Professional Documents

Culture Documents

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

Uploaded by

Ujol PraCopyright:

Available Formats

You might also like

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia Ghica100% (1)

- Hpe 2010 en PDFDocument102 pagesHpe 2010 en PDFdineshdubeyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNo ratings yet

- Two-Way Slab V2Document4 pagesTwo-Way Slab V2Eric AbedaniaNo ratings yet

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Document4 pages2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- Spreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68Document1 pageSpreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68roshan034No ratings yet

- Two-Way Slabs Design To BS 8110Document4 pagesTwo-Way Slabs Design To BS 8110samloo1997No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- RCC94 Two-Way Slabs (Tables)Document1 pageRCC94 Two-Way Slabs (Tables)curiosity12No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghNo ratings yet

- RCC94 Two-Way Slabs TablesDocument3 pagesRCC94 Two-Way Slabs TablesjohnyNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY 1f ChillerDocument1 pageRCC94 Two Way Slabs (Tables) MCY 1f ChillerYati ChanNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNo ratings yet

- 4.slab 2Document5 pages4.slab 2ikramNo ratings yet

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- Two-Way Solid Slabs - 1Document4 pagesTwo-Way Solid Slabs - 1rizwanjawaid.meenaNo ratings yet

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- 5 To 6: A To B: Villa BECDocument1 page5 To 6: A To B: Villa BECmohammedNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- PANEL08Document1 pagePANEL08Isaac JosephNo ratings yet

- Our Critical Slab DesignDocument5 pagesOur Critical Slab DesignIsmail AbdiNo ratings yet

- RCC94 Two-Way Slabs (Tables) - RS2Document1 pageRCC94 Two-Way Slabs (Tables) - RS2Arnold TunduliNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)christi SNo ratings yet

- 3.0RCC94 Two-Way Slabs - 2Document5 pages3.0RCC94 Two-Way Slabs - 2ikramNo ratings yet

- 1st Floor 2 Way SlabDocument4 pages1st Floor 2 Way SlabOyelade MuyiwaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- 5 To 6: A To B: Aktar BalushiDocument1 page5 To 6: A To B: Aktar BalushimohammedNo ratings yet

- Most Critical Interior PanelDocument1 pageMost Critical Interior PanelKagwi MauriceNo ratings yet

- CALC SHEET ZOLA - CompressedDocument33 pagesCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNo ratings yet

- 5 To 6: A To B: VillaDocument1 page5 To 6: A To B: VillamohammedNo ratings yet

- 5 To 6: A To B: Twin VillaDocument1 page5 To 6: A To B: Twin VillamohammedNo ratings yet

- TCC94 Two Way Slabs TablesDocument5 pagesTCC94 Two Way Slabs TablesMihai JNo ratings yet

- Valid Design: Design of Two Way Slab (S-1)Document1 pageValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNo ratings yet

- RCC94 Two-Way Slabs (Tables) - 1Document5 pagesRCC94 Two-Way Slabs (Tables) - 1samueladebo207No ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- Two-Way Slabs (Tables)Document5 pagesTwo-Way Slabs (Tables)hala_azhariNo ratings yet

- TCC94 Two-Way Slabs (Tables)Document5 pagesTCC94 Two-Way Slabs (Tables)Mario Sajulga Dela CuadraNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)Murthy GunaNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- Stair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialDocument5 pagesStair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialUjol PraNo ratings yet

- Docc PDFDocument2 pagesDocc PDFUjol PraNo ratings yet

- Stair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialDocument4 pagesStair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialUjol PraNo ratings yet

- DoccDocument1 pageDoccUjol PraNo ratings yet

- Known Data: H Z 2 I R S GDocument6 pagesKnown Data: H Z 2 I R S GUjol PraNo ratings yet

- All Commands in MS DosDocument42 pagesAll Commands in MS DosgodkeshavNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Computer ScientistDocument15 pagesComputer ScientistRenz Banayat Del RosarioNo ratings yet

- 2020 Express Water - Reverse Osmosis System Installation ManualDocument32 pages2020 Express Water - Reverse Osmosis System Installation ManualBobNo ratings yet

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDocument5 pagesDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- E Farming (BRS)Document6 pagesE Farming (BRS)Binish LoneNo ratings yet

- Improvement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaDocument2 pagesImprovement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaChandan MoharanaNo ratings yet

- ObmodsDocument6 pagesObmodsSean CrumpNo ratings yet

- L136T/Tl Marine EngineDocument2 pagesL136T/Tl Marine EngineAhmet GelişliNo ratings yet

- Ekg 6Document2 pagesEkg 6RachitNo ratings yet

- Allplan TutorialDocument330 pagesAllplan TutorialOana ScutarasuNo ratings yet

- Pompa Sirkulasi AP 156,3 LPM @60mDocument3 pagesPompa Sirkulasi AP 156,3 LPM @60mAndreas B KresnawanNo ratings yet

- Hydraulic Breaker Sandvik Br4511 City Sandvik Br4511 City-Jet Sandvik Br4511 City ProDocument28 pagesHydraulic Breaker Sandvik Br4511 City Sandvik Br4511 City-Jet Sandvik Br4511 City ProamontanocoNo ratings yet

- Slimdek Pattern BookDocument40 pagesSlimdek Pattern BookBabak WSP GroupNo ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Orphanage Master PlanDocument8 pagesOrphanage Master PlanNaguy FaquiraNo ratings yet

- Plano Electrico 16 MDocument25 pagesPlano Electrico 16 MRober TiconaNo ratings yet

- COBOLDocument171 pagesCOBOLgs_waiting_4_uNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- Surfcam 2014 r2 - 32bitDocument152 pagesSurfcam 2014 r2 - 32bitClaudio HinojozaNo ratings yet

- Service Manual: Chassis, Mast & OptionsDocument37 pagesService Manual: Chassis, Mast & OptionsIsos Cell0% (1)

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

- Suspension SystemDocument11 pagesSuspension SystemARUNSFRHNo ratings yet

- CV ReinaldoZerpa+PEOPDocument2 pagesCV ReinaldoZerpa+PEOPReinaldo Zerpa PeñaNo ratings yet

- Examples Class LecturesDocument27 pagesExamples Class Lecturesnickthegreek142857No ratings yet

- Solar Photovoltaic Wire 600V: DescriptionDocument1 pageSolar Photovoltaic Wire 600V: DescriptionAMARENDRA SINo ratings yet

- PM EquipmentDocument16 pagesPM Equipmentsiva prasadNo ratings yet

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

Uploaded by

Ujol PraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

F To G: 1 To 2: Spreadsheets To BS 8110 & EC2

Uploaded by

Ujol PraCopyright:

Available Formats

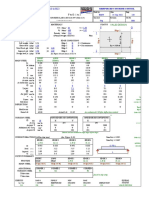

Project Spreadsheets to BS 8110 & EC2 REINFORCED CONCRETE COUNCIL

Client Advisory Group Made by Date Page

Location 32nd floor - corner panel F to G: 1 to 2 RMW 18-Dec-2018 130

2-WAY SPANNING INSITU CONCRETE SLABS to BS 8110:1997 (Table 3.14) Checked Revision Job No

Originated from RCC94.xls on CD © 1999 BCA for RCC chg - R68

DIMENSIONS MATERIALS STATUS VALID DESIGN

short span, lx m 8.10 fcu N/mm² 40 gc = 1.50 F G

long span, ly m 12.00 fy N/mm² 460 gs = 1.05 Edge 1

h mm 250 Density kN/m³ 23.6 1

Lx = 8.1 m

Top cover mm 20 (Normal weight concrete) Plan

Btm cover mm 20

Edge 4

Edge 2

LOADING characteristic EDGE CONDITIONS

Self weight kN/m² 5.90 Edge 1 D C = Continuous

Extra dead kN/m² 1.50 Edge 2 D D = Discontinuous Ly = 12 m

Total Dead, gk kN/m² 7.40 gf= 1.40 Edge 3 C

Imposed, qk kN/m² 5.00 gf= 1.60 Edge 4 C 2

Design load, n kN/m² 18.36 See Figure 3.8 and clauses 3.5.3.5-6 Edge 3

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4 BS8110

MAIN STEEL SPAN SPAN Free Free Continuous Continuous Reference

ßs 0.058 0.034 0.000 0.000 0.077 0.045 Table 3.14

M kNm/m 69.8 41.0 0.0 0.0 93.0 54.6

d mm 222.0 208.0 225.0 208.0 222.0 208.0

k' 0.156 0.156 0.156 0.156 0.156 0.156

k 0.035 0.024 0.000 0.000 0.047 0.032

Z mm 210.9 197.6 213.8 197.6 209.7 197.6 3.4.4.4

As req mm²/m 755 473 0 0 1013 631

As min mm²/m 325 325 325 325 325 325 Table 3.25

As deflection mm²/m 966 605 ~ ~ ~ ~

Ø mm 16 12 10 12 16 12

Layer B1 B2 T1 T2 T1 T2

@ mm 200 175 225 325 175 175

As prov mm²/m 1005 646 349 348 1149 646

= % 0.453 0.311 0.155 0.167 0.518 0.311 %

S max mm 616 636 685 636 397 530 Clause

Subclause (b) (a) (a) (a) (b) (b) 3.12.11.2.7

DEFLECTION

fs 230 225 0 0 270 299 Eqn 8

Mod factor 1.437 Eqn 7

Perm L/d 37.37 Actual L/d 36.49 As enhanced 27.9% for deflection control Table 3.10

TORSION STEEL BOTH EDGES DISCONTINUOUS ONE EDGE DISCONTINUOUS

Ø mm 10 X Y X Y

As req mm²/m 349 566 325 3.5.3.5

As prov T mm²/m 348 349 348

Additional As T req mm²/m 326 328 0 0

As prov B mm²/m 1005 646 1005 646

Bottom steel not curtailed in edge strips at free edges

SUPPORT REACTIONS (kN/m char uno) (See Figure 3.10) Sum ßvx = 0.888 Table 3.15

EDGE 1 EDGE 2 EDGE 3 EDGE 4 Sum ßvy = 0.660

1, F-G G, 2-1 2, F-G F, 2-1 equations

ßv 0.355 0.264 0.533 0.396 19 & 20

Dead kN/m 21.29 15.82 31.93 23.74

Imposed kN/m 14.38 10.69 21.57 16.04

Vs kN/m 52.8 39.3 79.2 58.9

OUTPUT/SUMMARY

SHORT LONG EDGE 1 EDGE 2 EDGE 3 EDGE 4

PROVIDE SPAN SPAN 1, F-G G, 2-1 2, F-G F, 2-1

MAIN STEEL T16 @ 200 B1 T12 @ 175 B2 T10 @ 225 T1 T12 @ 325 T2 T16 @ 175 T1 T12 @ 175 T2

ADDITIONAL 0 CORNER 2 CORNER 3 CORNER 4

TORSION STEEL 0 G1 G2 F2

X direction 0 5 T10 T placed in edge strips

Y direction 0 5 T10 T

CHECKS BAR Ø SINGLY MIN MAX GLOBAL

Lx > Ly < COVER REINFORCED SPACING SPACING DEFLECTION STATUS

OK OK OK OK OK OK VALID DESIGN

You might also like

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Felicia Ghica100% (1)

- Hpe 2010 en PDFDocument102 pagesHpe 2010 en PDFdineshdubeyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2JigarNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)HAFEELNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2christi SNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2ery achjariNo ratings yet

- Two-Way Slab V2Document4 pagesTwo-Way Slab V2Eric AbedaniaNo ratings yet

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Document4 pages2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2மாறன் செங்கேணிNo ratings yet

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- Spreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68Document1 pageSpreadsheets To BS 8110 & EC2 Advisory Group 32nd Floor - Corner Panel RMW 24-Aug-2020 130 CHG R68roshan034No ratings yet

- Two-Way Slabs Design To BS 8110Document4 pagesTwo-Way Slabs Design To BS 8110samloo1997No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document4 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Mohammed ElemamNo ratings yet

- 2 Way Slab DesignDocument3 pages2 Way Slab DesignAhmedNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)adelalwailyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- RCC94 Two-Way Slabs (Tables)Document1 pageRCC94 Two-Way Slabs (Tables)curiosity12No ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Yasiri LucNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document3 pagesRCC94 Two-Way Slabs (Tables)Mohammad Twaha JaumbocusNo ratings yet

- Two-Way Slab DesignDocument4 pagesTwo-Way Slab DesignRaghNo ratings yet

- RCC94 Two-Way Slabs TablesDocument3 pagesRCC94 Two-Way Slabs TablesjohnyNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY 1f ChillerDocument1 pageRCC94 Two Way Slabs (Tables) MCY 1f ChillerYati ChanNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)thusiNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document1 pageF To G: 1 To 2: Spreadsheets To BS 8110 & EC2janithNo ratings yet

- 4.slab 2Document5 pages4.slab 2ikramNo ratings yet

- Spreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130Document1 pageSpreadsheets To BS 8110 & EC2: First Floor-Edge Panel SH 07-Nov-2020 130buddikalrNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)Anonymous ELujOV3No ratings yet

- Two-Way Solid Slabs - 1Document4 pagesTwo-Way Solid Slabs - 1rizwanjawaid.meenaNo ratings yet

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- 5 To 6: A To B: Villa BECDocument1 page5 To 6: A To B: Villa BECmohammedNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- PANEL08Document1 pagePANEL08Isaac JosephNo ratings yet

- Our Critical Slab DesignDocument5 pagesOur Critical Slab DesignIsmail AbdiNo ratings yet

- RCC94 Two-Way Slabs (Tables) - RS2Document1 pageRCC94 Two-Way Slabs (Tables) - RS2Arnold TunduliNo ratings yet

- RCC94 Two Way Slabs (Tables) MCY RF CTDocument1 pageRCC94 Two Way Slabs (Tables) MCY RF CTYati ChanNo ratings yet

- Development On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaDocument12 pagesDevelopment On Plot No. Donyo Sabuk/Komarock BLOCK 1/25878 Client: Lilian Lutta MalobaAustin AnindoNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document5 pagesRCC94 Two-Way Slabs (Tables)christi SNo ratings yet

- 3.0RCC94 Two-Way Slabs - 2Document5 pages3.0RCC94 Two-Way Slabs - 2ikramNo ratings yet

- 1st Floor 2 Way SlabDocument4 pages1st Floor 2 Way SlabOyelade MuyiwaNo ratings yet

- RCC94 Two-Way Slabs (Tables)Document4 pagesRCC94 Two-Way Slabs (Tables)Jacksizo Mremanyo100% (1)

- 5 To 6: A To B: Aktar BalushiDocument1 page5 To 6: A To B: Aktar BalushimohammedNo ratings yet

- Most Critical Interior PanelDocument1 pageMost Critical Interior PanelKagwi MauriceNo ratings yet

- CALC SHEET ZOLA - CompressedDocument33 pagesCALC SHEET ZOLA - CompressedSami Abdelgadir MohammedNo ratings yet

- 5 To 6: A To B: VillaDocument1 page5 To 6: A To B: VillamohammedNo ratings yet

- 5 To 6: A To B: Twin VillaDocument1 page5 To 6: A To B: Twin VillamohammedNo ratings yet

- TCC94 Two Way Slabs TablesDocument5 pagesTCC94 Two Way Slabs TablesMihai JNo ratings yet

- Valid Design: Design of Two Way Slab (S-1)Document1 pageValid Design: Design of Two Way Slab (S-1)Pipoy ReglosNo ratings yet

- RCC94 Two-Way Slabs (Tables) - 1Document5 pagesRCC94 Two-Way Slabs (Tables) - 1samueladebo207No ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)christi SNo ratings yet

- Two-Way Slabs (Tables)Document5 pagesTwo-Way Slabs (Tables)hala_azhariNo ratings yet

- TCC94 Two-Way Slabs (Tables)Document5 pagesTCC94 Two-Way Slabs (Tables)Mario Sajulga Dela CuadraNo ratings yet

- Dimensions Materials Status: Spreadsheets To Eurocode 2Document1 pageDimensions Materials Status: Spreadsheets To Eurocode 2jasekan.dcNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document9 pagesRCC92 Ribbed Slabs (Tables)Murthy GunaNo ratings yet

- Transformer Slab PDFDocument1 pageTransformer Slab PDFfdfsdfsNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- Stair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialDocument5 pagesStair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialUjol PraNo ratings yet

- Docc PDFDocument2 pagesDocc PDFUjol PraNo ratings yet

- Stair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialDocument4 pagesStair - Docx Doc2.pdf Doc2.pdf Pun-Maya-Manandh Ar - Docx.qvci6if - PartialUjol PraNo ratings yet

- DoccDocument1 pageDoccUjol PraNo ratings yet

- Known Data: H Z 2 I R S GDocument6 pagesKnown Data: H Z 2 I R S GUjol PraNo ratings yet

- All Commands in MS DosDocument42 pagesAll Commands in MS DosgodkeshavNo ratings yet

- Relay Board Connection InstructionDocument6 pagesRelay Board Connection Instructionkum512No ratings yet

- Computer ScientistDocument15 pagesComputer ScientistRenz Banayat Del RosarioNo ratings yet

- 2020 Express Water - Reverse Osmosis System Installation ManualDocument32 pages2020 Express Water - Reverse Osmosis System Installation ManualBobNo ratings yet

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDocument5 pagesDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- E Farming (BRS)Document6 pagesE Farming (BRS)Binish LoneNo ratings yet

- Improvement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaDocument2 pagesImprovement Such As Widening & Strengthening To To 4 Lane From Ch. 8/000 KM To 12/000 KM of Defunct NH-5 Balugaon Road, in The District of KhurdhaChandan MoharanaNo ratings yet

- ObmodsDocument6 pagesObmodsSean CrumpNo ratings yet

- L136T/Tl Marine EngineDocument2 pagesL136T/Tl Marine EngineAhmet GelişliNo ratings yet

- Ekg 6Document2 pagesEkg 6RachitNo ratings yet

- Allplan TutorialDocument330 pagesAllplan TutorialOana ScutarasuNo ratings yet

- Pompa Sirkulasi AP 156,3 LPM @60mDocument3 pagesPompa Sirkulasi AP 156,3 LPM @60mAndreas B KresnawanNo ratings yet

- Hydraulic Breaker Sandvik Br4511 City Sandvik Br4511 City-Jet Sandvik Br4511 City ProDocument28 pagesHydraulic Breaker Sandvik Br4511 City Sandvik Br4511 City-Jet Sandvik Br4511 City ProamontanocoNo ratings yet

- Slimdek Pattern BookDocument40 pagesSlimdek Pattern BookBabak WSP GroupNo ratings yet

- IZenBridge PMI ACP Program PDFDocument4 pagesIZenBridge PMI ACP Program PDFadetolahNo ratings yet

- Orphanage Master PlanDocument8 pagesOrphanage Master PlanNaguy FaquiraNo ratings yet

- Plano Electrico 16 MDocument25 pagesPlano Electrico 16 MRober TiconaNo ratings yet

- COBOLDocument171 pagesCOBOLgs_waiting_4_uNo ratings yet

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07No ratings yet

- Gas LiftDocument43 pagesGas LiftAhmad FaizilNo ratings yet

- Moisture BarriersDocument31 pagesMoisture BarriersraviciviltNo ratings yet

- Surfcam 2014 r2 - 32bitDocument152 pagesSurfcam 2014 r2 - 32bitClaudio HinojozaNo ratings yet

- Service Manual: Chassis, Mast & OptionsDocument37 pagesService Manual: Chassis, Mast & OptionsIsos Cell0% (1)

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

- Suspension SystemDocument11 pagesSuspension SystemARUNSFRHNo ratings yet

- CV ReinaldoZerpa+PEOPDocument2 pagesCV ReinaldoZerpa+PEOPReinaldo Zerpa PeñaNo ratings yet

- Examples Class LecturesDocument27 pagesExamples Class Lecturesnickthegreek142857No ratings yet

- Solar Photovoltaic Wire 600V: DescriptionDocument1 pageSolar Photovoltaic Wire 600V: DescriptionAMARENDRA SINo ratings yet

- PM EquipmentDocument16 pagesPM Equipmentsiva prasadNo ratings yet