Professional Documents

Culture Documents

Stem

Stem

Uploaded by

vs.krishnakanth0 ratings0% found this document useful (0 votes)

30 views13 pagesStem

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

30 views13 pagesStem

Stem

Uploaded by

vs.krishnakanthStem

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 13

Shaped Tube Electrolytic

Machining

Nisarg Shah (11BIE021)

Dhruv Patel (11BIE024)

Rajat Patel (11BIE025)

Electrochemical Machining

• Electrochemical machining (ECM) is a Non-traditional machining

process that relies on the removal of work piece atoms by

electrochemical dissolution.

• The machining current passes through the electrolytic solution that

fills the gap between an anodic work piece and a preshaped cathodic

tool.

• The electrolyte removes the dissolution products, such as metal

hydroxides, heat, and gas bubbles, generated in the interelectrode

gap.

Introduction

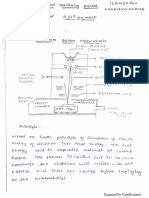

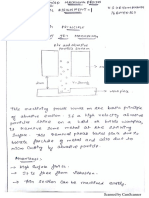

• Shaped tube electrolytic machining (STEM) is based on the dissolution

process when an electric potential difference is imposed between the

anodic work piece and a cathodic tool.

• Because of the presence of this electric field the electrolyte, often a

sulphuric acid, causes the anode surface to be removed.

• After the metal ions are dissolved in the solution, they are removed by

the electrolyte flow the tool is a conducting cylinder with an insulating

coating on the outside and is moved toward the work piece at a certain

feed rate while a voltage is applied across the machining gap. In this way

a cylindrically shaped hole is obtained.

S.T.E.M

• STEM is, therefore, a modified variation of the ECM that uses acidic

electrolytes.

• The process is capable of producing small holes with diameters of

0.76 to 1.62 mm and a depth-to-diameter ratio of 180:1 in electrically

conductive materials.

• It is difficult to machine such small holes using normal ECM as the

insoluble precipitates produced obstructs the flow path of the

electrolyte.

Process Parameters

• Electrolyte:

Type: Sulphuric, Nitric and Hydrochloric Acids

Concentration: 10–25% weight in water

Temperature: 38°C (sulphuric acid) and 21°C (others)

Pressure: 275–500 kPa

• Voltage:

Forwar0d: 8–14 V

Reverse: 0.1–1 times the forward

• Time:

Forward: 5–7 s

Reverse: 25–77 ms

• Feed rate: 0.75–3 mm/min

Process Capabilities

• Hole size: 0.5-6mm diameter at an aspect ratio of 150

• Hole tolerances: 0.5-mm diameter ± 0.050mm

1.5-mm diameter ± 0.075 mm

60-mm diameter ± 0.100 mm

Hole Depth ±0.050 mm

Advantages

• The depth-to-diameter ratio can be as high as 300.

• A large number of holes (up to 200) can be drilled in the same run.

• Nonparallel holes can be machined.

• Blind holes can be drilled.

• No recast layer or metallurgical defects are produced.

• Shaped and curved holes as well as slots can be produced.

Limitations

• The process is used for corrosion-resistant metals.

• STEM is slow if single holes are to be drilled.

• A special workplace and environment are required when handling

acid.

• Hazardous waste is generated.

• Complex machining and tooling systems are required.

Applications

• Because the process uses acid electrolytes, its use is limited to

drilling holes in stainless steel or other corrosion-resistant

materials in jet engines and gas turbine parts such as:

• Turbine blade cooling holes.

• Fuel nozzles.

• Any holes where EDM recast is not desirable.

• Starting holes for wire EDM.

• Drilling holes for corrosion-resistant metals of low conventional

machinability.

• Drilling oil passages in bearings where EDM causes cracks.

Thank You!!..

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PEM Electrolysis For Hydrogen Production Principles and ApplicationsDocument392 pagesPEM Electrolysis For Hydrogen Production Principles and Applicationso100% (5)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Michael Duncan Chemical Engineering Analysis and Design PDFDocument394 pagesMichael Duncan Chemical Engineering Analysis and Design PDFMarcelo Antonucci Cos100% (2)

- VTU BCHES102 Question BankDocument4 pagesVTU BCHES102 Question BankAbhishek Rai67% (3)

- Manual Generador 1Document172 pagesManual Generador 1gustavalc0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Metallurgy-Investigatory Project PDFDocument20 pagesMetallurgy-Investigatory Project PDFAbhishek yadav80% (5)

- Cyanide Remediation: Current and Past TechnologiesDocument26 pagesCyanide Remediation: Current and Past TechnologiesCoraKiriNo ratings yet

- Deep Drawing of Fiber Metal Laminates For Automotive Lightweight StructuresDocument5 pagesDeep Drawing of Fiber Metal Laminates For Automotive Lightweight Structuresvs.krishnakanthNo ratings yet

- LSM Da4 - 16BME0860Document5 pagesLSM Da4 - 16BME0860vs.krishnakanthNo ratings yet

- Café Coffee Day (CCD) : A Case Analysis: SSRN Electronic Journal September 2011Document15 pagesCafé Coffee Day (CCD) : A Case Analysis: SSRN Electronic Journal September 2011vs.krishnakanthNo ratings yet

- Ultrasonic TestingDocument6 pagesUltrasonic Testingvs.krishnakanthNo ratings yet

- Solar Thermal PDFDocument1 pageSolar Thermal PDFvs.krishnakanthNo ratings yet

- Soft SkillDocument15 pagesSoft Skillvs.krishnakanthNo ratings yet

- (U - oV.-M : ) DoteDocument3 pages(U - oV.-M : ) Dotevs.krishnakanthNo ratings yet

- Ultra SonicDocument4 pagesUltra Sonicvs.krishnakanthNo ratings yet

- Electrochemical Machining - Special Equipment and Applications in Aircraft IndustryDocument8 pagesElectrochemical Machining - Special Equipment and Applications in Aircraft Industryvs.krishnakanthNo ratings yet

- Motionpro Double-Wishbone Suspension: - Kinematic Modeling, Simulation and Optimization of ADocument1 pageMotionpro Double-Wishbone Suspension: - Kinematic Modeling, Simulation and Optimization of Avs.krishnakanthNo ratings yet

- Thickness of FilmDocument4 pagesThickness of Filmvs.krishnakanthNo ratings yet

- Liquid PenetrantDocument4 pagesLiquid Penetrantvs.krishnakanthNo ratings yet

- Advanced MachiningDocument21 pagesAdvanced Machiningvs.krishnakanthNo ratings yet

- Scanned by CamscannerDocument6 pagesScanned by Camscannervs.krishnakanthNo ratings yet

- Mechanical Engineering: The "Gears" of FutureDocument10 pagesMechanical Engineering: The "Gears" of Futurevs.krishnakanthNo ratings yet

- Fall 18-19 Reg Schedule PDFDocument1 pageFall 18-19 Reg Schedule PDFvs.krishnakanthNo ratings yet

- Ajm PDFDocument14 pagesAjm PDFvs.krishnakanthNo ratings yet

- Digital Assignment-1 DUE DATE: 31-08-2018 Question-1Document1 pageDigital Assignment-1 DUE DATE: 31-08-2018 Question-1vs.krishnakanthNo ratings yet

- Abrasive Jet MachiningDocument20 pagesAbrasive Jet Machiningvs.krishnakanthNo ratings yet

- School of Mechanical Engineering: Digital Assignment - II, September 2018-19 B.Tech. (BME/BPI), Fall Semester-2018-19Document1 pageSchool of Mechanical Engineering: Digital Assignment - II, September 2018-19 B.Tech. (BME/BPI), Fall Semester-2018-19vs.krishnakanthNo ratings yet

- Waja KimiaDocument4 pagesWaja KimiaAhmad IrsyadNo ratings yet

- ECRE Chapters - 1,2, 4 Solutions To Selected Problems PDFDocument20 pagesECRE Chapters - 1,2, 4 Solutions To Selected Problems PDFAdith RvNo ratings yet

- Necklace Hho 5Document89 pagesNecklace Hho 5RuddyMartiniNo ratings yet

- 9701 w13 QP 1Document44 pages9701 w13 QP 1Robert EdwardsNo ratings yet

- FULLTEXT01Document82 pagesFULLTEXT01푸나틸 미탈 란지쓰 ERICA 부설연구소 공학기술연구소 Post-Doc. No ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary Education Chemistry Paper 2 (Core) October/November 2005 1 Hour 15 MinutesDocument16 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary Education Chemistry Paper 2 (Core) October/November 2005 1 Hour 15 MinutesVarun PanickerNo ratings yet

- Cambridge IGCSE Chemistry Coursebook End-Of-Chapter AnswersDocument19 pagesCambridge IGCSE Chemistry Coursebook End-Of-Chapter Answerssachi -sanNo ratings yet

- Mole CalculationDocument19 pagesMole CalculationWilliamNo ratings yet

- Solar Hydrogen Energy Systems Science and Technology For The Hydrogen Economy by Gabriele Zini, Paolo TartariniDocument188 pagesSolar Hydrogen Energy Systems Science and Technology For The Hydrogen Economy by Gabriele Zini, Paolo TartariniJesús Javier Antuña CouceiroNo ratings yet

- Chemistry SPM SyllabusDocument5 pagesChemistry SPM SyllabusAcyl Chloride HaripremNo ratings yet

- H2 Chem Syllabus PDFDocument48 pagesH2 Chem Syllabus PDFSherman HoNo ratings yet

- Chemistry 4 Electrolysis QP Level Cie For Class 10 11Document24 pagesChemistry 4 Electrolysis QP Level Cie For Class 10 11Maryam KhanNo ratings yet

- A. Elementary Analysis: (Organic Acids, Boric, Hydrofluoric, Silicic and Phosphoric Acidb Being Absent)Document671 pagesA. Elementary Analysis: (Organic Acids, Boric, Hydrofluoric, Silicic and Phosphoric Acidb Being Absent)ShahzadAkhterNo ratings yet

- Electrodialysis Processes With Bipolar Membranes (EDBM) in Environmental Protection - A ReviewDocument22 pagesElectrodialysis Processes With Bipolar Membranes (EDBM) in Environmental Protection - A Reviewandreas.exaNo ratings yet

- Lecture 4 - Electro Chem PDFDocument49 pagesLecture 4 - Electro Chem PDFHedric VillenaNo ratings yet

- Faraday's Law Lab Web VersionDocument10 pagesFaraday's Law Lab Web Versionv9mpir5No ratings yet

- 5 ElectrochemistryDocument56 pages5 ElectrochemistryGabriel LagranaNo ratings yet

- EME LAB ManualDocument46 pagesEME LAB Manualsadhwaniheer5No ratings yet

- 1 s2.0 S0360319922007649 MainDocument11 pages1 s2.0 S0360319922007649 MainAndres NietoNo ratings yet

- Cambridge IGCSE (9-1) : Chemistry 0971/41Document16 pagesCambridge IGCSE (9-1) : Chemistry 0971/41Nam KhanhNo ratings yet

- Waec Syllabus For Chemistry PDFDocument40 pagesWaec Syllabus For Chemistry PDFXanderian XavierNo ratings yet

- Silver CoulometerDocument19 pagesSilver Coulometerarun rajaramNo ratings yet

- FinalDocument14 pagesFinalsnow ivoryNo ratings yet

- India Country Status Report On Hydrogen and Fuel CellDocument80 pagesIndia Country Status Report On Hydrogen and Fuel CellKRISH KUMARNo ratings yet