Professional Documents

Culture Documents

0%(1)0% found this document useful (1 vote)

535 views2G +5G

2G +5G

Uploaded by

Rahul MoottolikandyThis document is a Welding Procedure Specification (WPS) for KRANTZ ENGINEERS W.L.L. It specifies the welding processes of GTAW and SMAW to be used to weld 6-inch diameter SCH 80 pipe to pipe joints. The base metals will be API 5L Grade B pipe or equivalent, with thicknesses ranging from 5mm to 19mm for groove welds and all sizes for fillet welds. Filler metals will be ER70S-3 wire for GTAW and E7018 electrodes for SMAW. Tack welds are required and specific procedures for tacking are described.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS 2014-002 002 - 1G & 2G S 275 JRDocument2 pagesWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Slow Rate Penetration Resistance of Flexible Barrier Films and LaminatesDocument5 pagesSlow Rate Penetration Resistance of Flexible Barrier Films and LaminatesAlevj Db100% (4)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Hydrogen Embrittlement (Part of Shreir Handbook) PDFDocument26 pagesHydrogen Embrittlement (Part of Shreir Handbook) PDFbaneNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification Structural 3G PDFDocument3 pagesWelding Procedure Specification Structural 3G PDFsebincherian100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Ultrasonic Testing ReportDocument3 pagesUltrasonic Testing ReportsingaduraipandianNo ratings yet

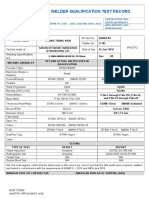

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- Need of Surface TreatmentDocument6 pagesNeed of Surface TreatmentRahul MoottolikandyNo ratings yet

- Mass Earth's Atmosphere: DensityDocument23 pagesMass Earth's Atmosphere: DensityRahul MoottolikandyNo ratings yet

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Document1 pageWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyNo ratings yet

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocument6 pagesPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Inspection NotesDocument1 pageInspection NotesRahul MoottolikandyNo ratings yet

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocument1 pageDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDocument4 pagesIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 pagesMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyNo ratings yet

- Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMarking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Gate Pass Request Form: Requested Date: Reference NoDocument1 pageGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyNo ratings yet

- Mandays 100Document1 pageMandays 100Rahul MoottolikandyNo ratings yet

- IZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportDocument1 pageIZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportRahul MoottolikandyNo ratings yet

- Gate Pass Request FormDocument38 pagesGate Pass Request FormRahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Document1 pageDate Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Rahul MoottolikandyNo ratings yet

- Welcome To The Test and Production Separation Production Separation PresentationDocument73 pagesWelcome To The Test and Production Separation Production Separation PresentationhamdiiiiiiiiiiiiiiiiNo ratings yet

- Exercise On Analog Circuits: PHYS 331: Junior Physics Laboratory IDocument6 pagesExercise On Analog Circuits: PHYS 331: Junior Physics Laboratory Iviso167No ratings yet

- Induced OmanDocument295 pagesInduced OmanWaleed EjazNo ratings yet

- NATO Vector GraphicsDocument16 pagesNATO Vector GraphicsMarius Lucian NeculaNo ratings yet

- Chapter 16: Semiconductor Devices: Maharashtra State BoardDocument18 pagesChapter 16: Semiconductor Devices: Maharashtra State BoardAmish ShahNo ratings yet

- MPR (22446) ManualDocument31 pagesMPR (22446) Manualsiddiquimuzammil876No ratings yet

- Acción de La Estructura. Miller.Document12 pagesAcción de La Estructura. Miller.Pedro SosaNo ratings yet

- Karnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDocument18 pagesKarnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDexter DoteNo ratings yet

- Datasheet 6ED1052-1MD00-0BA8: Installation Type/mountingDocument2 pagesDatasheet 6ED1052-1MD00-0BA8: Installation Type/mountingGuillermo ChamacheNo ratings yet

- Hendrickson Assignment4Document11 pagesHendrickson Assignment4Angel Nicole SorianoNo ratings yet

- Config - Multiple - T24 - Envir - Using - JBoss 6.XX EAPDocument12 pagesConfig - Multiple - T24 - Envir - Using - JBoss 6.XX EAPFin Technet100% (1)

- Yarn Examining MachineDocument3 pagesYarn Examining MachineAbrõ Wazir100% (1)

- Retina: Product CatalogDocument60 pagesRetina: Product CatalogMohamed GamalNo ratings yet

- What Is An Electrostatic Force?Document3 pagesWhat Is An Electrostatic Force?Carlton GrantNo ratings yet

- 7 From Prof. Dullea: CSC8490 Introduction To PL/SQLDocument36 pages7 From Prof. Dullea: CSC8490 Introduction To PL/SQLAkash KumarNo ratings yet

- Physical Characteristics of GrainsDocument10 pagesPhysical Characteristics of GrainsAyezza Jean Fermocil100% (1)

- CT AbdomenDocument2 pagesCT AbdomenVlog Anak DusunNo ratings yet

- Transcript PDFDocument1 pageTranscript PDFapi-486098227No ratings yet

- (Tex Ebook) - Advanced LatexDocument23 pages(Tex Ebook) - Advanced LatexenricosirolaNo ratings yet

- X-Ways Forensics v14.3 ManualDocument101 pagesX-Ways Forensics v14.3 Manualkjadhav2000No ratings yet

- Introduction To Data Analytics For Business - AnswersDocument8 pagesIntroduction To Data Analytics For Business - AnswersShabaan HossainNo ratings yet

- Lalit ISM FileDocument28 pagesLalit ISM Filelalit rawatNo ratings yet

- Liang Chapter 2Document62 pagesLiang Chapter 2THEO DOMINIC REQUERME SILVOSANo ratings yet

- Data Structure Using C NCS301 PDFDocument2 pagesData Structure Using C NCS301 PDFavinas_3marNo ratings yet

- EGMO 2012-19 EN With Solutions PDFDocument151 pagesEGMO 2012-19 EN With Solutions PDFgarciacapitan100% (1)

- Micro X Ray Fluorescence Spectroscopy First Edition PDFDocument31 pagesMicro X Ray Fluorescence Spectroscopy First Edition PDFAlberto Núñez CardezoNo ratings yet

- Experiment 9Document5 pagesExperiment 9Rohit BiswasNo ratings yet

2G +5G

2G +5G

Uploaded by

Rahul Moottolikandy0%(1)0% found this document useful (1 vote)

535 views1 pageThis document is a Welding Procedure Specification (WPS) for KRANTZ ENGINEERS W.L.L. It specifies the welding processes of GTAW and SMAW to be used to weld 6-inch diameter SCH 80 pipe to pipe joints. The base metals will be API 5L Grade B pipe or equivalent, with thicknesses ranging from 5mm to 19mm for groove welds and all sizes for fillet welds. Filler metals will be ER70S-3 wire for GTAW and E7018 electrodes for SMAW. Tack welds are required and specific procedures for tacking are described.

Original Description:

m

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a Welding Procedure Specification (WPS) for KRANTZ ENGINEERS W.L.L. It specifies the welding processes of GTAW and SMAW to be used to weld 6-inch diameter SCH 80 pipe to pipe joints. The base metals will be API 5L Grade B pipe or equivalent, with thicknesses ranging from 5mm to 19mm for groove welds and all sizes for fillet welds. Filler metals will be ER70S-3 wire for GTAW and E7018 electrodes for SMAW. Tack welds are required and specific procedures for tacking are described.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0%(1)0% found this document useful (1 vote)

535 views1 page2G +5G

2G +5G

Uploaded by

Rahul MoottolikandyThis document is a Welding Procedure Specification (WPS) for KRANTZ ENGINEERS W.L.L. It specifies the welding processes of GTAW and SMAW to be used to weld 6-inch diameter SCH 80 pipe to pipe joints. The base metals will be API 5L Grade B pipe or equivalent, with thicknesses ranging from 5mm to 19mm for groove welds and all sizes for fillet welds. Filler metals will be ER70S-3 wire for GTAW and E7018 electrodes for SMAW. Tack welds are required and specific procedures for tacking are described.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

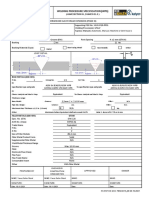

Welding Procedure Specifications (WPS)

Reference :ASME B31.3,ASME Sec IX and E.S.5.14.0010RA

KRANTZ ENGINEERS W.L.L

Company name : KRANTZ ENGINEERS W.L.L

WPS NO. : WPS-KE-001 Rev : 1 Date: 22-05-11 Welding Process(es) : GTAW + SMAW

PQR NO. : PQR-KE-001 Date: 09-04-11

Welding process(es):GTAW + SMAW (Non Impact Test) Type of process : MANUAL

JOINTS(QW-402)

Joints Design : SEE DETAILS BELOW Backing(Yes/No): NO

Backing Material(TYPE) : N/A

TACK WELDING PROCEDURE :

Minimum four bridge tacks required upto

6” & above 6” min 6 tacking required.

Tacking will be removed by grinding

consecutively on either side,one by one as

per root pass progresses.

Tack shall not be done in root face.

Tacking to be done as per parameter of

filter pass(SMAW).

Bridging material to be same as pipe

PQR TEST COUPON : 6” ØSCH 80(API5L Gr.B TO API5L Gr.B)PIPE TO PIPE material.

BASE METALS (QW 403) Also as per QW 420.2

P NO/S NO. 1 Group No. 1/2 To P-NO/S NO. 1 Group No. 1/2

Specification Type and Grade : API 5L Gr.B OR EQUIVALENT To

Specification Type and Grade : API 5L Gr.B OR EQUIVALENT OR

Chem. Analysis and Mech.Prop : NA

Thickness Range : Groove : 5mm to 19 mm ( MIN/MAX) Fillet : ALL SIZES

Diameter Range : Groove : 3ӯ AND ABOVE (NON РIMPACT) Fillet : ALL SIZES

Others : Thickness of individual pass shall not exceed 13 mm.

FILLER METALS (QW 404)

GTAW SMAW

F No : 6 4

A No : 1 1

Spec No.(SFA) : 5.18 5.1

A W S No (Class) : ER70S 3 E7018

Size of Filler Metals : 2.4 MM Dia 2.5/3.2mm

Groove : 8 mm Max 14mm Max

Fillet : ALL ALL

Electrode Flux : NONE NA

Trade Name : ESAB/OK TIG ROD 12.61/ ESAB OK

EQUIVALENT 48.00/EQUIVALENT

Consumable Insert : NA NA

KRANTZ TPI CLIENT

NAME

SIGNATURE

DATE

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS 2014-002 002 - 1G & 2G S 275 JRDocument2 pagesWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Slow Rate Penetration Resistance of Flexible Barrier Films and LaminatesDocument5 pagesSlow Rate Penetration Resistance of Flexible Barrier Films and LaminatesAlevj Db100% (4)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Hydrogen Embrittlement (Part of Shreir Handbook) PDFDocument26 pagesHydrogen Embrittlement (Part of Shreir Handbook) PDFbaneNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Wps Aws d1.1 Ss400 To Ss400 Gmaw-RevDocument2 pagesWps Aws d1.1 Ss400 To Ss400 Gmaw-RevAnonymous zfC1zo9C100% (2)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification Structural 3G PDFDocument3 pagesWelding Procedure Specification Structural 3G PDFsebincherian100% (1)

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocument1 page193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Ultrasonic Testing ReportDocument3 pagesUltrasonic Testing ReportsingaduraipandianNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WQT - WPS 01Document71 pagesWQT - WPS 01Gururaj P Kundapur100% (1)

- Welding Procedure Specification: Neo StructoDocument2 pagesWelding Procedure Specification: Neo Structohareesh13hNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- WPQ Certificates Klis14Document8 pagesWPQ Certificates Klis14AdhicharanNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Specification (WPS) : Demo-SmawDocument1 pageWelding Procedure Specification (WPS) : Demo-SmawakranganNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Wps PQR Aws d11 FormDocument2 pagesWps PQR Aws d11 Formflakosisas100% (1)

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- WPS Api 1104Document3 pagesWPS Api 1104miguelNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- Need of Surface TreatmentDocument6 pagesNeed of Surface TreatmentRahul MoottolikandyNo ratings yet

- Mass Earth's Atmosphere: DensityDocument23 pagesMass Earth's Atmosphere: DensityRahul MoottolikandyNo ratings yet

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Document1 pageWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyNo ratings yet

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocument6 pagesPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Inspection NotesDocument1 pageInspection NotesRahul MoottolikandyNo ratings yet

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- 026 To 033test ReportsDocument40 pages026 To 033test ReportsRahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocument1 pageDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 pagesMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNo ratings yet

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDocument4 pagesIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyNo ratings yet

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 pagesMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyNo ratings yet

- Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 pagesMarking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNo ratings yet

- Gate Pass Request Form: Requested Date: Reference NoDocument1 pageGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyNo ratings yet

- Mandays 100Document1 pageMandays 100Rahul MoottolikandyNo ratings yet

- IZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportDocument1 pageIZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportRahul MoottolikandyNo ratings yet

- Gate Pass Request FormDocument38 pagesGate Pass Request FormRahul MoottolikandyNo ratings yet

- Date Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Document1 pageDate Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Rahul MoottolikandyNo ratings yet

- Welcome To The Test and Production Separation Production Separation PresentationDocument73 pagesWelcome To The Test and Production Separation Production Separation PresentationhamdiiiiiiiiiiiiiiiiNo ratings yet

- Exercise On Analog Circuits: PHYS 331: Junior Physics Laboratory IDocument6 pagesExercise On Analog Circuits: PHYS 331: Junior Physics Laboratory Iviso167No ratings yet

- Induced OmanDocument295 pagesInduced OmanWaleed EjazNo ratings yet

- NATO Vector GraphicsDocument16 pagesNATO Vector GraphicsMarius Lucian NeculaNo ratings yet

- Chapter 16: Semiconductor Devices: Maharashtra State BoardDocument18 pagesChapter 16: Semiconductor Devices: Maharashtra State BoardAmish ShahNo ratings yet

- MPR (22446) ManualDocument31 pagesMPR (22446) Manualsiddiquimuzammil876No ratings yet

- Acción de La Estructura. Miller.Document12 pagesAcción de La Estructura. Miller.Pedro SosaNo ratings yet

- Karnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDocument18 pagesKarnaugh Map: Engr. Pablo B. Asi Engr. Leni A. Bulan Engr. Liza R. MaderazoDexter DoteNo ratings yet

- Datasheet 6ED1052-1MD00-0BA8: Installation Type/mountingDocument2 pagesDatasheet 6ED1052-1MD00-0BA8: Installation Type/mountingGuillermo ChamacheNo ratings yet

- Hendrickson Assignment4Document11 pagesHendrickson Assignment4Angel Nicole SorianoNo ratings yet

- Config - Multiple - T24 - Envir - Using - JBoss 6.XX EAPDocument12 pagesConfig - Multiple - T24 - Envir - Using - JBoss 6.XX EAPFin Technet100% (1)

- Yarn Examining MachineDocument3 pagesYarn Examining MachineAbrõ Wazir100% (1)

- Retina: Product CatalogDocument60 pagesRetina: Product CatalogMohamed GamalNo ratings yet

- What Is An Electrostatic Force?Document3 pagesWhat Is An Electrostatic Force?Carlton GrantNo ratings yet

- 7 From Prof. Dullea: CSC8490 Introduction To PL/SQLDocument36 pages7 From Prof. Dullea: CSC8490 Introduction To PL/SQLAkash KumarNo ratings yet

- Physical Characteristics of GrainsDocument10 pagesPhysical Characteristics of GrainsAyezza Jean Fermocil100% (1)

- CT AbdomenDocument2 pagesCT AbdomenVlog Anak DusunNo ratings yet

- Transcript PDFDocument1 pageTranscript PDFapi-486098227No ratings yet

- (Tex Ebook) - Advanced LatexDocument23 pages(Tex Ebook) - Advanced LatexenricosirolaNo ratings yet

- X-Ways Forensics v14.3 ManualDocument101 pagesX-Ways Forensics v14.3 Manualkjadhav2000No ratings yet

- Introduction To Data Analytics For Business - AnswersDocument8 pagesIntroduction To Data Analytics For Business - AnswersShabaan HossainNo ratings yet

- Lalit ISM FileDocument28 pagesLalit ISM Filelalit rawatNo ratings yet

- Liang Chapter 2Document62 pagesLiang Chapter 2THEO DOMINIC REQUERME SILVOSANo ratings yet

- Data Structure Using C NCS301 PDFDocument2 pagesData Structure Using C NCS301 PDFavinas_3marNo ratings yet

- EGMO 2012-19 EN With Solutions PDFDocument151 pagesEGMO 2012-19 EN With Solutions PDFgarciacapitan100% (1)

- Micro X Ray Fluorescence Spectroscopy First Edition PDFDocument31 pagesMicro X Ray Fluorescence Spectroscopy First Edition PDFAlberto Núñez CardezoNo ratings yet

- Experiment 9Document5 pagesExperiment 9Rohit BiswasNo ratings yet