Professional Documents

Culture Documents

Bait Boat Plans 3

Bait Boat Plans 3

Uploaded by

sebi270Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bait Boat Plans 3

Bait Boat Plans 3

Uploaded by

sebi270Copyright:

Available Formats

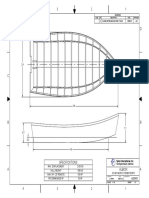

Bait Boats - Hull Construction

Plans

The first stage of the build process is to construct the hull. You will need a sheet of

6mm plywood that measure's 4'x 2'. Mark out all of the panel's needed to construct

the hull and cut them out. The measurements for these panels are on the plans,

which accompany this article. When cutting the base panel, cut the front edge at 45

degree's. Do the same on the top and bottom edge of the front panel of the hull. This

will create a neat joint, where the front join's the base. SEE PIC. Sand all edge's to

remove any splinter's of ply.

To fasten all of the panel's of the hull together, you will need a fibre glass kit, you

can get these from Halfords / B&Q / Motor world even some model shops. You will

also need a roll of duck tape or gaffer tape 2 inches wide. Place the base panel of

the hull on a flat workbench, and starting with one of the side panels. Tape a long

the outside of the joint, making sure the joint is as tight a possible, then the rear

panel/other side panel and finally the front panel, ensuring all the out side joint's are

sealed. SEE PIC.

Once this is completed and the hull the right way up. Get the fibre glass tissue/matting out of the kit and cut into

2inch wide strip's, and 2 inch longer than each of the joint's. Now mix up the resin as directed by the

manufacturer's of the kit. NOTE! GOES OFF IN ABOUT TEN MINUTES! So don't mix up too much in one go.

Now paint a joint inside the hull, then lay on your first piece of tissue ensuring the joint is in the center of the

tissue. Then dab on resin till tissue is completely soaked, ensuring you push it well into the joint. Do this to all

remaining joint's.

Once resin is touch dry repeat process, this time using matting, if you like you can

do this again to strengthen the joint's more. When everything is dry you can remove

tape from the outside joints and trim off any fiberglass that stick's out above top of

hull. Any small gaps in the outside joint's can be filled with Milliput. PIC SHOWS

THE GLASSED JOINTS.

Right you should now have a hull in its raw state, turn the hull upside down and draw a line straight down the

center from front to back. 35mm in from the rear of the hull, on the centerline drill an 8mm hole; this is to take

the rudder assembly. The next thing to do is! Starting 5 inches from the rear of the hull a long centerline cut a

slot 8mm wide by 35mm long to take the prop-shaft.

You might also like

- Zbook Affordaplaneupdatespackage2019 29000Document60 pagesZbook Affordaplaneupdatespackage2019 29000AlanNo ratings yet

- AWWA-AWWA D121-2014 GRP Bolted Water Storage TanksDocument89 pagesAWWA-AWWA D121-2014 GRP Bolted Water Storage TanksvirtechNo ratings yet

- Gassers For Newbies-8Document21 pagesGassers For Newbies-8Gary Hoffman100% (1)

- Open 5.70 User GuideDocument30 pagesOpen 5.70 User GuideOpen Sailing, Inc100% (1)

- Kitchen Rudders Going Full CircleDocument24 pagesKitchen Rudders Going Full CircleClyde Steamers100% (1)

- B&O M53 Wagontop Box Instructions - HODocument13 pagesB&O M53 Wagontop Box Instructions - HOJessica AllenNo ratings yet

- Berthelot SF 98 99 175 181 PDFDocument620 pagesBerthelot SF 98 99 175 181 PDFferroburakNo ratings yet

- Notice: Spira International, IncDocument2 pagesNotice: Spira International, Incidix bloodjackersNo ratings yet

- WH 2place ManualDocument5 pagesWH 2place ManualJessie O.BechaydaNo ratings yet

- Building The Osborne PlatterDocument9 pagesBuilding The Osborne PlatterHeman Lee50% (2)

- One Sheet SampanDocument5 pagesOne Sheet Sampanleather_nunNo ratings yet

- Lift System Calculator For HovercraftDocument5 pagesLift System Calculator For HovercraftRafaa Dalvi100% (1)

- Arvel Gentry - Studies of Mast Section AerodynamicsDocument10 pagesArvel Gentry - Studies of Mast Section AerodynamicsklzsailingNo ratings yet

- International Moth HydrofoilDocument20 pagesInternational Moth HydrofoilMorgan Rook100% (1)

- (NIIR) Phenolic Resins Technology HandbookDocument5 pages(NIIR) Phenolic Resins Technology HandbookHuỳnh TG0% (1)

- European Design Guide For Surface Tensile StructuresDocument12 pagesEuropean Design Guide For Surface Tensile StructuresHenry Zumaeta0% (1)

- Pipe and Mechanical Insulation BrochureDocument40 pagesPipe and Mechanical Insulation BrochuresleonNo ratings yet

- Mineral Wool CharacteristicsDocument14 pagesMineral Wool Characteristicsminsara madtNo ratings yet

- Polymer Matrix CompositesDocument121 pagesPolymer Matrix CompositesHitesh Shah100% (7)

- Pippie8Tender PDFDocument32 pagesPippie8Tender PDFleonel montillaNo ratings yet

- Bevin Skiff Building ManualDocument54 pagesBevin Skiff Building ManualKevin WilliamsNo ratings yet

- Amazing Hydroski-Foil PDFDocument3 pagesAmazing Hydroski-Foil PDFfrannetoNo ratings yet

- BlondieDocument21 pagesBlondieOmar Valencia CastillónNo ratings yet

- Happy Clam SkiffDocument11 pagesHappy Clam SkifffccfNo ratings yet

- ConfuciusDocument12 pagesConfuciusCarlos Emanuel Gomes Sousa100% (1)

- Coarse, Carp, Fly & Sea Fishing Tackle: Saturday 17th March 2018Document16 pagesCoarse, Carp, Fly & Sea Fishing Tackle: Saturday 17th March 2018Sorin MaleaNo ratings yet

- Motor Boats & Launch CatalogueDocument98 pagesMotor Boats & Launch CatalogueDeganchileNo ratings yet

- US6182619Document11 pagesUS6182619engine wang100% (1)

- AWKDocument14 pagesAWKMcMgNo ratings yet

- Study Plans For A Small Outboard Powered BoatDocument4 pagesStudy Plans For A Small Outboard Powered BoatjancudakNo ratings yet

- Herring SkiffDocument8 pagesHerring SkifflcortezbrNo ratings yet

- Sailing Canoe PlansDocument26 pagesSailing Canoe PlansJoao CalinhoNo ratings yet

- Saint Ayles SkiffDocument8 pagesSaint Ayles Skiffjimmy_wood0% (1)

- Max JonDocument2 pagesMax Jontwinscrewcanoe100% (1)

- 15 Foot SailboatDocument4 pages15 Foot SailboatAntónio OliveiraNo ratings yet

- Ferro Cement 2Document22 pagesFerro Cement 2Abhishek DorugadeNo ratings yet

- Planuri GyrocopterDocument21 pagesPlanuri GyrocopterDRAGOS BILGANo ratings yet

- Le Ptit GrosDocument10 pagesLe Ptit GrosKeith Williams100% (1)

- Sea HawkDocument19 pagesSea HawkAlphamatrix01100% (2)

- K&H Em-3360-3a PDFDocument2 pagesK&H Em-3360-3a PDFaswardiNo ratings yet

- Gyro GliderDocument3 pagesGyro GliderEmerson UR100% (1)

- Skoota 24 Studyplan 197Document11 pagesSkoota 24 Studyplan 197Dragana LekicNo ratings yet

- D4 Barca PlanDocument12 pagesD4 Barca PlanfirebirdsNo ratings yet

- Sunforce Solar Motion Light ManualDocument4 pagesSunforce Solar Motion Light Manual21st-Century-Goods.com100% (1)

- Gunter Mast Gaff Boom Bermuda RigDocument5 pagesGunter Mast Gaff Boom Bermuda RigRazook K SNo ratings yet

- Kepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SphereDocument34 pagesKepler Bottom Bracket Friction Drive For Sale (Finally) - Endless SpheregiacummoNo ratings yet

- Design and Build Dinghy Manual 2020Document78 pagesDesign and Build Dinghy Manual 2020Joao Calinho100% (2)

- Wilkinson - Building Wooden BoatsDocument12 pagesWilkinson - Building Wooden BoatsAna Isabel MarquezNo ratings yet

- Cal 20 Owners ManualDocument33 pagesCal 20 Owners ManualWil StuckeyNo ratings yet

- Kayak PlansDocument72 pagesKayak PlansAgnaldo AraujoNo ratings yet

- Plywood Hull ConstructionDocument15 pagesPlywood Hull ConstructionlavrikNo ratings yet

- How To Build A Foam Sandwich Composite Boat PDFDocument47 pagesHow To Build A Foam Sandwich Composite Boat PDFluisimtz100% (1)

- Clark Y Airfoil PDFDocument1 pageClark Y Airfoil PDFAziz Fahrur50% (2)

- Duck SkiffDocument61 pagesDuck SkiffKay Pratt100% (2)

- FM5 25 (1959)Document240 pagesFM5 25 (1959)Sajarah ZacariaNo ratings yet

- BrockwayfullDocument38 pagesBrockwayfullrajagula100% (1)

- Mistral HullDocument5 pagesMistral HullmikeNo ratings yet

- A 15'8" Fishing Punt: Start of The DiscussionDocument21 pagesA 15'8" Fishing Punt: Start of The DiscussionArmando GumucioNo ratings yet

- Soda Can Alcohol Stove PDFDocument2 pagesSoda Can Alcohol Stove PDFLéo BatistaNo ratings yet

- Vertical Axis Hydrokinetic Turbines: Numerical and Experimental Analyses: Volume 5From EverandVertical Axis Hydrokinetic Turbines: Numerical and Experimental Analyses: Volume 5No ratings yet

- Allplan 2016 SBS GeodesyDocument130 pagesAllplan 2016 SBS Geodesysebi270No ratings yet

- Bizhub c650 c550 c451 c353 c253 c203 I-Option 2-1-0 enDocument118 pagesBizhub c650 c550 c451 c353 c253 c203 I-Option 2-1-0 ensebi270No ratings yet

- Allplan 2015 SBS UrbanPlanningDocument169 pagesAllplan 2015 SBS UrbanPlanningAna Mocanu100% (2)

- Elite-7x: Operation ManualDocument0 pagesElite-7x: Operation Manualsebi270No ratings yet

- 6exp ManualDocument37 pages6exp ManualMohamed SamirNo ratings yet

- Non Metallic Materials Used For Machine Elements2Document42 pagesNon Metallic Materials Used For Machine Elements2RajanikantJadhavNo ratings yet

- Selecting A Homebuilt Design 03Document4 pagesSelecting A Homebuilt Design 03YvessNo ratings yet

- 12-MGDP-T-1037-0 (Spec For Fiber Optic Cable)Document32 pages12-MGDP-T-1037-0 (Spec For Fiber Optic Cable)cherif yahyaouiNo ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Ameron 2000m and 7000mDocument28 pagesAmeron 2000m and 7000mhadrijkNo ratings yet

- (UAV) - Building A Composite AircraftDocument5 pages(UAV) - Building A Composite AircraftVany BraunNo ratings yet

- Heydaraliyevculturalcentre 180131094714 PDFDocument23 pagesHeydaraliyevculturalcentre 180131094714 PDFSoundarya SuryaNo ratings yet

- Pulse Jet Filter Operation and Maintenance Manual: 312 SOUTH HWY. 73, PO BOX 398 FALLS CITY, NE 68355-0398 800-500-9777Document31 pagesPulse Jet Filter Operation and Maintenance Manual: 312 SOUTH HWY. 73, PO BOX 398 FALLS CITY, NE 68355-0398 800-500-9777Kartik Mendiratta100% (1)

- Research Proposal 1 PDFDocument5 pagesResearch Proposal 1 PDFMunem BushraNo ratings yet

- Finite Element Modeling of RC Beams Strengthened in Flexure Using FRP MaterialDocument12 pagesFinite Element Modeling of RC Beams Strengthened in Flexure Using FRP MaterialCu ToànNo ratings yet

- Thermo Lite BoardDocument1 pageThermo Lite BoardRamon SellersNo ratings yet

- Nema FG 1 PDFDocument23 pagesNema FG 1 PDFgilbertomjcNo ratings yet

- Rubberdam YOOIL BrochureDocument10 pagesRubberdam YOOIL BrochureAbhishek RajputNo ratings yet

- ELECTROSTOPDocument12 pagesELECTROSTOPJagdeesh ShettyNo ratings yet

- Report - 1cumberland Close - Balcony FRPDocument19 pagesReport - 1cumberland Close - Balcony FRPYousifNo ratings yet

- Tranquil - Product CatalogueDocument36 pagesTranquil - Product CatalogueAmit KhandelwalNo ratings yet

- Advanced CompositesDocument11 pagesAdvanced CompositessreeramNo ratings yet

- Mechanical Properties and Optimization of Processing Parameters For Epoxy Glass Fiber Reinforced CompositesDocument4 pagesMechanical Properties and Optimization of Processing Parameters For Epoxy Glass Fiber Reinforced CompositesNavid HoseiniNo ratings yet

- Winding Insulation and MaintenanceDocument11 pagesWinding Insulation and MaintenanceYogananda Madhava SettyNo ratings yet

- Aruba 1999 EnglishDocument20 pagesAruba 1999 Englishlstrector2008No ratings yet

- Aircraft Structure Design PrinciplesDocument28 pagesAircraft Structure Design PrinciplesVenugopal Krishna0% (1)

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Document168 pages(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- GRP Tanks CatalogueDocument16 pagesGRP Tanks Cataloguepipeco saleemNo ratings yet