Professional Documents

Culture Documents

Welding Electrode Calculation

Welding Electrode Calculation

Uploaded by

SarwarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Electrode Calculation

Welding Electrode Calculation

Uploaded by

SarwarCopyright:

Available Formats

Custom Search

English português Español русский

Home > Education Center > The ABC’s of Arc Welding > How to calculate welding consumption >

Education Center

The ABC’s of Arc Welding

The ABC’s of Arc

Welding

How to calculate welding consumption

Fundamentals of CO2

Arc Welding We recommend you to use the following

diagrams for a quick estimation of the

Welding of Medium /

High Carbon Steels and consumption of welding consumables for

Special Steels welding ferritic steel butt joints and fillet joints

respectively. Please follow the examples

Welding of Stainless indicated by gray arrows in the figures.

Steel

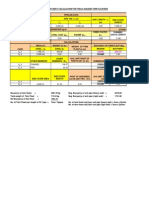

Welding References Figure 2 shows the calculated consumption of

welding consumables as a function of plate

Textbooks of Welding thickness, welding process, groove angle, and root opening for butt joints. With respect to fillet joints, Fig. 3 shows

the calculated consumption of welding consumables as a function of fillet size, welding process, and reinforcement

size. These diagrams were developed using the calculations obtained by the following equation for both groove and

fillet welding joints under the prerequisites given below.

C = [(A1 + A2) x L x G/E] x 1/10

Where

C: Consumption of welding consumables (kg)

A1: Area of Section A1 weld metal (mm2) ― Fig. 1

A2: Area of Section A2 reinforcement (mm2) ― Fig. 1

Figure 1. Weld sizes (θ in deg., H, R, S and T in mm)

L: Weld length (m)

G: Specific gravity of weld metal (7.85 g/cm3)

E: Deposition Efficiency (%) ―

SMAW covered electrodes: 55%

GMAW solid/metal-cored wires: 95%

FCAW flux-cored wires: 90%

SAW solid wires: 100%

Figure 2. Consumption of covered electrodes in SMAW and solid/metal-cored wires in GMAW of butt joints.

You might also like

- Door SheetDocument9 pagesDoor SheetAnilkumarNo ratings yet

- Steps of Making WPSDocument51 pagesSteps of Making WPSmohammadkhairy0% (2)

- 3013 - Spec For Pipeline Welding PDFDocument18 pages3013 - Spec For Pipeline Welding PDFsherviny100% (1)

- Certified Inspector Checklist: New Tank ConstructionDocument11 pagesCertified Inspector Checklist: New Tank ConstructionamevaluacionesNo ratings yet

- Heat Treatment of Thin Wall Tanks by Internal Oil Firing MethodDocument7 pagesHeat Treatment of Thin Wall Tanks by Internal Oil Firing MethodKrishna VachaNo ratings yet

- Welding Terminology and DefinitionsDocument66 pagesWelding Terminology and DefinitionsTrịnh Quốc TuyếnNo ratings yet

- Types of Heat Tracing Systems - PIPING GUIDEDocument9 pagesTypes of Heat Tracing Systems - PIPING GUIDERaakze MoviNo ratings yet

- The Welding Procedure and Its QualificationDocument51 pagesThe Welding Procedure and Its QualificationYousef Adel HassanenNo ratings yet

- Client Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved byDocument7 pagesClient Approval Remarks: Rev Date Descriptions Prepared by Reviewed by Approved bySARSAN NDTNo ratings yet

- Welding Procedure Specification (WPS) : JointsDocument2 pagesWelding Procedure Specification (WPS) : JointsNiel100% (1)

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu Kumar100% (1)

- Why Is Preheating NecessaryDocument3 pagesWhy Is Preheating NecessaryahmedNo ratings yet

- For Double Storey Linear MetreDocument2 pagesFor Double Storey Linear MetreJah RastaNo ratings yet

- Bolt Tightening Inspection Report Format FinalDocument2 pagesBolt Tightening Inspection Report Format FinalHugo FloresNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- How To Write A Welding Procedure Specification (WPS)Document5 pagesHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Daily Construction Report (DCR) : Project ManagerDocument5 pagesDaily Construction Report (DCR) : Project ManagerMoath AlhajiriNo ratings yet

- ASTM Materials Cross Reference ChartDocument1 pageASTM Materials Cross Reference Chartsgm6911No ratings yet

- t15b03-0102 - 0painting Specification For Whb&Steam DrumDocument36 pagest15b03-0102 - 0painting Specification For Whb&Steam DrumMuhammedHafisNo ratings yet

- Welding Calculator BOHLERDocument7 pagesWelding Calculator BOHLERKhamdi AfandiNo ratings yet

- Calculate Weld VolumeDocument4 pagesCalculate Weld VolumeTAUFIKNo ratings yet

- The Heat Affected ZoneDocument24 pagesThe Heat Affected ZoneRatan PanditNo ratings yet

- NoticeDocument1 pageNoticeAnirban Sen SharmaNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Demo Asme PWHT PreheatDocument54 pagesDemo Asme PWHT PreheatWalter TrajadaNo ratings yet

- SPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionDocument14 pagesSPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionAbdul Hakam Mohamed YusofNo ratings yet

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Welding Upto Gas WeldingDocument26 pagesWelding Upto Gas Weldingrams789No ratings yet

- Attach-10 Work Procedure For Process Piping Prefabrication and InstallationDocument17 pagesAttach-10 Work Procedure For Process Piping Prefabrication and InstallationSukalyan BasuNo ratings yet

- Scope of Supply T60Document25 pagesScope of Supply T60cmaduroheNo ratings yet

- MSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapDocument7 pagesMSFJ020D - Denso - CPT 1000 Innerwrap and CPT 1000 OuterwrapMakamu Max Las MokgaoganyiNo ratings yet

- RFI-157 Request For NDT (Only RT) Acceptance For PQR JointsDocument1 pageRFI-157 Request For NDT (Only RT) Acceptance For PQR JointsT C Hasan DmrNo ratings yet

- PFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFDocument8 pagesPFI ES-1-1992 Internal Machining and Solid Machined Backing Rings For Circumferential Butt Welds PDFfatapia74No ratings yet

- Asme Cal in TabularDocument14 pagesAsme Cal in TabularSundara MoorthyNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProceduregauravNo ratings yet

- Slope CheckDocument2 pagesSlope Checkคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Progress Piping PDFDocument1 pageProgress Piping PDFebsmsartNo ratings yet

- Material Linde: Asme Sec Ii A B 36.10 M B 16.25 Grade ASTMDocument40 pagesMaterial Linde: Asme Sec Ii A B 36.10 M B 16.25 Grade ASTMadarshNo ratings yet

- PQR - WPQ Witness ReportDocument1 pagePQR - WPQ Witness Reportsdkeskar40No ratings yet

- Rubber Gasket TypesDocument92 pagesRubber Gasket Typessushant_moreyNo ratings yet

- Ibr Inspection ProtocolDocument4 pagesIbr Inspection ProtocolLipika Gayen100% (1)

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- T 2171 - Diesel Storage TankDocument2 pagesT 2171 - Diesel Storage TankHuynh Thanh TamNo ratings yet

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 pagesCalculation Sheet For 700mm SQ Metal FloatersAdagharaNo ratings yet

- Block Calculator V 1.0 - EnglishDocument4 pagesBlock Calculator V 1.0 - EnglishJinishEGNo ratings yet

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Document18 pagesPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNo ratings yet

- Penawaran Pekerjaan DED 4 Unit Tanki Rev.0Document3 pagesPenawaran Pekerjaan DED 4 Unit Tanki Rev.0m khaeronNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- Esab, OK Autrod 12.22 (1222252800)Document1 pageEsab, OK Autrod 12.22 (1222252800)RodrigoNo ratings yet

- Piping General SpecificationDocument6 pagesPiping General Specificationcitra puspita sari100% (1)

- Spec For Welding RepairDocument3 pagesSpec For Welding RepairSiddiqui Abdul KhaliqNo ratings yet

- Welding QEDocument3 pagesWelding QEPritha DasNo ratings yet

- Weld CalculationDocument6 pagesWeld CalculationbalamuruganNo ratings yet

- How To Calculate Welding ConsumptionDocument3 pagesHow To Calculate Welding Consumptionmanivannann2000No ratings yet

- How To Calculate Welding ConsumptionDocument4 pagesHow To Calculate Welding ConsumptionOkayNo ratings yet

- Arc Welding - Calculator ChartDocument3 pagesArc Welding - Calculator ChartDr. Ladeesh V GopinathNo ratings yet

- Welding References - Education Center - KOBELCO - KOBE STEEL, LTD.Document6 pagesWelding References - Education Center - KOBELCO - KOBE STEEL, LTD.Ferdie UlangNo ratings yet

- Plate For Mounting Robotarm UR3 Item and Bosch ProfilesDocument1 pagePlate For Mounting Robotarm UR3 Item and Bosch ProfilesVickocorp SlpNo ratings yet

- Macsteel VRN VRN 200 DatasheetDocument1 pageMacsteel VRN VRN 200 DatasheetIgor NhamanoNo ratings yet

- CelikDocument3 pagesCeliknikolaNo ratings yet

- NZCAA-AC66-2.2 Aircraft Maintenance Engineer Licence - Examination Subject 2 - Aircraft Engineering KnowledgeDocument41 pagesNZCAA-AC66-2.2 Aircraft Maintenance Engineer Licence - Examination Subject 2 - Aircraft Engineering KnowledgeCyrol WamgonNo ratings yet

- Crystic-Chemical Resistance Guide Page - 4Document1 pageCrystic-Chemical Resistance Guide Page - 4KiranNo ratings yet

- Frontken TSADocument25 pagesFrontken TSAnurudin mohdhassanNo ratings yet

- Slide Ways of Machine ToolsDocument42 pagesSlide Ways of Machine ToolsTousif RezaNo ratings yet

- Surendra Yadav SirDocument27 pagesSurendra Yadav SirNikhil Sai KammaNo ratings yet

- BR DTI CatalogDocument20 pagesBR DTI CatalogRICHARDNo ratings yet

- IPE-4102-Machine Tool SessionalDocument29 pagesIPE-4102-Machine Tool SessionalNafiz AlamNo ratings yet

- Linde N2 EOR Case Study CantarellDocument26 pagesLinde N2 EOR Case Study CantarellEliza NunesNo ratings yet

- Degreasing Process and His Aplications in IndustryDocument3 pagesDegreasing Process and His Aplications in Industrysilicon14labsNo ratings yet

- BS 5176-Classification System For Vulcanized Rubbers-SpecificationDocument66 pagesBS 5176-Classification System For Vulcanized Rubbers-SpecificationTit fuckerNo ratings yet

- Industrial PharmacyDocument9 pagesIndustrial PharmacyMr nobodyNo ratings yet

- MIDREX Process BrochureDocument12 pagesMIDREX Process BrochuresurajNo ratings yet

- Alternative Photographic Access - Peter MrharDocument241 pagesAlternative Photographic Access - Peter Mrharmarina celis100% (1)

- Castable Grout: Chemdur - 42Document3 pagesCastable Grout: Chemdur - 42ghazanfarNo ratings yet

- SANDVIK 23.12.2.LR Covered Electrodes: DatasheetDocument3 pagesSANDVIK 23.12.2.LR Covered Electrodes: DatasheetFilipe CordeiroNo ratings yet

- ID3 19710613199702100518091301931prosiding-Nasional 3 Penulis 1Document18 pagesID3 19710613199702100518091301931prosiding-Nasional 3 Penulis 1Mhd KaharuddinNo ratings yet

- Local Fabrication of Polishing MachineDocument21 pagesLocal Fabrication of Polishing MachineANINKU AugustineNo ratings yet

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document1 page400 Bad Request 400 Bad Request Nginx/1.2.9muthuswamy77No ratings yet

- Transfermoulding 180721115139Document13 pagesTransfermoulding 180721115139Appu MukundanNo ratings yet

- Unit 2 - Manufacturing Process - WWW - Rgpvnotes.inDocument11 pagesUnit 2 - Manufacturing Process - WWW - Rgpvnotes.inIPL 2020 LIVE100% (1)

- Prosiding Korosi Pipeline BalikpapanDocument11 pagesProsiding Korosi Pipeline BalikpapanEmharion DinNo ratings yet

- Astm B618Document9 pagesAstm B618Anonymous 9xvU1FNo ratings yet

- Excalibur 7018 MR: Conformances Key FeaturesDocument2 pagesExcalibur 7018 MR: Conformances Key FeaturesAsongwe HansNo ratings yet

- Lehigh Valley Abrasives Product CatalogDocument10 pagesLehigh Valley Abrasives Product Catalognaturalfusion100% (2)

- Hef Durferrit QPQ Process EngDocument20 pagesHef Durferrit QPQ Process EngDemon'sHeartNo ratings yet

- Zam-Introduction (Steel)Document14 pagesZam-Introduction (Steel)lymacsausarangNo ratings yet

- Liquid 422Document2 pagesLiquid 422Erick CruzNo ratings yet