Professional Documents

Culture Documents

Part 1 General: SECTION 03230 Earthquake Cables

Part 1 General: SECTION 03230 Earthquake Cables

Uploaded by

JojolasCopyright:

Available Formats

You might also like

- Welding Principles and Applications 7th Edition Jeffus Test BankDocument8 pagesWelding Principles and Applications 7th Edition Jeffus Test BankGlennGarciacaweq100% (12)

- 18 - Confined Space THA-AHADocument7 pages18 - Confined Space THA-AHAJojolas50% (2)

- DN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)Document6 pagesDN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)JojolasNo ratings yet

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocument5 pages9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- SolveDocument2 pagesSolveJea Clarie Mendioro Espinas67% (3)

- Set 1 (Practical Problems #1: 1-100) : Bituminous Fiber Sewer PipeDocument12 pagesSet 1 (Practical Problems #1: 1-100) : Bituminous Fiber Sewer PipeMicah VicenteNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Eti Ohe 76 - 6 97 - PDFDocument16 pagesEti Ohe 76 - 6 97 - PDFCounter RoverNo ratings yet

- Air Distribution For Large Spaces PDFDocument7 pagesAir Distribution For Large Spaces PDFJojolasNo ratings yet

- Pipe Supports Std.Document98 pagesPipe Supports Std.Victor Hugo Carrasco Fuentes100% (1)

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Technical Specification - Special Screen Cable - WP4Document7 pagesTechnical Specification - Special Screen Cable - WP4nnNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- Scanned DocumentsDocument1 pageScanned DocumentsCivil structureNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- 63,100,200 & 315 kVA L.T. Distribution BoxDocument15 pages63,100,200 & 315 kVA L.T. Distribution BoxSandip AhireNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Technical Notes For TL (Brief)Document4 pagesTechnical Notes For TL (Brief)Dm InterioNo ratings yet

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocument10 pagesSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationrohitctppNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- 132 KV LaDocument169 pages132 KV LaGuru MishraNo ratings yet

- Sepcification of PSGSG149 CABLE TERMINATION PDFDocument10 pagesSepcification of PSGSG149 CABLE TERMINATION PDFzaheeruddin_mohdNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- Diagnostic Assessment B3 (SEC) - November 2022Document4 pagesDiagnostic Assessment B3 (SEC) - November 2022Yoshjordan LambNo ratings yet

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNo ratings yet

- TALLER PRESOSTATO 2 InglesDocument2 pagesTALLER PRESOSTATO 2 Inglesedisson garzonNo ratings yet

- Flow Transmitter GSECLDocument1 pageFlow Transmitter GSECLSudipto MajumderNo ratings yet

- QuizDocument2 pagesQuizTheod VilaNo ratings yet

- Apdcl TSDocument18 pagesApdcl TSBhavesh KeraliaNo ratings yet

- b5d56a6e5655c852617f13a8e858e3b8Document2 pagesb5d56a6e5655c852617f13a8e858e3b8julio RCNo ratings yet

- Set ADocument5 pagesSet AgregNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- Contact Wire CuSn02 DS ENDocument1 pageContact Wire CuSn02 DS ENRamiro FelicianoNo ratings yet

- Typical Rod Gap ArresterDocument11 pagesTypical Rod Gap ArresterMuhammad Asif Iqbal100% (1)

- Az847 5Document2 pagesAz847 5SarathBattaNo ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- α α α α CBH CBV Cbr-V / Cbr-H: AlphaDocument2 pagesα α α α CBH CBV Cbr-V / Cbr-H: AlphaCecep MarfuNo ratings yet

- Opties en Accessoires Remweerstand dbr3 2000 W DatasheetDocument8 pagesOpties en Accessoires Remweerstand dbr3 2000 W Datasheetlima logictel1No ratings yet

- Ficha Técnica HengtongDocument2 pagesFicha Técnica HengtongDaniel Avendaño GutierrezNo ratings yet

- Cap Pointer: Purpose/ FunctionDocument2 pagesCap Pointer: Purpose/ FunctionvkmsNo ratings yet

- Techspec 8 Shalini - Gupta@dvc - Gov.inDocument19 pagesTechspec 8 Shalini - Gupta@dvc - Gov.inchetan42688No ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- Guaranteed Technical ParticularsDocument3 pagesGuaranteed Technical ParticularsGuru MishraNo ratings yet

- Overhead Line Maint.Document12 pagesOverhead Line Maint.Srikanth VsrNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- DesignDocument3 pagesDesignparsialduateknikNo ratings yet

- TL Hardwares AccessoriesDocument16 pagesTL Hardwares AccessoriesAkd DeshmukhNo ratings yet

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNo ratings yet

- Spec กฟภ.กจน.ป (ด) -001.1-2561Document24 pagesSpec กฟภ.กจน.ป (ด) -001.1-2561patipanpanitanNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- Chapter 3XDocument38 pagesChapter 3XdsaNo ratings yet

- 400kv Quad Tls - GTPDocument8 pages400kv Quad Tls - GTPChatterjee TanmoyNo ratings yet

- 3 - Pipe Blocks & Sumps THA-AHADocument6 pages3 - Pipe Blocks & Sumps THA-AHAJojolasNo ratings yet

- Constant Velocity Duct DesignDocument5 pagesConstant Velocity Duct DesignJojolasNo ratings yet

- 4 - Powered Industrial Truck THA-AHADocument5 pages4 - Powered Industrial Truck THA-AHAJojolasNo ratings yet

- 47 - Hand Blasting THA-AHADocument5 pages47 - Hand Blasting THA-AHAJojolasNo ratings yet

- 1 - Construction Mobilization THA-AHADocument5 pages1 - Construction Mobilization THA-AHAJojolas0% (1)

- Project Management Project PlanDocument6 pagesProject Management Project PlanJojolasNo ratings yet

- Project Deployment Plan TemplateDocument42 pagesProject Deployment Plan TemplateJojolasNo ratings yet

- Fire Hydrant BrochureDocument2 pagesFire Hydrant BrochureJojolasNo ratings yet

- Look Ahead ScheduleDocument9 pagesLook Ahead ScheduleJojolasNo ratings yet

- 014 Water Reticulation System 2016 - 04 - 01Document10 pages014 Water Reticulation System 2016 - 04 - 01JojolasNo ratings yet

- Temperature Measuring DeviceDocument1 pageTemperature Measuring DeviceJojolasNo ratings yet

- Horizontal End Suction Pumps: Flowmore LimitedDocument36 pagesHorizontal End Suction Pumps: Flowmore LimitedJojolasNo ratings yet

- SECTION 09 24 00 Portland Cement PlasteringDocument11 pagesSECTION 09 24 00 Portland Cement PlasteringRima Baz FadousNo ratings yet

- Hollow Sections: European Delivery Programma 2010Document33 pagesHollow Sections: European Delivery Programma 2010Sorin LescaiNo ratings yet

- HoseReels s500Document32 pagesHoseReels s500Dark CenobiteNo ratings yet

- Company ProfileDocument53 pagesCompany ProfileGeoffrey FisherNo ratings yet

- Design Manual Post Bases ENG - RZDocument60 pagesDesign Manual Post Bases ENG - RZAmina Gaco100% (1)

- Technical CatalogueDocument80 pagesTechnical CatalogueHermanNo ratings yet

- Colorcoat HPS200 Ultra® Technical ManualDocument36 pagesColorcoat HPS200 Ultra® Technical ManualPeter ParkerNo ratings yet

- List of Paint Standards-SpecificationsDocument14 pagesList of Paint Standards-SpecificationsMuthuKumar100% (1)

- Instalpress2015 PDFDocument56 pagesInstalpress2015 PDFamijoski6051No ratings yet

- Astm F1667Document46 pagesAstm F1667Syed Mohammed ZakariaNo ratings yet

- Hilti Technical Manual ExtractDocument6 pagesHilti Technical Manual ExtractJecht SpadeNo ratings yet

- Ses H 001.01Document28 pagesSes H 001.01skmd87100% (1)

- Mounting Hardware Clamps (Wind Load Category "XM")Document1 pageMounting Hardware Clamps (Wind Load Category "XM")officeNo ratings yet

- Pressed Steel Door: By: Ar. Amandeep KaurDocument12 pagesPressed Steel Door: By: Ar. Amandeep KaurTushar VarshneyNo ratings yet

- BMW Technical Guideline Corrosion ProtectionDocument5 pagesBMW Technical Guideline Corrosion ProtectionJiahui WuNo ratings yet

- Section 2300 (Timber Construction)Document4 pagesSection 2300 (Timber Construction)akvosmNo ratings yet

- Swindon LV Switchboard and Generator Specification EHS (ME) 012013Document46 pagesSwindon LV Switchboard and Generator Specification EHS (ME) 012013Tukaram PawarNo ratings yet

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- 2013 CatalogDocument28 pages2013 CatalogScreenFabNo ratings yet

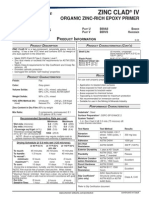

- Zinc Clad IVDocument4 pagesZinc Clad IVvitrolaNo ratings yet

- Metal Duct Selection and ApplicationDocument6 pagesMetal Duct Selection and ApplicationMoiz TinwalaNo ratings yet

- PIP CVC01018 (Project Data Sheet)Document15 pagesPIP CVC01018 (Project Data Sheet)bowitchhazel100% (1)

- Technical Specification For Earth WireDocument2 pagesTechnical Specification For Earth WirePritam Singh100% (1)

- NDV1600 2500 - Komplett Engl PDFDocument19 pagesNDV1600 2500 - Komplett Engl PDFTomuta StefanNo ratings yet

- GalvInfoNote 1 9Document4 pagesGalvInfoNote 1 9KYAW SOENo ratings yet

- Distek EPA ArticleDocument5 pagesDistek EPA ArticleNagendra KumarNo ratings yet

- Code of Practice - Concrete Structures For Retaining Aqueous Liquids: Part 1-General Requirements, Part 2 - Reinforced Concrete StructuresDocument63 pagesCode of Practice - Concrete Structures For Retaining Aqueous Liquids: Part 1-General Requirements, Part 2 - Reinforced Concrete StructuresYogesh BangNo ratings yet

- IS13229 For Molten ZincDocument2 pagesIS13229 For Molten ZincRaghwendra SaoNo ratings yet

- Tream Paper 2.8.editedDocument5 pagesTream Paper 2.8.editedPartho BasakNo ratings yet

Part 1 General: SECTION 03230 Earthquake Cables

Part 1 General: SECTION 03230 Earthquake Cables

Uploaded by

JojolasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part 1 General: SECTION 03230 Earthquake Cables

Part 1 General: SECTION 03230 Earthquake Cables

Uploaded by

JojolasCopyright:

Available Formats

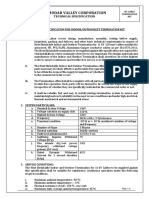

SECTION 03230

EARTHQUAKE CABLES

PART 1 GENERAL

1.1 DESCRIPTION

A. This section covers the work necessary for the tank earthquake cables, complete.

1.2 SUBMITTALS

A. The CONTRACTOR shall submit five copies of the quantity, location and details for the

ENGINEER’S approval before the earthquake cables are fabricated.

PART 2 PRODUCTS

2.1 EARTHQUAKE CABLES

A. Where called for on the Drawings, earthquake cables consisting of 7 wire galvanized strands,

meeting the minimum strength requirements on the Drawings shall be installed to connect wall and

wall footing. If no strength requirements are shown on the Drawings, the minimum ultimate

strength for 3/8” Ø and 1/2” Ø strand shall be 21,400 lbs. and 38,200 lbs., respectively.

B. The strands shall be hot-dipped galvanized before stranding with a minimum zinc coating of 0.85

oz./ft2.

C. Galvanized strands for earthquake cables shall meet the quantity and spacing outlined on the

Drawings.

2.2 CLOSED CELL NEOPRENE SEISMIC CABLE SLEEVES

A. Neoprene sleeves for seismic cables, which encase the galvanized strands, shall conform to the

minimum dimensions shown on the Drawings to permit unrestrained flexing of the strands inside

the sleeves under the maximum projected radial wall movements.

B. The material shall be medium grade closed cell neoprene conforming to 2A3 of ASTM D 1056-85

and as further specified here in and on the Drawings.

1. Compression deflection: 9 - 13 PSI

2. Shore 00 durometer: 60 - 80 PCF

3. Density: 12 - 28 PCF

4. Water absorption by weight: 5%

5. Temperature range:

a. low (flex without cracking): 30° F

b. high continuous: 150° F

c. high intermittent: 200° F

6. Heat aging (7 days @ 158° F) lineal shrinkage (max.): 5%

7. Tensile strength: 115 PSI min.

8. Elongation: 180% min.

03230 - 1 Earthquake Cables

SECTION 03230

EARTHQUAKE CABLES

9. Resilience (bayshore % rebound average 1/2” thickness @ 72° F): 20% - 40%

C. RUBATEX R431N or R423N or CYPRESS SPONGE 431N or 423N, or approved equal, are

acceptable materials.

2.3 MILD STEEL REINFORCING BARS

A. The mild steel reinforcing bars for the support of the earthquake cable anchors shall conform to the

requirements of Section 03210, Reinforcing Steel.

PART 3 EXECUTION

3.1 EARTHQUAKE CABLES

A. The cables may be cut to length with a burning torch.

B. Where necessary, the strands shall be pre bent before placing the units in wall and wall footings, as

called for on the Drawings.

C. The strands shall be tied to circumferential reinforcing as required and as shown on the Drawings.

D. In the footing, the strands shall be tied to the radial footing bars.

- END OF SECTION -

03230 - 2 Earthquake Cables

You might also like

- Welding Principles and Applications 7th Edition Jeffus Test BankDocument8 pagesWelding Principles and Applications 7th Edition Jeffus Test BankGlennGarciacaweq100% (12)

- 18 - Confined Space THA-AHADocument7 pages18 - Confined Space THA-AHAJojolas50% (2)

- DN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)Document6 pagesDN Tanks: Step1: Review Each "Hazard" With Identified Safety "Controls" and Determine RAC (See Above)JojolasNo ratings yet

- 9 - Aerial Lifts and Scissor Lifts THA-AHADocument5 pages9 - Aerial Lifts and Scissor Lifts THA-AHAJojolas100% (2)

- SolveDocument2 pagesSolveJea Clarie Mendioro Espinas67% (3)

- Set 1 (Practical Problems #1: 1-100) : Bituminous Fiber Sewer PipeDocument12 pagesSet 1 (Practical Problems #1: 1-100) : Bituminous Fiber Sewer PipeMicah VicenteNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- Eti Ohe 76 - 6 97 - PDFDocument16 pagesEti Ohe 76 - 6 97 - PDFCounter RoverNo ratings yet

- Air Distribution For Large Spaces PDFDocument7 pagesAir Distribution For Large Spaces PDFJojolasNo ratings yet

- Pipe Supports Std.Document98 pagesPipe Supports Std.Victor Hugo Carrasco Fuentes100% (1)

- Tech Specification Apepdcl TN 99Document23 pagesTech Specification Apepdcl TN 99Suresh SharmaNo ratings yet

- Technical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 ScopeDocument22 pagesTechnical Specifications For 11 KV Xlpe Insulated Underground Cables 1.0 Scopethomas chinNo ratings yet

- Technical Specifications For 33 KV Xlpe Insulated Underground Cables 1. ScopeDocument22 pagesTechnical Specifications For 33 KV Xlpe Insulated Underground Cables 1. Scopethumula.rameshNo ratings yet

- Tech Specs 1Document22 pagesTech Specs 1headqcNo ratings yet

- Technical Specification - Special Screen Cable - WP4Document7 pagesTechnical Specification - Special Screen Cable - WP4nnNo ratings yet

- 33kv Techni8cal Specification Edited FormatDocument16 pages33kv Techni8cal Specification Edited Formatvikas kumarNo ratings yet

- Scanned DocumentsDocument1 pageScanned DocumentsCivil structureNo ratings yet

- M.M.A. Welding ElectrodeDocument1 pageM.M.A. Welding ElectrodecwiksjNo ratings yet

- 06 - Fire Resistant CablesDocument13 pages06 - Fire Resistant CablesmlutfimaNo ratings yet

- 63,100,200 & 315 kVA L.T. Distribution BoxDocument15 pages63,100,200 & 315 kVA L.T. Distribution BoxSandip AhireNo ratings yet

- M.M.A. Welding Electrode: Classifications & ApprovalsDocument1 pageM.M.A. Welding Electrode: Classifications & ApprovalscwiksjNo ratings yet

- Technical Notes For TL (Brief)Document4 pagesTechnical Notes For TL (Brief)Dm InterioNo ratings yet

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocument10 pagesSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediNo ratings yet

- Technical SpecificationDocument7 pagesTechnical SpecificationrohitctppNo ratings yet

- 12a DPST Miniature Power RelayDocument2 pages12a DPST Miniature Power RelaykarkeraNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- 132 KV LaDocument169 pages132 KV LaGuru MishraNo ratings yet

- Sepcification of PSGSG149 CABLE TERMINATION PDFDocument10 pagesSepcification of PSGSG149 CABLE TERMINATION PDFzaheeruddin_mohdNo ratings yet

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesDocument13 pagesLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloNo ratings yet

- Diagnostic Assessment B3 (SEC) - November 2022Document4 pagesDiagnostic Assessment B3 (SEC) - November 2022Yoshjordan LambNo ratings yet

- Singleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundDocument6 pagesSingleturn Potentiometers PD200/210 20.0mm 100,000 Cycles WirewoundRafael CocãoNo ratings yet

- TALLER PRESOSTATO 2 InglesDocument2 pagesTALLER PRESOSTATO 2 Inglesedisson garzonNo ratings yet

- Flow Transmitter GSECLDocument1 pageFlow Transmitter GSECLSudipto MajumderNo ratings yet

- QuizDocument2 pagesQuizTheod VilaNo ratings yet

- Apdcl TSDocument18 pagesApdcl TSBhavesh KeraliaNo ratings yet

- b5d56a6e5655c852617f13a8e858e3b8Document2 pagesb5d56a6e5655c852617f13a8e858e3b8julio RCNo ratings yet

- Set ADocument5 pagesSet AgregNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- WB56S E7016-1Document1 pageWB56S E7016-1cwiksjNo ratings yet

- Contact Wire CuSn02 DS ENDocument1 pageContact Wire CuSn02 DS ENRamiro FelicianoNo ratings yet

- Typical Rod Gap ArresterDocument11 pagesTypical Rod Gap ArresterMuhammad Asif Iqbal100% (1)

- Az847 5Document2 pagesAz847 5SarathBattaNo ratings yet

- Vol-Ii (PART-II) : Guaranteed Technical ParticularsDocument70 pagesVol-Ii (PART-II) : Guaranteed Technical ParticularsNarendra ChhatriaNo ratings yet

- α α α α CBH CBV Cbr-V / Cbr-H: AlphaDocument2 pagesα α α α CBH CBV Cbr-V / Cbr-H: AlphaCecep MarfuNo ratings yet

- Opties en Accessoires Remweerstand dbr3 2000 W DatasheetDocument8 pagesOpties en Accessoires Remweerstand dbr3 2000 W Datasheetlima logictel1No ratings yet

- Ficha Técnica HengtongDocument2 pagesFicha Técnica HengtongDaniel Avendaño GutierrezNo ratings yet

- Cap Pointer: Purpose/ FunctionDocument2 pagesCap Pointer: Purpose/ FunctionvkmsNo ratings yet

- Techspec 8 Shalini - Gupta@dvc - Gov.inDocument19 pagesTechspec 8 Shalini - Gupta@dvc - Gov.inchetan42688No ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- Guaranteed Technical ParticularsDocument3 pagesGuaranteed Technical ParticularsGuru MishraNo ratings yet

- Overhead Line Maint.Document12 pagesOverhead Line Maint.Srikanth VsrNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- DesignDocument3 pagesDesignparsialduateknikNo ratings yet

- TL Hardwares AccessoriesDocument16 pagesTL Hardwares AccessoriesAkd DeshmukhNo ratings yet

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraNo ratings yet

- Spec กฟภ.กจน.ป (ด) -001.1-2561Document24 pagesSpec กฟภ.กจน.ป (ด) -001.1-2561patipanpanitanNo ratings yet

- Martensitic Stainless Steel EN 1.4021-QT 700Document2 pagesMartensitic Stainless Steel EN 1.4021-QT 700LebasNo ratings yet

- SS 420 PropertiesDocument2 pagesSS 420 PropertiesmrbookaniNo ratings yet

- En 1 4021 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4021 - 1408 Valbruna Nordic EnglishmrbookaniNo ratings yet

- Chapter 3XDocument38 pagesChapter 3XdsaNo ratings yet

- 400kv Quad Tls - GTPDocument8 pages400kv Quad Tls - GTPChatterjee TanmoyNo ratings yet

- 3 - Pipe Blocks & Sumps THA-AHADocument6 pages3 - Pipe Blocks & Sumps THA-AHAJojolasNo ratings yet

- Constant Velocity Duct DesignDocument5 pagesConstant Velocity Duct DesignJojolasNo ratings yet

- 4 - Powered Industrial Truck THA-AHADocument5 pages4 - Powered Industrial Truck THA-AHAJojolasNo ratings yet

- 47 - Hand Blasting THA-AHADocument5 pages47 - Hand Blasting THA-AHAJojolasNo ratings yet

- 1 - Construction Mobilization THA-AHADocument5 pages1 - Construction Mobilization THA-AHAJojolas0% (1)

- Project Management Project PlanDocument6 pagesProject Management Project PlanJojolasNo ratings yet

- Project Deployment Plan TemplateDocument42 pagesProject Deployment Plan TemplateJojolasNo ratings yet

- Fire Hydrant BrochureDocument2 pagesFire Hydrant BrochureJojolasNo ratings yet

- Look Ahead ScheduleDocument9 pagesLook Ahead ScheduleJojolasNo ratings yet

- 014 Water Reticulation System 2016 - 04 - 01Document10 pages014 Water Reticulation System 2016 - 04 - 01JojolasNo ratings yet

- Temperature Measuring DeviceDocument1 pageTemperature Measuring DeviceJojolasNo ratings yet

- Horizontal End Suction Pumps: Flowmore LimitedDocument36 pagesHorizontal End Suction Pumps: Flowmore LimitedJojolasNo ratings yet

- SECTION 09 24 00 Portland Cement PlasteringDocument11 pagesSECTION 09 24 00 Portland Cement PlasteringRima Baz FadousNo ratings yet

- Hollow Sections: European Delivery Programma 2010Document33 pagesHollow Sections: European Delivery Programma 2010Sorin LescaiNo ratings yet

- HoseReels s500Document32 pagesHoseReels s500Dark CenobiteNo ratings yet

- Company ProfileDocument53 pagesCompany ProfileGeoffrey FisherNo ratings yet

- Design Manual Post Bases ENG - RZDocument60 pagesDesign Manual Post Bases ENG - RZAmina Gaco100% (1)

- Technical CatalogueDocument80 pagesTechnical CatalogueHermanNo ratings yet

- Colorcoat HPS200 Ultra® Technical ManualDocument36 pagesColorcoat HPS200 Ultra® Technical ManualPeter ParkerNo ratings yet

- List of Paint Standards-SpecificationsDocument14 pagesList of Paint Standards-SpecificationsMuthuKumar100% (1)

- Instalpress2015 PDFDocument56 pagesInstalpress2015 PDFamijoski6051No ratings yet

- Astm F1667Document46 pagesAstm F1667Syed Mohammed ZakariaNo ratings yet

- Hilti Technical Manual ExtractDocument6 pagesHilti Technical Manual ExtractJecht SpadeNo ratings yet

- Ses H 001.01Document28 pagesSes H 001.01skmd87100% (1)

- Mounting Hardware Clamps (Wind Load Category "XM")Document1 pageMounting Hardware Clamps (Wind Load Category "XM")officeNo ratings yet

- Pressed Steel Door: By: Ar. Amandeep KaurDocument12 pagesPressed Steel Door: By: Ar. Amandeep KaurTushar VarshneyNo ratings yet

- BMW Technical Guideline Corrosion ProtectionDocument5 pagesBMW Technical Guideline Corrosion ProtectionJiahui WuNo ratings yet

- Section 2300 (Timber Construction)Document4 pagesSection 2300 (Timber Construction)akvosmNo ratings yet

- Swindon LV Switchboard and Generator Specification EHS (ME) 012013Document46 pagesSwindon LV Switchboard and Generator Specification EHS (ME) 012013Tukaram PawarNo ratings yet

- Catálogo SEDIVERDocument32 pagesCatálogo SEDIVEREnver Rojas DiazNo ratings yet

- 2013 CatalogDocument28 pages2013 CatalogScreenFabNo ratings yet

- Zinc Clad IVDocument4 pagesZinc Clad IVvitrolaNo ratings yet

- Metal Duct Selection and ApplicationDocument6 pagesMetal Duct Selection and ApplicationMoiz TinwalaNo ratings yet

- PIP CVC01018 (Project Data Sheet)Document15 pagesPIP CVC01018 (Project Data Sheet)bowitchhazel100% (1)

- Technical Specification For Earth WireDocument2 pagesTechnical Specification For Earth WirePritam Singh100% (1)

- NDV1600 2500 - Komplett Engl PDFDocument19 pagesNDV1600 2500 - Komplett Engl PDFTomuta StefanNo ratings yet

- GalvInfoNote 1 9Document4 pagesGalvInfoNote 1 9KYAW SOENo ratings yet

- Distek EPA ArticleDocument5 pagesDistek EPA ArticleNagendra KumarNo ratings yet

- Code of Practice - Concrete Structures For Retaining Aqueous Liquids: Part 1-General Requirements, Part 2 - Reinforced Concrete StructuresDocument63 pagesCode of Practice - Concrete Structures For Retaining Aqueous Liquids: Part 1-General Requirements, Part 2 - Reinforced Concrete StructuresYogesh BangNo ratings yet

- IS13229 For Molten ZincDocument2 pagesIS13229 For Molten ZincRaghwendra SaoNo ratings yet

- Tream Paper 2.8.editedDocument5 pagesTream Paper 2.8.editedPartho BasakNo ratings yet