Professional Documents

Culture Documents

Structural Bolts Rev 2017-02-21

Structural Bolts Rev 2017-02-21

Uploaded by

Gopi KrishnanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Bolts Rev 2017-02-21

Structural Bolts Rev 2017-02-21

Uploaded by

Gopi KrishnanCopyright:

Available Formats

Structural Bolting

ASTM F3125/F3125M is a structural bolt specification covering inch and metric bolt grades. This specification contains 4

inch series bolting grades: A325, F1852, A490, and F2280. These will be addressed in this article. When looking at the

mechanical requirements of bolts it appears that a grade A325 and SAE J429 Grade 5 are identical as do the grade A490

and the SAE J429 Grade 8.

This begs the question, “Can an SAE J429 Grade 5 be used when an ASTM F3125 grade A325 is specified?” The answer

is definitely no. This is also the case for substituting a Grade 8 when grade A490 is specified, and here are some reasons

why:

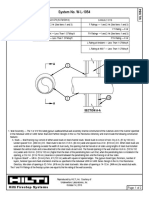

First, grade A325 and A490 bolts are produced with a heavy hex head

configuration which provides a wider bearing surface over which to distribute

the load. Grade 5 and 8 bolts are produced to standard hex cap screw

configuration and therefore cannot distribute the load as much as is needed for

structural applications.

Second, the shank length (non-threaded portion of the body) on the grade

A325 and A490 bolts is designed to be greater (shorter thread lengths) than

your standard hex bolt or hex cap screw. Remember, the weakest section of

standard carbon steel fasteners is through the threaded region. Minute design

changes such as this can create a stronger tensile connection.

Third, the difference in thread length is also likely to result in a change in shear

strength. The following two diagrams demonstrate this difference:

If both bolts are ¾-10 x 4, Bolt X has the shear plane acting through the body Notice the Grade 5 has a much smaller head

of the bolt, while Bolt N has its shear plane acting through the threaded configuration and a shorter shank then the grade A325

structural bolt.

portion. Assuming that both fasteners have an ultimate shear capacity of

72,000 PSI, just how many pounds would each fastener be capable of handling? To determine the load in pounds, one

must first calculate the area of material for each example.

Bolt X has the cross sectional area in the shank (body diameter). Therefore, in the worst case scenario the minimum body

diameter is 0.729 inches. By applying the principles of geometry one can calculate the area of a circle with this diameter.

Page 1 of 6 Revision 2009.03.04

Bolt X has a material cross sectional area of 0.417 square inches. Take 0.417 sq-in. and multiply by 72,000 PSI and you’re

left with nearly 30,000 pounds.

For Bolt N’s calculation the root area must be used (as the shear plane intersects the threads), which is 0.302 sq-in. Now

take this and multiply by the same 72,000 PSI and it results in approximately 21,740 pounds.

By merely ensuring that the shear load is applied to the body of the bolt, the shear strength can improve by 8,260 pounds.

On the other hand, if the application calls for the shank to be in the shear plane, substituting a Grade 5 (with its longer

thread length) would place the threads in the shear plane, resulting in an 8,260 lbs. reduction in shear strength.

Oftentimes, drawings and blueprints indicate the structural bolt with an X or an N designation. The X indicates that the

threads are excluded from the shear plane whereas the N indicates that the threads may be included in the shear plane.

Structural bolts are specifically designed for use with heavy hex nuts in the connection of structural members (as opposed

to tapped holes). The nuts for structural connections shall conform to ASTM A563 or ASTM A194. The following chart

will assist in proper structural nut selection. The washers used for structural connections shall meet ASTM F436

specifications. This specification covers both flat circular and beveled washers.

Mechanical Properties of ASTM F3125/F3125M Grades A325 & A490 Structural Bolts with Nut Compatibility

Min. Min.

Min. Proof Core Hardness

Tensile Yield Grade Identification Marking

Grade Type Material Style Strength Rockwell Compatible Nuts

Strength Strength

(psi) (psi) Min. Max. (psi) Type 1 Type 3

Carbon steel, carbon boron AST M A563 Grade C Heavy

T ype 1 steel, alloy steel or alloy steel Hex, DH or A194/A194M 2H

Heavy Hex

A325 with boron addition 85,000 120,000 C25 C34 92,000 if Galv

Head

T ype 3 Weathering steel AST M A563 Grade C3 or DH3

Carbon steel, carbon boron AST M A563 Grade C Heavy

T ype 1 steel, alloy steel or alloy steel Hex, DH or A194/A194M 2H

F1852 with boron addition T wist-Off 85,000 120,000 C25 C34 92,000 A325TC A325TC if Galv

T ype 3 Weathering steel AST M A563 Grade C3 or DH3

Alloy steel with or without 150,000 AST M A563 Grade DH or

T ype 1

boron Heavy Hex (min) A194/A194M 2H

A490 120,000 C33 C38 130,000

Head 173,000

T ype 3 Weathering steel (max) AST M A563 Grade DH3

Alloy steel with or without 150,000 AST M A563 Grade DH or

T ype 1

boron (min) A194/A194M 2H

F2280 T wist-Off 120,000

173,000

C33 C38 130,000 A490TC A490TC

T ype 3 Weathering steel AST M A563 Grade DH3

(max)

Grade A325 bolts are available in diameters from ½ to 1-1/2 inch (for diameters greater than 1-1/2, ASTM A449

specifications should be considered) with a minimum tensile strength of 120,000 PSI. They also come in two types. Type

1 is a medium carbon steel and can be galvanized; Type 3 is a weathering steel that offers atmospheric corrosion resistance

similar to that of ASTM A242 or A588 steels. Type 3 grade A325 bolts shall be marked “A325” to distinguish them from

standard grade A325s.

ASTM A490 bolts are available in diameters from ½ to 1-1/2 inch diameters with a minimum tensile strength of 150,000

PSI for all diameters, and are offered in two types. Type 1 is alloy steel, and Type 3 is weathering steel that offers

atmospheric corrosion resistance similar to that of ASTM A242 or A588 steels. Type 3 grade A490 bolts shall be marked

“A490”.

Grade A490 bolts should not be galvanized or electroplated. The problem with hot dip galvanizing is that the molten bath

of zinc exceeds the fastener’s tempering temperature and would cause the fastener to anneal in the bath. In addition, a

major problem with hot dip galvanizing and electroplating grade A490 bolts is the potential for hydrogen embrittlement.

Page 2 of 6 Revision 2009.03.04

This scenario may occur when atomic hydrogen is introduced during the pickling process that takes place prior the plating

or hot dip galvanizing process.

When a protective coating is required or specified, the only coating allowed by the ASTM F3125/3125M standard on

grade A490 is the ASTM F1136 Grade 3 or ASTM F2833 Grade 1. These coatings have undergone extensive hydrogen

embrittlement research in accordance with IFI 144. This is a great opportunity for those interested in corrosion resistant

high strength structural bolts. For more information on the F1136 and F2833 coatings, please contact the FEDS Group

at engineer@fastenal.com.

According to the Research Council on Structural Connections; American Institute of Steel Construction (AISC), for structural

applications there are generally three types of connections in which a bolt is used; snug-tightened, pre-tensioned, and slip

critical connections. In accordance with the AISC, bolts used in pre-tensioned or slip-critical connections are required to

be installed to within 70% of the minimum tensile strength of the bolt.

Due to the uncertainties involved with torque, it is not valid to use published values based on a torque-tension relationship

from a formula to obtain the accuracy required for structural connections requiring a minimum clamping force of 70% of

the minimum tensile strength of the bolt.

There are four methods of installation procedures recognized by the AISC to achieve the tension required for the fully

tensioned bearing or the slip critical connection:

1. Turn-of-nut method

2. Alternative design bolt method (tension control bolts)

3. Direct tension indicating method (DTI)

4. Calibrated wrench method.

Turn-of-Nut

This method involves tightening the fastener to a low initial “snug tight” condition and then applying a prescribed amount

of turn to develop the required preload. The actual preload will depend on how far the nut is turned as well as how much

preload was established prior to the turning.

1. Snug the joint to bring the assembly into firm contact. Apply a few impacts with impact wrench until solid sound

or apply full effort with a spud wrench.

2. Inspect the joint to verify “snug tight”.

3. Match mark bearing face of the nut and end of the bolt with a single straight line. Note: match marking is not a

part of the RSCS requirements, but can be helpful.

4. Using a systematic approach which would involve the appropriate bolting pattern, apply the required turns as

given in the table below

“Snug” tighten Mark nut and bolt Desired position achieved (1/3 turn

illustrated)

Page 3 of 6 Revision 2009.03.04

Condition Under Bolt Head and Under Nut

Bolt Length Both Faces One face sloped, Both faces

Flat (normal but not more sloped, but not

to bolt axis) than 1:20 more than 1:20

Less than or equal to 1/3 Turn ½ Turn 2/3 Turn

4D

More than 4D and less ½ Turn 2/3 Turn 5/6 Turn

than or equal to 8D

More than 8D and less 2/3 Turn 5/6 Turn 1 Turn

than or equal to 12D

D = Bolt Diameter

Applicable only to steel joints

Alternative Design Bolts (Tension Control Bolts)

1. Insert Fastener 2. Apply TC Gun 3. Tension Nut 4. Remove Gun

Tension control bolts use design features that

indirectly indicate tension. The most common

alternative design bolt is the twist-off bolt or

tension control (TC) bolt.

An assembly tool holds this bolt from the nut

end while an inner spindle on the tool grips a

spline section connected to the end of the bolt.

An outer spindle on the tool turns the nut and

tightens the fastener. When the designated

torque has been reached, the spline snaps off.

This type of torque control system allows for

quick inspection, if the spline is gone then, in theory, the bolt has been properly tightened.

Although each tension control bolt assembly (bolt, nut and washer) lot is tested by the manufacture to ensure it

meets the minimum required clamp load, this system is based on torque control to snap the spline. Because of this

torque based system, bolt assemblies must be used in their as-received (clean and lubricated by the manufacture),

and strict adherence to the requirements of the appropriate standard, particularly those for storage, cleanliness, and

verification is necessary.

The grade A325 equivalent TC bolts is grade F1852. The grade A490 equivalent TC bolts is grade F2280. Each

bolt is preassembled with an ASTM F436 flat washer and the appropriate heavy hex nut and sold as an assembly.

The grade F1852 bolts are available plain finished or mechanically galvanized. The grade F2280 bolts are only

available in plain finish.

Page 4 of 6 Revision 2009.03.04

Washer Control

Several types of DTI washers are available. The most common type of washer involves the use of hollow bumps

on one side of the washer. This style of washer is covered by the

DTI Assembly Squirter DTI Washer

Before Tensioning After Tensioning

Gap

Partial

Gap

Front Back

ASTM F959 (Standard Specification for Compressible-Washer Type Direct Tension Indicators for Use with

Structural Fasteners) standard and has both A325 and A490 washers. These bumps are flattened as the fastener is

tightened. A feeler gage is used to measure the gap developed by the bumps. When the fastener has developed the

appropriate tension, the feeler gage will no longer fit in the gap. Some newer types fill the void under the bumps

with colored silicone. The silicone squirts out once the bumps are compressed, thereby indicating proper tension.

The DTI washer has been used in the structural bolting industry for years and is now starting to carry over into

other fields as well.

It is important to consider that DTI washers can only indicate the minimum tension required to close the gap. If

over-tightening occurs, the washer would not be able indicate the amount of over tensioning. Moreover, this type

of system cannot monitor or display the amount of bolt relaxation. Since the bumps on the washer deform

plastically, they will not return to their original dimensions if the bolt relaxes.

Calibrated Wrench Method

As mentioned initially, for structural bolting, it is not valid to use published values

based on a torque-tension relationship. In other words, you cannot use torque from a

formula. The calibrated wrench method is only valid if installation procedures are

calibrated on a daily basis by tightening not fewer than three representative fastener

assemblies (typical) for each lot, diameter, length, and grade with nuts from each lot,

diameter, and grade and with a hardened washer tightened in a device (Skidmore-

Wilhelm) capable of measuring actual bolt tension.

The Skidmore-Wilhelm tester is one of the only

devices that is able to directly measure bolt

clamp load.

Page 5 of 6 Revision 2009.03.04

You might also like

- Shigley Mechanical Engineering Design 9th Edition Solutions Si Units PDFDocument5 pagesShigley Mechanical Engineering Design 9th Edition Solutions Si Units PDFMayonkFound ation0% (3)

- Ridder RW45 Motor Gearbox 1-Phase (3-Wire) : Product ManualDocument16 pagesRidder RW45 Motor Gearbox 1-Phase (3-Wire) : Product ManualrublasterNo ratings yet

- ASTM E 1065-1999 (R 2003) - Standard Guide For Evaluating Characteristics of Ultrasonic Search UnitDocument23 pagesASTM E 1065-1999 (R 2003) - Standard Guide For Evaluating Characteristics of Ultrasonic Search UnitKhemaraj PathmalingamNo ratings yet

- WWW Aws OrgDocument8 pagesWWW Aws OrgAkshay GaikwadNo ratings yet

- Physics of Welding Better VersionDocument3 pagesPhysics of Welding Better VersionKhurram RehmanNo ratings yet

- International Standard: Low-Voltage Electrical Installations - VerificationDocument8 pagesInternational Standard: Low-Voltage Electrical Installations - VerificationArjay TolentinoNo ratings yet

- Weldability Test For Thin Sheet MaterialsDocument6 pagesWeldability Test For Thin Sheet MaterialsAnonymous FHkX0ANo ratings yet

- Corrosion Science: ArticleinfoDocument9 pagesCorrosion Science: ArticleinfoalbertoNo ratings yet

- Hydrogen Embrittlement of An Interstitia PDFDocument6 pagesHydrogen Embrittlement of An Interstitia PDFArdu StuffNo ratings yet

- Stainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripDocument8 pagesStainless Chromium-Nickel Steel-Clad Plate, Sheet, and StripJosé Ramón GutierrezNo ratings yet

- Welding Symbols - An Introduction To Reading DrawingsDocument6 pagesWelding Symbols - An Introduction To Reading DrawingsBolarinwaNo ratings yet

- Esr 2236Document6 pagesEsr 2236MD MDDNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Quenched-and-Tempered, Chromium-Molybdenum, and Chromium - Molybdenum-VanadiumDocument4 pagesPressure Vessel Plates, Alloy Steel, Quenched-and-Tempered, Chromium-Molybdenum, and Chromium - Molybdenum-VanadiumJosé Ramón Gutierrez100% (1)

- Asme B31.3-2016 CC 181Document3 pagesAsme B31.3-2016 CC 181MubeenNo ratings yet

- TB10 Download Datablad Eng PDFDocument2 pagesTB10 Download Datablad Eng PDFDanny Milton Silva VasquezNo ratings yet

- E2014-Metallographic Laboratory SafetyDocument8 pagesE2014-Metallographic Laboratory SafetyGeorgon MontoyaNo ratings yet

- Licensed by Information Handling Services Licensed by Information Handling ServicesDocument24 pagesLicensed by Information Handling Services Licensed by Information Handling ServicesIlka RaffaelliNo ratings yet

- Fillet Weld Is Too LongDocument2 pagesFillet Weld Is Too Longgashung_luke9300No ratings yet

- Lawrence Ross FAQ 20200629Document31 pagesLawrence Ross FAQ 20200629John RangelNo ratings yet

- W L 1054Document2 pagesW L 1054shama093No ratings yet

- Astm A335 PDFDocument2 pagesAstm A335 PDFTeoTyJayNo ratings yet

- A5 5-A5 5M-2006PVDocument5 pagesA5 5-A5 5M-2006PVanonimous2516No ratings yet

- Effect of Heat Treatment On Mechanical PropertiesDocument11 pagesEffect of Heat Treatment On Mechanical Properties4035VAID P KULKARNI SEMECHANo ratings yet

- ANSI AWS A5 (1) .29 Specification For Low Alloy Steel ElectrodesDocument47 pagesANSI AWS A5 (1) .29 Specification For Low Alloy Steel ElectrodescatmanmayNo ratings yet

- Tig ParametersDocument4 pagesTig ParametersMohammed Elmodathir AliNo ratings yet

- E2230-13 Standard Practice For Thermal Qualification of Type B Packages For Radioactive MaterialDocument37 pagesE2230-13 Standard Practice For Thermal Qualification of Type B Packages For Radioactive Materialastewayb_964354182No ratings yet

- Alloy/Steel Bolting Materials For Low-Temperature ServiceDocument7 pagesAlloy/Steel Bolting Materials For Low-Temperature ServiceJosé Ramón GutierrezNo ratings yet

- Astm 787Document6 pagesAstm 787Anderson TeixeiraNo ratings yet

- SSPC-SP 16 Brush-Off Blast Cleaning of Non-Ferrous MetalsDocument5 pagesSSPC-SP 16 Brush-Off Blast Cleaning of Non-Ferrous MetalsPablo Ahumada G.No ratings yet

- Astm A217Document3 pagesAstm A217Whitebeard RagnarokNo ratings yet

- 2015 KOBELCO Defect PDFDocument25 pages2015 KOBELCO Defect PDFayushNo ratings yet

- Stainless Steel Chloride Corrosion PDFDocument8 pagesStainless Steel Chloride Corrosion PDFSaut Maruli Tua SamosirNo ratings yet

- API STD 1104 Sept. 2013 Errata1 April 2014 PDFDocument2 pagesAPI STD 1104 Sept. 2013 Errata1 April 2014 PDFIngenius TeamNo ratings yet

- AISE Anchor Bolt Details PDFDocument1 pageAISE Anchor Bolt Details PDFYash PaulNo ratings yet

- Carefully Evaluate Code RequirementsDocument3 pagesCarefully Evaluate Code Requirementsmayav1No ratings yet

- Tigweldarc Alloys: Certification of TestsDocument1 pageTigweldarc Alloys: Certification of TestsArunNo ratings yet

- Seamless and Welded Ferritic Stainless Steel Feedwater Heater TubesDocument7 pagesSeamless and Welded Ferritic Stainless Steel Feedwater Heater TubesMina RemonNo ratings yet

- H2S Corrosion 304 Vs 316Document10 pagesH2S Corrosion 304 Vs 316DigitalMastersTXNo ratings yet

- Iso 1011Document58 pagesIso 1011CüneytNo ratings yet

- Mil STD 2154Document44 pagesMil STD 2154Amar MohammedNo ratings yet

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocument3 pagesHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244No ratings yet

- Machine and Coil Chain: Standard Specification ForDocument4 pagesMachine and Coil Chain: Standard Specification ForDarwin DarmawanNo ratings yet

- 5 - Section 14 - Arc Welding ConsumablesDocument11 pages5 - Section 14 - Arc Welding Consumablesrizkialia12No ratings yet

- Atmosphere Reentry of A Hydrazine TankDocument11 pagesAtmosphere Reentry of A Hydrazine TankdroberNo ratings yet

- Astm A 278 - A 278M - 01 (2015)Document4 pagesAstm A 278 - A 278M - 01 (2015)Nguyễn Như ThếNo ratings yet

- Mil F 18240DDocument19 pagesMil F 18240DrjbelgauNo ratings yet

- Handbook On Clothing - 2nd EdDocument321 pagesHandbook On Clothing - 2nd Edcharliethwaites100% (1)

- Fiberglass Reinforced Thermoset PlasticDocument9 pagesFiberglass Reinforced Thermoset PlasticJesús Alberto Díaz CostaNo ratings yet

- G-0048 - Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution PDFDocument11 pagesG-0048 - Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution PDFEwan SutherlandNo ratings yet

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Metallic Materials - Tensile Testing at High Strain Rates - Part 1: Elastic-Bar-Type Systems (ISO 26203-1:2018)Document51 pagesMetallic Materials - Tensile Testing at High Strain Rates - Part 1: Elastic-Bar-Type Systems (ISO 26203-1:2018)DmitriyNo ratings yet

- Ansi SPS 1.1Document28 pagesAnsi SPS 1.1DedeNo ratings yet

- Astm A1008 CRC Crs PDFDocument9 pagesAstm A1008 CRC Crs PDFArul Edwin VijayNo ratings yet

- Nfa 49 310 Grade Tu 52 B Tubes PDFDocument1 pageNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNo ratings yet

- Introduction To Non-Destructive TestingDocument34 pagesIntroduction To Non-Destructive Testingegy pure100% (1)

- Astm A529 1975Document4 pagesAstm A529 1975dharlanuctcomNo ratings yet

- Propiedades Mecanicas - FastenerDocument4 pagesPropiedades Mecanicas - FastenerEHT pipe100% (1)

- Hex Bolt Head MarkingsDocument5 pagesHex Bolt Head MarkingscarangoretrepoNo ratings yet

- ASTM & SAE Grade Markings For Bolts and ScrewsDocument2 pagesASTM & SAE Grade Markings For Bolts and ScrewsDavid D'AgostinoNo ratings yet

- Properties and Grades of FastenersDocument3 pagesProperties and Grades of Fastenerschez ezNo ratings yet

- Properties and Grades of FastenersDocument4 pagesProperties and Grades of Fastenerschez ezNo ratings yet

- Concrete Repair SpecificationDocument113 pagesConcrete Repair SpecificationGopi KrishnanNo ratings yet

- Aluminium Manufacturers - 02Document3 pagesAluminium Manufacturers - 02Gopi KrishnanNo ratings yet

- Pages From Cocrete-978-3-89958-086-0.volltext - FreiDocument18 pagesPages From Cocrete-978-3-89958-086-0.volltext - FreiGopi KrishnanNo ratings yet

- P1.5 PLK BRG Cmu - Hollow Core Floor Plank Bearing On Interior Masonry Wall PDFDocument1 pageP1.5 PLK BRG Cmu - Hollow Core Floor Plank Bearing On Interior Masonry Wall PDFGopi KrishnanNo ratings yet

- Steel Grade: General InformationDocument2 pagesSteel Grade: General InformationGopi KrishnanNo ratings yet

- Structural Steel S235 S275 S355 Chemical Composition Mechanical Properties and Common ApplicationsDocument5 pagesStructural Steel S235 S275 S355 Chemical Composition Mechanical Properties and Common ApplicationsGopi KrishnanNo ratings yet

- Tata Steel Is - 26MnB5 HR - Data Sheet enDocument2 pagesTata Steel Is - 26MnB5 HR - Data Sheet enGopi KrishnanNo ratings yet

- Tata Steel Is - PalfingerAG Case Study enDocument4 pagesTata Steel Is - PalfingerAG Case Study enGopi KrishnanNo ratings yet

- And Steel Framing: Pressure Treated WoodDocument2 pagesAnd Steel Framing: Pressure Treated WoodGopi KrishnanNo ratings yet

- Eurocodes Plus Icerik ListesiDocument16 pagesEurocodes Plus Icerik ListesiGopi KrishnanNo ratings yet

- University of Kerala University of Kerala University of Kerala University of KeralaDocument2 pagesUniversity of Kerala University of Kerala University of Kerala University of KeralaGopi KrishnanNo ratings yet

- University of Kerala University of Kerala University of Kerala University of KeralaDocument2 pagesUniversity of Kerala University of Kerala University of Kerala University of KeralaGopi KrishnanNo ratings yet

- Yfick IomDocument21 pagesYfick IomJericho EstrellaNo ratings yet

- Fas 18Document17 pagesFas 18LPG Equipment Consulting and ServicesNo ratings yet

- Mae 451 Memo 3 FinalDocument36 pagesMae 451 Memo 3 Finalapi-299086014No ratings yet

- Sieg c1 Micro Lathe Mk2Document24 pagesSieg c1 Micro Lathe Mk2Anonymous f6goFflg3TNo ratings yet

- Ra Res - MHDocument6 pagesRa Res - MHTruong Phuoc TriNo ratings yet

- Lucas-Cav P/ N. OMAP P/n. Application - Verwendung - Application - ApplicazioneDocument12 pagesLucas-Cav P/ N. OMAP P/n. Application - Verwendung - Application - ApplicazioneDaniele AnsaloniNo ratings yet

- Journal of Rock Mechanics and Geotechnical Engineering: Saurabh Rawat, Ashok Kumar GuptaDocument11 pagesJournal of Rock Mechanics and Geotechnical Engineering: Saurabh Rawat, Ashok Kumar GuptaHari RamNo ratings yet

- NordicTrack C2400Document36 pagesNordicTrack C2400Guy ColvinNo ratings yet

- RssDocument1 pageRssgenial72No ratings yet

- EASTMAN D2 Parts Manual PDFDocument16 pagesEASTMAN D2 Parts Manual PDFFelipe VieiraNo ratings yet

- Kioti Daedong DK55 (DK501, DK551) Tractors Service ManualDocument19 pagesKioti Daedong DK55 (DK501, DK551) Tractors Service ManualLisakolyNo ratings yet

- STAUFF-English - Wind Energy ApplicationsDocument11 pagesSTAUFF-English - Wind Energy ApplicationscutekrystalNo ratings yet

- Installation Manual BYD Battery-Box Premium HVS&HVM V1.0 - AU 230512 (1) - 6480286aa41a2 (01-36)Document36 pagesInstallation Manual BYD Battery-Box Premium HVS&HVM V1.0 - AU 230512 (1) - 6480286aa41a2 (01-36)edou mawudoudjiNo ratings yet

- Plant Operation ManualDocument77 pagesPlant Operation ManualMahmoud Abd ElhamidNo ratings yet

- BRUCE MK4 Handling ProcedureDocument81 pagesBRUCE MK4 Handling ProcedureSamo SpontanostNo ratings yet

- Parte Numero JGK-JGTDocument81 pagesParte Numero JGK-JGTdiego yecid millan mendozaNo ratings yet

- Is 1948 1961 R 1996Document21 pagesIs 1948 1961 R 1996Nagaraju Chinta100% (4)

- 11 GB - Cold FormedDocument8 pages11 GB - Cold FormedMarcos AmorimNo ratings yet

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDocument11 pagesIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedNo ratings yet

- Peritrochanteric Nail TechniqueDocument28 pagesPeritrochanteric Nail TechniquePedro Garcia PorcelNo ratings yet

- 2.rigidity ModulusDocument4 pages2.rigidity Modulusmanas100% (1)

- 772 - Wall Penstock - MIDocument15 pages772 - Wall Penstock - MIJohn KurongNo ratings yet

- Weldlok Aluminium GratingDocument24 pagesWeldlok Aluminium GratingRobin Charles SamuelNo ratings yet

- 5BB1 Ives HingesActualDocument1 page5BB1 Ives HingesActualHjalmar Antenor Lopez HerradoraNo ratings yet

- 7.iso Cylinder CatalogueDocument14 pages7.iso Cylinder CatalogueVaijayanti JoshiNo ratings yet

- Toyo Thread Cutting AttachmentDocument12 pagesToyo Thread Cutting Attachmentiril anwarNo ratings yet

- TC-651M Reflex Horn Speaker: DescriptionDocument2 pagesTC-651M Reflex Horn Speaker: Descriptionbobindra71No ratings yet

- Fixture Design For ExcitersDocument24 pagesFixture Design For ExcitersJitendra ItankarNo ratings yet