Professional Documents

Culture Documents

Job Safety Analysis MDC Cylinder Replacement

Job Safety Analysis MDC Cylinder Replacement

Uploaded by

Maxi ProOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis MDC Cylinder Replacement

Job Safety Analysis MDC Cylinder Replacement

Uploaded by

Maxi ProCopyright:

Available Formats

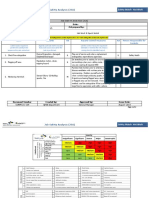

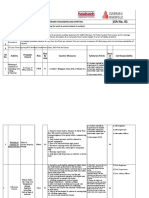

JOB SAFETY ANALYSIS

Job Safety Analysis No. Date

Description of Project/ Type of Job/Work to be Performed Balingueo 230 kV SS Project (Sp13.BSSP.Lt-0152) Replacement of Inert Gas Cylinders

NGCP Group/Dept/Division/Section Not applicable

Contractor/Subcontractor Maxipro Development Corporation/Fire Solutions Inc.

Project/Work Location NGCP Sta. Barbara Substation

Total No. of Personnel/Workers 5 Workers

All Potential Hazards, Risks, or

Detailed Activities/Job Adequate

Incident (What Could Possibly Existing/Current Controls Recommended Controls

Tasks/Steps (Y/N)

Go Wrong?)

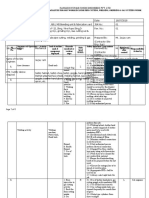

1. Transport of cylinders • Un-even surface of access road • Careful driving maneuver to avoid Y • Observe maximum safety towards

and personnel • Improper placement of cylinders accident driving & transporting of materials

inside the vehicle • Proper placement of cylinders Y • Follow traffic rules and regulations

during transport • Follow the proper way to stack pile

Y

cylinders during transport

2. Hauling of new gas • Strain/sprain due to manual lifting • Implementation of proper manual Y • Follow the methodology for the manual

cylinders to site area • Slipping and falling of cylinders lifting lifting & hauling of cylinders

that may cause gas leak or • Wear appropriate PPEs for the Y • Wear PPE at all times

explosion due to pressure particular task • Double check gauge for any gas leaks

• Exposure to gas content due to • Check cylinder and gas gauge for before and after hauling of cylinders

improper handling Y

any gas leak

• Ensure to follow safety work Y

protocol inside the substation

• Strain/sprain due to replacement • Prior to start of activity, a toolbox

3. Replacement of old Y • Secure clearance from substation

activity of cylinders meeting must be conducted

cylinders with new personnel before start of work

• Slipping and falling of cylinders • Ensure to wear personal

cylinders Y • Wear PPEs at all times

that may cause gas leak or protective equipment at all times

• Observe safety at all times when

explosion due to pressure • Check tools to be used prior to Y

transferring and replacing cylinders

• Dilapidated tools start of work

Y • Ensure tools to be used are working

1

All Potential Hazards, Risks, or

Detailed Activities/Job Adequate

Incident (What Could Possibly Existing/Current Controls Recommended Controls

Tasks/Steps (Y/N)

Go Wrong?)

4. Hauling of old gas • Strain/sprain due to manual lifting • Implementation of proper manual Y • Follow the methodology for the manual

cylinder to vehicle • Slipping and falling of cylinders lifting lifting & hauling of cylinders

that may cause personnel injury • Wear appropriate PPEs for the Y • Wear PPE at all times

particular task

Y

• Ensure to follow safety work

protocol inside the substation

JSA Prepared By REYNAN PAREJA – MDC Engineer Date OCTOBER 17, 2018

JSA Reviewed By REYNANTE B. BUENO – MDC VP for Operations Date OCTOBER 17, 2018

JSA Approved By ROBERTO G. LAZONA – CPM, NLPD Date

JSA Approved By MICHAEL ASUNCION – OIC, QSE Supervisor Date

JSA Approved By RICHARD LUBUGUIN – Acting QSE Officer Date

JSA Approved By ARMAND SORIANO – PE, BALINGUEO SS Date

JSA Approved By APOLINAR MARIANO JR. – OIC SS Mgr. NLD3 Date

JSA Approved By FLORENDO DE LUNA – OIC Dist. Sr. Mgr. NLD3 Date

You might also like

- Tunneling Work Safety (Boring Activity On Road Passageways) : Name: I/C: Index NoDocument8 pagesTunneling Work Safety (Boring Activity On Road Passageways) : Name: I/C: Index NoHelmi Ladin100% (1)

- Astm F1941 PDFDocument11 pagesAstm F1941 PDFKamal BhandariNo ratings yet

- Solution Manual For Introduction To Probability Models 7thDocument62 pagesSolution Manual For Introduction To Probability Models 7thJosé Carlos100% (3)

- JSA For The Conveyor BeltDocument1 pageJSA For The Conveyor BeltSaklain MustakNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechNo ratings yet

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (2)

- 4-JSA - Unloading Under Inert - F9030 B NewDocument6 pages4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNo ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- JSA-RMC Pump ConcreteingDocument6 pagesJSA-RMC Pump ConcreteingRakeshkasarla100% (2)

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Document5 pagesJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- JSA Hydrant Pipe LineDocument7 pagesJSA Hydrant Pipe Lineakshay pradeep100% (1)

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- MTA2018-JHA-012 Air Compressor OperationDocument10 pagesMTA2018-JHA-012 Air Compressor OperationKelvin TanNo ratings yet

- 2020 06 17 JSA For Installation of The AC Unit in The Server RoomDocument11 pages2020 06 17 JSA For Installation of The AC Unit in The Server RoomDarren OscarNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- General Civil Works Risk AssessmentDocument8 pagesGeneral Civil Works Risk AssessmentsufiyanNo ratings yet

- Mig Welding Work JSA HSE ProfessionalsDocument2 pagesMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn Bhd100% (1)

- JSA - Painting For PipeDocument6 pagesJSA - Painting For PipeNaveed Ahmed Get-Info100% (1)

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- Jsa For Radiography WorkDocument2 pagesJsa For Radiography WorkVipul ShankarNo ratings yet

- JSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaDocument4 pagesJSA For TIE in of Utility Water With Fire Water Line Near Train 1 AreaMohammed Minhaj100% (1)

- JSA Formet New Hot WorkDocument6 pagesJSA Formet New Hot Worksakthi venkat100% (1)

- 025 - TRA - Grouting Works - Rev 1Document3 pages025 - TRA - Grouting Works - Rev 1Rachel Flores100% (2)

- JSA - CivilDocument5 pagesJSA - CivilRajuNo ratings yet

- HEAT Job Safety Analyisis (JSA)Document6 pagesHEAT Job Safety Analyisis (JSA)คุณพ่อน้อง บิ๊กบอสNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- 02.JSA WeldingDocument2 pages02.JSA Weldingr0sh0% (1)

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- JSA For Fire Water LineDocument4 pagesJSA For Fire Water Linemyo lwinNo ratings yet

- Jsa No-01 Container UnloadingDocument4 pagesJsa No-01 Container Unloadingsumith s100% (1)

- Jobs Safety Analysis (JSA)Document9 pagesJobs Safety Analysis (JSA)uttam mishra100% (1)

- Jsa For Hvac Equipment InstallDocument4 pagesJsa For Hvac Equipment Installpowergroup engineersNo ratings yet

- Chipping Work (Manually)Document1 pageChipping Work (Manually)ChandruNo ratings yet

- Tanks Confined Space JSADocument5 pagesTanks Confined Space JSAkosoko100% (1)

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- JSA For Chimney Works 17.09.2021Document2 pagesJSA For Chimney Works 17.09.2021Brenden PalanithangamNo ratings yet

- JSA Fire Fighting WorkDocument8 pagesJSA Fire Fighting WorkMehul KolambkarNo ratings yet

- Jsa of Boiler Drum LiftingDocument10 pagesJsa of Boiler Drum LiftingGyanendra Narayan NayakNo ratings yet

- Welding and Gas CuttingDocument2 pagesWelding and Gas CuttingKrishna Patil100% (2)

- Job Safety & Environment Analysis: Revision NoDocument3 pagesJob Safety & Environment Analysis: Revision NonishanthNo ratings yet

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- National Safety Week or Day Celebration Global EHS 054Document24 pagesNational Safety Week or Day Celebration Global EHS 054Global EHSNo ratings yet

- PTW JHA Prayer Garment Hanging Rack InstallationDocument2 pagesPTW JHA Prayer Garment Hanging Rack InstallationPHH9834No ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- JHA Jack Hydraulic PalletDocument1 pageJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- Panipat Refinery & Petrochemical Complex Job Safety AnalysisDocument6 pagesPanipat Refinery & Petrochemical Complex Job Safety AnalysisSaiyad RiyazaliNo ratings yet

- JSA TrainingDocument28 pagesJSA Trainingkresna suryadiNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- 024 - Mobile Scaffold Inspection ChecklistDocument1 page024 - Mobile Scaffold Inspection ChecklistFaiez AripiNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JSA Any OprationDocument12 pagesJSA Any Oprationn.aboshhewaNo ratings yet

- SEOT JSA For Installation of Project Sign BoardDocument3 pagesSEOT JSA For Installation of Project Sign BoardArchana SoorajNo ratings yet

- White Sika Paper Strengthening ConcreteDocument12 pagesWhite Sika Paper Strengthening ConcreteRaed alkronz Raed alkronzNo ratings yet

- Revised PROOFREAD Thesis DocumentDocument74 pagesRevised PROOFREAD Thesis DocumentJohn Paul MadroñalNo ratings yet

- Test Bank For Human Development A Life Span View Third EditionDocument20 pagesTest Bank For Human Development A Life Span View Third Editiondenisedanielsbkgqyzmtr100% (28)

- Working Paper: Aeronautical Communications Panel (Acp) Twentyseventh Meeting of Working Group FDocument7 pagesWorking Paper: Aeronautical Communications Panel (Acp) Twentyseventh Meeting of Working Group FMark Angielo TrillanaNo ratings yet

- UMTS UL DL Capacity Improvement Solution 007Document65 pagesUMTS UL DL Capacity Improvement Solution 007Sandeep100% (1)

- Wort Clarity - eDocument3 pagesWort Clarity - eSylab InstrumentsNo ratings yet

- Upload TextilDocument2 pagesUpload TextilManoj MandavkarNo ratings yet

- Mba Iii 225 233 235 237Document58 pagesMba Iii 225 233 235 237Santosh HalakarniNo ratings yet

- International Multidisciplinary Research JournalDocument9 pagesInternational Multidisciplinary Research Journalkahkashan khurshidNo ratings yet

- Sonalika ProjectDocument86 pagesSonalika ProjectVivek ThakurNo ratings yet

- Pressure Control Valve: Wärtsilä 50 Spare Parts List 183-0006Document4 pagesPressure Control Valve: Wärtsilä 50 Spare Parts List 183-0006SaasiNo ratings yet

- Indigo 36X3: Manual de UsuarioDocument4 pagesIndigo 36X3: Manual de UsuarioEliana Guzman PachecoNo ratings yet

- (Integrated Circuits and Systems) Masashi Horiguchi, Kiyoo Itoh (Auth.) - Nanoscale Memory Repair-Springer-Verlag New York (2011)Document226 pages(Integrated Circuits and Systems) Masashi Horiguchi, Kiyoo Itoh (Auth.) - Nanoscale Memory Repair-Springer-Verlag New York (2011)SnehaNo ratings yet

- Labour Administration in A Changing World of WorkDocument160 pagesLabour Administration in A Changing World of WorkdomibrazilNo ratings yet

- Chapter III FinalDocument5 pagesChapter III FinalJeaneth PadrinaoNo ratings yet

- Ang Hiyas Campus Journalists Dominates DSPC 2018Document1 pageAng Hiyas Campus Journalists Dominates DSPC 2018Pauline Karen Macaisa-ConcepcionNo ratings yet

- Statistics: It'S Your TurnDocument7 pagesStatistics: It'S Your TurnMarjie Bay-asenNo ratings yet

- Definitions & Examples: C C C CDocument47 pagesDefinitions & Examples: C C C CSeroKeretaMasaroWidiarNo ratings yet

- Personal Selling - CH 6 - Adaptive Selling For Relationship BuildingDocument65 pagesPersonal Selling - CH 6 - Adaptive Selling For Relationship Buildingash.khanNo ratings yet

- Hitech Product SummaryDocument16 pagesHitech Product SummaryAlejandroVargasNo ratings yet

- Cost and Management Accounting Individual AssignmentDocument3 pagesCost and Management Accounting Individual AssignmentKIASHA NAIDUNo ratings yet

- CableDocument7 pagesCablerocketvtNo ratings yet

- Report of Large Motor ReliabilityDocument28 pagesReport of Large Motor Reliabilitythawatchai11222512100% (1)

- Clutches Brakes CtenDocument156 pagesClutches Brakes CtenRiz WanNo ratings yet

- Java Lab Guide Part1Document11 pagesJava Lab Guide Part1rishiprabhas 0807No ratings yet

- Amplitude ModulationDocument14 pagesAmplitude ModulationMuralidhar NakkaNo ratings yet

- LIC DeductionDocument1 pageLIC Deductionbala govindamNo ratings yet

- Latest Statistics On England Mortality Suggest...Document24 pagesLatest Statistics On England Mortality Suggest...David Souto AlcaldeNo ratings yet