Professional Documents

Culture Documents

Guía de Diseño - Recipiente

Guía de Diseño - Recipiente

Uploaded by

Matias Monroy0 ratings0% found this document useful (0 votes)

54 views6 pagesThis document provides details for a new flare unit being added to the Campana Refinery Expansion Project in Campana, Argentina. It includes specifications for a hydrocarbon flare knockout drum, designated SE-D-001, including design conditions, operating conditions, materials of construction, and notes. The drum is a horizontal vessel with an internal diameter of 4,270 mm and length of 10,970 mm, designed to operate at an internal pressure of 0.66 kg/cm2g at 210°C and include a heating coil. The document was revised from an initial version on February 17, 2016 to the current version dated March 15, 2016.

Original Description:

Guía de Diseño - Recipiente

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides details for a new flare unit being added to the Campana Refinery Expansion Project in Campana, Argentina. It includes specifications for a hydrocarbon flare knockout drum, designated SE-D-001, including design conditions, operating conditions, materials of construction, and notes. The drum is a horizontal vessel with an internal diameter of 4,270 mm and length of 10,970 mm, designed to operate at an internal pressure of 0.66 kg/cm2g at 210°C and include a heating coil. The document was revised from an initial version on February 17, 2016 to the current version dated March 15, 2016.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

54 views6 pagesGuía de Diseño - Recipiente

Guía de Diseño - Recipiente

Uploaded by

Matias MonroyThis document provides details for a new flare unit being added to the Campana Refinery Expansion Project in Campana, Argentina. It includes specifications for a hydrocarbon flare knockout drum, designated SE-D-001, including design conditions, operating conditions, materials of construction, and notes. The drum is a horizontal vessel with an internal diameter of 4,270 mm and length of 10,970 mm, designed to operate at an internal pressure of 0.66 kg/cm2g at 210°C and include a heating coil. The document was revised from an initial version on February 17, 2016 to the current version dated March 15, 2016.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

CAMPANA REFINERY EXPANSION PROJECT

PROCESS DATA SHEET Contract: A7XN

NEW FLARE UNIT (SE) Revision: 1

CAMPANA DOCUMENT NO.: A7XN-SE-25-DS-0003 Date: Mar 15, 2016

Page: 1 of 6

HYDROCARBON FLARE KO DRUM

SE-D-001

This document has been revised as indicated below and described in the revision record on the following

page. Please destroy all previous revisions.

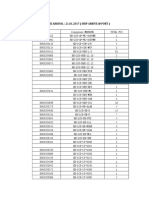

Revision

Date Originator Reviewed/Checked By Pages

No.

0 17-Feb-2016 V. Nguyen S. Khambaty All

1 15-Mar-2016 V. Nguyen S. Khambaty All

APPROVALS SIGNATURES DATE

Process Lead B. Wirth 15-Mar-2016

Engineering Manager

N/A

Project Manager

N/A

Axion Representative

N/A

Issued for FEED

ISSUED FOR Design Construction X Other (IFF)

Contract: A7XN

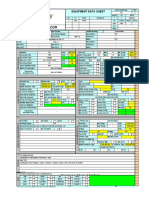

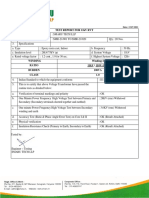

PRESSURE VESSEL Item No: SE-D-001

DATA SHEET Revision: 1 Date: 15-Mar-16

Unit: SE

P.O. No.:

A7XN-SE-25-DS-0003 Inquiry No.:

Sheet 2 of 6 REV

1 Client: Axion Energy Vendor:

2 Service: Hydrocarbon Flare KO Drum Plant: Campana Refinery Expansion Site: Campana, Argentina

3

4 DESIGN CONDITIONS

5 Design Basis: Stamping Requirements:

6 Internal Pressure: 3.5 kg/cm²g @ 343 °C

7 External Pressure FV kg/cm2g @ 175 °C

8 Minimum Design Metal Temp: °C @ kg/cm²g

9 Specific Gravity of Liquid: 0.708 @ 210 °C

10 High Liquid Level: 600 Normal Liquid Level: NA Low Liquid Level: 300

11 Vessel Orientation: Horizontal Inside Diameter: 4,270 mm Tan to Tan Length: 10,970 mm

12

13 OPERATING CONDITIONS

14 Internal Pressure: 0.66 kg/cm²g @ 210 °C

15 External Pressure kg/cm²g @ °C

16 Low Temperature: °C @ kg/cm²g

17 Hydrogen Partial Pressure: kg/cm²a @ °C

18

19 SPECIAL CONDITIONS CONSTRUCTION

20 Stress Relieve (Process Reason Only): YES NO Materials Corrosion Allowance

21 Vessel in Lethal Service: YES NO Shell: KCS 6 mm

22 Vessel in Wet Sour Service: YES NO Heads: KCS 6 mm

23 Steam Out Required: YES NO Nozzles: mm

24 Hydrogen Service: YES NO Boot Shell: mm

25 Cyclic Service: YES NO Boot Head: mm

26 No. of Cycles per Year / Design Life: / Internals: 316L SS mm

27 Lining/Cladding: mm

28

29 INTERNALS INSULATION

30 Bulk Density Liquid Holdup ΔP Type: Personel Protection

Description

31 kg/m³ Vol. % kPa Thickness: mm

32 Packing / Tray:

33 Catalyst: FIREPROOFING

34 Mist Eliminator: YES NO Thk: mm

35 Vortex Breaker: Inside Skirt Outside Skirt

36 Insulated or Fireproofed skirts to have

37 sleeved openings

38 Saddles

39

40

41 SPECIFICATIONS:

42

43

44

45

46

47

48 NOTES:

49 1. For Vessel Sketch, see Sheet 3

50 2. Vessel to include a heating coil designed for 5.6 kg/cm2 (g) at 308°C.

51

52

53

54 REVISION LOG

55 REV. ISSUE STATUS DATE BY CHECKED APPROVED

56 0 Issued for Client Review 17-Feb-16 VTN SMK BW

57 1 Issued for FEED (IFF) 15-Mar-16 VTN SMK BW

58

59

60

Notice: This drawing has not been published and is the sole property of Fluor, and is lent to the borrower for his confidential use only, and in consideration of the loan of this drawing, the borrower

to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically

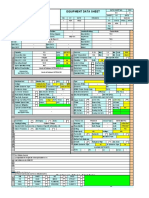

Contract: A7XN

PRESSURE VESSEL Item No: SE-D-001

DATA SHEET Revision: 1 Date: 15-Mar-16

Unit: SE

P.O. No.:

A7XN-SE-25-DS-0003 Inquiry No.:

Sheet 3 of 6 REV

1 VESSEL SKETCH

2 Outline of Equipment and Dimensions That Vendor Shall Hold

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Notice: This drawing has not been published and is the sole property of Fluor, and is lent to the borrower for his confidential use only, and in consideration of the loan of this drawing, the borrower

to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically

Contract: A7XN

PRESSURE VESSEL Item No: SE-D-001

DATA SHEET Revision: 1 Date: 15-Mar-16

Unit: SE

P.O. No.:

A7XN-SE-25-DS-0003 Inquiry No.:

of 6 Sheet 4 REV

1 NOZZLE SCHEDULE

2 SIZE PRESSURE

TAG QUANTITY DESCRIPTION

3 INCHES RATING

4 A1 1 42" 150# Relief Vapor Inlet

5 A2 1 42" 150# Relief Vapor Inlet

6 A3 1 6" 150# Fuel Gas Inlet

7 B1 1 48" 150# Vapor Outlet

8 B2 1 4" 150# Liquid Outlet

9 L1, L2 2 2" 300# Dp Level Instrument

10 L3 1 4" 150# Radar Level Instrument

11 M1, M2 2 24" 150# Manway

12 V1 1 10" 150# Vent Connection

13 P1 1 2" 150# Pressure Instrument

14 S1 1 3" 150# Steam Coil LP Steam Inlet

15 S2 1 3" 150# Steam Coil LP Condensate Outlet

16 S3 1 2" 150# Steam Out Connection

17 D1 1 3" 150# Drain Connection (Connected to the Liquid Outlet)

18 T1 1 2" 150# Temperature Element

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42 NOTES:

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Notice: This drawing has not been published and is the sole property of Fluor, and is lent to the borrower for his confidential use only, and in consideration of the loan of this drawing, the borrower

to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically

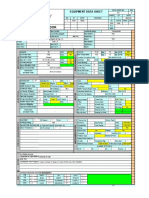

Contract: A7XN

PRESSURE VESSEL Item No: SE-D-001

DATA SHEET Revision: 1 Date: 15-Mar-16

Unit: SE

P.O. No.:

A7XN-SE-25-DS-0003 Inquiry No.:

Sheet 5 of 6 REV

1 SUPPLEMENTAL DATA

2 To be filled out by Mechanical only if vessel is inquired and purchased to this data sheet.

3 Post Weld Heat Treatment: Per Code Per Service

4 Radiographing: Joint Efficiency Shell: Joint Efficiency Head:

5 Shell Thickness: mm

6 Head Thickness (minimum after forming): Top/Ends: mm Bottom: mm

7 Number of Vacuum Stiffeners: Support stiffeners for Horizontal Vessels: N/A YES NO

8 Type of Heads: Top/Ends: Bottom:

9 Type of Body Flange: Shell:

10 Flange Face Finish:

11 Number of Supports: Type of Supports:

12 Lifting Lugs Tailing Lugs Anchor Bolt Template

13 Calculated MAP (New and Cold): kg/cm²g Limited By:

14 Shop Hydrostatic Test Pressure (New And Cold): kg/cm²g

15 Calculated MAWP @ Design Temperature: kg/cm²g Limited By:

16

17 MATERIAL SPECIFICATIONS

18 (a) Shell (k) Boot Shell / Heads

19 (b) Heads (l) Bolts (External)

20 (c) Cladding (m) Bolts (Internal)

21 (d) Support (n) Internals (Fixed)

22 (e) Support (o) Internals (Removable)

23 (f) Nozzle Necks & Pipe (p) Trays

24 (g) Flanges (External) (q) Packing

25 (h) Fittings (r) External Appurtenances

26 (i) Gaskets (External)

27 (j) Gaskets (Internal)

28 Paint:

29

30 ESTIMATED VESSEL WEIGHTS

31 (a) Trays kg.

32 (b) Fabricated kg.

33 (c) Empty (Field) kg.

34 (d) Operating (Incl. Oper. Liquid) kg.

35 (e) Full of Water (Field) kg.

36 (f) Erection kg.

37

38 APPLICABLE REFERENCE DRAWINGS

39 000.258.ST4021 Mist Eliminator Detail VEFV1119 Vessel; Column Davit

40 000.258.ST4022 Internal Ladder Rung Details VEFV1122 Vessel; Horizontal Insulation Supports

41 000.258.ST4155 Vertical Vessel Support Skirt Details VEFV1123 Vessel; Vertical, Insulation and Fireproofing Supports

42 000.258.ST4160 Vortex Breaker Details

43 VEFV1101 Vessel; Nameplate Bracket

44 VEFV1102 Vessel; Tolerances

45 VEFV1103 Vessel; Grounding Lug

46 VEFV1105 Vessel; Horizontal, Saddles Supported on Concrete

47 VEFV1106 Vessel; Horizontal, Saddles Supported on Steel

48 VEFV1107 Vessel; Vertical, Type "A" Base Plate w/ Gussets

49 VEFV1108 Vessel; Vertical, Type "B" Base Plate w/ Cap Plate and Gussets

50 VEFV1109 Vessel; Vertical, Type "C" Base Plate w/ Cap Plate and Offset Gussets

51 VEFV1110 Vessel; Vertical, Type "D" Base Plate w/ Top Ring and Gussets

52 VEFV1111 Vessel; Vertical, Beam Type Leg Supports

53 VEFV1112 Vessel; Vertical, Angle w/o Pad Type Leg Supports

54 VEFV1113 Vessel; Vertical, Angle w/ Pad Type Leg Supports

55 VEFV1114 Vessel; Vertical, Type "A" Support Lug Base Plate w/ Cap and Gussets

56 VEFV1115 Vessel; Vertical, Type "B" Support Lug Base Plate w/ Cap or Top Ring and Gussets

57 VEFV1116 Vessel; Manway Hinges

58 VEFV1117 Vessel; Manway Vertical Davit

59 VEFV1118 Vessel; Manway Horizontal Davit

60

Notice: This drawing has not been published and is the sole property of Fluor, and is lent to the borrower for his confidential use only, and in consideration of the loan of this drawing, the borrower

to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically

Contract: A7XN

PRESSURE VESSEL Item No: SE-D-001

DATA SHEET Revision: 1 Date: 15-Mar-16

Unit: SE

P.O. No.:

A7XN-SE-25-DS-0003 Inquiry No.:

Sheet 6 of 6 REV

1 BASE DETAILS

2 Moment at Base - due to Wind N-m

3 Shear Force at Base - due to Wind N

4 Moment at Base - due to Seismic N-m

5 Shear Force at Base - due to Seismic N

6 Number and Size of Anchor Bolts

7 Bolt Circle Diameter mm

8 Description of Support Base

9

10 GENERAL NOTES:

11 1. One vessel required mark National Board registration is required

12 2. Vessel fabricator shall furnish and install all parts unless otherwise noted

13 3. Blinded connections to be furnished with blind flange, studs, nuts and (2) gaskets.

14 4. All internals shall be removable through vessel manholes unless otherwise noted

15 5. Nozzle projections are from centerline of vessel to extreme face of flange except as noted

16 for and smaller

17 for and larger

18 6. All nozzle bolt holes to straddle principal vessel centerlines

19

20

21 Remarks:

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Notice: This drawing has not been published and is the sole property of Fluor, and is lent to the borrower for his confidential use only, and in consideration of the loan of this drawing, the borrower

to return it upon request and agrees that it shall not be reproduced, copied, lent or otherwise disposed of directly or indirectly, nor used for any purpose other than that for which it is specifically

You might also like

- Example Pump Selection: Equipment Data SheetDocument4 pagesExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNo ratings yet

- Oefc Technology1 Practice Files AnswersDocument15 pagesOefc Technology1 Practice Files Answershicham56% (9)

- Back Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelDocument4 pagesBack Pressure Exhaust System Calculation Generating Set Perkins 2X650 Kva Project NovotelWisnu Andra Isdianto100% (1)

- Motor ListDocument19 pagesMotor ListSivaram KumarNo ratings yet

- 9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)Document7 pages9060-ME-27-218, REV.1, Datasheet For Amine Reboiler (E-1005)engr anharNo ratings yet

- Low Activity Waste Pretreatment System: Hanford Site, Richland Wa PROJECT NUMBER 31269 (T5L01)Document5 pagesLow Activity Waste Pretreatment System: Hanford Site, Richland Wa PROJECT NUMBER 31269 (T5L01)Dintra AprillioNo ratings yet

- WHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchDocument18 pagesWHCP - Instrument Data Sheet: Mellitah Oil & Gas B.V. Libyan BranchYasin ElaswadNo ratings yet

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Document6 pages2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweNo ratings yet

- Vaporizador: Equipment Data SheetDocument1 pageVaporizador: Equipment Data SheetAlonso DIAZNo ratings yet

- RELOAD - 0025M - 12418 - MEIP Rev.3Document2 pagesRELOAD - 0025M - 12418 - MEIP Rev.3Claudio AmoneNo ratings yet

- 60-0 75ga8Document4 pages60-0 75ga8EsakkirajaNo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- L2CM 410 58 DS 502 - RBDocument9 pagesL2CM 410 58 DS 502 - RBidilfitriNo ratings yet

- GLP 001Document1 pageGLP 001Alonso DIAZNo ratings yet

- Revision Index: EngenhariaDocument2 pagesRevision Index: EngenhariaBruno AlfanoNo ratings yet

- Data Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoDocument7 pagesData Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoAARON HERRERANo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- Gas Development Project For Unitization of The Jambaran - Tiung Biru FieldDocument2 pagesGas Development Project For Unitization of The Jambaran - Tiung Biru FieldBintang AtdiNo ratings yet

- KTA - TB-PAC03-M07-007.Rev0 - OVERHEAD SYSTEM PIDDocument2 pagesKTA - TB-PAC03-M07-007.Rev0 - OVERHEAD SYSTEM PIDlamNo ratings yet

- Recipiente: Equipment Data SheetDocument1 pageRecipiente: Equipment Data SheetAlonso DIAZNo ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- Revision IndexDocument4 pagesRevision IndexBruno AlfanoNo ratings yet

- Vaporizador: Equipment Data SheetDocument1 pageVaporizador: Equipment Data SheetAlonso DIAZNo ratings yet

- Project Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LPL-06 5 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Document5 pagesProject Name Switchgear Name Panel Type Document Title Ekc Dwg. No. Total Sheet:::::: 11039-0-LPL-06 5 Bahregan Storage Tanks Development IRP/23, SS1/IRP/23, SS2/IRP/23Fatholla SalehiNo ratings yet

- System Design Manual - Generator Off Base Acoustic Protection - Design ManualDocument11 pagesSystem Design Manual - Generator Off Base Acoustic Protection - Design ManualNGUYEN HUU TUANNo ratings yet

- Example Pump Selection: Hoja de Datos de EquiposDocument2 pagesExample Pump Selection: Hoja de Datos de EquiposAlonso DIAZNo ratings yet

- KTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDDocument2 pagesKTA - TB-PAC03-M07-008.Rev0 - PRODUCED WATER PUMPS PIDlamNo ratings yet

- NGR PanelDocument17 pagesNGR PanelnikerNo ratings yet

- Design Manual - GT Air Filtration SystemDocument14 pagesDesign Manual - GT Air Filtration SystemNGUYEN HUU TUANNo ratings yet

- Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument6 pagesConsultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- 195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0Document8 pages195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0leejo100% (1)

- System Design Manual - Exhaust Enclosure Design ManualDocument8 pagesSystem Design Manual - Exhaust Enclosure Design ManualNGUYEN HUU TUANNo ratings yet

- Main Substation PDFDocument45 pagesMain Substation PDFFatholla SalehiNo ratings yet

- Cal P13018-P4-C-Au14-Rx-0001 - 0Document53 pagesCal P13018-P4-C-Au14-Rx-0001 - 0e_budzyNo ratings yet

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument4 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- Data Sheet For Injection Quill AssemblyDocument4 pagesData Sheet For Injection Quill AssemblysudjonoNo ratings yet

- Expansion Joint For EvaporateurDocument2 pagesExpansion Joint For EvaporateurLAKHTIRINo ratings yet

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Document5 pagesDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNo ratings yet

- Design Manual - Design Manual GT Atomizing Air SystemDocument21 pagesDesign Manual - Design Manual GT Atomizing Air SystemNGUYEN HUU TUANNo ratings yet

- Owner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument2 pagesOwner: Dangote Oil Refining Company: Consultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- J041A0088-Magnetic Level GaugeDocument3 pagesJ041A0088-Magnetic Level GaugesamboopathiNo ratings yet

- System Design Manual - Gas Fuel Skid 2g0 - Design ManualDocument12 pagesSystem Design Manual - Gas Fuel Skid 2g0 - Design ManualNGUYEN HUU TUANNo ratings yet

- Plano de SaturadorDocument6 pagesPlano de SaturadorRodrigo Andres CeledonNo ratings yet

- BFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)Document18 pagesBFP-Turbine-10071-9-V9B-MUSS-00057-Circuit Diagrams 220V DC EOP Starter Panel (BFPTurbine)mohamed abouraya100% (1)

- Design Manual - Cont Devices-TurbineDocument12 pagesDesign Manual - Cont Devices-TurbineNGUYEN HUU TUANNo ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- Tanque: Equipment Data SheetDocument1 pageTanque: Equipment Data SheetAlonso DIAZNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Consultant: Engineers India Limited Contractor: Onshore Construction FzeDocument4 pagesConsultant: Engineers India Limited Contractor: Onshore Construction Fzecrm 2No ratings yet

- Ehs-E076-Ics-Das-Cnl-0000-90011-00 G02Document8 pagesEhs-E076-Ics-Das-Cnl-0000-90011-00 G02Okoro KennethNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- Magnetic Examination Report: International Inspection Services L.L.CDocument1 pageMagnetic Examination Report: International Inspection Services L.L.CAzhar AhmadNo ratings yet

- FromDocument16 pagesFromคุณพ่อน้อง บิ๊กบอสNo ratings yet

- BFW Cooler Datasheet Rev 2Document3 pagesBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariNo ratings yet

- Pressure Switch DatasheetDocument1 pagePressure Switch DatasheetMohamed El MaadawyNo ratings yet

- NDT Request Form - 19Document3 pagesNDT Request Form - 19Firas AlbaweiNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- TRAINING PVE Hari 4 PDFDocument13 pagesTRAINING PVE Hari 4 PDFDheska AgungNo ratings yet

- Calorimetric Flow Detector Data SheetDocument1 pageCalorimetric Flow Detector Data Sheetlamisma09No ratings yet

- Spare Parts Data Package Phase-17 (SPDP)Document1,116 pagesSpare Parts Data Package Phase-17 (SPDP)Muhammad FaizalNo ratings yet

- Volume 13counters, Timers and TachometersDocument130 pagesVolume 13counters, Timers and TachometersCarmenNo ratings yet

- Catalogo de Partes Lycoming O 235Document81 pagesCatalogo de Partes Lycoming O 235Rodol MarskeNo ratings yet

- Ems 927Document21 pagesEms 927Er_raju100% (3)

- Perkhemahan SKPK Muar2012Document531 pagesPerkhemahan SKPK Muar2012Deen SallNo ratings yet

- Product Technical Bulletin: BackgroundDocument2 pagesProduct Technical Bulletin: BackgroundYolian Andres Aricapa CastañoNo ratings yet

- Processes of Ideal GasesDocument28 pagesProcesses of Ideal GasesVincent LagunillaNo ratings yet

- 2D Material ReviewDocument7 pages2D Material ReviewMatthew FangNo ratings yet

- Epi, LeopoldoDocument4 pagesEpi, Leopoldoyeng botzNo ratings yet

- 45CL4 eDocument21 pages45CL4 emrthumbNo ratings yet

- 606tiristor PDFDocument1 page606tiristor PDFHernan G SalazarNo ratings yet

- Crossword Puzzle QnA Magnetism and ElectricityDocument5 pagesCrossword Puzzle QnA Magnetism and ElectricitySharon DingNo ratings yet

- 1 0107 2Document8 pages1 0107 2oleg-spbNo ratings yet

- Assignment 1 Power System AnalysisDocument5 pagesAssignment 1 Power System AnalysisMaulana ZulfikarNo ratings yet

- Course Curriculum For April BatchDocument4 pagesCourse Curriculum For April BatchShaikh ArbaazNo ratings yet

- E 147 - 61 R01 - Rte0nwDocument7 pagesE 147 - 61 R01 - Rte0nwcaressaNo ratings yet

- Reciprocating Pump SDPD: Technical IndexDocument2 pagesReciprocating Pump SDPD: Technical IndexTrịnh Đức HạnhNo ratings yet

- Advantages and Disadvantages of Energy SourcesDocument4 pagesAdvantages and Disadvantages of Energy SourcesHimanshu PainulyNo ratings yet

- June 2011 (v1) QP - Paper 2 CIE Physics IGCSE PDFDocument20 pagesJune 2011 (v1) QP - Paper 2 CIE Physics IGCSE PDFύπατίαNo ratings yet

- Cooling Coil Design (SI Units)Document3 pagesCooling Coil Design (SI Units)Christopher PersaudNo ratings yet

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- Internship Report in SipradiDocument25 pagesInternship Report in SipradiSanim Amatya38% (8)

- Valuation Report of BPCLDocument24 pagesValuation Report of BPCLJobin JohnNo ratings yet

- Algal Biorefinery - An Integrated Approach For Sustainable Biodiesel ProductionDocument16 pagesAlgal Biorefinery - An Integrated Approach For Sustainable Biodiesel ProductionCarlos GamarraNo ratings yet

- ESG and Circular EconomyDocument22 pagesESG and Circular EconomyMamta GautamNo ratings yet

- Water Level Indicator Project PaperDocument4 pagesWater Level Indicator Project PaperMichelle Batad0% (1)

- Gateway LA 4 WhatIsTechnologyDocument28 pagesGateway LA 4 WhatIsTechnologyBarney The DinosaurNo ratings yet

- Wind PMSGDocument72 pagesWind PMSGNikol Doar Eu100% (1)

- RVT Test ReportDocument5 pagesRVT Test ReportAK YadavNo ratings yet