tanks. and not smaller than the outlet pipe diameter.

iv. The scour pipe shall be designed to empty the full capacity of reservoir

within six (6) hours.

c. Boundary Setback v. For gravity flow, the inlet pipe at the reservoir/ tank shall be of side or bottom

inlet while for pumping supply, the inlet pipe shall be of top-inlet (bellmouth).

Setback from the edge of structural foundation shall be flat all-round with at least 6.0 The outlet pipe shall be of side or bottom outlet.

m for ground reservoir/ tank and pumping station structures and 9.0 m for elevated

reservoir/ tank structure. Minimum distance between two (2) structures shall be 3.0 m.

f. Control Valves

d. Materials and Measures i. All incoming mains to the suction reservoir/ tank and gravity flow to the

service reservoir/ tank shall be controlled by a mechanical control valve

i. Reinforced concrete reservoir is preferred and suction reservoir/ tank shall

while the incoming pumping main shall be electrodes controlled.

be reinforced concrete. However, storage reservoir/ tank of other material

ii. Inlet control valve shall be of ball float valve type for mains size up to 300 mm

may be used, subject to the approval by SYABAS.

diameter. An additional inspection manhole with a suitable size for

ii. Storage reservoir/ tank with a capacity of more than 454,000 litres shall be of

maintenance purposes shall be constructed directly on it. Inspection

reinforced concrete.

manhole shall be fitted with safety railing and covered with stainless steel

iii. The usage of storage reservoir/ tank with a capacity of less than 454,000

chequered plate.

litres built with other materials as approved by SYABAS are allowed until

iii. For incoming main of size above 300 mm, a one way flow full bore altitude

year 2010. After year 2010, all the storage reservoir/ tank shall be of

valve complete with T-pot strainer and by-pass installed in one common

reinforced concrete.

chamber shall be used. Butterfly valves shall be used for isolation and by-

iv. Reinforced concrete elevated storage reservoir/ tank shall not exceed the capacity

pass purposes.

of 4.5 million litres. Capacity of elevated storage reservoir/ tank of other materials

iv. The altitude valve shall be of diaphragm or piston type for sizes of less than

shall be subject to the approval of SYABAS.

450 mm diameter and of piston type for sizes of 450 mm diameter and above.

v. The effective water depth for RC reservoir/ tank shall be not more than 5 m

v. The control valves shall be fitted with sluice valves/ butterfly valves for

for capacity of less than 4,540,000 litres and 7 m for capacity of 4,540,000

isolation and maintenance purposes.

litres and above. The water depth for non RC reservoir/ tank shall not be

vi. All by-pass pipes shall be of the same size of the incoming pipe.

more than 5 m.

vii. All valve chambers shall be well drained or with dewatering system installed.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-8

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

g. Pipe Strainers 3.4.3 Pumping Stations

i. All incoming mains to the suction reservoirs/ tanks and gravity flow to the a. General

service reservoirs/ tanks shall be fitted with pipe strainers.

ii. A pipe strainer shall be fitted after the sluice valve and installed together in a i. Platform levels of pumping stations and suction reservoirs/ tanks shall be

common valve chamber. The size of the valve chamber shall be constructed designed above 100 years ARI flood level.

to suit the fittings of the sluice valve and pipe strainer. ii. Pumping station shall be of reinforced concrete and bricks with reinforced concrete

iii. The strainer shall be of 10 ~ 15 mesh stainless steel screen (net). roof or roof tiles. Roof tiles can only be used for pumping station where the

pumping capacity does not exceed 100 m3/hr. If roof truss is to be used, the truss

shall be of steel type.

h. Miscellaneous iii. All pumping stations shall be equipped with toilet and sewerage system.

iv. Pumping station with pumping capacity exceeding 50 m3/hr shall have office/ store

i. External stairs of reservoir/ tank shall be of reinforced concrete and shall be room.

fenced. All stairs shall have brickwall enclosure complete with mild steel doors. v. Pumping station with pumping capacity exceeding 10 Mld shall be equipped with

Stairs inside the reservoir/ tank shall be of reinforced concrete or stainless steel two (2) unit quarters with three (3) bedrooms. Floor area of each quarter shall

(SS304). All stairs shall be fixed with safety railing. not be less than 65 m2.

ii. Two (2) nos. or more ladders shall be provided for reservoir/ tank with a vi. Security grilles shall be provided on the inside of the pumping station window.

capacity of more than 9.1 million litres. vii. Heavy duty floor tiling shall be provided.

iii. All reservoirs/ tanks shall be fitted with ‘Dial’ type level indicators. The size of viii. Ceramic wall tiling shall be provided up to 1.5 m height.

level indicator for ground reservoir/ tank and elevated reservoir/ tank shall ix. All windows shall be of steel-casement type.

not be less than 600 mm diameter and 900 mm diameter respectively. Only x. All suction, discharge pipes and fittings shall conform to Table 3.3. All pipes

stainless steel cable (tangle-free design) shall be allowed. shall be laid in trenches and well anchored.

iv. Perspex glass covers shall be provided on the roof of reservoir/ tank. xi. The minimum width of trenches shall be the size of pipe laid plus 300 mm

v. All valve chambers shall protrude above the ground level not more than 300 space on each side of the pipe. All trenches shall be well drained and

mm. covered with hot dipped galvanised grating or chequered plate. Trenches

vi. Site drains and overflow drains shall be designed as per Table 3.8. built below the drain level shall be provided with pump sump complete with

vii. Security fence for reservoir/ tank and pumping station area shall be built as isolator point and earth leakage relay or RCD.

per SYABAS Standard Drawings attached, and the reserve’s boundary shall xii. All exposed pipes and fittings shall be painted as per SYABAS requirements.

be marked with boundary stones at 6 m interval. xiii. Main switchboard shall be compartmentalized and located away from water

viii. All level ground within the reservoir/ tank and pumping station compound pipes. Minimum clear distance between the main switchboard to the wall

shall be premixed as per Table 3.9. shall be 1.5 m.

ix. Reservoirs/ tanks shall be painted as per SYABAS Specifications. xiv. Minimum clear distance between two (2) pump sets shall not be less than 1.0

x. Top water level, bottom water level and capacity of the reservoir/ tank shall m.

be printed on the reservoir/ tank’s wall. xv. All pumping stations shall be provided with fire extinguishers, first aid kits

and safety procedures.

xvi. The pumping station shall be painted and marked as per SYABAS

Specifications.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-9

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

b. Pump Plinths 3.4.4 Geotechnical Considerations

i. Pumpset shall be rigidly fixed in position on its foundation and shall be free from

a. Reservoir, Tank and Pumping Station Buffer Zones for Slopes

vibrations. The design of the foundation shall comply with the following criteria:-

• The pumpset foundation shall be sufficiently strong for its load. i. The setbacks or the distance from the toe or the crest of respective adjacent

• It shall be sufficiently strong and heavy for suppressing any vibrations. slopes to the edge of reservoir/ tank and pumping station structures shall not

be less than 9 m.

ii. The distance between the crest of a slope and any water pipes, water

ii. A good practice is to fix the pumpsets on concrete block, in reasonably good firm

retaining structures, retention ponds, etc shall not be less 5 m.

ground. The following standard depths for pumps with various powers shall be

iii. Berms shall be formed on slopes at every 5 m vertical interval. For rock cut in

followed:-

sound and strong rock such as grade I or II granite (BS 5930:1999 - Code of

• 7.5 - 15.0 kW - 200 mm to 250 mm

Practice for Site Investigations), the berm interval may be increased to 9 m.

• 15.0 - 40.0 kW - 250 mm to 450 mm

The minimum berm width is 1.8 m.

• 40.0 - 55.0 kW - 450 mm to 600 mm

iv. The reservoir/ tank and pumping station buffer zones for slopes are shown in

• 55.0 - 75.0 kW - 600 mm to 750 mm

Figure 3.1.

• 75.0 - 100.0 kW - 750 mm to 1000 mm

iii. In practice, for pumps with powers above 75.0 kW, foundation plinths shall be

b. Slope Stability Analysis

specially designed based on the following standards:-

• For electric motor driven pumps, the weight of an independent foundation

i. Except provided under Clause 3.4.4.b.vii below, all slopes whether on cut or

shall be at least three times more than the machine kerb weight of the

fill section shall be analysed for slope stability. In the analysis, groundwater

pumpset.

conditions and potential external loadings shall be considered.

• When anti-vibration material such as rubber, spring etc; is used between

ii. The required factors of safety (FS) for slope stability are 1.5, 1.2 and 1.1 for

the common base plate for pump and the prime mover, and the foundation,

normal groundwater conditions, 10-year return period rainfall and the worst

the weight of foundation can be reduce to half of the standard weight.

groundwater conditions respectively.

• Where any pipe of the pumping system passes through a building wall, pipe

iii. For natural slopes or existing manmade slopes more than 10 years old, the

bellow or anti-vibration material shall be employed to prevent the vibration

minimum values of the aforesaid FS may be reduced to 1.2, 1.1 and 1.0

from transmitting to the building.

respectively.

iv. For new and existing rock slopes, the above respective FS in clause ii and iii

iv. Apart from depth, the size of foundation plinth shall have a minimum border of 100

shall be applied.

mm to 150 mm all round while the top of the plinth shall be 100 mm to 150 mm

above the floor. The concrete mix for the plinths shall be Grade 25. v. Geological mapping and interpretation shall be carried out to analyse the

stability of rock slopes.

vi. The modes of potential failures such as wedge, toppling and/ or plane

failures shall be identified and suitable rock supports shall be provided as

suggested in Table 3.10.

vii. Slope stabilization measures shall be required when the FS is not adequate

in order to achieve the FS required above.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-10

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

viii. Slope stability analysis may not be required when:- Vetiver grass (Vetiveria zizanionides) or other grass with equivalent

morphological, physiological and ecological characteristics.

• Height of fill slope that does not exceed 10 m and slope gradient is

ii. Good agricultural practices such as introduction of topsoil, correct planting

gentler than 1:2 (v:h) with 1.8 m berm at every 5 m vertical interval.

techniques and quality control shall be carried out for vegetation on the

The fill is formed of well compacted suitable material having SPT N

slopes. New turf shall be watered in the dry season, turf shall not be placed

(no. of blows) > 8.

on very hard ground before introduction of topsoil and horizontal grooving

• Height of cut slope that does not exceed 10 m and slope gradient is

shall be formed before turfing.

gentler than 1:1.5 (v:h) with 1.8 m berm at every 5 m vertical interval.

iii. On difficult or unusual sites, which cannot support plant growth, such as

The cut is in ideal soils of silty to sandy nature having SPT N > 8.

hard soil, acidic soil and steep slopes, suitable slope surface protection

• Rock cut slope that does not exceed 10 m high and slope gradient is

method such as special treatment using geomat or guniting or other methods

gentler than 4:1 (v:h) in sound rocks such as Grade I or II granite, free

approved by SYABAS shall be used.

from loose or unstable blocks or fragments.

iv. Rock supports effective to the mode of potential failures such as wedge,

toppling and/ or plane failures as identified in Table 3.8 shall be provided.

v. All loose rock fragments shall be scaled. Fractures rock zones susceptible to

c. Drainage Provisions

erosion or rocks susceptible to deterioration shall be protected by a suitable

method such as shotcrete with proper drainage weepholes.

i. All slopes shall be provided with subsoil drainage such as horizontal drains:-

• At the toe of the slope.

• Where the presence of water bodies (for example, water catchment

e. Reservoir, Tank and Pumping Station Foundation

area, sewers, drains and water mains) is above the slope.

• Groundwater level is uncertain or likely to be higher than the design

All reservoirs/ tanks and pumping stations should preferably be founded on competent cut

value.

ground otherwise deep foundation such as pile foundation shall be provided.

• Drainage of groundwater is hindered by slope surface protection

works such as shotcrete (sprayed concrete).

3.5 MATERIALS

ii. Berm drains and interceptor drains shall be provided on the berms and at the

crest of the slope respectively. The drains shall be cast-in-situ and steel

a. All materials used for water supply system shall have the approval from SYABAS.

reinforced. All drains shall be designed as per Table 3.8.

SYABAS reserves the right to inspect the materials to be used before installation.

Unapproved materials/ products including the works completed using the unapproved

materials shall be cleared from the site. Otherwise, the development will not be taken

d. Slope Surface Protection

over by SYABAS.

b. The types of incoming mains (without tapping) are as shown in Table 3.3.

i. All slope surface shall be fully (closed) turfed or protected against erosion

c. The types of reticulation pipes are as shown in Table 3.4.

upon completion of reservoir/ tank and pumping station construction. The

grass shall be hardy, have extensive and strong root system which is

effective for erosion control and perennial (long lasting) such as cow grass,

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-11

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

3.6 CHECKLIST Table 3.1 : Estimation of water consumption

Residential Daily Water Usage (l/d)

The checklist shall be completed and endorsed by a consulting engineer and shall be

Low cost house and low cost flat 1,000 /unit

attached together with the submission document. The design checklist of External Water

Medium low cost flat and medium cost house 1,500 /unit

Supply System is shown in APPENDIX C.

Single and double storey terrace house 1,500 /unit

Apartment/ condominium 1,500 /unit

Single and double storey semi detached house 2,000 /unit

Single and double storey bungalow (Additional 2,000 /unit

450 litres per room if more than 4 bedrooms)

Commercial

Single storey shop 2,000 /unit

Multiple storey shop house 1,500 /storey

Office 1,000 /100m2

Petrol station – a) With car washing bay 50,000 /unit

b) Without car washing bay 10,000 /unit

Market – a) Dry stall 450 /stall

b) Wet stall 1,500 /stall

Hawker Centre 1,500 /stall

Hotel 1,500 /room

Shopping complex 1,000 /100m2

Industrial lots According to daily water usage (Note 1)

Light industrial workshop 1,500 /unit

Terrace factory 5,000 /unit

Warehouse 1,500 /unit

Public and Social

Hospital 1,500 /bed

Mosque/ Surau 50 /person

Community Hall 25,000 /unit

Club House 50,000 /unit

Balai Raya 2,000 /unit

Day school 50 /student

Boarding school 250 /student

Institution 25,000 /ha

Kindergarten 30 /child

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-12

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Note:- Table 3.3 : Materials for incoming main/ main pipe (without tapping)

1. The consulting engineer shall estimate and justify the water demand consumption, Conditions Incoming Main Pipe Materials

otherwise 75,000 l/d for every hectare of land shall apply.

2. If the premises category/ usage is not stated in Table 3.1, further information shall be - Mild Steel (for diameter ≥ 700 mm) (note 1)

Non-corrosive soil

obtained from SYABAS. - Ductile Iron (note 3)

- HDPE

- ABS

Corrosive soil/ coastal area - GRP

- Ductile Iron with thicker zinc coating (note 3)

- Mild Steel (for diameter ≥ 700 mm) (note 1 & 2)

Table 3.2 : Hazen-William Coefficient C for various pipe materials

- Pumping main

- Mild Steel (for diameter ≥ 700 mm) (note 1)

Type of Pipe Hazen-William Coefficient C - Gravity main in undulating area,

- Ductile Iron (note 4)

sloping/ hilly area

Ductile Iron (cement lined) 100

Steel (cement lined) 100

- Mild Steel (for diameter ≥ 700 mm) (note 1)

HDPE/ ABS/ GRP 120

Under roadways - Ductile Iron (note 3)

- HDPE/ ABS/ GRP with RC pipe sleeve

Note :

1. Mild steel pipes with diameter of below 700 mm complete with full internal lining

protection acceptable to SYABAS and with CCTV confirmation may be

considered. Alternatively, flange jointed mild steel pipes are acceptable.

2. Mild steel pipes shall not be used for corrosive soil, however it can be

considered if protected with anodic/ cathodic protection.

3. Ductile iron pipes shall be push-in jointed complete with PE wrapping.

4. Ductile iron pipes shall be flange jointed or restraint tie bar jointed complete with

PE wrapping.

5. All plastic pipes shall be of PN 12 and above.

6. All pipeworks shall be as per SYABAS Specifications.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-13

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Table 3.4 : Materials for reticulation pipes Table 3.5 : Sampling box

Conditions Reticulation Pipe Materials No. of Connections No. of Sampling Box

Below 200 Not required

- HDPE

- ABS 201 – 1,000 1

Corrosive soil, coastal area,

- GRP Additional 1 no. of sampling

ex-mining land, etc

- Ductile Iron with thicker zinc coating 1,001 and above box for every 1,000

- Mild Steel (for diameter ≥ 700 mm) (note 1 & 2) connections

Fully industrial area, commercial,

- Ductile Iron

flats, condominium and shop houses

- HDPE

Residential area and mixed - ABS

developement - GRP Table 3.6 : DMZ chamber requirements for each hydraulic zone

- Ductile Iron

No. of Connections No. of DMZ Chamber

Below 500 Not required

- Mild Steel (for diameter ≥ 700 mm) (note 1)

Under roadways - Ductile Iron 501 – 2,000 1

- HDPE/ ABS/ GRP with RC pipe sleeve

Additional 1 no. of DMZ

2,001 and above chamber for every 2,000

connections

Note :

1. Mild steel pipes with diameter of below 700 mm complete with full internal lining

protection acceptable to SYABAS and with CCTV confirmation may be

considered. Alternatively, flange jointed mild steel pipes are acceptable.

2. Mild steel pipes shall not be used for corrosive soil, however it can be

considered if protected with anodic/ cathodic protection.

3. All plastic pipes shall be of PN 12 and above.

4. All pipeworks shall be as per SYABAS Specifications.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-14

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Table 3.7 : Storage capacity requirements for reservoirs/ tanks Table 3.8 : Storm drainage system design requirements

Storage Requirement (day of total

Drain Type Design Flow

average daily water demand)

Conditions

Reservoir Tank (within

(external) consumer premises) General site drainage 5 years ARI + check 100 years ARI

RESIDENTIAL, SHOPHOUSES, OFFICES, GOVERNMENT BUILDINGS AND EDUCTIONAL 5 years ARI + check 100 years ARI

BUILDINGS

Overflow discharge drain to or

Demand < 1 Mld Not Required 2 approved discharge point 5 years ARI + Overflow

whichever is the greater

Low rise (5 storey and below) development with

1 1

demand ≥ 1 Mld

High rise (6 storeys and above) development with

Not Required 2

demand ≥ 1 Mld

Mixed development (low rise and high rise) with

demand ≥ 1 Mld:-

a) High rise Not Required 2

Table 3.9 : Premix road pavement structures

b) Low rise with demand ≥ 1 Mld 1 1

c) Low rise with demand < 1 Mld Not Required 2 Thickness (mm)

Pavement Structure

All developments within Putrajaya Already Provided 2 Trafficable Area Non-trafficable Area

Road Base (crusher run) 250 150

All developments within Cyberjaya 1 2

Binder Course 60 60

INDUSTRIAL AREA/ FACTORY, HOSPITAL, HOTELS, RESORTS AND COMMERCIAL Wearing Course 40 40

COMPLEXES

a) Demand ≥ 1Mld 1 2

b) Demand < 1 Mld Not Required 3

MIXED DEVELOPMENT OF RESIDENTIAL,

Combination of the above principles

INDUSTRIAL AND COMMERCIAL

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-15

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Table 3.10 : Rock Slope Stabilization Measures

STABILIZATION MEASURES

POTENTIAL

FAILURE TYPE

Excavation Structural Support Drainage Rockfall Control

Permeable (masonry) facing

Local structural "dentition"

Screeded (paved) surface

Move structure/highway

Scaling of loose blocks

Long drainholes/ adits

Rock trap fence/wall

Local excavation

Short drainholes

Name (with sketch)

Rock trap ditch

Drainage ditch

Anchored wall

Flatten Slope

Gunite facing

Buttress

Anchor

Netting

Bench

Dowel

Strap

Bolt

Figure 3.1 : Typical reservoir/ water tank – slopes configuration

Plane Failure

√ √ √ √ √ √ √ √ √ √ √ √

Wedge Failure

√ √ √ √ √ √ √ √ √ √

Toppling Failure

√ √ √ √ √ √ √

Rock or Debris Fall &

General Degradation

√ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √ √

* Table 3.10 is extracted from “Geotechnical Manual for Slopes”, Geotechnical Engineering Office, Civil Engineering

Department, The Government of the Hong Kong Special Administrative Region, 2000.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 3-16

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

4.0 INTERNAL PLUMBING SYSTEM d. Only pipes, valves, tanks and other installations that have been approved by SYABAS can

be used.

4.1 PLANS e. Pipe to kitchen sinks shall be drawn directly from the incoming pipe before it branches to a

tank (not applicable for developments with central storage).

a. Consulting Engineers shall submit three (3) sets of finalized plans of A1 size including f. All other tapping from the incoming pipe within the premise shall only be channelled

one (1) no. CD containing the soft copy of the drawings in AutoCAD format to the to the storage/ break tank to avoid contamination in the main pipeline.

respective SYABAS District for approval. The plans required are as follows:- g. Water piping system for domestic water supply, air conditioning and fire fighting system

shall be separated.

i. Site plan.

h. Automatic flushing is not allowed.

ii. Building plans that are approved by local Authority.

i. Manual flushing or flush valve shall be used for urinal.

iii. Floor plan and cross section including meter location, fittings location, valves,

j. Separate pipe from storage tank shall be provided for system adopting flush valve.

pipeline route, etc.

k. All saddle used shall have protective coating as per SYABAS requirement.

iv. Detailed plan of cross sections showing tank and pump room locations.

l. Saddles for High Density Polyethylene (HDPE) pipe shall be of electro-fusion tapping.

v. Schematic diagram of pipework layout.

m. All bolts and nuts underground shall be of stainless steel.

vi. A copy of approved letter for external water supply system and a copy of

approved letter for tapping point from SYABAS’ Headquarters for proposed

development with demand exceeding 50,000 litres per day.

4.2.2 Pipes and Valves

b. For building of three (3) storeys and below without pumping system, two (2) sets of

calculations by design chart method shall be submitted by the architect, mechanical a. Nominal size, type and class of pipes shall be stated in the drawings.

engineer, civil engineer or hydraulic engineer. b. Detailed information including catalogues of valves shall be submitted to SYABAS.

c. For building with pumping system or development of four (4) storeys and above, c. Minimum internal diameter for internal plumbing shall be 15 mm.

two (2) sets of hydraulic calculations shall be submitted and endorsed by d. Usage of G.I. and uPVC pipes are not allowed.

mechanical or civil engineer. e. Types of pipe allowed for cold-water system are shown in Table 4.1.

d. All plans for fire fighting system shall be referred to BOMBA. f. For dropper pipes with pressure exceeding 30 m head, pressure reducing valve or break

e. Fire fighting pipes shall be of red colour and domestic pipes shall be of blue colour. tank shall be used.

g. Connection for HDPE pipe shall be of electro-fusion and butt weld.

h. Control valves (ball or stop cock type), shall be installed on : -

4.2 TECHNICAL REQUIREMENTS i. All incoming pipes to suction tank and roof storage tank at 1.8 m above floor

level.

4.2.1 General ii. All outgoing pipes from suction tank in an accessible position at maximum 1.8 m

above floor level.

a. All plumbers trained by SYABAS will be provided with an ID card that contains personal iii. Pipes to each toilet compartment and pipes to fittings such as sink, basin, WC

details and photograph to ensure that only qualified plumbers are allowed to carry out and urinal.

plumbing installation works.

b. Tapping works shall only be conducted by Licensed Plumber Type 2.

c. All pipe installation works within a building shall be carried out by a registered plumber.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 4-1

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

4.2.3 Water Tanks within Consumer Premises c. Safety and Security

a. Capacity i. The storage tank (including any tap fitted to the storage tank) and its

ancillary equipment shall be kept properly locked at all time.

i. Generally, the effective capacity of storage tank (actual volume of water that ii. All roof storage tanks shall be easily to access with proper staircase within

can be drawn for usage) shall be as shown in Table 3.7 and Table 4.2. the premises. Only spiral or walk up staircase shall be used and no cat ladder

ii. Factory with future expansion plan shall allocate sufficient space for ultimate shall be allowed.

storage requirement. iii. There shall be proper access for removal and replacement of the storage

iii. Top Water Level (TWL) for suction tank and roof storage tank shall be in Ordnance tank without removing or damaging any part of the building.

Datum Level (ODL). iv. The storage tank shall be placed on flat RC slabs complete with proper

iv. For low cost house/ flat, water tub of minimum 120 litres shall be provided in the drainage system. Timber and angle iron shall not be used for the support.

bathroom. v. The base of the storage tank shall be fully supported over its whole area by a

v. Separate water tank for food court in building shall be provided. durable, rigid, flat and level platform sufficiently strong to withstand the

weight of the cistern without deflection when filled with water.

b. Pipeworks and Materials

4.2.4 Pumping Systems

i. Water tank with capacity of less than 4,500 litres shall have overflow pipe which

shall also function as a warning pipe and shall be installed at a visible location. a. Total pumping head shall be as per design and not more than 75 m per stage. For

ii. Water tank with capacity of 4,500 litres and above shall have separate overflow case where the pumping head is more than 75 m per stage, a break tank with a

and warning pipe and shall be installed at a visible location. capacity of 11.5 m3 shall be introduced.

iii. Overflow pipe and scour pipe shall be one size larger than the incoming pipe and b. Pumping system operation shall have automatic control by stainless steel electrodes

not smaller than the outlet pipe. located within the suction tank and storage tank.

iv. Scour pipe shall be installed underneath the tank and channelled to the nearest c. Selector switch shall be provided at the starter panel in order for the pump to be operated

floor trap, sump or drain at a visible location. manually.

v. Sampling pipe shall be provided at the water storage tank for building which d. Maximum pumping rate for on duty pump shall be adequate to fill the commercial or office

provides water for food or beverage purposes. storage tank in eight (8) hours and residential storage tank in twelve (12) hours.

vi. The types of tanks allowed to be used as water storage tanks in buildings are e. Suction tank shall be sized to be between 33% to 50% of daily water demand and roof

subject to the approval by SYABAS. The following materials are approved:- storage tank shall be sized to be between 50% to 67% of daily water demand.

f. For cases where the number of pumps on standby is 200%, roof storage tank may be

• Reinforced Concrete (RC)

reduced to a size not less than 30% of daily water demand, and suction tank to have not

• High Density Polyethylene (HDPE)

less than 70% of storage capacity.

• Stainless Steel

g. For pumping design using pressurized system where the storage is 100% in ground floor

• Glass Coated Steel

storage tank,

i. The number of pumps on standby shall be 200% of duty pumps.

ii. Pumping system shall be of variable speed drive type if applicable.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 4-2

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

iii. A standby generator shall be provided. 4.3 WATER CONSERVATION

h. Alarm system shall be provided to give signal when the water level in the storage tank is

4.3.1 General

lower than pump start level.

i. For buildings with rain water collection system, the size of water storage tank may be

Water shall be used efficiently and effectively at all times. Consumers are encouraged to

reduced to 75% of daily water demand.

adopt water conservation measures in all non-domestic and domestic premises and

j. For building with multi-basement lower than external road level, pumps and suction

construction sites to conserve water.

tanks shall not be located at the lowest level of the basement to avoid water

contamination and damaged to pumping equipment. For building with single

basement, pumps and suction tanks located at basement shall be provided with

4.3.2 Water Conservation Measures

proper drainage system to prevent flooding.

a. Use of Water Saving Devices

4.2.5 Hot Water Systems i. Residential premises

Install constant flow regulators at wash basin taps, wash basin mixers,

a. Hot water piping system shall be separated and drawn directly from the storage tank.

shower taps and shower mixers.

Pumping system is only allowed after the water tank.

b. Control valve shall not be fixed at the heater outlet pipe for instant water heater. ii. Toilets and washrooms in all premises

c. Safety valve, whether using vent pipe or pressure relief valve, shall be drained to the Use low capacity dual flushing cisterns with capacity not exceeding 6 litres in

bathroom floor trap for storage type water heater. all new premises and existing premises undergoing renovation.

d. Types of pipes allowed for hot-water system are subject to approval of SYABAS. The

types of pipes approved are stainless steel, copper and PP-R pipes. iii. Toilets and washrooms in non-residential premises

• Install self-closing delayed-action taps at all wash basins and shower

points.

4.2.6 Swimming Pools • Install constant flow regulators at all wash basin mixers and shower

mixers.

a. Pool capacity, turnover time, rate of water cycle, rate of filtration and make-up water

volume, which consists of backwash water, water displacement, and evaporation iv. Kitchens and cooking areas in non-residential areas

loss shall be mentioned in the drawing. Install constant flow regulators at all sink taps and mixers.

b. Detailed schematic drawing of swimming pool piping system shall be submitted to

SYABAS. v. Canteens

c. Technical details and catalogue for pump and filter shall be submitted to SYABAS. Install self-closing delayed-action taps at all wash basins and wash troughs.

d. Swimming pool shall be designed in order to be filled within one (1) day to three (3) days.

vi. Laboratories

Install constant flow regulators at all wash basins and sink taps except for

safety reasons.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 4-3

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

vii. Factories Table 4.1: Internal Pipe Materials

Adopt the following measures in factories where possible and applicable:-

Type of Pipe D < 100 mm dia. D = 100 mm dia.– 150 mm dia.

• Setting up of water recovery system for boilers to recover condensate

water as make-up water. Stainless Steel/ HDPE (for

Communication Flanged Mild Steel/ Ductile

• Setting up water recycling system to reclaim water for reuse in the selected suppliers only)(Note 5)/

Pipe Iron

production process and other non-potable purposes. Polysteel

• Use of non-water cooled systems such as for cooling purposes.

Stainless Steel/ ABS/ PP-R/

Flanged Mild Steel/ ABS/

Service Pipe Copper/ Polybutelene/ Polysteel/

b. Rainwater Harvesting System Ductile Iron/ HDPE

POB/ GRP

Implement rainwater harvesting system which involves the collection, storage and

distribution of rainwater from the roof of a premises. Pumped Riser Flanged Mild Steel/ Ductile

Stainless Steel/ Copper/ Polysteel

Pipe Iron (Note 2)

4.4 CHECKLIST

Distribution Stainless Steel/ ABS/ PP-R/ Flanged Mild Steel/ ABS/

The checklist shall be completed and endorsed by consulting engineer and shall be Pipe Copper / Polysteel/ POB/ GRP Ductile Iron/ HDPE

attached together with the submission document. The design checklist of Internal

Plumbing System is shown in APPENDIX C.

Note:-

1. Polysteel pipe shall subject to the quality of work inspections by pipe manufacturer.

2. Ductile iron pipe for pumped riser shall be flange ended or push-in jointed complete

with restraint tie bars.

3. All plastic pipes shall be of PN 12 and above.

4. All pipeworks shall be as per SYABAS Specifications.

5. The usage of HDPE pipe as communication pipe shall be those approved by

SYABAS.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 4-4

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

Table 4.2: Internal storage tank (within consumer premises) effective capacity

according to types of premise or usage

Effective Capacity

(equivalent to 1-day

Item Type of Premises

average demand)

litres

1 Low cost house or low cost flat 1,000 /unit

2 Medium cost flat and medium cost house 1,000 /unit

Single or double storey terrace house, apartment and

3 1,500 /unit

condominium

Single or double storey semi-detached house and bungalow

4 2,000 /unit

(Additional 450 litres per room if more than 4 bedrooms)

5 Single storey shop house 2,000 /unit

6 Multiple storey shop house 1,500 /floor

7 Office 1,000 /100m2

8 Shopping Complex 1,000 /100m2

9 Hotel 1,500 /room

10 Hospital 1,500 /bed

11 Day School 50 /student

12 Boarding School 250 /student

13 Kindergarten 30 /child

14 Institution 25,000 /hectare

15 Mosque/ Surau 50 /person

16 Market - Dry Stall 450 /unit

17 Market - Wet Stall 1,500 /unit

18 Hawker Centre 1,500 /unit

19 Community Hall 25,000 /unit

20 Balai Raya 2,000 /unit

21 Club House 50,000 /unit

22 Petrol Station (without car washing bay) 10,000 /unit

23 Petrol Station (with car washing bay) 50,000 /unit

24 Light industrial workshop 1,500 /unit

25 Terrace factory 5,000 /unit

26 Warehouse 1,500 /unit

According to daily

27 Industrial Area

water usage

* Mutiply accordingly for any additional water storage as required under Table 3.7.

SEPAKAT SETIA PERUNDING (SDN) BHD. (14142-M)

Consulting Engineers 4-5

DRAFT FINAL

SYABAS GUIDELINES ON PLANNING AND DESIGN FOR WATER SUPPLY SYSTEM

5.0 METERING disconnect. A meter should preferably be installed in a box recessed into the wall

and shall not be at the corridor that will affects human traffic flow. Site verification

5.1 GENERAL with SYABAS is necessary before meter stand installation.

g. For meters laced in shaft or boxed in chambers, sufficient natural light must be

a. In general, water supply for different premises and for different uses shall be available for ease of reading. Alternatively, electrical lighting shall be provided.

metered. The need to have a meter and its location shall be determined by SYABAS.

b. All supplies to fire hydrants and other fire fighting devices installed in a consumer’s

premises or within its compound shall be metered. 5.3 SIZES OF METERS

c. For multi-unit premises, water is supplied through bulk meters which measure the

total volume of water measured by sub-meters fixed at the individual units. The The size of mechanical water meter for each premises shall be determined based on the

registered consumer for the bulk meter shall be responsible to pay for the water water flow rates and water usage as shown in Table 5.1. Table 5.2 shows the size details of

charges based on the difference between the registered consumption of the bulk electro-magnetic water meter.

meter and all the sub-meters, including leakages.