Professional Documents

Culture Documents

Kaushik Shah Date: 2011 Form 001 - Format C

Kaushik Shah Date: 2011 Form 001 - Format C

Uploaded by

sriramOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kaushik Shah Date: 2011 Form 001 - Format C

Kaushik Shah Date: 2011 Form 001 - Format C

Uploaded by

sriramCopyright:

Available Formats

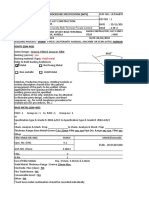

Koch Chemical Technology Group India Pvt. Ltd.

315-317 Sakarda Bhadarva Road, Moxi, Tal.Savli, Baroda-391780

Welding Procedure Specification (WPS)

WPS No.: 08 Date: 07-05-2001 Rev. No.: 02 Date: 01-03-2013 Page 1 of 2

Supporting PQR(s): 08 ; 59

Welding Process(es) / Type(s): (1) GTAW / Manual

Joint Design (QW-402)

Weld Type: Groove and fillet welds

Joint Type Backing Root Opening Groove Angle Root Face Groove Radius

Single-V groove Gouged & back welded. 3mm max 50 deg min 2 mm max

Double-V groove Gouged & back welded. 3mm max 50 deg min 2 mm max

Single-bevel groove Gouged & back welded. 3mm max 45 deg min 2 mm max

Double-bevel groove Gouged & back welded. 3mm max 45 deg min 2 mm max

Square groove Gouged & back welded. 3mm max

Square groove T-Joint. -----

Fillet Welds: All fillet sizes on all base metal thicknesses and all diameters.(QW-451.4)

Retainers: None

All complete joint penetration, requiring double sided welding shall be ground or gouged to sound weld metal prior to welding the reverse

side.

WELD JOINT DESCRIPTIONS SHOWN ARE NOT INCLUSIVE OF ALL THOSE FOUND ON A JOB. WELD JOINT DESIGN REFERENCE IN AN

ENGINEERING SPECIFICATION OR A DESIGN DRAWING SHALL TAKE PRECEDENCE OVER WELD JOINTS SHOWN IN THIS WPS.

Base Metals (QW-403)

P-No. 8 Group No. 1 Thickness Range: 1.5 mm to 12.0 mm

to P-No. 8 Group No. 1

Preheat (QW-406) Postweld Heat Treatment (QW-407)

Minimum Preheat Temperature: 10 °C PWHT Type: No PWHT will be performed

Maximum Interpass Temperature: 175 °C PWHT Temperature : None °C

Preheat Maintenance: None PWHT Holding Time: None

Minimum preheating temperature shall be maintain during, tacking,

thermal cutting and welding operation.

Initial and Interpass Cleaning: with wire brush and/or grinding as required.

Method of Back Gouging: By grinding, ground or gauged to sound weld metal

Initial Cleaning:With wire brush or grinding clean 25 mm on both the sides of weld joint prior to welding, as required.

Inter pass cleaning: By grinding or wire brush clean all oxide, slag and other foreign particle after every inter pass welding, as required.

Use alumina or silicon carbide wheel for grinding and stainless steel wire brush for cleaning that is un used previously on carbon or low alloy

steel.

When welding is completed, remove all spatter, slag and/or projection.

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Code.

Prepared By: 01-03-2013 Asst. Manager QA

Kaushik Shah Date

2011 Form 001 - Format C

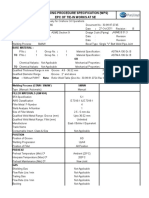

Koch Chemical Technology Group India Pvt. Ltd.

Welding Procedure Specification (WPS)

WPS No.: 08 Rev. No.: 02 Page 2 of 2

First Process: GTAW Type: Manual

Filler Metal (QW-404)

Weld Deposit Limits: 12.0 mm maximum

AWS Classification: Opt Note Table-1 SFA Specification: 5.9 F-No.: 6

A-No. or Chemical Composition: 8

Filler Metal Product Form: Bare (Solid)

Consumable Insert: None GTAW Flux: None

Position (QW-405) Technique (QW-410)

Position of Joint: All Positions Stringer or Weave Bead: Stringer and weave bead

Weld Progression: Vertical up Nozzle / Gas Cup Size: 9.5mm to 16mm

Gas (QW-408) Peening: None

Shielding: 99.996% Argon / 7-12 L/min Multiple / Single Pass (per side): Single or multipass

Backing: None / - L/min

Trailing: None / - L/min

Electrical Characteristics (QW-409)

Current Type and Polarity: DCEN (straight)

Pulsed Current: Allowed

Tungsten Type: EWTh-2 Size: 2.4mm Dia.

Max. Heat Input (J/mm): None

High frequency circuit will be used for starting the arc for all GTAW process.

Pulsating current may be used for this process, if allowed by customer.

First Process Welding Parameters

Layer(s) Filler Metal Current Travel Speed

and/or AWS Size Type and Amperage Voltage Range

Pass(es) Classification (mm) Polarity Range Range (mm/min)

Any Opt Note Table-1 1.6 DCEN (straight) 70-150 n/r Var.

Any Opt Note Table-1 2.4 DCEN (straight) 80-180 n/r Var.

Any Opt Note Table-1 3.2 DCEN (straight) 130-275 n/r Var.

Any Opt Note Table-1 4.8 DCEN (straight) 200-375 n/r Var.

Notes

Material condition: Welding shall not be performed when the material surface is wet or damp. Work must be free from oxides, dirt, oil and

moisture.

Autogenous welding is not allowed. Filler metal is required for this welding process.

Shielding gases used in welding processes meet industry requirements for welding gas purity and moisture content. (Requirements for welding

gas with higher purity and lower moisture content can be accommodated by special request.)

No supplementary filler metal, alloying elements, retainers or consumable inserts used with this procedure.

No peening will be done by this process.

Weld Maps are submitted with equipment drawings specifying where this WPS will be applied. Refer to the supplied filler metal for joint types

and weld information as it will be applied to the equipment for the order.

Table-1: per ASME Section IX QW-404.4 and QW-404.5 the following filler base metal application will be allowed.

Filler Metal Base Metal Filler Metal Base Metal

ER308/ER308L 304 ER308L 304L

ER308H 304H ER316/ER316L 316

ER316L 316L ER317/ER317L 317

ER317L 317L ER347 321

ER347 347

2011 Form 001 - Format C

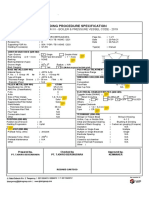

Koch Chemical Technology Group India Pvt. Ltd.

315-317 Sakarda Bhadarva Road, Moxi, Tal.Savli, Baroda-391780

Procedure Qualification Record (PQR)

PQR No.: 08 Date: 07-05-2001 WPS No.: 08 Page 1 of 2

Welding Process(es) / Type(s): (1) GTAW / Manual

Joint Design (QW-402) Base Metals (QW-403)

Weld Type: Groove weld Specification Type and Grade:

Groove Type: Single-V groove SA-240, Type 304 to SA-240, Type 304

Backing: Back-gouged and back welded P-No. 8 Group No. 1 to P-No. 8 Group No. 1

Root Opening: 1-1.5 mm Root Face: 0.5-1 mm Thickness (mm): 6

Groove Angle: 60-70 ° Preheat (QW-406)

Minimum Preheat Temperature: 10 °C

Preheat Maintenance: None

Maximum Interpass Temperature: 175 °C

Postweld Heat Treatment (QW-407)

Type: No PWHT performed

PWHT Temperature: None °C

PWHT Holding Time: None hr.

First Process: GTAW Type: Manual

Filler Metals (QW-404) Electrical Characteristics (QW-409)

AWS Classification: ER308 Current Type and Polarity: DCEN (straight)

SFA Specification: 5.9 F-No.: 6 Tungsten Type: EWTh-2 Size: 3mm

A-No. or Chemical Composition: 8 Pulsed Current: None

Filler Metal Trade Name: N/R Welding Details

Filler Metal Product Form: Bare (Solid) Filler Metal Size (mm): 1.6 | - | -

Consumable Insert: None Amperage Used: 70-72 | - | -

GTAW Flux: None Voltage Used: 18-20 | - | -

Weld Deposit 't' (mm): 6 Travel Speed (mm/min): 100 | - | -

Positions (QW-405) Technique (QW-410)

Position of Joint: 1G - Flat Stringer or Weave Bead: Stringer bead

Weld Progression: N/A Nozzle / Gas Cup Size: 10mm

Gas (QW-408) Multiple / Single Pass (per side): Multipass

Shielding: 99.996% Argon / 7 L/min

Backing: None / - L/min

Trailing: None / - L/min

High frequency circuit is used for starting the arc.

2011 Form 001 - Format C

Koch Chemical Technology Group India Pvt. Ltd.

Procedure Qualification Record (PQR)

PQR No.: 08 Page 2 of 2

Tensile Test (QW-150)

Width Thickness Area Ultimate Total Ultimate Unit Failure Type

Specimen No. (mm) (mm) (mm²) Load (N) Stress (MPa) and Location

T1 21.40 5.93 127 75266 593 Weld metal

T2 21.10 5.82 123 74285.4 604 Weld metal

Guided Bend Tests (QW-160)

Type and Figure No. Result Type and Figure No. Result

QW-462.3(a) Face bend Acceptable QW-462.3(a) Root bend Acceptable

QW-462.3(a) Face bend Acceptable QW-462.3(a) Root bend Acceptable

Visual Examination: Satisfactory

Welder's Name: Zala, Jaydeep I.D.: W4 Stamp No.: W4

PQR was done and welding of coupon was witnessed by: Kaushik Shah

Test conducted by: Met-Heat Engineering Pvt.Ltd. Lab Test No.: 158PA/2001

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Code.

Prepared By: 07-05-2001 Asst. Manager QA

Kaushik Shah Date

2011 Form 001 - Format C

Koch Chemical Technology Group India Pvt. Ltd.

315-317 Sakarda Bhadarva Road, Moxi, Tal.Savli, Baroda-391780

Procedure Qualification Record (PQR)

PQR No.: 59 Date: 20-02-2013 WPS No.: 08 Page 1 of 2

Welding Process(es) / Type(s): (1) GTAW / Manual

Joint Design (QW-402) Base Metals (QW-403)

Weld Type: Groove weld Specification Type and Grade:

Groove Type: Single-V groove SA-240, Type 304L to SA-240, Type 304L

Backing: Back-gouged and back welded P-No. 8 Group No. 1 to P-No. 8 Group No. 1

Root Opening: 1-3 mm Root Face: 1-2 mm Thickness (mm): 6

Groove Angle: 60-70 ° Preheat (QW-406)

Minimum Preheat Temperature: 34 °C

Preheat Maintenance: None

Maximum Interpass Temperature: 145 °C

Postweld Heat Treatment (QW-407)

Type: No PWHT performed

PWHT Temperature: None °C

PWHT Holding Time: None hr.

First Process: GTAW Type: Manual

Filler Metals (QW-404) Electrical Characteristics (QW-409)

AWS Classification: ER308L Current Type and Polarity: DCEN (straight)

SFA Specification: 5.9 F-No.: 6 Tungsten Type: EWTh-2 Size: dia.2.5mm

A-No. or Chemical Composition: 8 Pulsed Current: None

Filler Metal Trade Name: N/R Welding Details

Filler Metal Product Form: Bare (Solid) Filler Metal Size (mm): 1.6 | 2.4 | -

Consumable Insert: None Amperage Used: 118-142 | 142-160 | -

GTAW Flux: None Voltage Used: 13-15 | 14-16 | -

Weld Deposit 't' (mm): 6 Travel Speed (mm/min): 108-110 | 140 | -

Positions (QW-405) Technique (QW-410)

Position of Joint: 1G - Flat Thermal Processes: No

Weld Progression: N/A Stringer or Weave Bead: Stringer and weave bead

Gas (QW-408) Multiple / Single Pass (per side): Multipass

Shielding: 100% Argon(99.996% pure) / 8 L/min

Backing: None / - L/min

Trailing: None / - L/min

High frequency circuit used for starting the arc.

Additional Welding Parameters

Layer(s) Filler Metal Current Travel Speed

and/or AWS Size Type and Amperage Voltage Range

Pass(es) Process Classification (mm) Polarity Range Range (mm/min)

Root GTAW ER308L 1.6 DCEN (straight) 118-140 13-15 108

1st GTAW ER308L 1.6 DCEN (straight) 123-142 13-15 110

Final GTAW ER308L 2.4 DCEN (straight) 146-158 14-16 140

After BG GTAW

1st GTAW ER308L 2.4 DCEN (straight) 142-160 14-16 140

2011 Form 011 - Format C

Koch Chemical Technology Group India Pvt. Ltd.

Procedure Qualification Record (PQR)

PQR No.: 59 Page 2 of 2

Tensile Test (QW-150)

Width Thickness Area Ultimate Total Ultimate Unit Failure Type

Specimen No. (mm) (mm) (mm²) Load (N) Stress (MPa) and Location

T1 20 5.92 118.40 70250 593.33 Ductile - WM

T2 20 5.89 117.80 73000 619.69 Ductile - WM

Guided Bend Tests (QW-160)

Type and Figure No. Result Type and Figure No. Result

QW-462.3(a) Face bend Acceptable QW-462.3(a) Root bend Acceptable

QW-462.3(a) Face bend Acceptable QW-462.3(a) Root bend Acceptable

Hardness Test - Vickers hardness

Location Readings

SA-240, Type 304L BM 187 186 185 186 185 183

SA-240, Type 304L HAZ 213 212 210 209 207 210

Weld metal 236 235 233 232 235

Visual Examination: Satisfactory

IGC Test as per ASTM A262 Practice “E” : Acceptable.

Ferrite content test by Ferritoscope :

A) Weld Metal :7.6% to 9.5%

B) HAZ : 0.6% to 1.1%

C) Parent metal : 0.68 to 1.3 %

Welder's Name: Yadav, Patiraj I.D.: W06 Stamp No.: W06

PQR was done and welding of coupon was witnessed by: Mr. Hitesh Bhavsar (BVIL - Surveyor)

Test conducted by: Met-Heat Engineering Pvt.Ltd. Lab Test No.: As per below

Laboratory test numbers : 65-YL/2013; 71-YL/2013; 581LY/2013 & 520-MX/2013.

Prepared By: 01-03-2013 Asst. Manager QA

Kaushik Shah Date

2011 Form 011 - Format C

You might also like

- Forensic Science Fundamentals and Investigations 2nd Edition by Bertino ISBN Test BankDocument7 pagesForensic Science Fundamentals and Investigations 2nd Edition by Bertino ISBN Test Bankmark100% (33)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Computational Propaganda Political Parties, Politicians, and Political Manipulation On Social Media (Samuel C - Woolley, Philip N. Howard)Document273 pagesComputational Propaganda Political Parties, Politicians, and Political Manipulation On Social Media (Samuel C - Woolley, Philip N. Howard)João SousaNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- E-Book No.05 On Material Safety Data Sheets (MSDS)Document32 pagesE-Book No.05 On Material Safety Data Sheets (MSDS)sriram100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS 8 To 1-3-1 Rev2 (10-1-13)Document5 pagesWPS 8 To 1-3-1 Rev2 (10-1-13)ERA SSNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (2)

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- STD WPSDocument1 pageSTD WPSWaqas WaqasNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps Format Tube Welding Cs With Tig V&s JalashawaDocument3 pagesWps Format Tube Welding Cs With Tig V&s JalashawaVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- 2005-05 - WPS & PQR C5Document6 pages2005-05 - WPS & PQR C5misthahNo ratings yet

- WPS Gtaw) - 47Document2 pagesWPS Gtaw) - 47Dharmendra BhardwajNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Weld Procedure Specification (WPS)Document2 pagesWeld Procedure Specification (WPS)Senthil Kumaran50% (2)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- WPS 11-23-1Document3 pagesWPS 11-23-1Anoop Raj RaoNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- DraftDocument32 pagesDraftAnilkumarNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Mailam Mig 410Document1 pageMailam Mig 410sriramNo ratings yet

- Acc. Valves in - To PED N Air Sepa On The Ba Aration Un Asis of AD Nits D 2000Document4 pagesAcc. Valves in - To PED N Air Sepa On The Ba Aration Un Asis of AD Nits D 2000sriramNo ratings yet

- Mailam Mig 410Document1 pageMailam Mig 410sriramNo ratings yet

- Your Header: Welding Procedure Approval Test CertificateDocument5 pagesYour Header: Welding Procedure Approval Test CertificatesriramNo ratings yet

- SAW InverterDocument1 pageSAW InvertersriramNo ratings yet

- Importance of Stress Management in Corporate Sector: Dr. Tejovati S.PrabhuDocument6 pagesImportance of Stress Management in Corporate Sector: Dr. Tejovati S.PrabhusriramNo ratings yet

- SAMPLE 265558 Submerged Arc Welding CC 2014 enDocument6 pagesSAMPLE 265558 Submerged Arc Welding CC 2014 ensriramNo ratings yet

- Popular Science The Big Book of HacksDocument5 pagesPopular Science The Big Book of HackssriramNo ratings yet

- (Progress in Colloid and Polymer Science) M. Ed. Schwuger - Surfactants and Colloids in The Environment (1994, Not Avail)Document190 pages(Progress in Colloid and Polymer Science) M. Ed. Schwuger - Surfactants and Colloids in The Environment (1994, Not Avail)sriramNo ratings yet

- PWM DC With RPWM & LPWM NewDocument2 pagesPWM DC With RPWM & LPWM NewsriramNo ratings yet

- SchizophreniaDocument39 pagesSchizophreniaChikezie OnwukweNo ratings yet

- Manual Usuario NSX-AV800Document80 pagesManual Usuario NSX-AV800observador1980No ratings yet

- Goodman ss-gsz16Document36 pagesGoodman ss-gsz16nam nguyenNo ratings yet

- Water Quality For Supercritical Units Steag FormatDocument40 pagesWater Quality For Supercritical Units Steag FormatAmit MukherjeeNo ratings yet

- Introduction To PBLDocument21 pagesIntroduction To PBLChipego NyirendaNo ratings yet

- Power Dynamics in Shakespeare's The TempestDocument5 pagesPower Dynamics in Shakespeare's The TempestDavid GómezNo ratings yet

- 1 Year Bachillerato VERB TENSES REVIEWDocument4 pages1 Year Bachillerato VERB TENSES REVIEWLucía CatalinaNo ratings yet

- CHP 15 MULTIDIMENSIONAL SCALING FOR BRAND POSITIONING Group 1 & 2Document16 pagesCHP 15 MULTIDIMENSIONAL SCALING FOR BRAND POSITIONING Group 1 & 2alfin luanmasaNo ratings yet

- Bonding QuizDocument7 pagesBonding Quiz卜一斐No ratings yet

- Irp Test-1 (07!12!17) (Solution) (Jee Mains) Code-AbDocument20 pagesIrp Test-1 (07!12!17) (Solution) (Jee Mains) Code-Abvejoshi21699No ratings yet

- 01 Lord Krishna-VrindavanDocument304 pages01 Lord Krishna-VrindavanJey AnandNo ratings yet

- Prediksi SOal UAS Kelas XII WAJIBDocument14 pagesPrediksi SOal UAS Kelas XII WAJIBDinda Anisa Meldya Salsabila100% (2)

- 6 MD 85Document1,256 pages6 MD 85Yahya DarNo ratings yet

- Chapter 12: Personality Assessment - An Overview What Is Personality?Document4 pagesChapter 12: Personality Assessment - An Overview What Is Personality?John ArthurNo ratings yet

- Short Keys f1-f12Document2 pagesShort Keys f1-f12Farhan Khan NiaZiNo ratings yet

- 3 - APUSH Period 8 Notes 3 - Eisenhowers Cold WarDocument60 pages3 - APUSH Period 8 Notes 3 - Eisenhowers Cold WarChrisNo ratings yet

- Surah Al Asr (Explanation)Document4 pagesSurah Al Asr (Explanation)Adil KhatriNo ratings yet

- The History of GymnasticsDocument2 pagesThe History of Gymnasticsblessed cccNo ratings yet

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- National Open University of Nigeria: Wallet Payment StatusDocument4 pagesNational Open University of Nigeria: Wallet Payment Statusokoro collinsNo ratings yet

- Indian ClimateDocument7 pagesIndian ClimatePrakash Kumar Kumar100% (1)

- CBP 9550Document29 pagesCBP 9550danny.np2006No ratings yet

- Measure of Central Tendency (Mean, Median, Mode)Document12 pagesMeasure of Central Tendency (Mean, Median, Mode)Najia SalmanNo ratings yet

- Research and Development in Nigeria's Tertiary Institutions: Issues, Challenges and Way ForwardDocument9 pagesResearch and Development in Nigeria's Tertiary Institutions: Issues, Challenges and Way ForwardInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Invariants and Monovariants: Adithya Bhaskar January 24, 2016Document5 pagesInvariants and Monovariants: Adithya Bhaskar January 24, 2016zarif hossainNo ratings yet

- Process Design and Economics For The Conversion of The Lignocellulosic To HydrocarbonsDocument133 pagesProcess Design and Economics For The Conversion of The Lignocellulosic To HydrocarbonsCristhian Camilo Vargas QuinteroNo ratings yet

- English Mid Test A: Hawaiian TraditionsDocument4 pagesEnglish Mid Test A: Hawaiian TraditionsAnugrah WijagauNo ratings yet

- Airman in Pakistan Airforce This Booklet ContainsDocument8 pagesAirman in Pakistan Airforce This Booklet ContainsAMIR RAHMAN100% (3)