Professional Documents

Culture Documents

Buckling S

Buckling S

Uploaded by

sandeep0 ratings0% found this document useful (0 votes)

97 views49 pageshydra

Original Title

Buckling s

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthydra

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

97 views49 pagesBuckling S

Buckling S

Uploaded by

sandeephydra

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 49

TECHNICAL DATA

JIS STANDARDS

FOR LEAKAGE AMOUNT 236

PISTON PACKING

LEAKAGE AND WEAR 237

ROD PACKING

LEAKAGE AND WEAR — 238

MINIMUM

SERVICE PRESSURE 239

SLIDING RESISTANCE — 240~241

LOW TEMPERATURE

RESISTANCE PACKINGS ——— 242

BUFFER RINGS See ea

PACKINGS FOR EXTREMELY

SHORT STROKES 244~245

PHENOMENON OF

BURNING ——————— 246 ~247

STICK/SLIP ————————- 248

BREAKAGE DUE TO

PRESSURE BUILD-UP 249

BLOW-THROUGH LEAKAGE

(PASSING) ——- 250.

SWELLING MECHANISM 251

ROUGHNESS OF

CONTACTING OBJECT ———- 252

SEALING SYSTEM

(COMBINATION EFFECT) ——— 253

235

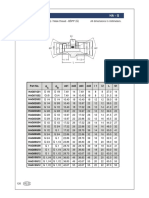

1. JIS STANDARDS FOR LEAKAGE AMOUNT (Old JIS B 8354 :1992)

MIPISTON PACKING (INTERNAL OIL LEAKAGE)

Old JIS B 8354; 1992 states that, when the maximum,

pressure is applied to one side of an immabilized piston and

the amount of oil leakage to the other side of the piston must

be less than those listed in the Table 1-1,under the test

condition shown in the right. With combined seals (SPG,

SPGW), the amount of the internal oil leakage must be less

than twice the Figures in Table 4-1

- Acceptable amount of internal oil leakage for piston packings

‘Testing Conditions

Oil used: Hydraulic ol, unless speciied otherwise,

shall be equivalent to 2 kinds of turbine

‘ll specified by JIS K 2213 with viscosity

‘rade ISO VG32 or VG4E.

ll temperature : 505°C unless specified otherwise.

Piston speed: 0

Unit: mi tomin

LD. (mm) areseigs 4.9. (mm) ae 1.D. (mm) aes

3231.5) 02 100 20 [200 78

[40 03 185 28 | 20s) 10

2 05 140 30 250 10

oa) os 0 (SO

0 13 || 180 63

+ Acceptable leakage amount for combined seal is doubie othe listed value.

WROD PACKING (EXTERNAL OIL LEAKAGE)

Old IS B 8354: 1992 states “that there should be no leakage,

except from the rod, under any operating condition, when

piston makes reciprocating motion under the test condition

as described below with regard to external oil leakage of

hydraulic eylinder.” Oil leakage from rod is classified into

Type A, Type B and Type C as given ia Fig.