Professional Documents

Culture Documents

Flat Knitting

Flat Knitting

Uploaded by

mohsinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flat Knitting

Flat Knitting

Uploaded by

mohsinCopyright:

Available Formats

Flat Bed Knitting

Flat knitting is an important division of weft knitting industry. The first flat-bed machine was

demonstrated in 1862 and patented in 1865 by Isaac Wixon Lamb.

The fabrics which can be produced on circular knitting machines can be easily produced on

V-bed flat knitting machines, but some of the fabrics which can be produced on V-bed

machines are difficult and sometimes impossible to get produced on circular weft knitting

machines.

Machine Types and Classification

The flat-bed machines are divided into three groups as given below:

1. V-bed machines

2. Horizontal opposed flat-bed machines

3. Straight-Bar multi-sectional full fashioning machines

Main Features

- Flat knitting machine has two stationary needle beds

- Latch needles are used

- Multifunctional cam system is used

- The CAM system is attached to the underside of the cam carriage

- The carriage traverses in a reciprocating manner across the machine width

- There is a separate cam system for each needle bed

Advantages of Flat Knitting Machine

- The stitch length range is wide and there is the possibility of changing the machine

gauge

- A wide range of yarn counts may be knitted per machine gauge including a number

of ends of yarn in one knitting system

- The operation and supervision of the machine is easy compare to circular weft

knitting machine

- The number of garments or panels (garment parts, i.e., sleeve, back part of the body,

front part of the body etc.) simultaneously knitted across the machine is dependent

upon its knitting width, yarn carrier arrangement, yarn path and package

accommodation.

End product of Flat Knitting Machine

Pullovers, jumpers, cardigans, suits, trousers, hats, rib collar and cuff , cleaning clothes,

three-dimensional and fashioned products.

You might also like

- Santoni SeamlessDocument2 pagesSantoni SeamlessSudheer SinghNo ratings yet

- 3 Bed TypesDocument42 pages3 Bed Typesrajurana25No ratings yet

- Sayem M. Digital Fashion Innovations. Advances in Design, Simulation,... 2023Document219 pagesSayem M. Digital Fashion Innovations. Advances in Design, Simulation,... 2023jhnvlsqzNo ratings yet

- 04 Train en PDFDocument120 pages04 Train en PDFRonicito MujicaNo ratings yet

- M05 Weft Knitting Technologies I SWDocument10 pagesM05 Weft Knitting Technologies I SWMamun Zaman100% (1)

- The Need For Proper Classification of FabricsDocument10 pagesThe Need For Proper Classification of FabricsJie LiNo ratings yet

- Sania Ansari GP DocumentDocument67 pagesSania Ansari GP Documentsambit kumarNo ratings yet

- Minimization of Defects in Knitted Fabric 02Document7 pagesMinimization of Defects in Knitted Fabric 02Sarah SebâaNo ratings yet

- Fabric Science - I: Unit-4 Testing of FibresDocument24 pagesFabric Science - I: Unit-4 Testing of FibresRAHUL16398No ratings yet

- 6.2 Assign 1-SNLS MachineDocument25 pages6.2 Assign 1-SNLS MachineAreef Khan100% (1)

- Knitting Production Calculation Details RequiredDocument1 pageKnitting Production Calculation Details RequiredSivam RaviNo ratings yet

- Sweaters and Costing of A SweaterDocument14 pagesSweaters and Costing of A SweaterViveek Rules67% (3)

- Computer Jacquard System Technical Manual: Namad Parda Co. Iran-TehranDocument23 pagesComputer Jacquard System Technical Manual: Namad Parda Co. Iran-Tehranbechir azzouzNo ratings yet

- Apparel Internship atDocument32 pagesApparel Internship atdipalimodiNo ratings yet

- Wal-Mart Canada Missy: LabelDocument4 pagesWal-Mart Canada Missy: LabelsalyNo ratings yet

- 6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenDocument20 pages6 Sem. B.Tech (Fashion & Apparel Technology) : PCFT 4304 Knitting & Non WovenBebi WakaNo ratings yet

- Understanding The Global Apparel Manufacturing ProcessDocument18 pagesUnderstanding The Global Apparel Manufacturing Processyasin husen100% (1)

- Knitting GSM Calculations PDFDocument11 pagesKnitting GSM Calculations PDFHifza khalidNo ratings yet

- Wool Standard r5Document26 pagesWool Standard r5Eddy Edwin WNo ratings yet

- Application of Surface EmbellishmentDocument23 pagesApplication of Surface EmbellishmenthajaraNo ratings yet

- GMTDocument22 pagesGMTEusha NightangelNo ratings yet

- ApparelDocument23 pagesApparelcamarondearingerNo ratings yet

- Color Reduction and CleaningDocument170 pagesColor Reduction and CleaningDora BANo ratings yet

- Spin Knit Win PreviewDocument7 pagesSpin Knit Win PreviewInterweaveNo ratings yet

- SpmeDocument27 pagesSpmeRajiv RanjanNo ratings yet

- Page1 8Document21 pagesPage1 8Yuvraj PahujaNo ratings yet

- Knit Fabric Production ParametersDocument10 pagesKnit Fabric Production Parameterssuvrodev812No ratings yet

- Basic Garment Pattern Design ConsizpdfDocument11 pagesBasic Garment Pattern Design ConsizpdfAhmad El TahanNo ratings yet

- Manual Merchandising (New)Document396 pagesManual Merchandising (New)Muhammad Mubeen Iqbal PuriNo ratings yet

- By Sunil Talekar, Student handout-SOFT - PuneDocument20 pagesBy Sunil Talekar, Student handout-SOFT - PuneRoohi VermaNo ratings yet

- Knit Asia Operation ProcessDocument12 pagesKnit Asia Operation ProcessParvezMridhaNo ratings yet

- Single Jersey FabricDocument4 pagesSingle Jersey FabricMrcr Kapzap0% (1)

- Txl131 LecturesDocument18 pagesTxl131 LecturesRamjiNo ratings yet

- Comparative Analysis For Manufacturing A PDFDocument20 pagesComparative Analysis For Manufacturing A PDFMearegNo ratings yet

- Raymond Visit ReportDocument12 pagesRaymond Visit ReportMandy Terrell100% (1)

- Seam, Classification of Seam, Features of Seam, Uses of SeamDocument13 pagesSeam, Classification of Seam, Features of Seam, Uses of SeamJahidul IslamNo ratings yet

- Online Knitting Technology CourseDocument48 pagesOnline Knitting Technology CourseMoniruzzaman MoNirNo ratings yet

- Textile Testing PDFDocument12 pagesTextile Testing PDFMih Mojumder ShahedNo ratings yet

- 1.fabric Defects and IdentificationDocument16 pages1.fabric Defects and IdentificationRuhi gnextNo ratings yet

- KNT 305Document113 pagesKNT 305Farhad Rana100% (2)

- Principle of Lockstitch FormationDocument9 pagesPrinciple of Lockstitch FormationAsif AnwarNo ratings yet

- What Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsDocument1 pageWhat Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsMoktar Hossain0% (1)

- Chapter One PDFDocument24 pagesChapter One PDFKibromGereNo ratings yet

- Security, C-TPAT, GSV, Occupational Safety and Social Compliance GuidanceDocument51 pagesSecurity, C-TPAT, GSV, Occupational Safety and Social Compliance GuidanceSaloniNo ratings yet

- In-Plant Training Report PresentationDocument60 pagesIn-Plant Training Report Presentationrajhossie9335100% (3)

- Brother Home StudyDocument78 pagesBrother Home StudyknitnutterNo ratings yet

- Garment Production and Machinery EquipmentsDocument31 pagesGarment Production and Machinery EquipmentsShreya Bahl100% (1)

- Apparel Inntern JuryDocument61 pagesApparel Inntern JurypriyalNo ratings yet

- Dry Cleaning Fastness TestDocument5 pagesDry Cleaning Fastness TestAkriti Dixit0% (1)

- KnittingDocument13 pagesKnittingrakibNo ratings yet

- BixbyDocument19 pagesBixbyjoynahidNo ratings yet

- Stitch LengthDocument4 pagesStitch LengthAjeet KumarNo ratings yet

- Sewn Products Machinery and Equipments-: Assignment Ii PresentationDocument7 pagesSewn Products Machinery and Equipments-: Assignment Ii PresentationNiharika SinhaNo ratings yet

- Automation in Apparel Industry: By: Jaideep Singh & Yogesh PrasadDocument16 pagesAutomation in Apparel Industry: By: Jaideep Singh & Yogesh PrasadpriyalNo ratings yet

- Apparel Industrial EngineeringDocument4 pagesApparel Industrial EngineeringkbalabalaNo ratings yet

- Beyond Basic Knitting: Techniques and Projects to Expand Your SkillsFrom EverandBeyond Basic Knitting: Techniques and Projects to Expand Your SkillsRating: 3 out of 5 stars3/5 (2)

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- Modern Cotton Spinning Machinery, Its Principles and ConstructionFrom EverandModern Cotton Spinning Machinery, Its Principles and ConstructionNo ratings yet

- Mphil ReferencesDocument2 pagesMphil ReferencesmohsinNo ratings yet

- 5th ClassDocument18 pages5th ClassmohsinNo ratings yet

- Advanced Fabric Structure and ProductionDocument15 pagesAdvanced Fabric Structure and ProductionmohsinNo ratings yet

- NaturalDocument4 pagesNaturalmohsinNo ratings yet

- Review Knitting NeedlesDocument6 pagesReview Knitting NeedlesmohsinNo ratings yet

- 3rd and 4thDocument16 pages3rd and 4thmohsinNo ratings yet

- Luxury Consumption FactorsDocument18 pagesLuxury Consumption FactorsmohsinNo ratings yet

- MSWDocument2 pagesMSWmohsinNo ratings yet

- NaturalDocument4 pagesNaturalmohsinNo ratings yet

- Garments 3 Inches 6 Inches 6 TO 9 9 Inches Auto Stickers Barres Bumper Stickers ChemicalsDocument4 pagesGarments 3 Inches 6 Inches 6 TO 9 9 Inches Auto Stickers Barres Bumper Stickers ChemicalsmohsinNo ratings yet

- Microeconomics Question 2011Document2 pagesMicroeconomics Question 2011mohsinNo ratings yet

- An Industrilal Attachment PDFDocument118 pagesAn Industrilal Attachment PDFmohsinNo ratings yet

- Chrono Loom FDocument3 pagesChrono Loom FmohsinNo ratings yet

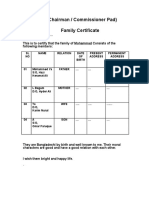

- (Chairman / Commissioner Pad) Family Certificate: SL Name Relation Date Present Permanent NO OF Address Address BirthDocument1 page(Chairman / Commissioner Pad) Family Certificate: SL Name Relation Date Present Permanent NO OF Address Address Birthmohsin100% (3)

- Circular Knitting MachineDocument24 pagesCircular Knitting MachinemohsinNo ratings yet

- Course CoordinatorDocument9 pagesCourse CoordinatormohsinNo ratings yet

- Buffer Stock SystemsDocument2 pagesBuffer Stock SystemsmohsinNo ratings yet

- Yarn Quality Problems: Contamination (Black, Red)Document1 pageYarn Quality Problems: Contamination (Black, Red)mohsinNo ratings yet

- NAZ Bangladesh LTD: Knitting Quality Assurance DepartmentDocument8 pagesNAZ Bangladesh LTD: Knitting Quality Assurance DepartmentmohsinNo ratings yet

- Naz Bangladesh Limited: Knittting Section Weekly Off Day Effective From 01.06.2015 General - ShiftDocument2 pagesNaz Bangladesh Limited: Knittting Section Weekly Off Day Effective From 01.06.2015 General - ShiftmohsinNo ratings yet

- Yarn Test ReportDocument2 pagesYarn Test ReportmohsinNo ratings yet