Professional Documents

Culture Documents

Espol 38.00 Revised 07032016

Espol 38.00 Revised 07032016

Uploaded by

Vinay YadavOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Espol 38.00 Revised 07032016

Espol 38.00 Revised 07032016

Uploaded by

Vinay YadavCopyright:

Available Formats

Product Data Sheet (Provisional)

espolTM 38.00

Epoxy Vinyl Ester Resin (VER)

Technical Specification Product Specification

espol™ is the product trade mark of [Confirm to IS 6746-1994; Reaffirmed 2005]

formulated/branded speciality unsaturated polyester Physical Data in Liquid State

resins synthesized at Satyen Polymers Private Limited.

Unit Value TM

These resins are tailored to meet the diverse needs of Properties

GRP/FRP industry and meeting the requirements of Appearance Visual

Clear amber

TM-31

customers interest of improved efficiency and superior liquid

Specific Gravity. g/cm3 1.05± 2 TM-11

performance of finished products.

Visc.@25 oC a cPs 300--400 TM-05

Volatile Content % 45±2 TM-08

Features & Applications

Acid value mgKOH/gm 8±3 TM-06

espol™ 38.00 is a Bis-Phenol-A based epoxy vinyl 18—25s

ester resin designed to provide good mechanical Minutes 15—20w TM-07

Gel time @ 250C b

properties viz. impact, elongation and toughness. It

offers good resistance to acids, alkalis, bleaches agents

and solvents. Due to its various end applications and Peak Exotherm 0

C 140--160 TM-07

Temp.

application technologies, it is standard corrosion

Stability in the Dark

resistance resin for the composites industry and Months 3 TM-32

(Below 250C)

provides safety against damages during installation and

shipping. . It is non promoted, non pre-accelerated and a Brookfield RVT viscometer, spindle #2, 20 RPM)

non thixotropic resin. b Using accelerator Co 6% 0.4 mL , promote DMA 10% 0.5 mL

Addition of thixotropic agents and fillers can and MEKP Butanox M 50 1.5ml, as a catalyst to measure gel, cure

compromise the corrosion resistance. Please consult time and peak exotherm temperature.

our technical department before using these. s-summer , w-winter

Typical Application Mechanical Properties

espol™ 38.00 can be used to fabricate FRP storage Properties Units Values# TS

tanks, vessels, ducts and other applications, particularly ASTM D –

Barcol Hardness BHU 35

in chemicals operations. It can also be used for 2583

Heat Distortion

fabrication of bridge support, ladder etc. to be Temp.

0

C 105 ISO- R 75

exposed to stringent, sewerage & effluents. Specific Gravity g/cm3 1.15± 0.02 IS0-R1183

Volume Shrinkage % 7-8 ISO-3521

It is designed for use in hand layup, spray up, filament ISO – R

winding, Pultrusion, compression molding and resin Tensile Strength N/sq.mm 80

527

transfer molding. ISO – R

Tensile Modulus N/sq.mm 3200±200

527

The information herein is a general information designed based on our own research and findings to assist customers in

determining whether our products are suitable for their applications. We recommend customers to inspect and test our

products before use and to satisfy themselves as to contents and suitability for their specific applications. Nothing herein shall

constitute any warranty express or implied, and M/s. Satyen Polymers Pvt. Ltd. cannot assume any responsibility for

performance or results obtained through the use of our products herein described, nor do we accept any liability for loss or

damages directly or indirectly caused by our products.

Satyen Polymers Pvt. Ltd.

(An ISO 9001:2008 certified Company)

307 A to Z Industrial Estate, G. K. Marg, Lower Parel (West), Mumbai – 400 013

Tel. No.: +91-22-42201555, Fax No.: +91-22-24911262; E-mail: info@resadh.com Website: www.satyenpolymers.com

espol™ is registered trade mark of Satyen Polymers Pvt. Ltd.

Product Data Sheet (Provisional)

Elongation at break % 4.5-5.5

ISO – R Material Safety

527 Users are recommended to do not add metal salts

Flexural Strength N/sq.mm 125 ISO – R178 (promoters) or promoted resins to a peroxide. When

Flexural Modulus N/sq.mm 3400±200 ISO –R 178 adding peroxides to a resin solution, promptly and

#Post Cured Values, TS-Test Standard thoroughly mix the resulting product. Never add

organic peroxides to a hot diluent or process. Prevent

Guidelines for Usage contamination with foreign materials during its handling.

espol™ 38.00 performs best if the laminate is Read the product Material Safety Data Sheet before

completely post cured. The quantity of catalyst and handling, storing or using this product. MSDS for the

accelerator can be adjusted to get a shorter or product is available on request.

longer gel time. In order to mix the accelerator and

catalyst in resin, users are recommended to establish Revision

the required gel time as per working temperature.

When adding peroxides to a resin solution, promptly The product data sheet has been revised as per below

and thoroughly mix the resulting product. It is reference.

recommended to mature the products for 24 hours

and post curing should be done for minimum of two Revision Description Date

hours at 120oC to get the optimum properties.

espolTM 38.00

Packing ISO- 9001- 05.03.2016

Epoxy Vinyl

2008 Rev-01

espol™ 38.00 is available in 35 kg carboys and 200 kg Ester Resin (VER)

drums

Storage Guidelines

The resin should be stored indoors in the original,

unopened and undamaged packaging, in a dry place

away from heat ignition sources and sunlight at

temperatures below 25°C. Keep containers closed

when not in use. Shelf life is reduced at higher

temperatures and the properties of the resin might

change during storage. The shelf life is 90 days for these

resins when stored indoors in closed, opaque

containers at 25°C out of direct sunlight. Storage

conditions at higher temperatures or in direct sunlight

will reduce the self life and may also cause the resin to

experience gel time and viscosity drift. Version: 0108/1.1; Date of Issue: March, 2016.

The information herein is a general information designed based on our own research and findings to assist customers in

determining whether our products are suitable for their applications. We recommend customers to inspect and test our

products before use and to satisfy themselves as to contents and suitability for their specific applications. Nothing herein shall

constitute any warranty express or implied, and M/s. Satyen Polymers Pvt. Ltd. cannot assume any responsibility for

performance or results obtained through the use of our products herein described, nor do we accept any liability for loss or

damages directly or indirectly caused by our products.

Satyen Polymers Pvt. Ltd.

(An ISO 9001:2008 certified Company)

307 A to Z Industrial Estate, G. K. Marg, Lower Parel (West), Mumbai – 400 013

Tel. No.: +91-22-42201555, Fax No.: +91-22-24911262; E-mail: info@resadh.com Website: www.satyenpolymers.com

espol™ is registered trade mark of Satyen Polymers Pvt. Ltd.

You might also like

- Pickling and Passivation Report PDFDocument1 pagePickling and Passivation Report PDFVinay Yadav100% (2)

- Asm Handbook Volume 5 PDFDocument4 pagesAsm Handbook Volume 5 PDFIrfan GhaniNo ratings yet

- Inspection Report FORMATDocument6 pagesInspection Report FORMATVinay Yadav100% (1)

- CSA W47.1 W59 13 Guides WeldCanadaDocument5 pagesCSA W47.1 W59 13 Guides WeldCanadamehdi810100% (2)

- Sample Questions For AWS D1.1-2010: Structural Welding Code - SteelDocument13 pagesSample Questions For AWS D1.1-2010: Structural Welding Code - SteelArroyo H WoosNo ratings yet

- Fixation For PlasticsDocument16 pagesFixation For PlasticsSharad100% (1)

- Batch ReportsDocument2 pagesBatch ReportsR K ParidaNo ratings yet

- 11 KV Ue Heat Shrink Indoor Gtp-1987 R-0Document1 page11 KV Ue Heat Shrink Indoor Gtp-1987 R-0Prasad Yeluripati0% (1)

- VRM PresentationDocument49 pagesVRM PresentationMKPashaPasha100% (4)

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Blind Rivet Quality Certification ReportDocument1 pageBlind Rivet Quality Certification ReportZain Abedeen0% (1)

- Price List No. 164 Price List No. 164Document12 pagesPrice List No. 164 Price List No. 164mshNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- 10 MM Test CertificateDocument1 page10 MM Test CertificatesimbamikeNo ratings yet

- 4620D Test Report (For Thickness AA15)Document2 pages4620D Test Report (For Thickness AA15)weiiiiiNo ratings yet

- 40 CR 4 Mo 3Document3 pages40 CR 4 Mo 3Ravi NaikNo ratings yet

- Tram Grooved Rails New Catalog January 2018Document12 pagesTram Grooved Rails New Catalog January 2018Szabolcs Attila KöllőNo ratings yet

- TSL Bhushan - Colour CoatedDocument21 pagesTSL Bhushan - Colour Coatedabdul jawad100% (1)

- Is 2062 E350 - Fe 490 Steel Plate - Steel PlateDocument4 pagesIs 2062 E350 - Fe 490 Steel Plate - Steel PlateAmit GauravNo ratings yet

- Goel TMT Physical Report-SignedDocument4 pagesGoel TMT Physical Report-Signedsitaramap10 sathupallyNo ratings yet

- IS 4923 Chemical CompositionDocument1 pageIS 4923 Chemical CompositionTulasidas MalajiNo ratings yet

- Essar Steel Galvanised BrochureDocument9 pagesEssar Steel Galvanised BrochureSukanya Sen DuttaNo ratings yet

- Material Test Certificates: Supplied ToDocument2 pagesMaterial Test Certificates: Supplied ToShaheen Andre ChikkuNo ratings yet

- Astm A239Document4 pagesAstm A239Ngô Trung NghĩaNo ratings yet

- RealEstate-STP Real EstateDocument143 pagesRealEstate-STP Real Estaterakesh patiNo ratings yet

- Test Report 63MmDocument3 pagesTest Report 63Mmamit chauhanNo ratings yet

- TolerancesDocument2 pagesTolerancesAdithya ShourieNo ratings yet

- Test CertificateDocument1 pageTest CertificatequalityNo ratings yet

- TMT Fe-550D, 500DDocument9 pagesTMT Fe-550D, 500DRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Andhra Pradesh Class 1 Registration Certificate FormatDocument2 pagesAndhra Pradesh Class 1 Registration Certificate Formatgsatyasrikanth0% (3)

- Epimastic 5200: Product DescriptionDocument2 pagesEpimastic 5200: Product DescriptionsreeNo ratings yet

- QAP For MS Pipes RevisedDocument3 pagesQAP For MS Pipes RevisedAnuj PandeyNo ratings yet

- Door Cum Partition SectionsDocument27 pagesDoor Cum Partition SectionsPRASENJIT DHARNo ratings yet

- Material Test Certificate: Diamond Pipe Supports Pvt. LTDDocument1 pageMaterial Test Certificate: Diamond Pipe Supports Pvt. LTDAneesh ConstantineNo ratings yet

- Test Report: Issued ToDocument3 pagesTest Report: Issued TojitendraNo ratings yet

- JSSL Brochure PDFDocument6 pagesJSSL Brochure PDFJindal HydraulicsNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- 2721 Chain LinkDocument8 pages2721 Chain LinkPankaj GargNo ratings yet

- Rate of Material Used For Making P.P.C Batch 1Document7 pagesRate of Material Used For Making P.P.C Batch 1Seema DubeyNo ratings yet

- Somasila Grey Granite Test ReportDocument2 pagesSomasila Grey Granite Test ReportRakesh ReddyNo ratings yet

- Aropol in 5334Document2 pagesAropol in 5334GautamNo ratings yet

- JSW Steel Limited: Test Certificate For Cold Reduced Low Carbon Steel Sheet & StripDocument1 pageJSW Steel Limited: Test Certificate For Cold Reduced Low Carbon Steel Sheet & StripVenkatesh KumarNo ratings yet

- Sintex Junction Box Price List 01.01.2021Document1 pageSintex Junction Box Price List 01.01.2021Rajesh Dey100% (1)

- Non-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSDocument1 pageNon-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSSumit Gupta100% (1)

- Technical Handbook: Heavy Duty Slurry PumpDocument12 pagesTechnical Handbook: Heavy Duty Slurry PumpDejanNo ratings yet

- Sika Grout Vhs QacDocument1 pageSika Grout Vhs QacSushil RajakNo ratings yet

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785Document9 pagesAshirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785mohd shirazNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- Specification & Size Chart For Non VRF/ Non VRV Air Condition Grade Copper Tubes (For Split, Package & Ductable Air Conditioners)Document1 pageSpecification & Size Chart For Non VRF/ Non VRV Air Condition Grade Copper Tubes (For Split, Package & Ductable Air Conditioners)Adil Amin100% (1)

- GSB FormatDocument1 pageGSB Formatskm mmNo ratings yet

- Guide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)Document26 pagesGuide For Internal Audit and Management Review For Conformity Assessment Bodies (Laboratories / PTP / RMP)karthikkanda100% (1)

- 20MM - 63.150 TonDocument1 page20MM - 63.150 TonRAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- 4 MM Plate - MTC - SS-304Document1 page4 MM Plate - MTC - SS-304Mohammad AdilNo ratings yet

- Amendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationDocument3 pagesAmendment No. 6 June 2021 To Is 1239 (Part 1) : 2004 Steel Tubes, Tubulars and Other Wrought Steel Fittings - SpecificationRaghav TiwaryNo ratings yet

- Bartec Datasheet PDS001rev24 - BF PDFDocument26 pagesBartec Datasheet PDS001rev24 - BF PDFSaidi NadjimNo ratings yet

- IS 16172 2014 Coupler Splice BarDocument16 pagesIS 16172 2014 Coupler Splice BarMayank KumarNo ratings yet

- st44 2 PDFDocument1 pagest44 2 PDFAraby Gamal GamalNo ratings yet

- IS 2062 E250A 25mm PlateDocument3 pagesIS 2062 E250A 25mm PlateKandula RajuNo ratings yet

- M25 (PPC)Document2 pagesM25 (PPC)Jagdev GuleriaNo ratings yet

- Barbed Wire MTC - 230912Document1 pageBarbed Wire MTC - 230912dmtcl selcp1No ratings yet

- 2013 DTH Hammer Catalog PDFDocument61 pages2013 DTH Hammer Catalog PDFNelson de la RosaNo ratings yet

- Asian Pipes CatalogueDocument7 pagesAsian Pipes Cataloguerutuja roge100% (1)

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- En 8Document3 pagesEn 8ajaykrishnaaNo ratings yet

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036No ratings yet

- Mill TC en 19 6.00MMDocument1 pageMill TC en 19 6.00MMKamal BhandariNo ratings yet

- Orthophthalic Food Grade Espol 14.01: Technical SpecificationDocument1 pageOrthophthalic Food Grade Espol 14.01: Technical SpecificationrohanbagadiyaNo ratings yet

- Commented GA.Document4 pagesCommented GA.Vinay YadavNo ratings yet

- Pipe MTCDocument1 pagePipe MTCVinay YadavNo ratings yet

- AZITP-J-902-01 Rev 00 Metallic Instrument and Control CableDocument5 pagesAZITP-J-902-01 Rev 00 Metallic Instrument and Control CableVinay YadavNo ratings yet

- Test Sheet: Customer References Johnson ReferencesDocument18 pagesTest Sheet: Customer References Johnson ReferencesVinay YadavNo ratings yet

- Azmeel Inspection Checklist: General - Electrical Equipment, Storage, Handling & Preservation AZIC-P-3001 ElectricalDocument3 pagesAzmeel Inspection Checklist: General - Electrical Equipment, Storage, Handling & Preservation AZIC-P-3001 ElectricalVinay YadavNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- Aramco Balance Material Site IssuesDocument12 pagesAramco Balance Material Site IssuesVinay Yadav100% (1)

- Pipe and Fitting Packing ListDocument2 pagesPipe and Fitting Packing ListVinay YadavNo ratings yet

- Visit Report - 325 Dated 25.09.18Document3 pagesVisit Report - 325 Dated 25.09.18Vinay YadavNo ratings yet

- MTCDocument19 pagesMTCVinay YadavNo ratings yet

- Discipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalDocument7 pagesDiscipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalVinay YadavNo ratings yet

- Visit Report - 312Document4 pagesVisit Report - 312Vinay YadavNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- Travel PolicyDocument1 pageTravel PolicyVinay YadavNo ratings yet

- Index: Po SR No Po No Item SR NO Item Description Drawing Number Quantity RemarkDocument1 pageIndex: Po SR No Po No Item SR NO Item Description Drawing Number Quantity RemarkVinay YadavNo ratings yet

- 4422-XZ-SG-000000000005 - B2-Materials in SevereDocument114 pages4422-XZ-SG-000000000005 - B2-Materials in SeverePaul NieNo ratings yet

- 111111111111111111seminar - I INJECTION MOULD DESIGNDocument64 pages111111111111111111seminar - I INJECTION MOULD DESIGNMuhammed K MNo ratings yet

- Universal Rutile Electrode: Tip ColourDocument1 pageUniversal Rutile Electrode: Tip Colourmohamed AdelNo ratings yet

- Nickel Desktop StudyDocument18 pagesNickel Desktop StudyMuhamad IchlasNo ratings yet

- Educational Resources PamphletDocument9 pagesEducational Resources PamphletBala SingamNo ratings yet

- Specification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServiceDocument18 pagesSpecification For Alloy-Steel and Stainless Steel Bolting Materials For High-Temperature ServicesergioprybyszNo ratings yet

- Flange Isolation Kits: For Sealing and Isolation of FlangesDocument4 pagesFlange Isolation Kits: For Sealing and Isolation of FlangesAimon JahangirNo ratings yet

- SMAWDocument8 pagesSMAWmostafaNo ratings yet

- Work Immersion TarpDocument23 pagesWork Immersion TarpFiya CalmaNo ratings yet

- Toner Hopper Drill Hole Fixture FOR HP® P1005/P1006/P1505: Photo 3Document1 pageToner Hopper Drill Hole Fixture FOR HP® P1005/P1006/P1505: Photo 3servicerNo ratings yet

- Roomlogs 1122Document234 pagesRoomlogs 1122Rhona TaanNo ratings yet

- Butt Welding Method StatmentDocument8 pagesButt Welding Method StatmentAbelNo ratings yet

- Continuous CrystallizersDocument22 pagesContinuous CrystallizersAravind Vicky0% (1)

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- Exercise Questions - Introduction and Module # 1Document10 pagesExercise Questions - Introduction and Module # 1Justin Carrasco SanchezNo ratings yet

- Poster Corrosion Well Logging 9Document1 pagePoster Corrosion Well Logging 9Moh Abd Ben100% (1)

- TB1001Document2 pagesTB1001dolopezNo ratings yet

- EMC 3273 E-Cat MechDocument4 pagesEMC 3273 E-Cat Mechrichard gutierrezNo ratings yet

- Impact Hammer Crushers Okd enDocument1 pageImpact Hammer Crushers Okd enMartin ŠimurdaNo ratings yet

- Cherry® Nut-Plate Rivet: Table IDocument6 pagesCherry® Nut-Plate Rivet: Table IFredNo ratings yet

- Swaged and Lightweight Welding NozzlesDocument5 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Chapter III - Investment (2023) AnswersDocument10 pagesChapter III - Investment (2023) AnswersHany NassifNo ratings yet

- Boysen Paint CoverageDocument2 pagesBoysen Paint CoverageAkoto At IkawyanNo ratings yet

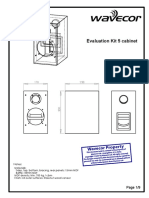

- Evaluation Kit 5 Cabinet: Wavecor Prop ErtyDocument9 pagesEvaluation Kit 5 Cabinet: Wavecor Prop ErtyAntonioPallone0% (1)

- 0302 Brass Fittings CatalogueDocument59 pages0302 Brass Fittings CatalogueCHALERMKIAT JIRARUNGSATEAN0% (1)