Professional Documents

Culture Documents

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Uploaded by

DenkaCopyright:

Available Formats

You might also like

- Presentation For Supercritical TechnologyDocument113 pagesPresentation For Supercritical TechnologyVIVEK100% (2)

- HL-class Fact SheetDocument2 pagesHL-class Fact SheetadanasporNo ratings yet

- Alstom GT26 - Presentation PDFDocument39 pagesAlstom GT26 - Presentation PDFluriahNo ratings yet

- Hitachi Boiler PDFDocument5 pagesHitachi Boiler PDFRichard Andrianjaka LuckyNo ratings yet

- State-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerDocument4 pagesState-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerRezwana SarwarNo ratings yet

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDocument5 pagesExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolNo ratings yet

- Operation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODocument5 pagesOperation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODaniel DubeNo ratings yet

- Chapter CogenerationDocument6 pagesChapter Cogenerationpratosh1313No ratings yet

- performance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFDocument36 pagesperformance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFarunrajmech09100% (1)

- Super Critical Boiler Technology MaturesDocument24 pagesSuper Critical Boiler Technology MaturespapudasNo ratings yet

- 700 MW Plant DescripionDocument6 pages700 MW Plant Descripionsathesh100% (1)

- Vocational Training at Cesc LimitedDocument45 pagesVocational Training at Cesc LimitedRohit BaruaNo ratings yet

- Development of M701F Gas Turbine For Integrated VR Gasification Combined Cycle PlantsDocument3 pagesDevelopment of M701F Gas Turbine For Integrated VR Gasification Combined Cycle PlantsMizan SarkarNo ratings yet

- Service: Monitor ManualDocument70 pagesService: Monitor ManualDoge ModerationNo ratings yet

- Super Critical BoilerDocument46 pagesSuper Critical BoilerParveen NakwalNo ratings yet

- Industrial AttachmentDocument43 pagesIndustrial AttachmentemperornafsinNo ratings yet

- Thermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorDocument7 pagesThermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorrudisamosirNo ratings yet

- 07 Power CyclesDocument122 pages07 Power CyclesNahfi JimNo ratings yet

- Steam Blowing Procedure Unit-1 ParadeepDocument9 pagesSteam Blowing Procedure Unit-1 ParadeepMahadev KovalliNo ratings yet

- Super Critical Boiler TechnologyDocument35 pagesSuper Critical Boiler Technologyritesh MishraNo ratings yet

- Report On Jamshoro Thermal Power PlantDocument24 pagesReport On Jamshoro Thermal Power PlantSuresh Kumar100% (2)

- Advanced Cycles JIPTDocument26 pagesAdvanced Cycles JIPTjp mishraNo ratings yet

- Ijetae 0314 111Document3 pagesIjetae 0314 111Knowledge BytesNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power Plantmprasad_veena100% (1)

- Chapter 8 - Gas Turbine Power PlantsDocument30 pagesChapter 8 - Gas Turbine Power PlantsBaslielNo ratings yet

- Introduction of Hitachinaka Thermal Power Station Unit 2, Tokyo Electric Power CompanyDocument3 pagesIntroduction of Hitachinaka Thermal Power Station Unit 2, Tokyo Electric Power CompanyEdzwan RedzaNo ratings yet

- NK57-SMT (Technical Attributes) Ready For Deployment RV5 (JB06062023)Document10 pagesNK57-SMT (Technical Attributes) Ready For Deployment RV5 (JB06062023)NANCY MARTINEZNo ratings yet

- 116 MW Gas Based Power Plant - Tech Details PDFDocument5 pages116 MW Gas Based Power Plant - Tech Details PDFProject AnalysisNo ratings yet

- Presentation For Sugar Mill Energy ReportDocument17 pagesPresentation For Sugar Mill Energy ReportTrinathBanikNo ratings yet

- Steam Turbine Design & Operation by Mr. Lee Kim TiakDocument47 pagesSteam Turbine Design & Operation by Mr. Lee Kim TiakGOBLIN XXX100% (1)

- Siemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas TurbinesDocument2 pagesSiemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas Turbinespartha6789No ratings yet

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNo ratings yet

- Commercial Operation of 600 MW UnitDocument5 pagesCommercial Operation of 600 MW Unitwaleed emaraNo ratings yet

- Datos Técnicos Del BWRDocument3 pagesDatos Técnicos Del BWRANANo ratings yet

- Boiler and Its AuxilliariesDocument22 pagesBoiler and Its Auxilliariesabhijit.adgube3376No ratings yet

- PEPOI Power Plant and Performance Basics PresentationDocument36 pagesPEPOI Power Plant and Performance Basics PresentationFranz MonsantoNo ratings yet

- Fdocuments - in Ceramic Microturbine Program Pollution Infohousep2ricorgref2019275pdfceramicDocument34 pagesFdocuments - in Ceramic Microturbine Program Pollution Infohousep2ricorgref2019275pdfceramicNelson ArturoNo ratings yet

- Waste Heat Recovery Power Generation: Eagle Group S.A.EDocument16 pagesWaste Heat Recovery Power Generation: Eagle Group S.A.EAMIRNo ratings yet

- S08 USC TurbineDocument93 pagesS08 USC Turbineindia100% (4)

- SOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFDocument19 pagesSOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFMallu BroNo ratings yet

- 0 - Kota Tharmal Plant New PDFDocument52 pages0 - Kota Tharmal Plant New PDFRahul LodhaNo ratings yet

- OM0401 Overview of Turbine Version GDocument41 pagesOM0401 Overview of Turbine Version Gمحمد خالد100% (1)

- Annex 6.1.6-2 Description and Drawings of Steam Turbine (Eng) PDFDocument21 pagesAnnex 6.1.6-2 Description and Drawings of Steam Turbine (Eng) PDFvschintapalliNo ratings yet

- Intro - Gas TurbineDocument5 pagesIntro - Gas TurbineMie Dts100% (1)

- 349 Advance Us CT Boiler DesDocument6 pages349 Advance Us CT Boiler DesRobin IndiaNo ratings yet

- Coal PulverizedDocument113 pagesCoal PulverizedSherwin Naldoza Dela Cruz100% (2)

- Boiler Firing Control Design Using Model Predictive TechniquesDocument6 pagesBoiler Firing Control Design Using Model Predictive TechniquesAqmal FANo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- Carrier XP ENERGY Air To Water Heat PumpDocument2 pagesCarrier XP ENERGY Air To Water Heat PumpZeljko DjukicNo ratings yet

- Moscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramDocument1 pageMoscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramAntonio ChoquevilcaNo ratings yet

- Attachment 04 - Milan Conference 2005Document29 pagesAttachment 04 - Milan Conference 2005ElMacheteDelHuesoNo ratings yet

- Siemens Industrial Steam Turbine SST 040 EN PDFDocument4 pagesSiemens Industrial Steam Turbine SST 040 EN PDFAdrian García MoyanoNo ratings yet

- Presentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedDocument34 pagesPresentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedJay JobanputraNo ratings yet

- Buderus SB745WS/1550 Stainless Steel Condensing Boiler: Engineering Submittal SheetDocument5 pagesBuderus SB745WS/1550 Stainless Steel Condensing Boiler: Engineering Submittal Sheetdaboo sanatNo ratings yet

- Steam Turbine AnalysisDocument3 pagesSteam Turbine Analysissai ramanaNo ratings yet

- Steam Turbine and Auxiliary EquipmentDocument11 pagesSteam Turbine and Auxiliary EquipmentReza Mustofa100% (1)

- Design Features and Commissioning of The 700 MW Coal-Fired BoilerDocument5 pagesDesign Features and Commissioning of The 700 MW Coal-Fired Boilervijayk1968100% (1)

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationFrom EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationNo ratings yet

- Power Plant QuestionsDocument20 pagesPower Plant QuestionsDenkaNo ratings yet

- Thajudeen ResumeDocument2 pagesThajudeen ResumeDenkaNo ratings yet

- 1 Construction SafetyDocument26 pages1 Construction SafetyDenkaNo ratings yet

- MSG For UDocument18 pagesMSG For UDenkaNo ratings yet

- TSTPP Turbine Protection InterlockDocument7 pagesTSTPP Turbine Protection InterlockDenkaNo ratings yet

- Index To Volumes: I. Operation & Maintenance Manual - BoilerDocument2 pagesIndex To Volumes: I. Operation & Maintenance Manual - BoilerDenkaNo ratings yet

- TSTPP Turbine InterlocksDocument39 pagesTSTPP Turbine InterlocksDenkaNo ratings yet

- 007PDF 0 17 809 00566 2 0Document1 page007PDF 0 17 809 00566 2 0DenkaNo ratings yet

- NTPCVBR1Document91 pagesNTPCVBR1DenkaNo ratings yet

- Introduction About Thermal Power Station 010807Document2 pagesIntroduction About Thermal Power Station 010807DenkaNo ratings yet

- 001PDF 1 42 010 02377 0 0Document1 page001PDF 1 42 010 02377 0 0DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Document1 pageBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaNo ratings yet

- Electromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliDocument31 pagesElectromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliDenkaNo ratings yet

- AssemblyDocument1 pageAssemblyDenkaNo ratings yet

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDocument1 pageHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaNo ratings yet

- 007PDF 0 17 809 00566 2 0Document1 page007PDF 0 17 809 00566 2 0DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Remark Designation Drawing NoDocument1 pageBharat Heavy Electricals Limited: Remark Designation Drawing NoDenkaNo ratings yet

- Superheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6Document1 pageSuperheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Document1 pageBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaNo ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument6 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDenkaNo ratings yet

- Economizer Coils: Non Flow PanelsDocument1 pageEconomizer Coils: Non Flow PanelsDenkaNo ratings yet

- 002PDF 0 00 056 11072 5 0Document1 page002PDF 0 00 056 11072 5 0DenkaNo ratings yet

- Solar Power Capacity Utilization FactorDocument18 pagesSolar Power Capacity Utilization Factorparthosarothy mukherjiNo ratings yet

- Ahmed 2019Document23 pagesAhmed 2019adnan bin sultanNo ratings yet

- Electric Bus Bar Layout Proposal-ModelDocument1 pageElectric Bus Bar Layout Proposal-ModelHamad GulNo ratings yet

- Mineral and Energy Resources: Suryaveer SinghDocument4 pagesMineral and Energy Resources: Suryaveer SinghKolluri Saisriram KarthikeyaNo ratings yet

- ABB Solar Solutions Brochure Dec14 (Web)Document12 pagesABB Solar Solutions Brochure Dec14 (Web)Muhamad Nur HusenNo ratings yet

- Waaree Energies - R - 29122016Document4 pagesWaaree Energies - R - 29122016swopnilrNo ratings yet

- Aruna Biomass-Company-ProfileDocument8 pagesAruna Biomass-Company-ProfileAdhavan ThamizhanNo ratings yet

- Variable Renewable EnergyDocument2 pagesVariable Renewable EnergySatyender Kumar JainNo ratings yet

- 2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)Document2 pages2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)DertySulistyowatiNo ratings yet

- Vapour and Combine Power CyclesDocument4 pagesVapour and Combine Power CyclesKishore KrishNo ratings yet

- Fuel Oil Treatment System GT HFO PDFDocument9 pagesFuel Oil Treatment System GT HFO PDFVidyasenNo ratings yet

- Solar Net Metering in MaharashtraDocument6 pagesSolar Net Metering in MaharashtraShilpa GodboleNo ratings yet

- FL ModelDocument1 pageFL ModelmanhngoducNo ratings yet

- Energía Geotérmica en El Perú.: Ing. Alcides ClarosDocument15 pagesEnergía Geotérmica en El Perú.: Ing. Alcides ClarosRichard Gonzales CapchiNo ratings yet

- 9e03 04 Fact Sheet April 2015Document2 pages9e03 04 Fact Sheet April 2015AniNo ratings yet

- Thailand LAWI Reference List - Master - 190620Document16 pagesThailand LAWI Reference List - Master - 190620Manoj SinghNo ratings yet

- 84.32 KWP Hope Hall RK Puram SLD E-02Document1 page84.32 KWP Hope Hall RK Puram SLD E-02Sunil SinghNo ratings yet

- Geothermal Energy - HandoutsDocument2 pagesGeothermal Energy - HandoutsNexan Delos AngelesNo ratings yet

- Coal Conversion ProcessesDocument66 pagesCoal Conversion ProcessesRehman ManiNo ratings yet

- Technician Development Program: Safe, Clean, Reliable & Efficient PowerDocument1 pageTechnician Development Program: Safe, Clean, Reliable & Efficient PowerSyarifudinNo ratings yet

- Rrs-Group-Company-Profile PT - Raja Rafa SamudraDocument36 pagesRrs-Group-Company-Profile PT - Raja Rafa SamudraYathi SyahriNo ratings yet

- Eng Day Enamel For Air PreheaterDocument15 pagesEng Day Enamel For Air PreheaterBangun WijayantoNo ratings yet

- MITRE - Meeting The Targets & Putting Renewables To WorkDocument4 pagesMITRE - Meeting The Targets & Putting Renewables To WorkCognosferaNo ratings yet

- Solid FuelDocument6 pagesSolid FuelKen Denver Maglinte100% (1)

- Burners PDFDocument26 pagesBurners PDFJaymin PatelNo ratings yet

- Geothermal Power PlantDocument31 pagesGeothermal Power PlantPao CastillonNo ratings yet

- ITEC in Abu Ghaleb Welcome !Document19 pagesITEC in Abu Ghaleb Welcome !Abdelrahman AdelNo ratings yet

- Distribution of Coal in India: Gondwana Coalfields & Tertiary CoalfieldsDocument19 pagesDistribution of Coal in India: Gondwana Coalfields & Tertiary CoalfieldsJEFY JEAN ANo ratings yet

- Plantilla Excel Control de TaxiDocument65 pagesPlantilla Excel Control de TaxiNacho RojasNo ratings yet

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Uploaded by

DenkaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Application of Leading-Edge High-Efficiency USC Lignite-Fired Power Plant in Turow, Poland

Uploaded by

DenkaCopyright:

Available Formats

Mitsubishi Heavy Industries Technical Review Vol. 54 No.

3 (September 2017)

2

Application of Leading-Edge High-Efficiency USC

Lignite-Fired Power Plant in Turow, Poland

MASATAKA YOROZU*1 DAYAN RAJAPAKSE*2

YOSHINORI TAGUCHI*3 MASASHI MITSUKAWA*4

JӦRG BӦWE*5

The Turow Power Plant (447.5MW (Net), 262bar(a)/597°C/609°C) in Poland is currently

under construction, with the start of commercial operation scheduled for April 2020. The plant is

targeting the world's highest level of efficiency for a lignite-fired power plant. Mitsubishi Hitachi

Power Systems, Ltd. (MHPS) provides high-efficiency lignite-fired plant by applying its own

lignite-fired tower boiler technology, lignite mill burner technology, ultra-supercritical (USC)

technology and boiler flue gas heat recovery system. This report introduces the high-efficiency

USC lignite firing technology applied to the Turow Power Plant.

|1. Introduction

In Poland, lignite is produced in abundance, and many lignite-fired thermal power plants

have been constructed. In 2014, MHPS received the order for the construction of the Turow Power

Plant from Polska Grupa Energetyczna S.A. (PGE), which is the largest Polish energy company,

and construction has been proceeding toward the commencement of commercial operation in April

2020. MHPS's own lignite-fired tower boiler technology, lignite mill and burner technology, USC

technology, air quality control system (AQCS) and boiler flue gas heat recovery system are applied

in this plant. As a lignite-fired power plant, this plant is targeting the world's highest level of

efficiency. The high-efficiency USC lignite-fired technology applied to the Turow Power Plant is

introduced below.

|2. Project overview

In the Turow new unit construction project, Polska Grupa Energetyczna S.A. (PGE) is

constructing a supercritical lignite-fired thermal power plant at its site near the Turow coal mines.

Three-company consortium consisting of the MHPS Group (MHPS and consortium leader,

Mitsubishi Hitachi Power Systems Europe GmbH (MHPS-EDE)), Tecnicas Reunidas (Spain) and

Budimex SA (Poland) was selected as the Engineering, Procurement and Construction (EPC)

contractor and received the order in July 2014. Construction of the new unit was started on

December 1, 2014. Plant construction period is 65 months and the commencement of commercial

operation is scheduled for the end of April 2020.

MHPS-EDE within the EPC contractor consortium will deliver a lignite-fired tower boiler

and boiler auxiliaries and environmental facilities (including the NOx removal equipment and the

electrostatic precipitator). MHPS will deliver turbine/generator set and turbine plant auxiliaries in

addition to supplying the flue gas desulfurization (FGD) equipment. Tecnicas Reunidas and

Budimex SA will be in charge of the supply of plant electrical equipment facilities and the cooling

tower, as well as the civil engineering, civil works and equipment installation work.

Figure 1 shows the exterior view of the plant, and Table 1 presents the major specifications

of the Turow Power Plant.

*1 Chief Staff Manager, Power Systems Project Engineering Department, Power Systems Project Management Division, Mitsubishi Hitachi Power Systems, Ltd.

*2 Chief Staff Manager, Power Systems Project Engineering Department, Power Systems Project Management Division, Mitsubishi Hitachi Power Systems, Ltd.

*3 Chief Staff Manager, Air Quality Control Systems Project Management Department, Air Quality Control Systems Technology Division,

Mitsubishi Hitachi Power Systems, Ltd.

*4 Plant Engineering Department, Plant Engineering Division, Mitsubishi Hitachi Power Systems, Ltd.

*5 Mitsubishi Hitachi Power Systems Europe GmbH CTO Dipl.-Ing.(Germany)

Mitsubishi Heavy Industries Technical Review Vol. 54 No. 3 (September 2017)

3

Table 1 Major specifications of

Turow Power Plant

Item Specifications

Plant output 447.5 MW (Net)

Plant efficiency >43% (Net)

Boiler Tower type (120m) lignite-fired

Steam conditions: 271bar (a)/600/610°C

Steam flow rate: 1275 t/h (SH),

1061t/h (RH)

Turbine Double flow 48-inch (TC2F-48)

Steam conditions: 262bar (a)/597/609°C

Generator 603MVA, 21kV

Cooling system Natural draft cooling tower

Noise 55dB(A) or less (45dB(A) at night)

Figure 1 Exterior view of the plant (image) (site boundary)

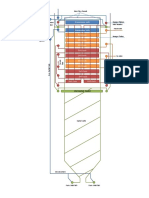

|3. Lignite-fired tower boiler

Lignite coal is used as main fuel. In general, high-temperature heat source is required for

drying lignite coal because it has high moisture content. It also has high volatile matter and good

combustibility, and as such it ignites easily. Since lignite has these characteristics, the combustion

system that differs from that of bituminous coal and subbituminous coal was adopted in this plant.

Figure 2 presents an overview of the combustion system configuration of the boiler, and

Table 2 shows the major specifications of the boiler.

Table 2 Leading specifications of the boiler

Item Specifications

Boiler type Tower boiler

(once-through,

supercritical variable

pressure, single reheat)

Steam conditions

Main steam flow rate 1275 t/h

Superheater outlet pressure 271 bar (a)

Superheater outlet temperature 600°C

Reheater outlet temperature 610°C

Burner type RS® burner

Mill type DGS® mill

Draft system Balanced draft

Steam temperature control

SH outlet Water/fuel ratio control,

Spray attemperator

RH outlet Spray attemperator

Figure 2 Overview of the combustion system

configuration of the lignite-fired boiler

(1) Coal drying method

Because high-temperature drying heat source is required, part of the flue gas is circulated

from the furnace outlet as a coal drying heat source. On the other hand, lignite has a high

volatility and ignites easily. Therefore, the required drying temperature and maximum oxygen

concentration are adjusted by mixing the hot flue gas discharged from the furnace with the cold

flue gas downstream of the electrostatic precipitator (ESP) and hot air.

(2) Fan-mill

The fan-mill is an apparatus that has the functions of a primary fan and mill for

conveyance and crushing. MHPS has two types: NV (Nasskohlen Ventilator) mill and DGS

(Distributor Gebläse Schläger) mill. The NV mill crushes coal just by using the beater wheel,

while the DGS® mill crushes coal using the beater heads in addition to the beater wheel. The

type of mill to be used is selected by the properties of the coal to be used. The lignite coal used

in the Turow Power Plant is relatively difficult to be crushed among lignite, and so the DGS®

mill was adopted.

Mitsubishi Heavy Industries Technical Review Vol. 54 No. 3 (September 2017)

4

(3) Burner

The RS® (Rund Strahl) burner that was developed as a burner for lignite to achieve

controlled ignition and combustion which lead to low NOx emissions. The burners are installed

all around the furnace wall. Three burners are linearly disposed in the vertical direction of the

furnace wall from one mill.

(4) Burnout grate

At the bottom of the furnace, burnout grates are installed so that unburned carbon in ash

is combusted to improve the boiler efficiency.

|4. Flue gas heat recovery system

4.1 Overview

Lignite is characterized as a low heating value fuel with high water content. Due to these

characteristics, the combustion air and the flue gas flow rate of the lignite-fired boiler is larger than

that of the same class bituminous coal-fired boiler, and the size of the boiler is also larger. In

general coal fired boiler, the heat of the flue gas is recovered in combustion air and utilized for

improvement of the plant efficiency. However, in the lignite-fired boiler, the heat of the flue gas is

larger than the required heat for the combustion air, and therefore, the surplus flue gas heat will be

released through flue gas into atmosphere. In the Turow Power Plant, boiler flue gas heat recovery

system is installed to exchange the surplus flue gas heat with the turbine plant feed water /

condensate water, to improve the plant efficiency.

An overview of the system configuration and the operation method are described below.

4.2 System configuration

Figure 3 shows an overview of the system configuration of the boiler flue gas heat recovery

system adopted in the Turow Power Plant. The boiler flue gas heat recovery system consists of two

flue gas water heaters.

i. Flue-Gas-High-Pressure-Water-Heater system (FGHPWH system): High-pressure flue gas

water heater exchanges the heat from flue gas to feed water.

ii. Flue-Gas-Low-Pressure-Water-Heater system (FGLPWH system): Low-pressure flue gas

water heater exchanges the heat from flue gas to condensate water.

Figure 3 Overview of the system - Boiler flue gas heat recovery system

(1) High-pressure heat recovery system (water side)

The water side of the FGHPWH is arranged in bypass line of the high-pressure feedwater

heaters and the dry heater. At the upstream of the high-pressure feedwater heaters, a three way

control valve is installed and distributes the feedwater flow to the high-pressure feedwater

heaters and FGHPWH. The feedwater in the FGHPWH is heated up and the preheated water is

Mitsubishi Heavy Industries Technical Review Vol. 54 No. 3 (September 2017)

5

led back to the main feedwater system via a three way control valve.

(2) Low-pressure heat recovery system (water side)

The water of the FGLPWH is taken from the downstream of the low-pressure condensate

heaters and the preheated condensate from FGLPWH outlet is led back to the feedwater tank. A

booster pump is installed to prevent flash of the condensate water at the FGLPWH outlet. In

addition, a circulating pump is installed, which returns part of the hot condensate at the

FGLPWH outlet to the inlet, to prevent the precipitation of SO2 caused by the lowering boiler

flue gas temperature.

4.3 Operation

(1) High-pressure heat recovery system

The feed water flow through the FGHPWH is load dependent. The required flow is

adjusted by the three way control valve at the upstream of the high-pressure feedwater

preheaters.

(2) Low-pressure heat recovery system

The inlet water temperature of the FGLPWH is controlled by the feed flow through the

FGLPWH. The flow is adjusted by the control valve and the temperature set point depends on

the SO2 content.

|5. Conclusion

This report introduced the high-efficiency USC lignite-fired technology applied to the Turow

Power Plant. In Poland and other countries in Eastern Europe, lignite is produced in abundance,

and high expectations have been placed on lignite-fired thermal power plants. At the same time,

however, due to the rise in environmental awareness in recent years, further development of

high-efficiency technology and environmental protection technology is required. MHPS has been

working on developing high-efficiency USC technologies for many years. We will continue to

make efforts to develop such technologies and contribute to the utilization of energy resources and

the preservation of the global environment.

You might also like

- Presentation For Supercritical TechnologyDocument113 pagesPresentation For Supercritical TechnologyVIVEK100% (2)

- HL-class Fact SheetDocument2 pagesHL-class Fact SheetadanasporNo ratings yet

- Alstom GT26 - Presentation PDFDocument39 pagesAlstom GT26 - Presentation PDFluriahNo ratings yet

- Hitachi Boiler PDFDocument5 pagesHitachi Boiler PDFRichard Andrianjaka LuckyNo ratings yet

- State-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerDocument4 pagesState-Of-The-Art Technologies For The 1,000-Mw 24.5-Mpa/ 600°C/600°C Coal-Fired BoilerRezwana SarwarNo ratings yet

- Experiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerDocument5 pagesExperiences in Designing and Operating The Latest 1,050-MW Coal-Fired BoilerswatkoolNo ratings yet

- Operation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODocument5 pagesOperation Results of IHI Flue Gas Desulfurization System - Unit No.1 (1000 MW) of Hitachinaka Thermal Power Station For TEPCODaniel DubeNo ratings yet

- Chapter CogenerationDocument6 pagesChapter Cogenerationpratosh1313No ratings yet

- performance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFDocument36 pagesperformance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFarunrajmech09100% (1)

- Super Critical Boiler Technology MaturesDocument24 pagesSuper Critical Boiler Technology MaturespapudasNo ratings yet

- 700 MW Plant DescripionDocument6 pages700 MW Plant Descripionsathesh100% (1)

- Vocational Training at Cesc LimitedDocument45 pagesVocational Training at Cesc LimitedRohit BaruaNo ratings yet

- Development of M701F Gas Turbine For Integrated VR Gasification Combined Cycle PlantsDocument3 pagesDevelopment of M701F Gas Turbine For Integrated VR Gasification Combined Cycle PlantsMizan SarkarNo ratings yet

- Service: Monitor ManualDocument70 pagesService: Monitor ManualDoge ModerationNo ratings yet

- Super Critical BoilerDocument46 pagesSuper Critical BoilerParveen NakwalNo ratings yet

- Industrial AttachmentDocument43 pagesIndustrial AttachmentemperornafsinNo ratings yet

- Thermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorDocument7 pagesThermodynamic Analysis of Triple Pressure Heat Recovery Steam GeneratorrudisamosirNo ratings yet

- 07 Power CyclesDocument122 pages07 Power CyclesNahfi JimNo ratings yet

- Steam Blowing Procedure Unit-1 ParadeepDocument9 pagesSteam Blowing Procedure Unit-1 ParadeepMahadev KovalliNo ratings yet

- Super Critical Boiler TechnologyDocument35 pagesSuper Critical Boiler Technologyritesh MishraNo ratings yet

- Report On Jamshoro Thermal Power PlantDocument24 pagesReport On Jamshoro Thermal Power PlantSuresh Kumar100% (2)

- Advanced Cycles JIPTDocument26 pagesAdvanced Cycles JIPTjp mishraNo ratings yet

- Ijetae 0314 111Document3 pagesIjetae 0314 111Knowledge BytesNo ratings yet

- Thermal Power PlantDocument16 pagesThermal Power Plantmprasad_veena100% (1)

- Chapter 8 - Gas Turbine Power PlantsDocument30 pagesChapter 8 - Gas Turbine Power PlantsBaslielNo ratings yet

- Introduction of Hitachinaka Thermal Power Station Unit 2, Tokyo Electric Power CompanyDocument3 pagesIntroduction of Hitachinaka Thermal Power Station Unit 2, Tokyo Electric Power CompanyEdzwan RedzaNo ratings yet

- NK57-SMT (Technical Attributes) Ready For Deployment RV5 (JB06062023)Document10 pagesNK57-SMT (Technical Attributes) Ready For Deployment RV5 (JB06062023)NANCY MARTINEZNo ratings yet

- 116 MW Gas Based Power Plant - Tech Details PDFDocument5 pages116 MW Gas Based Power Plant - Tech Details PDFProject AnalysisNo ratings yet

- Presentation For Sugar Mill Energy ReportDocument17 pagesPresentation For Sugar Mill Energy ReportTrinathBanikNo ratings yet

- Steam Turbine Design & Operation by Mr. Lee Kim TiakDocument47 pagesSteam Turbine Design & Operation by Mr. Lee Kim TiakGOBLIN XXX100% (1)

- Siemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas TurbinesDocument2 pagesSiemens HL-class: The Next Generation of Siemens Advanced Air-Cooled Gas Turbinespartha6789No ratings yet

- A Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)Document5 pagesA Case Study On Thermodynamic Analysis of Cogeneration Power Plant (IRJET-V2I9163)luis hyungNo ratings yet

- Commercial Operation of 600 MW UnitDocument5 pagesCommercial Operation of 600 MW Unitwaleed emaraNo ratings yet

- Datos Técnicos Del BWRDocument3 pagesDatos Técnicos Del BWRANANo ratings yet

- Boiler and Its AuxilliariesDocument22 pagesBoiler and Its Auxilliariesabhijit.adgube3376No ratings yet

- PEPOI Power Plant and Performance Basics PresentationDocument36 pagesPEPOI Power Plant and Performance Basics PresentationFranz MonsantoNo ratings yet

- Fdocuments - in Ceramic Microturbine Program Pollution Infohousep2ricorgref2019275pdfceramicDocument34 pagesFdocuments - in Ceramic Microturbine Program Pollution Infohousep2ricorgref2019275pdfceramicNelson ArturoNo ratings yet

- Waste Heat Recovery Power Generation: Eagle Group S.A.EDocument16 pagesWaste Heat Recovery Power Generation: Eagle Group S.A.EAMIRNo ratings yet

- S08 USC TurbineDocument93 pagesS08 USC Turbineindia100% (4)

- SOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFDocument19 pagesSOW For Heat Exchanger RFQ 29868 UZB1005 Revised 2017-06-01 PDFMallu BroNo ratings yet

- 0 - Kota Tharmal Plant New PDFDocument52 pages0 - Kota Tharmal Plant New PDFRahul LodhaNo ratings yet

- OM0401 Overview of Turbine Version GDocument41 pagesOM0401 Overview of Turbine Version Gمحمد خالد100% (1)

- Annex 6.1.6-2 Description and Drawings of Steam Turbine (Eng) PDFDocument21 pagesAnnex 6.1.6-2 Description and Drawings of Steam Turbine (Eng) PDFvschintapalliNo ratings yet

- Intro - Gas TurbineDocument5 pagesIntro - Gas TurbineMie Dts100% (1)

- 349 Advance Us CT Boiler DesDocument6 pages349 Advance Us CT Boiler DesRobin IndiaNo ratings yet

- Coal PulverizedDocument113 pagesCoal PulverizedSherwin Naldoza Dela Cruz100% (2)

- Boiler Firing Control Design Using Model Predictive TechniquesDocument6 pagesBoiler Firing Control Design Using Model Predictive TechniquesAqmal FANo ratings yet

- DR NTTPSDocument41 pagesDR NTTPSnagasuresh100% (1)

- Carrier XP ENERGY Air To Water Heat PumpDocument2 pagesCarrier XP ENERGY Air To Water Heat PumpZeljko DjukicNo ratings yet

- Moscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramDocument1 pageMoscow TPP-26 Combined-Cycle CHP Plant: Simplified Flow DiagramAntonio ChoquevilcaNo ratings yet

- Attachment 04 - Milan Conference 2005Document29 pagesAttachment 04 - Milan Conference 2005ElMacheteDelHuesoNo ratings yet

- Siemens Industrial Steam Turbine SST 040 EN PDFDocument4 pagesSiemens Industrial Steam Turbine SST 040 EN PDFAdrian García MoyanoNo ratings yet

- Presentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedDocument34 pagesPresentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedJay JobanputraNo ratings yet

- Buderus SB745WS/1550 Stainless Steel Condensing Boiler: Engineering Submittal SheetDocument5 pagesBuderus SB745WS/1550 Stainless Steel Condensing Boiler: Engineering Submittal Sheetdaboo sanatNo ratings yet

- Steam Turbine AnalysisDocument3 pagesSteam Turbine Analysissai ramanaNo ratings yet

- Steam Turbine and Auxiliary EquipmentDocument11 pagesSteam Turbine and Auxiliary EquipmentReza Mustofa100% (1)

- Design Features and Commissioning of The 700 MW Coal-Fired BoilerDocument5 pagesDesign Features and Commissioning of The 700 MW Coal-Fired Boilervijayk1968100% (1)

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- A Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationFrom EverandA Polygeneration Process Concept for Hybrid Solar and Biomass Power Plant: Simulation, Modelling, and OptimizationNo ratings yet

- Power Plant QuestionsDocument20 pagesPower Plant QuestionsDenkaNo ratings yet

- Thajudeen ResumeDocument2 pagesThajudeen ResumeDenkaNo ratings yet

- 1 Construction SafetyDocument26 pages1 Construction SafetyDenkaNo ratings yet

- MSG For UDocument18 pagesMSG For UDenkaNo ratings yet

- TSTPP Turbine Protection InterlockDocument7 pagesTSTPP Turbine Protection InterlockDenkaNo ratings yet

- Index To Volumes: I. Operation & Maintenance Manual - BoilerDocument2 pagesIndex To Volumes: I. Operation & Maintenance Manual - BoilerDenkaNo ratings yet

- TSTPP Turbine InterlocksDocument39 pagesTSTPP Turbine InterlocksDenkaNo ratings yet

- 007PDF 0 17 809 00566 2 0Document1 page007PDF 0 17 809 00566 2 0DenkaNo ratings yet

- NTPCVBR1Document91 pagesNTPCVBR1DenkaNo ratings yet

- Introduction About Thermal Power Station 010807Document2 pagesIntroduction About Thermal Power Station 010807DenkaNo ratings yet

- 001PDF 1 42 010 02377 0 0Document1 page001PDF 1 42 010 02377 0 0DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Document1 pageBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaNo ratings yet

- Electromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliDocument31 pagesElectromatic Relief Valve TYPE 1525 VX: Bharat Heavy Electricals Limited TiruchirapalliDenkaNo ratings yet

- AssemblyDocument1 pageAssemblyDenkaNo ratings yet

- Hanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDocument1 pageHanger System - Heating Surfaces 1.48760/00 213-0009: Zugehörige Zeichnungen / Relevant DrawingsDenkaNo ratings yet

- 007PDF 0 17 809 00566 2 0Document1 page007PDF 0 17 809 00566 2 0DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Remark Designation Drawing NoDocument1 pageBharat Heavy Electricals Limited: Remark Designation Drawing NoDenkaNo ratings yet

- Superheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6Document1 pageSuperheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6DenkaNo ratings yet

- Bharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)Document1 pageBharat Heavy Electricals Limited: Neyveli Lignite Corporation Limited (NLC LTD)DenkaNo ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument6 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDenkaNo ratings yet

- Economizer Coils: Non Flow PanelsDocument1 pageEconomizer Coils: Non Flow PanelsDenkaNo ratings yet

- 002PDF 0 00 056 11072 5 0Document1 page002PDF 0 00 056 11072 5 0DenkaNo ratings yet

- Solar Power Capacity Utilization FactorDocument18 pagesSolar Power Capacity Utilization Factorparthosarothy mukherjiNo ratings yet

- Ahmed 2019Document23 pagesAhmed 2019adnan bin sultanNo ratings yet

- Electric Bus Bar Layout Proposal-ModelDocument1 pageElectric Bus Bar Layout Proposal-ModelHamad GulNo ratings yet

- Mineral and Energy Resources: Suryaveer SinghDocument4 pagesMineral and Energy Resources: Suryaveer SinghKolluri Saisriram KarthikeyaNo ratings yet

- ABB Solar Solutions Brochure Dec14 (Web)Document12 pagesABB Solar Solutions Brochure Dec14 (Web)Muhamad Nur HusenNo ratings yet

- Waaree Energies - R - 29122016Document4 pagesWaaree Energies - R - 29122016swopnilrNo ratings yet

- Aruna Biomass-Company-ProfileDocument8 pagesAruna Biomass-Company-ProfileAdhavan ThamizhanNo ratings yet

- Variable Renewable EnergyDocument2 pagesVariable Renewable EnergySatyender Kumar JainNo ratings yet

- 2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)Document2 pages2B1. Hydrogen-from-Coal Process (HYCOL) : Coal-Fired Power Generation Technologies (Gasification Technologies)DertySulistyowatiNo ratings yet

- Vapour and Combine Power CyclesDocument4 pagesVapour and Combine Power CyclesKishore KrishNo ratings yet

- Fuel Oil Treatment System GT HFO PDFDocument9 pagesFuel Oil Treatment System GT HFO PDFVidyasenNo ratings yet

- Solar Net Metering in MaharashtraDocument6 pagesSolar Net Metering in MaharashtraShilpa GodboleNo ratings yet

- FL ModelDocument1 pageFL ModelmanhngoducNo ratings yet

- Energía Geotérmica en El Perú.: Ing. Alcides ClarosDocument15 pagesEnergía Geotérmica en El Perú.: Ing. Alcides ClarosRichard Gonzales CapchiNo ratings yet

- 9e03 04 Fact Sheet April 2015Document2 pages9e03 04 Fact Sheet April 2015AniNo ratings yet

- Thailand LAWI Reference List - Master - 190620Document16 pagesThailand LAWI Reference List - Master - 190620Manoj SinghNo ratings yet

- 84.32 KWP Hope Hall RK Puram SLD E-02Document1 page84.32 KWP Hope Hall RK Puram SLD E-02Sunil SinghNo ratings yet

- Geothermal Energy - HandoutsDocument2 pagesGeothermal Energy - HandoutsNexan Delos AngelesNo ratings yet

- Coal Conversion ProcessesDocument66 pagesCoal Conversion ProcessesRehman ManiNo ratings yet

- Technician Development Program: Safe, Clean, Reliable & Efficient PowerDocument1 pageTechnician Development Program: Safe, Clean, Reliable & Efficient PowerSyarifudinNo ratings yet

- Rrs-Group-Company-Profile PT - Raja Rafa SamudraDocument36 pagesRrs-Group-Company-Profile PT - Raja Rafa SamudraYathi SyahriNo ratings yet

- Eng Day Enamel For Air PreheaterDocument15 pagesEng Day Enamel For Air PreheaterBangun WijayantoNo ratings yet

- MITRE - Meeting The Targets & Putting Renewables To WorkDocument4 pagesMITRE - Meeting The Targets & Putting Renewables To WorkCognosferaNo ratings yet

- Solid FuelDocument6 pagesSolid FuelKen Denver Maglinte100% (1)

- Burners PDFDocument26 pagesBurners PDFJaymin PatelNo ratings yet

- Geothermal Power PlantDocument31 pagesGeothermal Power PlantPao CastillonNo ratings yet

- ITEC in Abu Ghaleb Welcome !Document19 pagesITEC in Abu Ghaleb Welcome !Abdelrahman AdelNo ratings yet

- Distribution of Coal in India: Gondwana Coalfields & Tertiary CoalfieldsDocument19 pagesDistribution of Coal in India: Gondwana Coalfields & Tertiary CoalfieldsJEFY JEAN ANo ratings yet

- Plantilla Excel Control de TaxiDocument65 pagesPlantilla Excel Control de TaxiNacho RojasNo ratings yet