Professional Documents

Culture Documents

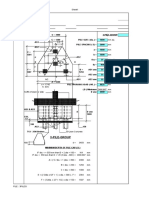

STP Rusayl Oman: Double Shell Combined Circular Tank

STP Rusayl Oman: Double Shell Combined Circular Tank

Uploaded by

RahulOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

STP Rusayl Oman: Double Shell Combined Circular Tank

STP Rusayl Oman: Double Shell Combined Circular Tank

Uploaded by

RahulCopyright:

Available Formats

STP RUSAYL OMAN Double shell Combined Circular Tank 12/07/2018

Structural Concrete grade fck= 25 MPa

Reinforcement grade fy= 415 MPa

Modulus of Elasticity of steel Es = 2.00E+05 Mpa

Modulus of Elasticity of concrete Ec = 25000 Mpa Modular ratio a= 11.200

Section width b= 1000 mm

Section depth D= 275 mm

Vertical Flexure Design

Proposed Bar-dia f= 12 mm

Spacing of reinforcement s= 150 mm

Clear cover c= 25 mm Eff Depth de= 244 mm

Bending Moment on section, @ service loads M= 40 KN-m

Bending Moment on section, factored M= 60 KN-m

Compute K for vertical BM K= 0.0403117 < 0.156

Compute z/d z/d= 0.9530002 > 0.95, Hence ADOPT 0.95

Compute area of steel for Vert BM Asvreqd= 716.92 sq mm

Area of tensile reinforcement proposed to be provided As= 754.0 sq mm Reinf Ratio p= 0.00309

Crack-width calculation

Vertical crack-width

Compute x/d, NA ratio at service condition x/d= 0.2307508 Compute x x= 56.30 mm

Compute z/d, LA ratio at service condition z/d= 0.9230831 Compute z z= 225.23 mm

D-x = 218.70 mm

de-x = 187.70 mm

Compute stress in tensile reinforcement, at service load M/(As x z) = 235.54195 Mpa

Compute Strain in steel es = 0.0011777

Compute Strain at concrete surface e1 = 0.0013722

Stiffening effect (strain) e2 = 0.000563 Net strain at level of cracking em = 0.000809

Compute maximum crack dist from nearest bar-surface acr= 75.15 mm

Compute crack-width in flexure wcrm= 0.1250 mm < 0.20 mm Flexure-Crack controlled

Compute minimum steel for crack distribution rcrit= 481.25 sq mm

Spacing required for the above steel area s= 235.00745 mm Bar-Spg provided OK

Horizontal crack-widths

Proposed Bar-dia f= 10 mm

Spacing of reinforcement s= 110 mm

Clear cover c= 40 mm Eff Depth de= 230 mm

Area of tensile reinforcement proposed to be provided, each face As= 714.0 sq mm Reinf Ratio p= 0.00310

Input stress-ratio fct/fb fct/fb= 0.6666667

Input Restraint factor R= 0.50

Input coeff of thermal expansion a= 0.000012 /deg C

Input design temp-variation T1= 30 deg C

Compute crack-width due to temp-variation wcrt1= 0.193 mm < 0.20 mm Thermal Cracking controlled

Direct tension in wall Ft= 580 KN

(Check For Limit state of ultimate strength in direct tension)

Area of steel required for Direct tension, for ultimate strength AsDT= 2248.996 sq mm

Area of steel required for Direct tension, each face Asdtf= 1124.498 sq mm

Check by calculating crack-width for Direct tension in wall

Area of steel proposed to be provided for Direct tension AsDT,pr= 1428.00 sq mm Satisfies LS of Ult strength

Stress in horizontal steel provided s= 406.16 MPa

Corresponding Strain in steel e1 = 0.002031 <= (Max strain= 0.001660

Stiffening effect e2 = 0.000642

Net strain em = 0.001389

acr= 66.06 mm

Crack-width due to direct horizontal tension cw= 0.28 mm > 0.20 mm REVISE

Min steel required for Direct tension, each face Asmin= 618.75 sq mm

Spacing required for the above steel area s= 127 mm Spg provided OK

Area of steel actually being provided, each face As= 714.0 sq mm Steel provided OK

You might also like

- Trial ExcelDocument15 pagesTrial ExcelCyndrille John BragatNo ratings yet

- Design of Cable Trench - R0Document17 pagesDesign of Cable Trench - R0RahulNo ratings yet

- Proholz Cross-Laminated Timber Structural Design PDFDocument191 pagesProholz Cross-Laminated Timber Structural Design PDFWilian LiNo ratings yet

- Thumb Rules For Structural DesignDocument3 pagesThumb Rules For Structural DesignRajesh Mary75% (4)

- CWT - Roof Flat Slab & BaseDocument31 pagesCWT - Roof Flat Slab & BaseNaziemi AhmadNo ratings yet

- Column Loading:: Distribution of Load On Individual Pile of A Pile GroupDocument16 pagesColumn Loading:: Distribution of Load On Individual Pile of A Pile GroupWRay TanNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- 09 bs8007 CrackwidthDocument11 pages09 bs8007 CrackwidthMUTHUKKUMARAMNo ratings yet

- DESIGN CalculationDocument47 pagesDESIGN CalculationZayyan Romjon100% (2)

- Project Flat SlabDocument4 pagesProject Flat SlabRahul Harsha ThatiNo ratings yet

- Design of Cast in Situ Box Culvert (1.5x1.5) Without Earth CushionDocument2 pagesDesign of Cast in Situ Box Culvert (1.5x1.5) Without Earth CushionshashiNo ratings yet

- D.2.1 Design of Two Way Roof Slab (Between A-B & 7-8) DataDocument9 pagesD.2.1 Design of Two Way Roof Slab (Between A-B & 7-8) DatamohanNo ratings yet

- Pump House Wall Outer: Design of Wall Using Moody's Chart (Design Is Based Upon Limit State Method)Document35 pagesPump House Wall Outer: Design of Wall Using Moody's Chart (Design Is Based Upon Limit State Method)amit_halcrowNo ratings yet

- SumpDocument3 pagesSumpChong Chee YenNo ratings yet

- Continous Composite Beam13Document27 pagesContinous Composite Beam13Matthew ChinNo ratings yet

- Slab Design of Partially Fixed Circular SlabDocument4 pagesSlab Design of Partially Fixed Circular SlabBithika DattaNo ratings yet

- Load Calculation: Static Water PressureDocument18 pagesLoad Calculation: Static Water PressureSheikh Mizanur RahmanNo ratings yet

- Purlin Design (YCP 1020) : Table 7 CL 4.2.3Document2 pagesPurlin Design (YCP 1020) : Table 7 CL 4.2.3JONAS NGNo ratings yet

- PIle FoundationDocument6 pagesPIle FoundationsaravananNo ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- Design-Pad-Chimney-Foundation-1 For Tower SUTETDocument42 pagesDesign-Pad-Chimney-Foundation-1 For Tower SUTETBonnico NicoNo ratings yet

- Slab DesignDocument1 pageSlab DesignFarshad perouzNo ratings yet

- DGHDGDocument2 pagesDGHDGjude100% (1)

- ACI Column Design - V1.01Document38 pagesACI Column Design - V1.01Ibrahim El SharNo ratings yet

- Column Design 1Document9 pagesColumn Design 1shamen amarasekaraNo ratings yet

- Steel Beam DesignDocument36 pagesSteel Beam DesignTan Choon LengNo ratings yet

- Two Way Slab - IS Code - LSMDocument12 pagesTwo Way Slab - IS Code - LSMNitesh SinghNo ratings yet

- Design of Foundation: Design Inputs 120.5 KN 1247.1 KN 127.1 KNDocument7 pagesDesign of Foundation: Design Inputs 120.5 KN 1247.1 KN 127.1 KNprince francisNo ratings yet

- Strong Col Weak BeamDocument2 pagesStrong Col Weak BeamlaxmiNo ratings yet

- Design of Flash Mixer at Kurawar - 1ADocument13 pagesDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWNo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Combined Footing SalinDocument30 pagesCombined Footing SalinSujan SinghNo ratings yet

- Thursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlDocument3 pagesThursday, June 20, 2019, 07:28 AM: Page 1 of 226 E:/Kuliah/Semester IV/PBTS/Tugas Besar/YI - AnlRyandhon GyandhaniNo ratings yet

- Design of Footing For Corner ColumnDocument4 pagesDesign of Footing For Corner ColumnMegatech Engineering ConsultantsNo ratings yet

- Combined FootingDocument480 pagesCombined FootingAnonymous HJ7hmihhNo ratings yet

- Column SlenderDocument11 pagesColumn SlenderchaNo ratings yet

- Valve Pit (2.5X2.5)Document8 pagesValve Pit (2.5X2.5)rachanaNo ratings yet

- Project by Location: Girting Design ADocument10 pagesProject by Location: Girting Design AJurie_sk3608No ratings yet

- Retaining Wall 2Document124 pagesRetaining Wall 2shaikh ismailNo ratings yet

- 1.SHEAR (Or) MOMENT CONNE-GENERALDocument272 pages1.SHEAR (Or) MOMENT CONNE-GENERALbalaNo ratings yet

- BS Ref Calculation Remarks: Purlins DesignDocument7 pagesBS Ref Calculation Remarks: Purlins DesignHauzhiNo ratings yet

- IBC 2006 and ASCE 7-05Document1 pageIBC 2006 and ASCE 7-05Omar RubioNo ratings yet

- Pile RectifyingDocument2 pagesPile RectifyingAnonymous O404LiV4CNo ratings yet

- Bukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementDocument4 pagesBukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementazwanNo ratings yet

- MEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDDocument3 pagesMEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDAlisa Jane TuboroNo ratings yet

- Shear Wall Design-ManualDocument55 pagesShear Wall Design-ManualDhana SekaranNo ratings yet

- Coupling Beam Steel PlateDocument2 pagesCoupling Beam Steel PlateShashankSinghNo ratings yet

- Indian Concrete CodeDocument25 pagesIndian Concrete CodePiv0terNo ratings yet

- Design of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Document4 pagesDesign of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Prasad SamantNo ratings yet

- Design of Cantilever Slab As Per Is 456 2000Document2 pagesDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- Coupling BeamDocument5 pagesCoupling BeamjanethNo ratings yet

- Known Data: H Z 2 I R S GDocument6 pagesKnown Data: H Z 2 I R S GUjol PraNo ratings yet

- Column & FootingDocument32 pagesColumn & FootingAmol potdarNo ratings yet

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNo ratings yet

- BEAMDESIGN XLSMDocument4 pagesBEAMDESIGN XLSMSaurabh PednekarNo ratings yet

- 408010745-Rigid-Pavement-xls CopiedDocument17 pages408010745-Rigid-Pavement-xls CopiedrajNo ratings yet

- Input Data: Top Slab DesignDocument7 pagesInput Data: Top Slab DesignRameez Ahmed AbbasiNo ratings yet

- Design of BearingsDocument24 pagesDesign of BearingsFarrukh RizwanNo ratings yet

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Document2 pagesAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Beam1 Working StressDocument36 pagesBeam1 Working Stresssoumi bhattacharyaNo ratings yet

- Limit State Design of Tank With Crack Check - 03.02.2020.Document14 pagesLimit State Design of Tank With Crack Check - 03.02.2020.monaliNo ratings yet

- Corbel DesignDocument3 pagesCorbel DesignLim EcNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Seismic Load Sprectrum - ProjectDocument13 pagesSeismic Load Sprectrum - ProjectRahulNo ratings yet

- Welding DevelopDocument101 pagesWelding DevelopRahulNo ratings yet

- Imp Design GuideDocument32 pagesImp Design GuideRahulNo ratings yet

- Welding of Girders To Insert Plates of Composite Steel-Concrete StructureDocument8 pagesWelding of Girders To Insert Plates of Composite Steel-Concrete StructureRahulNo ratings yet

- Design of TankDocument22 pagesDesign of TankRahul100% (2)

- Wing Wall Design-FinalDocument25 pagesWing Wall Design-FinalRahulNo ratings yet

- Design Calculations For Bottom RaftDocument3 pagesDesign Calculations For Bottom RaftRahulNo ratings yet

- Safety Factor Foundation - EnglishDocument2 pagesSafety Factor Foundation - EnglishRahulNo ratings yet

- SWD Aci 318 19Document86 pagesSWD Aci 318 19Mike SmithNo ratings yet

- Beam To Col WebDocument10 pagesBeam To Col WebAlma M. LaraNo ratings yet

- Evaluation and Modification of Open-Web Steel Joists and Joist GirdersDocument41 pagesEvaluation and Modification of Open-Web Steel Joists and Joist GirdersCharlie HNo ratings yet

- Nominal CoverDocument2 pagesNominal CoverselinaNo ratings yet

- Construction Technology & Material - VII: B.Arch. Seventh Semester (C.B.S.)Document1 pageConstruction Technology & Material - VII: B.Arch. Seventh Semester (C.B.S.)Megha PanchariyaNo ratings yet

- Eca Euniflow 700Document2 pagesEca Euniflow 700Ahmed aalatbeeyNo ratings yet

- Data - Sheet Non Shrink Precision Grout 1585 00Document2 pagesData - Sheet Non Shrink Precision Grout 1585 00dennis_dizon_6No ratings yet

- Rigid Pavement Versus Flexible Pavement of Roads/HighwaysDocument5 pagesRigid Pavement Versus Flexible Pavement of Roads/HighwaysJowell Leshner NavarroNo ratings yet

- BOQ of Screen House For Saplings For KathmanduDocument1 pageBOQ of Screen House For Saplings For Kathmanduavs kfleNo ratings yet

- Voided Biaxial Slabs - State of Art: IOP Conference Series: Earth and Environmental ScienceDocument10 pagesVoided Biaxial Slabs - State of Art: IOP Conference Series: Earth and Environmental ScienceShinde vishalNo ratings yet

- Industrial Shed DBRDocument25 pagesIndustrial Shed DBRAkarshGowda100% (2)

- Odisha Plinth Area Rate 2019Document2 pagesOdisha Plinth Area Rate 2019Sabyasachi Naik (Zico)100% (10)

- Btech 1 M1Document12 pagesBtech 1 M1corbitecoNo ratings yet

- Millau BridgeDocument28 pagesMillau BridgeTamour KhalilNo ratings yet

- Plastic ... Chap..5Document61 pagesPlastic ... Chap..5ABAMELANo ratings yet

- Precast Segmental Concrete BridgesDocument2 pagesPrecast Segmental Concrete BridgesmemomsmNo ratings yet

- BOM (Bolt, Nut & Washer) Silo Stair TowerDocument6 pagesBOM (Bolt, Nut & Washer) Silo Stair TowerIlham KelanaNo ratings yet

- Introduction To Plate BucklingDocument22 pagesIntroduction To Plate BucklingCharles AjayiNo ratings yet

- Shanghai TowerDocument11 pagesShanghai TowerErik Nevala-LEe50% (2)

- Cables & Arches NotesDocument2 pagesCables & Arches NotesHamza MujahidNo ratings yet

- 1.0 Design of Bottom Block and Lifting Beam: Sketch of Bottom BlockDocument5 pages1.0 Design of Bottom Block and Lifting Beam: Sketch of Bottom Blockjanapati venkateswarluNo ratings yet

- No199 - Proceedings of Eurosteel 1999Document719 pagesNo199 - Proceedings of Eurosteel 1999Nuno Telmo LopesNo ratings yet

- Royal Institution of Surveyors Malaysia Building Cost Information CentreDocument1 pageRoyal Institution of Surveyors Malaysia Building Cost Information CentreaihusnaNo ratings yet

- Is SP 21 2005 PDFDocument929 pagesIs SP 21 2005 PDFAamaniVeeranamNo ratings yet

- This Site: Lot Area 125 SQMDocument1 pageThis Site: Lot Area 125 SQMFrancis Lloyd MalganaNo ratings yet

- Method Statement Tiling WorksDocument8 pagesMethod Statement Tiling WorksNara Kong100% (2)

- Design of Slabs For ResidentialDocument12 pagesDesign of Slabs For ResidentialWilbert ReuyanNo ratings yet

- Explicit Dynamic Behaviour of Textile Reinforced Concrete Retrofitted RC Column Under Blast LoadDocument35 pagesExplicit Dynamic Behaviour of Textile Reinforced Concrete Retrofitted RC Column Under Blast LoadBlessy V XavierNo ratings yet