Professional Documents

Culture Documents

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Uploaded by

ingenieriacivil01Copyright:

Available Formats

You might also like

- Doll SarahDocument25 pagesDoll SarahZlaya100% (11)

- Chem 100 Exam 1 Study GuideDocument7 pagesChem 100 Exam 1 Study GuideMatt JordanNo ratings yet

- Materials AircraftDocument14 pagesMaterials Aircraftdyna3dNo ratings yet

- Use of Zeolite Powder As A Supplement of Cement in Concrete: A ReviewDocument7 pagesUse of Zeolite Powder As A Supplement of Cement in Concrete: A Reviewalaa albalahNo ratings yet

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah Mshivanand hippargaNo ratings yet

- Construction and Building Materials: E. Küçükyıldırım, B. UzalDocument6 pagesConstruction and Building Materials: E. Küçükyıldırım, B. UzalMarden Rengifo RuizNo ratings yet

- Mohamad 2019 IOP Conf. Ser. Mater. Sci. Eng. 601 012026Document13 pagesMohamad 2019 IOP Conf. Ser. Mater. Sci. Eng. 601 012026hemanthreddyNo ratings yet

- Mechanical Properties of Fly Ash Concrete Composite Reinforced With Nano-Sio and Steel FibreDocument9 pagesMechanical Properties of Fly Ash Concrete Composite Reinforced With Nano-Sio and Steel FibreAri Endra NasutionNo ratings yet

- Use of Natural Zeolite As A Supplementary Cementitious MaterialDocument8 pagesUse of Natural Zeolite As A Supplementary Cementitious MaterialHuseyin OzturkNo ratings yet

- Valipour Mahdi 2012Document10 pagesValipour Mahdi 2012Hugo VilemaNo ratings yet

- Composite Sand Cement Brick Containing Recycle Agg. and PET PDFDocument8 pagesComposite Sand Cement Brick Containing Recycle Agg. and PET PDFMuhammad AzriNo ratings yet

- Engineering Properties of Alkali-Activated Natural Pozzolan ConcreteDocument10 pagesEngineering Properties of Alkali-Activated Natural Pozzolan ConcreteAvani DedhiaNo ratings yet

- Kesikidou 2019Document6 pagesKesikidou 2019manayagamaryjoy9No ratings yet

- Using Wood Fiber Waste, Rice Husk Ash, and Limestone Powder Waste As Cement Replacement Materials For Lightweight Concrete BlocksDocument5 pagesUsing Wood Fiber Waste, Rice Husk Ash, and Limestone Powder Waste As Cement Replacement Materials For Lightweight Concrete BlocksANDRES FABIAN HERNANDEZ CARONo ratings yet

- Construction and Building Materials: Javad Torkaman, Alireza Ashori, Ali Sadr MomtaziDocument5 pagesConstruction and Building Materials: Javad Torkaman, Alireza Ashori, Ali Sadr MomtaziAboalmaail AlaminNo ratings yet

- Zeolite Synthesis From Low-Cost Materials and Environmental Applications - A Review - ScienceDirectDocument29 pagesZeolite Synthesis From Low-Cost Materials and Environmental Applications - A Review - ScienceDirectSALOMANRAVINo ratings yet

- An Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteDocument5 pagesAn Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Butar-Butar 2018 J. Phys. Conf. Ser. 970 012017Document6 pagesButar-Butar 2018 J. Phys. Conf. Ser. 970 012017Taufik Hidayat SiregarNo ratings yet

- Experimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)Document5 pagesExperimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)anon_884442402No ratings yet

- Cement With Eggshell Ash in M20 Grade ConcreteDocument9 pagesCement With Eggshell Ash in M20 Grade ConcreteNico YamatoNo ratings yet

- Properties of ShellDocument15 pagesProperties of ShellJay-Ar S. SungaNo ratings yet

- Irjet V6i6166Document6 pagesIrjet V6i6166shivanand hippargaNo ratings yet

- A Review of Fresh and Hardened Properties of ConcrDocument16 pagesA Review of Fresh and Hardened Properties of ConcrYitayewamlak AregaNo ratings yet

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah MS I DesaiNo ratings yet

- Research Into The Properties of Concrete Modified With Natural Zeolite AdditionDocument6 pagesResearch Into The Properties of Concrete Modified With Natural Zeolite AdditionDaji MhargudeNo ratings yet

- Construction and Building Materials: Nihat Kabay, M. Mansur Tufekci, Ahmet B. Kizilkanat, Didem OktayDocument8 pagesConstruction and Building Materials: Nihat Kabay, M. Mansur Tufekci, Ahmet B. Kizilkanat, Didem OktayMarden Rengifo RuizNo ratings yet

- Micro Estructural 2Document16 pagesMicro Estructural 2Luis FelixNo ratings yet

- Binder CharacterizationDocument10 pagesBinder CharacterizationkarthisekarNo ratings yet

- A Comprehensive Approach For Designing Workable Bio-Based Cementitious CompositesDocument13 pagesA Comprehensive Approach For Designing Workable Bio-Based Cementitious Compositeschen linNo ratings yet

- Krishna - Bhavani - Siram - 2022 - IOP - Geo AggregateDocument10 pagesKrishna - Bhavani - Siram - 2022 - IOP - Geo AggregateVideo Kill Radio StarsNo ratings yet

- Effect of Adding Sawdust On Mechanical Physical Properties of Ceramic Bricks To Obtain Lightweight Building MaterialDocument5 pagesEffect of Adding Sawdust On Mechanical Physical Properties of Ceramic Bricks To Obtain Lightweight Building MaterialMayson Ronal Quispe mamaniNo ratings yet

- Irjet V6i6166Document5 pagesIrjet V6i6166shivanand hippargaNo ratings yet

- Materials Today: Proceedings: Avinash Ojha, Lokesh GuptaDocument4 pagesMaterials Today: Proceedings: Avinash Ojha, Lokesh GuptaKashyap PanchalNo ratings yet

- In Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and MortarDocument13 pagesIn Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and Mortardummy dumdumNo ratings yet

- 543 373 1 PBDocument12 pages543 373 1 PBsuba vNo ratings yet

- Mechanical Behavior of Plaster Reinforced With Abaca FibersDocument8 pagesMechanical Behavior of Plaster Reinforced With Abaca FibersLeidy Vanessa Trujillo SanchezNo ratings yet

- Caronge 2017 IOP Conf. Ser. Mater. Sci. Eng. 271 012018Document7 pagesCaronge 2017 IOP Conf. Ser. Mater. Sci. Eng. 271 012018matrix builtNo ratings yet

- A Case Study On Fly Ash Based Geo-Polymer Concrete: ArticleDocument6 pagesA Case Study On Fly Ash Based Geo-Polymer Concrete: ArticleVIRAJ GawadeNo ratings yet

- Construction and Building Materials: H. Paiva, A.S. Silva, A. Velosa, P. Cachim, V.M. FerreiraDocument11 pagesConstruction and Building Materials: H. Paiva, A.S. Silva, A. Velosa, P. Cachim, V.M. FerreiraMateriales FicNo ratings yet

- Microstructure and Hardened State Properties On Pozzolan PDFDocument11 pagesMicrostructure and Hardened State Properties On Pozzolan PDFMateriales FicNo ratings yet

- RA and Fly Ash Mix ProportionDocument9 pagesRA and Fly Ash Mix ProportionMd imam hossen mehediNo ratings yet

- Experimental Investigation of Recycled Coarse Aggregate in Concrete With Mineral AdmixturesDocument6 pagesExperimental Investigation of Recycled Coarse Aggregate in Concrete With Mineral AdmixturesShahid BhatNo ratings yet

- Flexible Concrete For Structural Applications Using Polypropylene FiberDocument7 pagesFlexible Concrete For Structural Applications Using Polypropylene FiberLohith Kumar HPNo ratings yet

- Efectos Del Uso de Diatomita y Polvo de Mármol Residual Como Reemplazo Parcial Del Cemento Sobre Las Propiedades Mecánicas Del Hormigón.Document7 pagesEfectos Del Uso de Diatomita y Polvo de Mármol Residual Como Reemplazo Parcial Del Cemento Sobre Las Propiedades Mecánicas Del Hormigón.JHON CARLOS MONSALVE DIAZNo ratings yet

- Biochar As A Partial Cement Replacement Material For Developing Sustainable Concrete: An OverviewDocument12 pagesBiochar As A Partial Cement Replacement Material For Developing Sustainable Concrete: An Overviewmohamme.arif63No ratings yet

- Rfa 6Document11 pagesRfa 6tyagi rishabhNo ratings yet

- Materials Processing and CharacterizationDocument7 pagesMaterials Processing and CharacterizationSky abyrnNo ratings yet

- Feduik 2017 IOP Conf. Ser. Earth Environ. Sci. 87 092010Document7 pagesFeduik 2017 IOP Conf. Ser. Earth Environ. Sci. 87 092010Alexandra ErmuracheNo ratings yet

- (Asce) CC 1943-5614 0001173Document13 pages(Asce) CC 1943-5614 0001173Diya lizbeth joseNo ratings yet

- Hasan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1087 012001Document8 pagesHasan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1087 012001Hamzani HasbiNo ratings yet

- Odeyemi 2020 IOP Conf. Ser. Earth Environ. Sci. 445 012034Document12 pagesOdeyemi 2020 IOP Conf. Ser. Earth Environ. Sci. 445 012034Shimbarlu AtwiksonNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialsMarden Rengifo RuizNo ratings yet

- 1 s2.0 S2214509522003886 MainDocument13 pages1 s2.0 S2214509522003886 Mainanunciano GuterresNo ratings yet

- A Review On Natural Fibre Reinforced Polymer Composites: C. W. Nguong, S. N. B. Lee, and D. SujanDocument8 pagesA Review On Natural Fibre Reinforced Polymer Composites: C. W. Nguong, S. N. B. Lee, and D. SujanLamia Nour Ben abdelrahmenNo ratings yet

- Application of Sustainable Cement Alternatives in ConcreteDocument6 pagesApplication of Sustainable Cement Alternatives in ConcreteCARLOS ALTAMIRANO GUPIOCNo ratings yet

- Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshDocument10 pagesPartial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshSnehal AbhyankarNo ratings yet

- Lightweight Mortar Made With Recycled Polyurethane FoamDocument6 pagesLightweight Mortar Made With Recycled Polyurethane Foamelmer cervantesNo ratings yet

- FlyashndplasticstripsDocument11 pagesFlyashndplasticstripsAraبs UnofficialNo ratings yet

- Study On Addition of The Natural Fibers Into Concrete PDFDocument6 pagesStudy On Addition of The Natural Fibers Into Concrete PDFGayaThri GaYuzNo ratings yet

- Swamy Nadh 2018Document6 pagesSwamy Nadh 2018swamyNo ratings yet

- Indian Based Fly Ash & International Based Fly Ash: A Review PaperDocument6 pagesIndian Based Fly Ash & International Based Fly Ash: A Review PaperAnuraagNo ratings yet

- Corrosion Permeability Resistance of Concrete With Nanoplastic As AdmixtureDocument14 pagesCorrosion Permeability Resistance of Concrete With Nanoplastic As AdmixtureIsrael WakumaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Quantification of Residual Stresses in External Attachment Welding ApplicationDocument16 pagesQuantification of Residual Stresses in External Attachment Welding ApplicationAnonymous GhPzn1xNo ratings yet

- Rings CatalogDocument36 pagesRings CatalogpaulogameiroNo ratings yet

- Organic ChemDocument4 pagesOrganic ChemCherry GalamitonNo ratings yet

- Extraction From C4 HydrocarbonsDocument2 pagesExtraction From C4 HydrocarbonsAubrey TawandaNo ratings yet

- EBY Fasteners Product Range Aug 2020Document2 pagesEBY Fasteners Product Range Aug 2020Mark KNo ratings yet

- Boxes. Bowls and BasketsDocument116 pagesBoxes. Bowls and BasketsPatricia Arias G100% (4)

- Textile Science - Session 3Document35 pagesTextile Science - Session 3ALOK KUMARNo ratings yet

- Engineering ChemistryDocument21 pagesEngineering Chemistryjai kumarNo ratings yet

- A Review On Economically Adsorbents On Heavy Metals Removal in Water and Wastewater PDFDocument19 pagesA Review On Economically Adsorbents On Heavy Metals Removal in Water and Wastewater PDFLaura LambreaNo ratings yet

- Film Formation in Rubber GlovesDocument6 pagesFilm Formation in Rubber Glovestrader123No ratings yet

- En 10083 3 Technical Delivery Conditions For Alloy SteelsDocument2 pagesEn 10083 3 Technical Delivery Conditions For Alloy SteelskicklOpNo ratings yet

- PURIN Polyurethane Stone BinderDocument13 pagesPURIN Polyurethane Stone BinderHany EdwardNo ratings yet

- Offshore Riser Splash Zone Protection CoatingDocument46 pagesOffshore Riser Splash Zone Protection CoatingMohamad PizulNo ratings yet

- Engineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedDocument8 pagesEngineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedMatheus Paes PeçanhaNo ratings yet

- Ejectors & Vacuum Systems: Process Systems Pvt. LTDDocument2 pagesEjectors & Vacuum Systems: Process Systems Pvt. LTDboeiniNo ratings yet

- Line History SheetDocument4 pagesLine History SheetBethel NdifonNo ratings yet

- Dr. Hari Singh Gour Vishwdhyalaya, Sagar (M.P) : Importance of Fuel and Steel in Modern EconomyDocument26 pagesDr. Hari Singh Gour Vishwdhyalaya, Sagar (M.P) : Importance of Fuel and Steel in Modern EconomyGarima SinghNo ratings yet

- GeneralChemistry1 - Q2 - Module 3 - Types of Bonding and Their Properties - v5Document16 pagesGeneralChemistry1 - Q2 - Module 3 - Types of Bonding and Their Properties - v5JilyAh BellaNo ratings yet

- Receitas AmigurumiDocument62 pagesReceitas Amigurumialice bianchi alice100% (1)

- 1 s2.0 S0169409X16301028 Main PDFDocument30 pages1 s2.0 S0169409X16301028 Main PDFLeo Lopez100% (1)

- Diccionario TextilDocument220 pagesDiccionario TextilJean Gutierrez0% (1)

- Pdms CommandsDocument3 pagesPdms CommandsNithin ZsNo ratings yet

- Iodometric Determination of Copper and Iron in One SolutionDocument3 pagesIodometric Determination of Copper and Iron in One SolutionSianiiChavezMoránNo ratings yet

- Nafion Hydrogen Form ExpansionDocument2 pagesNafion Hydrogen Form ExpansionAlexander OliverosNo ratings yet

- Iclp 2016LPofCFRPID256Document9 pagesIclp 2016LPofCFRPID256daniel govantesNo ratings yet

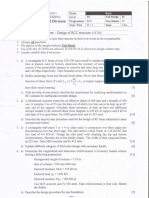

- Design of RCC StructureDocument14 pagesDesign of RCC Structuremark bingNo ratings yet

- Atoms vs. Ions Worksheet: CationsDocument5 pagesAtoms vs. Ions Worksheet: CationsR NovNo ratings yet

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Uploaded by

ingenieriacivil01Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Binary Cementitious Blends With Natural Zeolite Addition: A Review

Uploaded by

ingenieriacivil01Copyright:

Available Formats

Binary Cementitious Blends with Natural Zeolite

Addition: A Review

By

Perez-Diaz E.D. Sandoval-Herazo L.C.

Doctorate in science of the engineer, Post-

Master in Science, Postgrad Department

grad Depart.

Universidad Autónoma de Querétaro Instituto Tecnológico de Orizaba

Querétaro, México. Orizaba, México.

edgarperezd@hotmail.com lcsandovalh@gmail.com

Abstract

This article demonstrates that replacing Portland cement with natural zeolite as a poz-

zolanic material improves the properties of a cementitious mixture (pastes, mortars and

concretes) with the durability of a concrete benefiting. The mechanical strength as a

fundamental property of a concrete increases with the incorporation of natural zeolite,

within the percentages with better mechanical behavior is a range between 10%

and 20% of natural zeolite with respect to the weight of the cement, however be-

tween 20% and 40% (perhaps a little more) are generated concrete with adequate

mechanical resistance.

Introduction A zeolite concrete can be used perfectly in

any field of civil engineering, zeolite is an

The zeolite tuffs resulting from the reaction economical material in comparison to other

of volcanic ash deposited in salt lakes are pozzolanic materials.

considered as a natural material with poz-

zolanic characteristics. Results

The International Concrete Association de-

fines natural pozzolans as a material com-

posed of silica and aluminum.

The territory of Mexico, in an approximate

proportion of 50%, is formed by volcanic

sequences of the pliocene type.

Currently presenting 30 NZ deposits, predominating zeo-

lite type Clinoptilolite, being cataloged as one of the main

exporting countries of zeolite in America, after Cuba.

PC production consumes a high amount of energy and raw materials, this industry is The low permeability of these concretes would con-

responsible for the large amounts of CO2 emitted every year, approximately 7% of the siderably increase the durability of the structural

total caused by man members.

Conclusion

This paper summarizes the present research of the incorporation of natural zeolite in cementitious

mixtures based on PC, highlighting the fundamental properties that this material acquires by the sub-

stitution. The latest carried out research agrees that the use of natural zeolite for the production of

concrete and its derivatives is 100% recommended for its high mechanical performance and for the

increase of the durability of the members made with this binary material. The implementation of natu-

ral zeolite as a pozzolanic material should not be a second option but a fact, a study of the technical-

budget processes of production of binary cement based on natural zeolite should be done with the aim

of changing the construction paradigms and start using alternative materials to help mitigate environ-

mental damage.

References

B. Leguori, F. Lucolano, B. Gennaro, M. Marroccoli and D. Caputo, “Zeolitized tuff in environmental friendly production of

cementitious material: Chemical and mechanical characterization”. Construction and Building Materials journal, vol. 99, pp.

272-278, 2015B.

Uzal, L. Turanli, “Blended cements containing high volume of natural zeolites: Properties, hydration and paste microstructure”,

Cement & Concrete Composites, Vol. 34, pp. 101–109, 2012

M. Najimi, J. Sobhani, B. Ahmadi and M. Shekarchi, “An experimental study on durability properties of concrete containing

zeolite as a highly reactive natural pozzolan”, Construction and Building Materials, vol. 35, pp. 1023-1033, 2012

ACKNOWLEDGMENT

You might also like

- Doll SarahDocument25 pagesDoll SarahZlaya100% (11)

- Chem 100 Exam 1 Study GuideDocument7 pagesChem 100 Exam 1 Study GuideMatt JordanNo ratings yet

- Materials AircraftDocument14 pagesMaterials Aircraftdyna3dNo ratings yet

- Use of Zeolite Powder As A Supplement of Cement in Concrete: A ReviewDocument7 pagesUse of Zeolite Powder As A Supplement of Cement in Concrete: A Reviewalaa albalahNo ratings yet

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah Mshivanand hippargaNo ratings yet

- Construction and Building Materials: E. Küçükyıldırım, B. UzalDocument6 pagesConstruction and Building Materials: E. Küçükyıldırım, B. UzalMarden Rengifo RuizNo ratings yet

- Mohamad 2019 IOP Conf. Ser. Mater. Sci. Eng. 601 012026Document13 pagesMohamad 2019 IOP Conf. Ser. Mater. Sci. Eng. 601 012026hemanthreddyNo ratings yet

- Mechanical Properties of Fly Ash Concrete Composite Reinforced With Nano-Sio and Steel FibreDocument9 pagesMechanical Properties of Fly Ash Concrete Composite Reinforced With Nano-Sio and Steel FibreAri Endra NasutionNo ratings yet

- Use of Natural Zeolite As A Supplementary Cementitious MaterialDocument8 pagesUse of Natural Zeolite As A Supplementary Cementitious MaterialHuseyin OzturkNo ratings yet

- Valipour Mahdi 2012Document10 pagesValipour Mahdi 2012Hugo VilemaNo ratings yet

- Composite Sand Cement Brick Containing Recycle Agg. and PET PDFDocument8 pagesComposite Sand Cement Brick Containing Recycle Agg. and PET PDFMuhammad AzriNo ratings yet

- Engineering Properties of Alkali-Activated Natural Pozzolan ConcreteDocument10 pagesEngineering Properties of Alkali-Activated Natural Pozzolan ConcreteAvani DedhiaNo ratings yet

- Kesikidou 2019Document6 pagesKesikidou 2019manayagamaryjoy9No ratings yet

- Using Wood Fiber Waste, Rice Husk Ash, and Limestone Powder Waste As Cement Replacement Materials For Lightweight Concrete BlocksDocument5 pagesUsing Wood Fiber Waste, Rice Husk Ash, and Limestone Powder Waste As Cement Replacement Materials For Lightweight Concrete BlocksANDRES FABIAN HERNANDEZ CARONo ratings yet

- Construction and Building Materials: Javad Torkaman, Alireza Ashori, Ali Sadr MomtaziDocument5 pagesConstruction and Building Materials: Javad Torkaman, Alireza Ashori, Ali Sadr MomtaziAboalmaail AlaminNo ratings yet

- Zeolite Synthesis From Low-Cost Materials and Environmental Applications - A Review - ScienceDirectDocument29 pagesZeolite Synthesis From Low-Cost Materials and Environmental Applications - A Review - ScienceDirectSALOMANRAVINo ratings yet

- An Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteDocument5 pagesAn Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Butar-Butar 2018 J. Phys. Conf. Ser. 970 012017Document6 pagesButar-Butar 2018 J. Phys. Conf. Ser. 970 012017Taufik Hidayat SiregarNo ratings yet

- Experimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)Document5 pagesExperimental Investigation On Bendable Concrete Using Natural and Artificial Fibres (Jute and Nylon)anon_884442402No ratings yet

- Cement With Eggshell Ash in M20 Grade ConcreteDocument9 pagesCement With Eggshell Ash in M20 Grade ConcreteNico YamatoNo ratings yet

- Properties of ShellDocument15 pagesProperties of ShellJay-Ar S. SungaNo ratings yet

- Irjet V6i6166Document6 pagesIrjet V6i6166shivanand hippargaNo ratings yet

- A Review of Fresh and Hardened Properties of ConcrDocument16 pagesA Review of Fresh and Hardened Properties of ConcrYitayewamlak AregaNo ratings yet

- Materials Today: Proceedings: Gowram Iswarya, Beulah MDocument8 pagesMaterials Today: Proceedings: Gowram Iswarya, Beulah MS I DesaiNo ratings yet

- Research Into The Properties of Concrete Modified With Natural Zeolite AdditionDocument6 pagesResearch Into The Properties of Concrete Modified With Natural Zeolite AdditionDaji MhargudeNo ratings yet

- Construction and Building Materials: Nihat Kabay, M. Mansur Tufekci, Ahmet B. Kizilkanat, Didem OktayDocument8 pagesConstruction and Building Materials: Nihat Kabay, M. Mansur Tufekci, Ahmet B. Kizilkanat, Didem OktayMarden Rengifo RuizNo ratings yet

- Micro Estructural 2Document16 pagesMicro Estructural 2Luis FelixNo ratings yet

- Binder CharacterizationDocument10 pagesBinder CharacterizationkarthisekarNo ratings yet

- A Comprehensive Approach For Designing Workable Bio-Based Cementitious CompositesDocument13 pagesA Comprehensive Approach For Designing Workable Bio-Based Cementitious Compositeschen linNo ratings yet

- Krishna - Bhavani - Siram - 2022 - IOP - Geo AggregateDocument10 pagesKrishna - Bhavani - Siram - 2022 - IOP - Geo AggregateVideo Kill Radio StarsNo ratings yet

- Effect of Adding Sawdust On Mechanical Physical Properties of Ceramic Bricks To Obtain Lightweight Building MaterialDocument5 pagesEffect of Adding Sawdust On Mechanical Physical Properties of Ceramic Bricks To Obtain Lightweight Building MaterialMayson Ronal Quispe mamaniNo ratings yet

- Irjet V6i6166Document5 pagesIrjet V6i6166shivanand hippargaNo ratings yet

- Materials Today: Proceedings: Avinash Ojha, Lokesh GuptaDocument4 pagesMaterials Today: Proceedings: Avinash Ojha, Lokesh GuptaKashyap PanchalNo ratings yet

- In Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and MortarDocument13 pagesIn Uence of Bottom Ash and Limestone Powder On The Properties of Ternary Cement and Mortardummy dumdumNo ratings yet

- 543 373 1 PBDocument12 pages543 373 1 PBsuba vNo ratings yet

- Mechanical Behavior of Plaster Reinforced With Abaca FibersDocument8 pagesMechanical Behavior of Plaster Reinforced With Abaca FibersLeidy Vanessa Trujillo SanchezNo ratings yet

- Caronge 2017 IOP Conf. Ser. Mater. Sci. Eng. 271 012018Document7 pagesCaronge 2017 IOP Conf. Ser. Mater. Sci. Eng. 271 012018matrix builtNo ratings yet

- A Case Study On Fly Ash Based Geo-Polymer Concrete: ArticleDocument6 pagesA Case Study On Fly Ash Based Geo-Polymer Concrete: ArticleVIRAJ GawadeNo ratings yet

- Construction and Building Materials: H. Paiva, A.S. Silva, A. Velosa, P. Cachim, V.M. FerreiraDocument11 pagesConstruction and Building Materials: H. Paiva, A.S. Silva, A. Velosa, P. Cachim, V.M. FerreiraMateriales FicNo ratings yet

- Microstructure and Hardened State Properties On Pozzolan PDFDocument11 pagesMicrostructure and Hardened State Properties On Pozzolan PDFMateriales FicNo ratings yet

- RA and Fly Ash Mix ProportionDocument9 pagesRA and Fly Ash Mix ProportionMd imam hossen mehediNo ratings yet

- Experimental Investigation of Recycled Coarse Aggregate in Concrete With Mineral AdmixturesDocument6 pagesExperimental Investigation of Recycled Coarse Aggregate in Concrete With Mineral AdmixturesShahid BhatNo ratings yet

- Flexible Concrete For Structural Applications Using Polypropylene FiberDocument7 pagesFlexible Concrete For Structural Applications Using Polypropylene FiberLohith Kumar HPNo ratings yet

- Efectos Del Uso de Diatomita y Polvo de Mármol Residual Como Reemplazo Parcial Del Cemento Sobre Las Propiedades Mecánicas Del Hormigón.Document7 pagesEfectos Del Uso de Diatomita y Polvo de Mármol Residual Como Reemplazo Parcial Del Cemento Sobre Las Propiedades Mecánicas Del Hormigón.JHON CARLOS MONSALVE DIAZNo ratings yet

- Biochar As A Partial Cement Replacement Material For Developing Sustainable Concrete: An OverviewDocument12 pagesBiochar As A Partial Cement Replacement Material For Developing Sustainable Concrete: An Overviewmohamme.arif63No ratings yet

- Rfa 6Document11 pagesRfa 6tyagi rishabhNo ratings yet

- Materials Processing and CharacterizationDocument7 pagesMaterials Processing and CharacterizationSky abyrnNo ratings yet

- Feduik 2017 IOP Conf. Ser. Earth Environ. Sci. 87 092010Document7 pagesFeduik 2017 IOP Conf. Ser. Earth Environ. Sci. 87 092010Alexandra ErmuracheNo ratings yet

- (Asce) CC 1943-5614 0001173Document13 pages(Asce) CC 1943-5614 0001173Diya lizbeth joseNo ratings yet

- Hasan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1087 012001Document8 pagesHasan 2021 IOP Conf. Ser. Mater. Sci. Eng. 1087 012001Hamzani HasbiNo ratings yet

- Odeyemi 2020 IOP Conf. Ser. Earth Environ. Sci. 445 012034Document12 pagesOdeyemi 2020 IOP Conf. Ser. Earth Environ. Sci. 445 012034Shimbarlu AtwiksonNo ratings yet

- Construction and Building MaterialsDocument10 pagesConstruction and Building MaterialsMarden Rengifo RuizNo ratings yet

- 1 s2.0 S2214509522003886 MainDocument13 pages1 s2.0 S2214509522003886 Mainanunciano GuterresNo ratings yet

- A Review On Natural Fibre Reinforced Polymer Composites: C. W. Nguong, S. N. B. Lee, and D. SujanDocument8 pagesA Review On Natural Fibre Reinforced Polymer Composites: C. W. Nguong, S. N. B. Lee, and D. SujanLamia Nour Ben abdelrahmenNo ratings yet

- Application of Sustainable Cement Alternatives in ConcreteDocument6 pagesApplication of Sustainable Cement Alternatives in ConcreteCARLOS ALTAMIRANO GUPIOCNo ratings yet

- Partial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshDocument10 pagesPartial Replacement of Portland-Composite Cement by Fluidized Bed Combustion Fly AshSnehal AbhyankarNo ratings yet

- Lightweight Mortar Made With Recycled Polyurethane FoamDocument6 pagesLightweight Mortar Made With Recycled Polyurethane Foamelmer cervantesNo ratings yet

- FlyashndplasticstripsDocument11 pagesFlyashndplasticstripsAraبs UnofficialNo ratings yet

- Study On Addition of The Natural Fibers Into Concrete PDFDocument6 pagesStudy On Addition of The Natural Fibers Into Concrete PDFGayaThri GaYuzNo ratings yet

- Swamy Nadh 2018Document6 pagesSwamy Nadh 2018swamyNo ratings yet

- Indian Based Fly Ash & International Based Fly Ash: A Review PaperDocument6 pagesIndian Based Fly Ash & International Based Fly Ash: A Review PaperAnuraagNo ratings yet

- Corrosion Permeability Resistance of Concrete With Nanoplastic As AdmixtureDocument14 pagesCorrosion Permeability Resistance of Concrete With Nanoplastic As AdmixtureIsrael WakumaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Quantification of Residual Stresses in External Attachment Welding ApplicationDocument16 pagesQuantification of Residual Stresses in External Attachment Welding ApplicationAnonymous GhPzn1xNo ratings yet

- Rings CatalogDocument36 pagesRings CatalogpaulogameiroNo ratings yet

- Organic ChemDocument4 pagesOrganic ChemCherry GalamitonNo ratings yet

- Extraction From C4 HydrocarbonsDocument2 pagesExtraction From C4 HydrocarbonsAubrey TawandaNo ratings yet

- EBY Fasteners Product Range Aug 2020Document2 pagesEBY Fasteners Product Range Aug 2020Mark KNo ratings yet

- Boxes. Bowls and BasketsDocument116 pagesBoxes. Bowls and BasketsPatricia Arias G100% (4)

- Textile Science - Session 3Document35 pagesTextile Science - Session 3ALOK KUMARNo ratings yet

- Engineering ChemistryDocument21 pagesEngineering Chemistryjai kumarNo ratings yet

- A Review On Economically Adsorbents On Heavy Metals Removal in Water and Wastewater PDFDocument19 pagesA Review On Economically Adsorbents On Heavy Metals Removal in Water and Wastewater PDFLaura LambreaNo ratings yet

- Film Formation in Rubber GlovesDocument6 pagesFilm Formation in Rubber Glovestrader123No ratings yet

- En 10083 3 Technical Delivery Conditions For Alloy SteelsDocument2 pagesEn 10083 3 Technical Delivery Conditions For Alloy SteelskicklOpNo ratings yet

- PURIN Polyurethane Stone BinderDocument13 pagesPURIN Polyurethane Stone BinderHany EdwardNo ratings yet

- Offshore Riser Splash Zone Protection CoatingDocument46 pagesOffshore Riser Splash Zone Protection CoatingMohamad PizulNo ratings yet

- Engineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedDocument8 pagesEngineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedMatheus Paes PeçanhaNo ratings yet

- Ejectors & Vacuum Systems: Process Systems Pvt. LTDDocument2 pagesEjectors & Vacuum Systems: Process Systems Pvt. LTDboeiniNo ratings yet

- Line History SheetDocument4 pagesLine History SheetBethel NdifonNo ratings yet

- Dr. Hari Singh Gour Vishwdhyalaya, Sagar (M.P) : Importance of Fuel and Steel in Modern EconomyDocument26 pagesDr. Hari Singh Gour Vishwdhyalaya, Sagar (M.P) : Importance of Fuel and Steel in Modern EconomyGarima SinghNo ratings yet

- GeneralChemistry1 - Q2 - Module 3 - Types of Bonding and Their Properties - v5Document16 pagesGeneralChemistry1 - Q2 - Module 3 - Types of Bonding and Their Properties - v5JilyAh BellaNo ratings yet

- Receitas AmigurumiDocument62 pagesReceitas Amigurumialice bianchi alice100% (1)

- 1 s2.0 S0169409X16301028 Main PDFDocument30 pages1 s2.0 S0169409X16301028 Main PDFLeo Lopez100% (1)

- Diccionario TextilDocument220 pagesDiccionario TextilJean Gutierrez0% (1)

- Pdms CommandsDocument3 pagesPdms CommandsNithin ZsNo ratings yet

- Iodometric Determination of Copper and Iron in One SolutionDocument3 pagesIodometric Determination of Copper and Iron in One SolutionSianiiChavezMoránNo ratings yet

- Nafion Hydrogen Form ExpansionDocument2 pagesNafion Hydrogen Form ExpansionAlexander OliverosNo ratings yet

- Iclp 2016LPofCFRPID256Document9 pagesIclp 2016LPofCFRPID256daniel govantesNo ratings yet

- Design of RCC StructureDocument14 pagesDesign of RCC Structuremark bingNo ratings yet

- Atoms vs. Ions Worksheet: CationsDocument5 pagesAtoms vs. Ions Worksheet: CationsR NovNo ratings yet