Professional Documents

Culture Documents

Flash Code 15 - Temp Sensor Low: Section

Flash Code 15 - Temp Sensor Low: Section

Uploaded by

libertyplusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flash Code 15 - Temp Sensor Low: Section

Flash Code 15 - Temp Sensor Low: Section

Uploaded by

libertyplusCopyright:

Available Formats

15 FLASH CODE 15 - TEMP SENSOR LOW

Section Page

15.1 DESCRIPTION OF FLASH CODE 15 ...................................................... 15-3

15.2 SAE J1587 EQUIVALENT CODES FOR FLASH CODE 15 .................... 15-3

15.3 TROUBLESHOOTING FLASH CODE 15 ................................................ 15-4

Figure 15-1 Coolant Temperature Sensor (Oil Temperature Sensor similar)

All information subject to change without notice.

15-2 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

DDEC III/IV SINGLE ECM TROUBLESHOOTING GUIDE

15.1 DESCRIPTION OF FLASH CODE 15

Flash Code 15 indicates that the Coolant Temperature Sensor (CTS), or Oil Temperature Sensor

(OTS), see Figure 15-1, input to the ECM has dropped below 5% (normally < 0.25 volts) of

the sensor supply voltage.

This diagnostic condition is typically:

Sensor signal is shorted to the sensor return circuit or to ground

15.2 SAE J1587 EQUIVALENT CODES FOR FLASH CODE 15

The SAE J1587 equivalent codes for Flash Code 15 are:

p 110/4 - coolant temperature circuit low

p 175/4 - oil temperature circuit low

All information subject to change without notice.

6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION 15-3

15.3 TROUBLESHOOTING FLASH CODE 15

15.3 TROUBLESHOOTING FLASH CODE 15

The following procedure will troubleshoot Flash Code 15.

15.3.1 Code Check

Perform the following steps to check for codes.

1. Turn vehicle ignition ON.

2. Plug in diagnostic data reader (DDR) and determine which code is logged.

[a] If codes PID 110-FMI 4 are logged, refer to section 15.3.2.

[b] If codes PID 175-FMI 4 are logged, refer to section 15.3.3.

15.3.2 Coolant Temperature Sensor Check

Perform the following steps to check the coolant temperature sensor (CTS).

1. Turn vehicle ignition OFF.

2. Disconnect (unplug) CTS connector.

3. Start and run the engine for eight minutes.

4. Read active codes with engine still running.

[a] If code 110/4 or any other codes are logged, refer to section 15.3.4.

[b] If any codes except code 110/4 are logged, refer to section 15.3.6.

All information subject to change without notice.

15-4 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

DDEC III/IV SINGLE ECM TROUBLESHOOTING GUIDE

15.3.3 Oil Temperature Sensor Check

Perform the following steps to check the oil temperature sensor (OTS).

1. Turn vehicle ignition OFF.

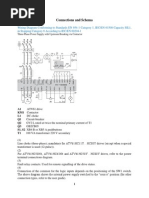

2. Disconnect OTS connector. See Figure 15-2.

3. Start and run the engine for eight minutes.

4. Read active codes with engine running.

[a] If code 175/4 is logged, refer to section 15.3.7.

[b] If any codes except code 175/4 are logged, refer to section 15.3.5.

Figure 15-2 Temperature Sensor Circuits

All information subject to change without notice.

6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION 15-5

15.3 TROUBLESHOOTING FLASH CODE 15

15.3.4 Check Coolant Temperature Sensor Connectors

Perform the following steps to check the CTS connectors.

1. Check terminals at the CTS connector (both sensor and harness side) for damage; bent,

corroded and unseated pins or sockets. See Figure 15-3.

[a] If terminals and connectors are in good condition, replace the CTS.

Refer to section 15.3.10.

[b] If the terminals and connectors are damaged, repair them. Refer to section 15.3.10.

Figure 15-3 Temperature Sensor Circuits

All information subject to change without notice.

15-6 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

DDEC III/IV SINGLE ECM TROUBLESHOOTING GUIDE

15.3.5 Check Oil Temperature Sensor Connectors

Perform the following steps to check the OTS connectors.

1. Check terminals at the OTS connector (both sensor and harness side) for damage: bent,

corroded and unseated pins or sockets. See Figure 15-4.

[a] If terminals or connectors are damaged, repair them. Refer to section 15.3.10.

[b] If terminals and connectors are not damaged, replace the OTS.

Refer to section 15.3.10.

Figure 15-4 Temperature Sensor Circuits

All information subject to change without notice.

6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION 15-7

15.3 TROUBLESHOOTING FLASH CODE 15

15.3.6 Check for Short

Perform the following steps to check for a short.

1. Turn ignition OFF.

2. Disconnect the engine harness connector at the ECM.

3. Measure resistance between sockets P3 (#133) and Y2 (#452) on the engine harness

connector. See Figure 15-5.

4. Measure resistance between socket P3 and a good ground.

[a] If the resistance measurement between sockets P3 and Y2, or P3 and battery ground,

is less than or equal to 5 , the signal line (#133) is shorted to the return line (#452)

or battery ground. Repair the short. Refer to section 15.3.10.

[b] If the resistance measurement between sockets P3 and Y2 is greater than 5 or open,

and the resistance measurement between sockets P3 and a good ground is greater

than or equal to 5 or open, refer to section 15.3.8.

Figure 15-5 ECM Engine Harness Connector

All information subject to change without notice.

15-8 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

DDEC III/IV SINGLE ECM TROUBLESHOOTING GUIDE

15.3.7 Check for Short

Perform the following steps to check for a short.

1. Turn ignition OFF.

2. Disconnect the engine harness connector at the ECM.

3. Measure resistance between sockets R2, (#120) and Y2 (#452) on the engine harness

connector. See Figure 15-6.

4. Measure resistance between socket R2 and a good ground.

[a] If the resistance measurement between sockets R2 and Y2, or R2 and battery (-) is

less than or equal to 5 , the signal line (#120) is shorted to the return line (#452) or

battery ground. Repair the short. Refer to section 15.3.10.

[b] If the resistance measurement between socket R2 and Y2 is greater than 5 or open,

and the resistance measurement between socket R2 and a good ground is greater than

or equal to 5 or open, refer to section 15.3.9.

Figure 15-6 ECM Engine Harness Connector

All information subject to change without notice.

6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION 15-9

15.3 TROUBLESHOOTING FLASH CODE 15

15.3.8 Check ECM Connectors

Perform the following steps to check the ECM connectors.

1. Check terminals at the ECM engine harness connector (both ECM and harness side)

for damage: bent, corroded and unseated pins or sockets. Check terminals P3 and Y2

of the ECM connector. See Figure 15-7.

[a] If terminals or connectors are damaged, repair them. Refer to section 15.3.10.

[b] If terminals and connectors are not damaged, reprogram the ECM.

Refer to section 15.3.10.

Figure 15-7 ECM Engine Harness Connector

All information subject to change without notice.

15-10 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

DDEC III/IV SINGLE ECM TROUBLESHOOTING GUIDE

15.3.9 Check ECM Connectors

Perform the following steps to check the ECM connectors.

1. Check terminals at the ECM engine harness connector (both ECM and harness side)

for damage: bent, corroded and unseated pins or sockets. Check terminals R2 and Y2

of the ECM connector. See Figure 15-8.

[a] If terminals or connectors are damaged, repair them. Refer to section 15.3.10.

[b] If terminals and connectors are not damaged, reprogram the ECM. Contact Detroit

Diesel Technical Service Group. Refer to section 15.3.10.

Figure 15-8 ECM Engine Harness Connector

All information subject to change without notice.

6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION 15-11

15.3 TROUBLESHOOTING FLASH CODE 15

15.3.10 Verify Repairs

Perform the following steps to verify repairs.

1. Turn vehicle ignition OFF.

2. Reconnect all connectors.

3. Turn vehicle ignition ON.

4. Clear codes

5. Start and run the engine for one minute.

6. Stop engine.

7. Check DDR for codes.

[a] If no codes are logged, troubleshooting is complete.

[b] If code 110 or 175/4 and any other codes are logged, all system diagnostics are

complete. Review this section to find the error. Refer to section 15.3.1.

[c] If any codes except code 110 or 175/4 are logged, refer to section 9.1.

All information subject to change without notice.

15-12 6SE497 0303 Copyright © 2003 DETROIT DIESEL CORPORATION

You might also like

- Detroit Diesel Series 60 DDEC II To DDEC IV Conversion 18SP546Document8 pagesDetroit Diesel Series 60 DDEC II To DDEC IV Conversion 18SP546wild04593% (14)

- Automotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedFrom EverandAutomotive Diagnostic Systems: Understanding OBD-I & OBD-II RevisedRating: 4 out of 5 stars4/5 (3)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- 3512 Throttle Position Error 91-8Document13 pages3512 Throttle Position Error 91-8harikrishnanpd3327100% (3)

- Rivertrace Engineering Smart Cell Bilge ManualDocument29 pagesRivertrace Engineering Smart Cell Bilge ManualTaufiq Omar Hasan100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Bentley Audi A6 C5 IgnitionDocument82 pagesBentley Audi A6 C5 Ignitiontjonkka100% (3)

- HAR-1058 LS2 Harness Instructions 10Document15 pagesHAR-1058 LS2 Harness Instructions 10Jacob HernandezNo ratings yet

- Error Code 590-9Document6 pagesError Code 590-9Rajan Mullappilly80% (5)

- Dodge Nitro KA - 2007 - Ignition Control Electrical PDFDocument19 pagesDodge Nitro KA - 2007 - Ignition Control Electrical PDFeephantomNo ratings yet

- (See Below) : 2006 - Current Electronic Fuel Injection Wiring Harness W/ Manual or Non-Electronic Automatic TransmissionDocument15 pages(See Below) : 2006 - Current Electronic Fuel Injection Wiring Harness W/ Manual or Non-Electronic Automatic TransmissionDaniel Jue100% (1)

- Br005-03 - VSC Light On - DTC c1203Document8 pagesBr005-03 - VSC Light On - DTC c120358bjjonesNo ratings yet

- Engine Speed Timing Sensor - CalibrateDocument9 pagesEngine Speed Timing Sensor - Calibratewagner_guimarães_150% (2)

- Manual For: LS2 LS3 Drive by Cable EFI Harness InstructionsDocument15 pagesManual For: LS2 LS3 Drive by Cable EFI Harness InstructionsJacob Hernandez100% (1)

- DEF Consumption Too Low P20F4Document1 pageDEF Consumption Too Low P20F4libertyplusNo ratings yet

- NOx Exceedance - Root Cause Unknown First Level P11609BDocument1 pageNOx Exceedance - Root Cause Unknown First Level P11609BlibertyplusNo ratings yet

- NOx Exceedance - Root Cause Unknown First Level P11609BDocument1 pageNOx Exceedance - Root Cause Unknown First Level P11609BlibertyplusNo ratings yet

- LeanBooklet in OrderDocument32 pagesLeanBooklet in OrderioanchiNo ratings yet

- For Information Only, Will Not Be Exchanged When Altered!: Spare Parts ListDocument13 pagesFor Information Only, Will Not Be Exchanged When Altered!: Spare Parts Listhorica7167% (3)

- EEE Association Magazine 2k12 (Bapatla Engineering College)Document72 pagesEEE Association Magazine 2k12 (Bapatla Engineering College)k rajendraNo ratings yet

- Flash Code 14 - Temp Sensor High: SectionDocument13 pagesFlash Code 14 - Temp Sensor High: SectionlibertyplusNo ratings yet

- 1-SECM-03-18 Flash Code 18 PDFDocument10 pages1-SECM-03-18 Flash Code 18 PDFCarlos TecnicNo ratings yet

- 1-SECM-04a Check For Shorted Data LinkDocument6 pages1-SECM-04a Check For Shorted Data LinkMarco Antonio Rubiano Gómez100% (1)

- 10 Intermittentfault10Document94 pages10 Intermittentfault10libertyplusNo ratings yet

- 43.1 Description of Flash Code 43: Ddec Iii/Iv Single Ecm Troubleshooting GuideDocument4 pages43.1 Description of Flash Code 43: Ddec Iii/Iv Single Ecm Troubleshooting GuideMarco Antonio Rubiano GómezNo ratings yet

- 1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionDocument12 pages1GR-FE ENGINE CONTROL: SFI SYSTEM: P0340, P0342, P0343, P0345, P0347, P0348: Camshaft Position Sensor Circuit MalfunctionwilliamNo ratings yet

- Renr1297renr1297 Sis (1) EngineDocument2 pagesRenr1297renr1297 Sis (1) EngineAmber SmithNo ratings yet

- Engine Pressure Sensor TestDocument11 pagesEngine Pressure Sensor Testsamsularief03100% (1)

- Multi-ECM Engines For Commercial and Industry Application PDFDocument18 pagesMulti-ECM Engines For Commercial and Industry Application PDFmortezaNo ratings yet

- Enine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Document8 pagesEnine Timing Clibration Engine Speed Timing Sensor Calibrate RENR9319Khaled Kamel100% (2)

- Flash Code 67 - Map Sensor Fault: SectionDocument18 pagesFlash Code 67 - Map Sensor Fault: SectionЕвгенийNo ratings yet

- Detroit 60 Series Owners-ManualDocument23 pagesDetroit 60 Series Owners-ManualDam100% (8)

- Engine Speed&Timing Sensor - Calibrate (RENR9319)Document8 pagesEngine Speed&Timing Sensor - Calibrate (RENR9319)Cesar Arturo Pajuelo Espinoza83% (6)

- Mb900 Trouble Guide - Part4Document106 pagesMb900 Trouble Guide - Part4Eckard GuendelNo ratings yet

- 626 Es V6-2.5L Dohc (1997)Document539 pages626 Es V6-2.5L Dohc (1997)Jesus Campos LunaNo ratings yet

- Cylinder Cutout TestDocument17 pagesCylinder Cutout Testbreyesdelgadillo92No ratings yet

- Prueba Sensores PM1360Document7 pagesPrueba Sensores PM1360miguel oswaldo gonzalez benitezNo ratings yet

- 2.16 Ddec Iii/Iv Electronic Control ModuleDocument6 pages2.16 Ddec Iii/Iv Electronic Control Modulevictover100% (2)

- Speed Timing SensorsDocument7 pagesSpeed Timing SensorsBishoo ShenoudaNo ratings yet

- Injector Solenoid Circuit - TestDocument15 pagesInjector Solenoid Circuit - TestNghiaNguyentrungNo ratings yet

- MID 039 - CID 0171 - FMI 04: TroubleshootingDocument4 pagesMID 039 - CID 0171 - FMI 04: TroubleshootingNerminTurkenceNo ratings yet

- Chevrolet Blazer 4wd Workshop Manual v8 350-5-7l Vin L 4 BBL 1982Document4,028 pagesChevrolet Blazer 4wd Workshop Manual v8 350-5-7l Vin L 4 BBL 1982gato0ariasNo ratings yet

- BerniniDocument13 pagesBerniniPanagiotis KarafillisNo ratings yet

- Ignition Control ElectricalDocument19 pagesIgnition Control ElectricalBình Trần100% (1)

- Transmision SIS 2.0Document25 pagesTransmision SIS 2.0antoniogolzz23No ratings yet

- 18SP546 (Search Manual Online - Com)Document8 pages18SP546 (Search Manual Online - Com)Jesus Vega HummerNo ratings yet

- Condition:: Models: Musso & Korando With The Btra A/TDocument7 pagesCondition:: Models: Musso & Korando With The Btra A/Tfrancisca19No ratings yet

- MID 039 - CID 0544 - FMI 08: TroubleshootingDocument4 pagesMID 039 - CID 0544 - FMI 08: TroubleshootingNerminTurkenceNo ratings yet

- Pump Condition MonitorDocument30 pagesPump Condition Monitorsan droidNo ratings yet

- Engine Cranks But Does Not Start: Diagnostic Codes, and Electrical Power Supply To The ECMDocument3 pagesEngine Cranks But Does Not Start: Diagnostic Codes, and Electrical Power Supply To The ECMFaresNo ratings yet

- 11111111 (2)Document11 pages11111111 (2)Efren AngelesNo ratings yet

- User Manual: Bedienungsanleitung/ Mode D'emploi/ Manual de Instrucciones/ Manuale Utente/ BruksanvisningDocument11 pagesUser Manual: Bedienungsanleitung/ Mode D'emploi/ Manual de Instrucciones/ Manuale Utente/ BruksanvisningBilal al zeitawiNo ratings yet

- Service Bulletin: Area Application: Europe Model Name: Corolla, Corolla Verso Model Code: ZNR11#, NDE120#Document8 pagesService Bulletin: Area Application: Europe Model Name: Corolla, Corolla Verso Model Code: ZNR11#, NDE120#Jou Power100% (1)

- Manual Vanguard ATRT-03Document150 pagesManual Vanguard ATRT-03JuanJose2012No ratings yet

- Installation of The 170-3519 Timing Calibration Harness Assembly (1900, 1905) CaterpillarDocument3 pagesInstallation of The 170-3519 Timing Calibration Harness Assembly (1900, 1905) Caterpillarlonghu1984No ratings yet

- Chevrolet Cavalier Workshop Manual (Cavalier-Z24 V6-191 3.1L VIN T MFI (1994) )Document9,629 pagesChevrolet Cavalier Workshop Manual (Cavalier-Z24 V6-191 3.1L VIN T MFI (1994) )Enedine Ramirez100% (1)

- Engine Pressure Sensor Open or Short PDFDocument14 pagesEngine Pressure Sensor Open or Short PDFNydRomG100% (2)

- 3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsDocument6 pages3000 and 4000 Product Families Troubleshooting Manual-Allison 4 Generation ControlsElectroventica ElectroventicaNo ratings yet

- MID 039 - CID 0167 - FMI 12: TroubleshootingDocument5 pagesMID 039 - CID 0167 - FMI 12: TroubleshootingNerminTurkenceNo ratings yet

- MID 039 - CID 1595 - FMI 05: TroubleshootingDocument319 pagesMID 039 - CID 1595 - FMI 05: TroubleshootingAngga Budi Pratama100% (9)

- 113 1933 5Document3 pages113 1933 5Diego Orlando Santos BuitragoNo ratings yet

- BlowerDocument491 pagesBlowerozdemir_kucukler86% (7)

- G3612Document12 pagesG3612Victor NunezNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- VRS-Lab Quick User Guide en US EdbDocument4 pagesVRS-Lab Quick User Guide en US EdblibertyplusNo ratings yet

- VRS-Lab Instalation Guide Windows en US EddDocument29 pagesVRS-Lab Instalation Guide Windows en US EddlibertyplusNo ratings yet

- NOx Exceedence - Deactivation of EGR 2Document1 pageNOx Exceedence - Deactivation of EGR 2libertyplusNo ratings yet

- LBT 281 - Manual - Making Money Servicing Hybrids Book V2 Printer Version - 50731Document57 pagesLBT 281 - Manual - Making Money Servicing Hybrids Book V2 Printer Version - 50731libertyplusNo ratings yet

- Ev FH M530 2461DDocument1 pageEv FH M530 2461DlibertyplusNo ratings yet

- J1587 SIDs - EngineDocument5 pagesJ1587 SIDs - EnginelibertyplusNo ratings yet

- VRS-Lab Acquisition Module 565 en US EdbDocument7 pagesVRS-Lab Acquisition Module 565 en US EdblibertyplusNo ratings yet

- I-Shift - Optidrive Dual-Clutch Transmission Volvo - Renault - Rema - GermanyDocument5 pagesI-Shift - Optidrive Dual-Clutch Transmission Volvo - Renault - Rema - Germanylibertyplus100% (1)

- HGTP10N40C1D, Hgtp10n40e1d, HGTP10N50C1D, Hgtp10n50e1dDocument7 pagesHGTP10N40C1D, Hgtp10n40e1d, HGTP10N50C1D, Hgtp10n50e1dlibertyplusNo ratings yet

- TM55-65 Servicemanual enDocument57 pagesTM55-65 Servicemanual enlibertyplusNo ratings yet

- Foxwel CRD 7000Document22 pagesFoxwel CRD 7000libertyplusNo ratings yet

- Valeo Service ManualDocument56 pagesValeo Service ManuallibertyplusNo ratings yet

- Amana Refrig ARB2214 Tech Sheet 12642402 PDFDocument2 pagesAmana Refrig ARB2214 Tech Sheet 12642402 PDFlibertyplusNo ratings yet

- Briggs Stratto PartsDocument21 pagesBriggs Stratto PartslibertyplusNo ratings yet

- Codigo Can Presente en TallerDocument1 pageCodigo Can Presente en TallerlibertyplusNo ratings yet

- Flash Code 14 - Temp Sensor High: SectionDocument13 pagesFlash Code 14 - Temp Sensor High: SectionlibertyplusNo ratings yet

- Inquiries Investigation and ImmersionDocument61 pagesInquiries Investigation and Immersionmutsuko100% (4)

- Gea-May1-2014flatplate-List-Price-Catalog Plate Heat ExchangerDocument16 pagesGea-May1-2014flatplate-List-Price-Catalog Plate Heat ExchangerpogisimpatikoNo ratings yet

- 40-Ipl32l-Pwg1xg China Psu PDFDocument3 pages40-Ipl32l-Pwg1xg China Psu PDFotavio jose sbarainiNo ratings yet

- Convention On BiodiversityDocument8 pagesConvention On Biodiversitymaximum jicaNo ratings yet

- Datasheet 3L2Document6 pagesDatasheet 3L2juan carlos diaz cardozoNo ratings yet

- Wiw3362 W 503 PDFDocument1 pageWiw3362 W 503 PDFabathunNo ratings yet

- The Epidemiological Triangle On COVID 19Document2 pagesThe Epidemiological Triangle On COVID 19Pinku KhanNo ratings yet

- Smoke, Heat, Multi Detector and Base - Datasheet (Copper)Document2 pagesSmoke, Heat, Multi Detector and Base - Datasheet (Copper)Raton121 RahmanNo ratings yet

- Admission Notification: 3 Floor, Composite Arts Building, Golapbag Golapbag, Burdwan: - 713 104 West Bengal, IndiaDocument3 pagesAdmission Notification: 3 Floor, Composite Arts Building, Golapbag Golapbag, Burdwan: - 713 104 West Bengal, IndiaHemnath Patra দর্শনNo ratings yet

- Pengelolaan Retribusi Parkir Untuk Pemberdayaan Masyarakat (Studi Pada Lembaga Pemberdayaan Masyarakat Kelurahan Kuta, Kecamatan Kuta)Document8 pagesPengelolaan Retribusi Parkir Untuk Pemberdayaan Masyarakat (Studi Pada Lembaga Pemberdayaan Masyarakat Kelurahan Kuta, Kecamatan Kuta)Fransisca RosalinNo ratings yet

- Development of Verification IP For AMBA AXI 5.0 Protocol: Praveen Chandrashekhar MetriDocument8 pagesDevelopment of Verification IP For AMBA AXI 5.0 Protocol: Praveen Chandrashekhar MetriSubbuNaiduNo ratings yet

- Connections and SchemaDocument7 pagesConnections and SchemaKukuh WidodoNo ratings yet

- Open System Theory PDFDocument8 pagesOpen System Theory PDFDoc AemiliusNo ratings yet

- Finallist 2012Document147 pagesFinallist 2012tracker1234No ratings yet

- SmartEdgeOpen ImplementationGuideDocument16 pagesSmartEdgeOpen ImplementationGuidevuductrungNo ratings yet

- 74HC00Document9 pages74HC00jnax101No ratings yet

- 非谓语动词练习题(学生)Document2 pages非谓语动词练习题(学生)huangyj970218No ratings yet

- Perfect Polymers - Product-Introduction - SUNPAL Multiwall Cell) Polycarbonate Standing-Seam Architectural SystemDocument28 pagesPerfect Polymers - Product-Introduction - SUNPAL Multiwall Cell) Polycarbonate Standing-Seam Architectural SystemGirish DhawanNo ratings yet

- Set TheoryDocument3 pagesSet TheoryMaria IvanovaNo ratings yet

- AssessmentsDocument5 pagesAssessmentsapi-319482993No ratings yet

- Balancing Chemical Equations HTML Guide - enDocument2 pagesBalancing Chemical Equations HTML Guide - enMiguel ApazaNo ratings yet

- Admisie Aer-En 2013Document8 pagesAdmisie Aer-En 2013ionut2007No ratings yet

- Walking With God in The DesertDocument24 pagesWalking With God in The DesertF. Remy Diederich100% (2)

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- BX-Y08 User ManualDocument57 pagesBX-Y08 User Manualghatevinod9360No ratings yet

- DIY Smart Phone Microscope Biology Performance TaskDocument3 pagesDIY Smart Phone Microscope Biology Performance TaskArvie QuijanoNo ratings yet

- Required Labs Manual - MSJ 2016Document26 pagesRequired Labs Manual - MSJ 2016Semwezi EnockNo ratings yet