Professional Documents

Culture Documents

9.0 Tightening of Nuts, Screws and Bolts: Recommended Assembly Torque in Newton Metre (NM)

9.0 Tightening of Nuts, Screws and Bolts: Recommended Assembly Torque in Newton Metre (NM)

Uploaded by

firarizkiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9.0 Tightening of Nuts, Screws and Bolts: Recommended Assembly Torque in Newton Metre (NM)

9.0 Tightening of Nuts, Screws and Bolts: Recommended Assembly Torque in Newton Metre (NM)

Uploaded by

firarizkiCopyright:

Available Formats

9.

0 Tightening of Nuts, Screws and Bolts

9.1. Introduction

Nuts, screws and bolts, generally called "fasteners", should be tightened to the torque recommended in this

instruction unless specified elsewhere. The correct torque depends on the material of which the fastener is made

and the items that it is holding together. Read this instruction before deciding on the appropriate torque for a

particular case.

The torque of some fasteners must be checked during assembly and periodically thereafter as nominated in other

sections of this manual. The bearing torque values can be found in the bearing maintenance section.

The importance of correct torque applies mainly to:

Fasteners which secure fans and pedestals, etc., to foundations.

Fasteners which secure bearing housings to pedestals and secure bearing halves together.

Fasteners which connect the two halves of a coupling.

Fasteners which attach a stator of the motor to a bedplate.

There are many other fasteners which must be correctly tightened. This may often be done according to the

judgement of an experienced fitter rather than by measurement of the torque.

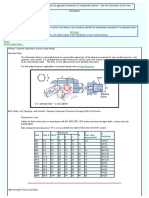

9.2. High Tensile Fasteners

High tensile screws and bolts are manufactured from a Strength Grade 8.8.

Marking: Manufacturer's Symbol "M" for Metric

"8.8" for Strength Grade 8.8

Recommended Assembly Torque in Newton metre (Nm)

SIZE M10 M12 M16 M20 M24 M30 M36

TORQUE 44 77 190 370 640 1310 2300

Higher strength grades are available and this would be indicated on the bolt head. Refer to manufacturer for assembly

torque.

9.3. Commercial Grade Fasteners

Commercial bolts and screws are manufactured from a Strength Grade 4.6.

Marking: Manufacturer's Symbol "M" for Metric

Recommended Assembly Torque in Newton metre (Nm)

SIZE M10 M12 M16 M20 M24 M30 M36 M42

TORQUE 17 30 73 143 248 491 864 1378

Page 9-1

You might also like

- TorquesDocument108 pagesTorquesnaruxzNo ratings yet

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- MF CX330 Tier3 GBDocument281 pagesMF CX330 Tier3 GBjose luis baldiviezo olmosNo ratings yet

- Service Manual Cat G3416eDocument753 pagesService Manual Cat G3416eUsaha Mandiri100% (1)

- Torque Specification - CAT METRIC (ISO)Document4 pagesTorque Specification - CAT METRIC (ISO)Osvaldo Urbano100% (1)

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- 1ZFI209205-437-en - Installation Instructions Tightening TorqueDocument5 pages1ZFI209205-437-en - Installation Instructions Tightening Torquethomasvicson24No ratings yet

- Tightenes Torgue Wartsila 8L32Document30 pagesTightenes Torgue Wartsila 8L32Сергей ДенисенкоNo ratings yet

- Eg 00010 PDFDocument7 pagesEg 00010 PDFAnonymous EhdILsAwmsNo ratings yet

- Metal Plug TorqueDocument2 pagesMetal Plug TorqueArun JaisonNo ratings yet

- Case Excavator Crawler Cx330 Tier3 TrainingDocument20 pagesCase Excavator Crawler Cx330 Tier3 Trainingcynthia100% (60)

- TorquesDocument2 pagesTorquesCRISTIANNo ratings yet

- Chapter 07 - Torque Settings and Use of Hydraulic ToolsDocument40 pagesChapter 07 - Torque Settings and Use of Hydraulic ToolsnikolasthermosolutionsNo ratings yet

- Metric (ISO) Fasteners: Torque SpecificationsDocument6 pagesMetric (ISO) Fasteners: Torque SpecificationsOsorio Meza Tavo FernandoNo ratings yet

- Metric (ISO) Fasteners: Torque SpecificationsDocument3 pagesMetric (ISO) Fasteners: Torque SpecificationsSMKN 6 SAMARINDA PANGESTUNo ratings yet

- 914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationDocument4 pages914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationAsfiannur ade setiawanNo ratings yet

- 1185028747.1 en-US - Mining and Rock Excavation Torque SpecificationsDocument24 pages1185028747.1 en-US - Mining and Rock Excavation Torque SpecificationsOscar VergaraNo ratings yet

- 9852 2423 01 Boom Overhaul Kit But 28Document39 pages9852 2423 01 Boom Overhaul Kit But 28Jorge B100% (1)

- Torque Information - Fuller FastenersDocument3 pagesTorque Information - Fuller FastenersdangmiuNo ratings yet

- Bolt & Nut Torque Table PDFDocument6 pagesBolt & Nut Torque Table PDFFandy MaulanNo ratings yet

- M 73 TorquesDocument95 pagesM 73 TorqueslocochakaNo ratings yet

- TOQUES Mms.Document4 pagesTOQUES Mms.jose diego vallejos llamoNo ratings yet

- 1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesDocument13 pages1 General Remarks: Original Installation and Maintenance Instructions For Bibby Torque Limiters With ModulesAmirmasoudNo ratings yet

- Tightening Torque1Document1 pageTightening Torque1EngrMuhammadAzizNo ratings yet

- Socket Screws MetricDocument32 pagesSocket Screws MetricBib GmzNo ratings yet

- Section 10 Useful Information: General Information - Stainless Steel FastenersDocument1 pageSection 10 Useful Information: General Information - Stainless Steel FastenersMiguel QueirosNo ratings yet

- Metric (ISO) FastenerDocument4 pagesMetric (ISO) FastenermostafaNo ratings yet

- Torque Figures: The Ralin Group LTD (Bespoke Bolting)Document1 pageTorque Figures: The Ralin Group LTD (Bespoke Bolting)LLNo ratings yet

- Non Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2Document2 pagesNon Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2vomawew647No ratings yet

- Non Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2Document2 pagesNon Pre-Load Bolt Assemblies BS EN 15048 Parts 1 & 2George AlexiadisNo ratings yet

- Tightening of Non Preloadable PDFDocument2 pagesTightening of Non Preloadable PDFFaisal MuhammadNo ratings yet

- Clutch HornoDocument37 pagesClutch Horno5hfjmwggmpNo ratings yet

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002No ratings yet

- Fastenr GradesDocument5 pagesFastenr GradesVipul ShereNo ratings yet

- FD202LDocument7 pagesFD202LGrzegorz samuraiNo ratings yet

- Conversion Table/ General Tightening Torque SpecificationsDocument6 pagesConversion Table/ General Tightening Torque SpecificationsioNo ratings yet

- Metric Bolt Torque Table NM - CNCexpoDocument1 pageMetric Bolt Torque Table NM - CNCexpoNepoleon KaruppiahNo ratings yet

- Maintenance Manual: Safety Instructions in MaintenanceDocument9 pagesMaintenance Manual: Safety Instructions in MaintenanceYankonde ChisenseNo ratings yet

- ENG1 FastDocument5 pagesENG1 FastAlexNo ratings yet

- STPC520 - Viti A Testa Cilindrica Con Esagono IncassatoDocument18 pagesSTPC520 - Viti A Testa Cilindrica Con Esagono IncassatoLucaNo ratings yet

- Metric (ISO) Fasteners: SMCS - 7553Document5 pagesMetric (ISO) Fasteners: SMCS - 7553Jhon AlejandoNo ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Torque Specifications Metric BoltsDocument4 pagesTorque Specifications Metric BoltsRoy SilayenNo ratings yet

- Engineer's Handbook General Part: Torque Specification For Bolted ConnectionsDocument2 pagesEngineer's Handbook General Part: Torque Specification For Bolted ConnectionsenzobvNo ratings yet

- Engine Adjusment StandardsDocument1 pageEngine Adjusment StandardsmeinhardNo ratings yet

- 13.-En NT Bolts UtilcellDocument3 pages13.-En NT Bolts Utilcellnu.arabiaNo ratings yet

- Din 9021 Specifications: Bucket Elevator PartsDocument2 pagesDin 9021 Specifications: Bucket Elevator PartsstefanbrindusaNo ratings yet

- Din 934Document1 pageDin 934Chuan ChuNo ratings yet

- Metric (ISO) Fasteners: SmcsDocument4 pagesMetric (ISO) Fasteners: SmcsAnonymous cS9UMvhBqNo ratings yet

- SUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFDocument18 pagesSUMITOMO R450LC-7 EXCAVATOR Service Repair Manual PDFsekfsekmddde100% (4)

- SKF Instalacion de AcoplesDocument10 pagesSKF Instalacion de AcoplesEdwin Casadiego AvilaNo ratings yet

- Metric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PDocument1 pageMetric, Hex Thin Nuts, DIN 936, Plain: Page 1 of 1 REV-03 Date: October 9, 2015 M.936.PSatnam Rachna FastenersNo ratings yet

- Metric: Hex Nut Style 2 Class 9Document1 pageMetric: Hex Nut Style 2 Class 9Ratendra kumarNo ratings yet

- 4D5 SeriesDocument45 pages4D5 Seriesco.videojornalismoNo ratings yet

- Wrench ClearancesDocument2 pagesWrench ClearancesRowan JoguilonNo ratings yet

- CR Manual enDocument2 pagesCR Manual endenisNo ratings yet

- Ancon Tapered Thread Couplers International Version PDFDocument16 pagesAncon Tapered Thread Couplers International Version PDFAhmadHamdyNo ratings yet

- Group 2 Tightening Torque: 1. Major ComponentsDocument3 pagesGroup 2 Tightening Torque: 1. Major ComponentsDenNo ratings yet

- Point Sheave - 1Document2 pagesPoint Sheave - 1Gilney FreitasNo ratings yet

- Torriani Gianni S.N.C.: Installation and Maintenace For Worm Gear Combination SystemDocument3 pagesTorriani Gianni S.N.C.: Installation and Maintenace For Worm Gear Combination SystemSuhas JadhavNo ratings yet