Professional Documents

Culture Documents

Ammonia Vaporizer ITP

Ammonia Vaporizer ITP

Uploaded by

Karthikeyan ShanmugavelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ammonia Vaporizer ITP

Ammonia Vaporizer ITP

Uploaded by

Karthikeyan ShanmugavelCopyright:

Available Formats

1 of 2

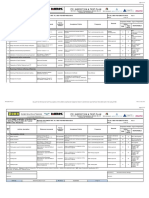

Inspection and Test Plan (ITP)

Document no. : ITP-Pre-002

Project No./Name : PTT CHEM I-4/2 PLANT SCR De-Nox Project Job No./name :- H=Hold Point Rev No. :0

Customer/Client : PTT Chemical Public Co.,Ltd. Item-Description Name : AQUEOUS AMMONIA VAPORIZER R=Review Point Date :23.04.2011

Customer Project no : - Serial No. : S-3101 TO S-3105 ASSEMBLY W=Witness Point

Manufacturer : Getabec Energy Co.,Ltd. Drawing No./Rev. : PTT CHEM: S-11-A1-D2-31-001,CTCIT:XE38-0DENOX-022,Rev.0 SW=Spot witness

CODE : N/A CODE Stamp. :- D=Documented

Quality Surveillance

Document

GETABEC

A.I CUSTOMER

Reference Document/Drawings/ Standard Production QA/QC

Item Area of activity Quality control activity Acceptance Criteria

Code

Point

Point

Point

Point

Signature Date Signature Date Signature Date Signature Date

1 Design calculation and drawings

1.1 Design data/calculations Review design data and calculations Technical requirement

D H H

Design code and standard ASME VIII & Project spec.

1.2 Drawing for approval Review drawing for approval Design Calculation,code and standard ASME VIII & Project spec. D H H

1.3 Drawing for construction Review drawing for construction Design calculations

D H H

Approved drawing ASME VIII & Project spec.

2 Material

2.1 Raw material for pressure part Verify material certificates and mfg. stencil marks Material certificates

D H H

Material receiving reports Material specification

22

2.2 Raw material for non-presure pt.

pt Visual and dimensional inspection Drawing for construction

D H H

Purchase order Material specification

2.3 Welding consumable material Verify and visual inspection WPS

D H H

Material receiving reports Mfg. specification

3 Welding

3.1 Welding Procedure Specification Review WPS Drawing for construction ASME IX D H H

(WPS)

3.2 Procedure Qualification Record Review test records (existing) WPS ASME IX D H H

(PQR) Witness PQR test (new) and review test records. Test records D H H

3.3 Welder Qualifiaction Test (WQT) Review welder certificates (existing) Welder certificates,WPS ASME IX D H H

Witness welder test (new) and review test records. Drawing for construction D H H

3.4 Weld map/Welding NDE scedule Weld map and Weld&NDE schedule preparation Drawing for construction & WPS ASME IX,WPS D H H

4 Pre- fabrication

4.1 1) Material Material identification check Material identification record UG-77,UG-94Sec VIII Div.1 H H

4.1.2 Shell

1) Material Material identification check Material identification record UG-77,UG-94Sec VIII Div.1 H H

2) Cut lay-out Dimension check Drawing for con., WPS As Drawing R R

3) Cutting & beveling a) Dimension check Drawing for con., WPS Weld map,drawing H H

4) Fit-up

Fit up b) Edge Preparation check Drawing for con

con., WPS UW 31 UW 32 UW 33

UW-31,UW-32,UW-33, H H

(alignment,gap,cleanliness inspection)

5) Forming (rolling) Out of roundness Drawing for con. UG-79,UG-96, Sec VIII Div.1 H H

6) Longitudinal weld a)WPS,welder,visual Inspection Drawing for con., WPS UW-31,UW-32,UW-33, H H

b) Roundness check Drawing for con. Sec VIII Div.1,Drawing H H

c) RT at manual weld seam Weld map,welding&NDESchedule UW-51,Sec VIII Div.1 H H

d) Review RT Film & Reports RT Film & Reports UW-51,Sec VIII Div.1 D - R

4.2 Nozzle

1) Material Material identification Material identification record UG-77,UG-94Sec VIII Div.1 H H

2) Cut lay-out Dimension check Drawing for con., WPS As Drawing R R

3) Cutting & grinding Edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, R R

4) Fit-up flange to neck & weld a) Dimension check Drawing for con., WPS Weld map,drawing H H

b) Alignment,gap,cleanliness inspection Drawing for con., WPS UW-31,32,33,Sec VIII Div.1 H H

c) WPS,welder,visual Drawing for con., WPS UW-47,48,35 H H

5 Assembly

5.1 Shell-to Shell

5.1.1 Fit-up a) Dimension check Drawing for con., WPS As Drawing H H

b) edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, H H

(alignment fit up cleanliness inspection)

(alignment,fit-up,cleanliness

c)Visual Drawing for con., WPS UW-47,48,35

5.1.2 Circumferential weld a)WPS,welder,visual Inspection Drawing for con., WPS UW-31,UW-32,UW-33, H H

b) Roundness check Drawing for con. Sec VIII Div.1,Drawing H H

c) RT at manual weld seam Weld map,welding&NDESchedule UW-51,Sec VIII Div.1 H H

d) Review RT Film & Reports RT Film & Reports UW-51,Sec VIII Div.1 D - R

5.2 Flange to Shell

5.2.1 Fit-up a) Dimension check Drawing for con., WPS As Drawing H H

b) edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, H H

(alignment,fit-up,cleanliness inspection)

c)Visual Drawing for con., WPS UW-47,48,35

5.2.2 Circumferential weld - CW1 a)WPS,welder,visual Inspection Drawing for con., WPS UW-31,UW-32,UW-33, H H

b) Roundness check Drawing for con. Sec VIII Div.1,Drawing H H

c) RT at manual weld seam Weld map,welding&NDESchedule UW-51,Sec VIII Div.1 H H

d) Review RT Film & Reports RT Film & Reports UW-51,Sec VIII Div.1 D - R

5.3 Plate Flange to Shell

5.3.1 Fit-up a) Dimension check Drawing for con., WPS As Drawing H H

b) edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, H H

(alignment,fit-up,cleanliness inspection)

c)Visual Drawing for con., WPS UW-47,48,35

5.3.2 Circumferential weld a)WPS,welder,visual Inspection Drawing for con., WPS UW-31,UW-32,UW-33, H H

b) R

Roundness

d check

h k Drawing for con

con. S

Sec VIII Di 1D i

Div.1,Drawing H H

c) RT at manual weld seam Weld map,welding&NDESchedule UW-51,Sec VIII Div.1 H H

d) Review RT Film & Reports RT Film & Reports UW-51,Sec VIII Div.1 D - R

d) Review RT Film & Reports RT Film & Reports UW-51,Sec VIII Div.1 D - R

5.4 Manhole MH To Shell

1) Opening on Head wall Orientation & elevation check Drawing for con., As drawing H H

2) Fit-up a) Dimension check Drawing for con., WPS As drawing H H

b) edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, H H

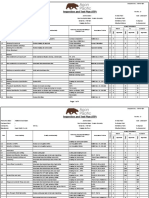

2 of 2

Inspection and Test Plan (ITP)

Document no. : ITP-Pre-002

Project No./Name : PTT CHEM I-4/2 PLANT SCR De-Nox Project Job No./name :- H=Hold Point Rev No. :0

Customer/Client : PTT Chemical Public Co.,Ltd. Item-Description Name : AQUEOUS AMMONIA VAPORIZER R=Review Point Date :23.04.2011

Customer Project no : - Serial No. : S-3101 TO S-3105 ASSEMBLY W=Witness Point

Manufacturer : Getabec Energy Co.,Ltd. Drawing No./Rev. : PTT CHEM: S-11-A1-D2-31-001,CTCIT:XE38-0DENOX-022,Rev.0 SW=Spot witness

CODE : N/A CODE Stamp. :- D=Documented

Quality Surveillance

Document

GETABEC

A.I CUSTOMER

Reference Document/Drawings/ Standard Production QA/QC

Item Area of activity Quality control activity Acceptance Criteria

Code

Point

Point

Point

Point

Signature Date Signature Date Signature Date Signature Date

(alignment,fit-up,cleanliness inspection)

3) Welding a)WPS,welder,visual Inspection Weld map,welding&NDESchedule UW-47,48,35,36 R R

b) Review PT reports PT Reports Sec VIII Div.1 D - R

5.5 Support & Accessory to Shell

1) Fit-up a) Dimension check Drawing for con., WPS As drawing R R

b) edge preparation check Drawing for con., WPS UW-31,UW-32,UW-33, R R

(alignment,fit-up,cleanliness inspection)

2) Welding a)WPS,welder,visual Inspection Drawing for con., WPS UW-47,48,35 R R

b) Review PT reports PT Reports Sec VIII Div.1 D - R

6 1) Finishing (for internals & externals) a) PT all temporary weld Fabrication standard Sec VIII Div.1

Div 1 H H

b) Final visual & dimension check Drawing for con., WPS As drawing H H

c) Final weld inspection Drawing for con., WPS No defect & clean H H

2) Inside Inspection Inside Cleanliness,Visual Inspection Project Spec,Fabrication Standard No defect & clean H H

7 Hydrostatic Test a) Pressure Gauge calibration Calibration records Sec VIII Div.1 D H H

b) proper support Visual - R R

c) Test medium Water test report Clean neutral water D H H R

d) Holding time (1 Hr. , Held) Drawing for con., Design & Pressure test reports UG-102,vSec.VIII Div.1 H H H

e) Leakage test Drawing for con., Design & Pressure test reports UG-102,vSec.VIII Div.1 D H H H

8 Surface Finishing Visual Check Drawing for con., As per spec. R R

9 Painting Visual Check Drawing for con., As per spec. R R R

10 Name plate Visual & Dimension Check Section VIII,Div.1 Section VIII,Div.1 H H R

11 Manufacturer's Data Report (MDR) Prepare and review MDR As request D - R R

----------- End of Ammonia Vaporizer Fabrication Process and Ready for Transport to site------------------

Prepared by Approved by Accepted by Reviewed by

QA/AC Engineer QA/QC Manager Authorized Inspector (A.I) Customer

You might also like

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Safe Distance Stored Energy Calculator - Pneumatic TestingDocument3 pagesSafe Distance Stored Energy Calculator - Pneumatic TestingKarthikeyan ShanmugavelNo ratings yet

- Vetco H-4 ConnectorsDocument6 pagesVetco H-4 ConnectorsRobert Hogg100% (1)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

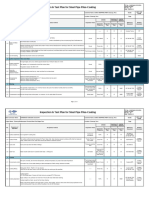

- Appendix 1 - Inspection & Test PlanDocument2 pagesAppendix 1 - Inspection & Test Planwagwahkiabathe100% (1)

- NO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionDocument123 pagesNO. Inspection/Test Item Action by Remarks Reference Document (S) Acceptance Criteria Method of InspectionYoseph Maulana0% (1)

- AISI 1015 Carbon Steel (UNS G10150) : Topics CoveredDocument3 pagesAISI 1015 Carbon Steel (UNS G10150) : Topics CoveredKarthikeyan ShanmugavelNo ratings yet

- ITPDocument2 pagesITPKarthikeyan Shanmugavel100% (1)

- ITP SampleDocument4 pagesITP SampleKarthik S100% (1)

- Quality Control Plan For Ducting: Project Name: TokushimaDocument4 pagesQuality Control Plan For Ducting: Project Name: TokushimaNguyen Anh TuanNo ratings yet

- Vendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument3 pagesVendor Fabrica Tion Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- CHECSAC-CCCC4TH-QAQC-ITP-0007 Rev.00 2022.2.14Document4 pagesCHECSAC-CCCC4TH-QAQC-ITP-0007 Rev.00 2022.2.14Mauricio Jacinto GomezNo ratings yet

- FM-NM-002 LPPDocument2 pagesFM-NM-002 LPPphutthawongdanchai041215No ratings yet

- Metallic Tanks - Sample ITPDocument2 pagesMetallic Tanks - Sample ITPSuraj ShettyNo ratings yet

- Sub Station Structure.Document33 pagesSub Station Structure.suria qaqcNo ratings yet

- TS - S-000-1360-0002V - F9 - 0020 (Piping Line Class)Document23 pagesTS - S-000-1360-0002V - F9 - 0020 (Piping Line Class)miteshNo ratings yet

- LineClassTableF8 With Vender Piping - 20170826Document21 pagesLineClassTableF8 With Vender Piping - 20170826miteshNo ratings yet

- PDF JoinerDocument4 pagesPDF Joinerحسن كاظم ريسان B-4No ratings yet

- Afi SC03 QRBN Ci 00233Document4 pagesAfi SC03 QRBN Ci 00233حسن كاظم ريسان B-4No ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- 2021 0126 Mwci Aquagen 2021 T 0329Document16 pages2021 0126 Mwci Aquagen 2021 T 0329Mark BenjieNo ratings yet

- IndraDocument2 pagesIndravsv mnaNo ratings yet

- QA MATRIX SHEET - RadiatorDocument4 pagesQA MATRIX SHEET - RadiatorBaljeet SinghNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- Organizational APQP Responsibilities and Interfaces: ElementDocument2 pagesOrganizational APQP Responsibilities and Interfaces: ElementTutis05No ratings yet

- 4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectDocument20 pages4710-MDB-9520 FDR TO MAINT BLD SWBD-4710-RMU-9522 CUBICLE-1: LFF (Scotland) Ltd. Tco Ib Moa ProjectрусланNo ratings yet

- Bench MarkDocument1 pageBench Markhow2beliveNo ratings yet

- Innehållsförteckning/ Table of Contents: Control WiringDocument7 pagesInnehållsförteckning/ Table of Contents: Control Wiringfadhlidzil0% (1)

- CPC07E-ITP-STR-0010 Inspection and Test PlanDocument5 pagesCPC07E-ITP-STR-0010 Inspection and Test PlanMariam MousaNo ratings yet

- PP23100001P PDFDocument37 pagesPP23100001P PDFRashmi AgarwalNo ratings yet

- Revision History: 10kW Inverter Gate Driver Public Release TIDA-01606 - Gate Driver E4 TIDA-01606Document4 pagesRevision History: 10kW Inverter Gate Driver Public Release TIDA-01606 - Gate Driver E4 TIDA-01606hafizimtiazNo ratings yet

- COP5 - F06 Level 3 Audit ChecklistDocument9 pagesCOP5 - F06 Level 3 Audit ChecklistEdgar G. Sánchez A.No ratings yet

- Rfi Log 24.12.2020Document67 pagesRfi Log 24.12.2020Deepu CNo ratings yet

- Tidrqm7 PDFDocument11 pagesTidrqm7 PDFzizouhicheNo ratings yet

- PDV-22007C - MARTA FlooringDocument1 pagePDV-22007C - MARTA FlooringFERCHICHI NawelNo ratings yet

- Itp E0841-12Document4 pagesItp E0841-12Asep Barkah MuhadiNo ratings yet

- VD-LINE-906-MP-4-0004-055 - CAUSE AND EFFECT DIAGRAM - Rev.EDocument18 pagesVD-LINE-906-MP-4-0004-055 - CAUSE AND EFFECT DIAGRAM - Rev.Ehusen123 alhusadaNo ratings yet

- 64350-K60 - B600 Cover, R Under Side - DoneDocument17 pages64350-K60 - B600 Cover, R Under Side - DoneMiguel HernandezNo ratings yet

- Lab Nation Ank-523-18-19 Tech Bid PDFDocument80 pagesLab Nation Ank-523-18-19 Tech Bid PDFRadhakrishna MadabhushiNo ratings yet

- GA 33 KV VCB HT Panel - Siddharth Nagar Project. UPDocument17 pagesGA 33 KV VCB HT Panel - Siddharth Nagar Project. UPaayushNo ratings yet

- 1MNS500222-AAAC - 33kV FEEDER-2019-05-15 PDFDocument75 pages1MNS500222-AAAC - 33kV FEEDER-2019-05-15 PDFBishnu RegmiNo ratings yet

- Appendix 1 - Inspection & Test PlanDocument4 pagesAppendix 1 - Inspection & Test PlanwagwahkiabatheNo ratings yet

- R-216G-311 - 0 Manual Valve With Limit SwitchDocument3 pagesR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiNo ratings yet

- Anpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRDocument1 pageAnpqp - Component Supply Chain Chart (CSCC) : Nissan Important Part Renault - CSRjefry sitorusNo ratings yet

- Revision History: High Efficiency and Cost Cometitive 3k5 PFC Public Release TIDA-00779 E1 TIDA-00779 TIDA-00779Document4 pagesRevision History: High Efficiency and Cost Cometitive 3k5 PFC Public Release TIDA-00779 E1 TIDA-00779 TIDA-00779g4okk8809100% (2)

- Ir 02Document2 pagesIr 02Ahmad SaqqaNo ratings yet

- 132 - 33kV Trafo C&R PanelDocument55 pages132 - 33kV Trafo C&R PanelPrashant SoniNo ratings yet

- Power Board Icc20 PDFDocument4 pagesPower Board Icc20 PDFSaber AbidiNo ratings yet

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- Revision History: Ultrasonic Flow Transmitter Public Release TIDA-01486 E1 TIDA-01486 N/ADocument4 pagesRevision History: Ultrasonic Flow Transmitter Public Release TIDA-01486 E1 TIDA-01486 N/AmaddabdulNo ratings yet

- Project Timeline - Over All Project Plan - Master Template PDFDocument1 pageProject Timeline - Over All Project Plan - Master Template PDFSachin RamdurgNo ratings yet

- VDRL Pangkalan SusuDocument1 pageVDRL Pangkalan SusuAddin hanifNo ratings yet

- Ee10 SopDocument2 pagesEe10 Sopk.mehaboob bashaNo ratings yet

- Dell Inspiron N5010-AMDDocument95 pagesDell Inspiron N5010-AMDDeddy Suyanto100% (1)

- Scheme Diagram For Reserve Power Supply Line of Utf SwitchgearDocument1 pageScheme Diagram For Reserve Power Supply Line of Utf SwitchgearSivachandran RNo ratings yet

- Dell 13321-1Document104 pagesDell 13321-1Carlos Alberto Miranda PerezNo ratings yet

- Request For IMDS Data Registration of New PartDocument2 pagesRequest For IMDS Data Registration of New Partminhchi2608No ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- 3) T-30B8 - Weld Map Shell PlateDocument1 page3) T-30B8 - Weld Map Shell PlateKarthikeyan ShanmugavelNo ratings yet

- 5) T-30B8 - Weld Map Roof PlateDocument1 page5) T-30B8 - Weld Map Roof PlateKarthikeyan ShanmugavelNo ratings yet

- Appendix 3 Inspection Classes For PipingDocument2 pagesAppendix 3 Inspection Classes For PipingKarthikeyan ShanmugavelNo ratings yet

- ASME Section I and VIII-Div-1 Training Course OutlineDocument2 pagesASME Section I and VIII-Div-1 Training Course OutlineKarthikeyan ShanmugavelNo ratings yet

- Ship Loose Spools Packing DetailsDocument2 pagesShip Loose Spools Packing DetailsKarthikeyan ShanmugavelNo ratings yet

- 2) T-30B8 RT Map Bottom PlateDocument1 page2) T-30B8 RT Map Bottom PlateKarthikeyan ShanmugavelNo ratings yet

- KT-100/ KT-200 Series Ultrasonic Thickness GaugesDocument1 pageKT-100/ KT-200 Series Ultrasonic Thickness GaugesKarthikeyan ShanmugavelNo ratings yet

- Rietu To: TR TR Saving CurrentDocument2 pagesRietu To: TR TR Saving CurrentKarthikeyan ShanmugavelNo ratings yet

- Cooker ManualDocument2 pagesCooker ManualKarthikeyan ShanmugavelNo ratings yet

- ASTM ComparisonDocument1 pageASTM ComparisonKarthikeyan ShanmugavelNo ratings yet

- Iob Service Charges 01012019Document4 pagesIob Service Charges 01012019Karthikeyan ShanmugavelNo ratings yet

- Flow Chart - QCDocument2 pagesFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- ITPDocument2 pagesITPKarthikeyan Shanmugavel100% (1)

- CH4 2 Welding Joint PreparationDocument46 pagesCH4 2 Welding Joint PreparationMatija BušićNo ratings yet

- Ammonia Vaporizer ITPDocument2 pagesAmmonia Vaporizer ITPKarthikeyan ShanmugavelNo ratings yet

- Release Note For DeliveryDocument6 pagesRelease Note For DeliveryKarthikeyan ShanmugavelNo ratings yet

- Pipe and Tube Comparison and Application AreasDocument8 pagesPipe and Tube Comparison and Application AreasKarthikeyan ShanmugavelNo ratings yet

- All in One Standards Introduction PDFDocument136 pagesAll in One Standards Introduction PDFKarthikeyan ShanmugavelNo ratings yet

- Chart Hydrostatic Test ASME RenewalDocument4 pagesChart Hydrostatic Test ASME RenewalKarthikeyan ShanmugavelNo ratings yet

- Realistic Airplane Manual by Inkompetent 2018-04-04Document75 pagesRealistic Airplane Manual by Inkompetent 2018-04-04Francisco EstradaNo ratings yet

- Transonic Wind TunnelDocument3 pagesTransonic Wind TunnelKarthick Murugesan100% (1)

- Under Water WeldingDocument16 pagesUnder Water Weldingsam clastineNo ratings yet

- Parts Manual: CMP20-30L FX20-30L SF20-30LDocument117 pagesParts Manual: CMP20-30L FX20-30L SF20-30LLuiz SchwindenNo ratings yet

- Whats The Difference Between Enthalpy and EntropyDocument12 pagesWhats The Difference Between Enthalpy and EntropyShahzaib BukhariNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- MS ThesisDocument180 pagesMS ThesisvinujohnpanickerNo ratings yet

- Hydrodynamic Braking SystemDocument5 pagesHydrodynamic Braking SystemRajeev VarmaNo ratings yet

- PGM FiDocument36 pagesPGM FiJuan Sánchez LópezNo ratings yet

- DME - II Solutions I Mid Term Test 2020-21Document21 pagesDME - II Solutions I Mid Term Test 2020-21djadja nakamayaNo ratings yet

- Scaffold Design SampleDocument39 pagesScaffold Design SampleOkanga Anjichi100% (1)

- Aircraft Equipment List05200729032017 PDFDocument270 pagesAircraft Equipment List05200729032017 PDFJacob Jack YoshaNo ratings yet

- Rexroth Flush ValveDocument2 pagesRexroth Flush ValveanandsubbiahNo ratings yet

- MCQ For Exam - Advanced Machine DesignDocument7 pagesMCQ For Exam - Advanced Machine DesignUG COORDINATOR NITA MECHANICALNo ratings yet

- The Welding Journal 1958 2Document144 pagesThe Welding Journal 1958 2AlexeyNo ratings yet

- Electric 48 Volt (: 3-WHEEL/4-WHEELDocument8 pagesElectric 48 Volt (: 3-WHEEL/4-WHEELThanh Ngoc100% (1)

- HPI Catalog - Pumps - GeneralDocument131 pagesHPI Catalog - Pumps - GeneralMichi MichiNo ratings yet

- Non Metallics Inspection: B. Gray, B.Sc. Feb 2012Document26 pagesNon Metallics Inspection: B. Gray, B.Sc. Feb 2012HAMZANo ratings yet

- New Holland CR9040, CR9060, CR9070 Combine Service Repair ManualDocument31 pagesNew Holland CR9040, CR9060, CR9070 Combine Service Repair ManualggjjjjotonesNo ratings yet

- Uponor Infrastructure: Uponor Gravity Sewer SystemsDocument20 pagesUponor Infrastructure: Uponor Gravity Sewer Systemsarjun 11No ratings yet

- Beams and ReactionsDocument42 pagesBeams and ReactionsbackuponecolosoNo ratings yet

- Culvert 1Document104 pagesCulvert 1rahulgehlot2008No ratings yet

- Test 2 DJJ50203 Sesi I-23-24Document4 pagesTest 2 DJJ50203 Sesi I-23-24AmmarNo ratings yet

- The Biomechanics of Kicking in Soccer: A Review: A. Lees, T. Asai, T. B. Andersen, H. Nunome, & T. SterzingDocument14 pagesThe Biomechanics of Kicking in Soccer: A Review: A. Lees, T. Asai, T. B. Andersen, H. Nunome, & T. SterzingFikri ZainuriNo ratings yet

- Chapter 4 - Motion in A PlaneDocument30 pagesChapter 4 - Motion in A PlaneHakim Abbas Ali PhalasiyaNo ratings yet

- Cabezal Cole Parmer 07519-20Document67 pagesCabezal Cole Parmer 07519-20hexapodo2No ratings yet

- Pulsar LS 135 TRG Note Final - 24.11 PDFDocument47 pagesPulsar LS 135 TRG Note Final - 24.11 PDFALISSON ANDREA RODRIGUEZ RODRIGUEZ100% (1)

- Utility Services in Process PlantsDocument25 pagesUtility Services in Process PlantsAulia RahmadsyahNo ratings yet

- 683 Mastercopy SparepartsDocument517 pages683 Mastercopy SparepartsмаргаритаNo ratings yet