Professional Documents

Culture Documents

ASTM A370 Hardness Conversion

ASTM A370 Hardness Conversion

Uploaded by

Antonio JOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A370 Hardness Conversion

ASTM A370 Hardness Conversion

Uploaded by

Antonio JCopyright:

Available Formats

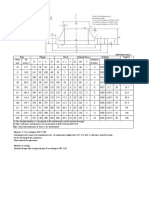

TECHNICAL/GUIDE/HCT-A370

HARDNESS CONVERSION TABLES

15/10/2015 - Ref.: ASTM table A370-03a ASTM A370

Table 1: HV-HRC Table 2: HRC-HV-HB-HRA-HRB-Rm conversion for carbon and alloy steel

conversion

HRC

HV

HB

HRA

Rm

HRB

HV

HB

HRA

Rm

HV HRC Diam. Vickers Brinell Diam. N/mm2 1/16’’ Vickers Brinell Diam. N/mm2

cone 30 3000 kgf cone MPa sphere 30 3000 kgf cone MPa

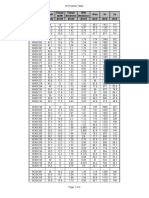

2270 85

68 940 — 85.6 — 100 240 240 61.5 800

2190 84 67 900 — 85.0 — 99 234 234 60.9 785

2110 83 66 865 — 84.5 — 98 228 228 60.2 750

2030 82 65 832 739 83.9 — 97 222 222 59.5 715

1950 81 64 800 722 83.4 — 96 216 216 58.9 705

1865 80 63 772 706 82.8 — 95 210 210 58.3 690

1787 79 62 746 688 82.3 — 94 205 205 57.6 675

1710 78 61 720 670 81.8 — 93 200 200 57.0 650

1633 77 60 697 654 81.2 — 92 195 195 56.4 635

59 674 634 80.7 2420 91 190 190 55.8 620

1556 76

58 653 615 80.1 2330 90 185 185 55.2 615

1478 75

57 633 595 79.6 2240 89 180 180 54.6 605

1400 74

56 613 577 79.0 2160 88 176 176 54.0 590

1323 73 55 595 560 78.5 2070 87 172 172 53.4 580

1245 72 54 577 543 78.0 2010 86 169 169 52.8 570

1160 71 53 560 525 77.4 1950 85 165 165 52.3 565

1076 70 52 544 512 76.8 1880 84 162 162 51.7 560

1004 69 51 528 496 76.3 1820 83 159 159 51.1 550

940 68 50 513 482 75.9 1760 82 156 156 50.6 530

920 67,5 49 498 468 75.2 1700 81 153 153 50.0 505

900 67 48 484 455 74.7 1640 80 150 150 49.5 495

47 471 442 74.1 1580 79 147 147 48.9 485

The highlighted values 46 458 432 73.6 1520 78 144 144 48.4 475

written in bold are reliable 45 446 421 73.1 1480 77 141 141 47.9 470

values but outside the

44 434 409 72.5 1430 76 139 139 47.3 460

ASTM table. The

highlighted values written 43 423 400 72.0 1390 75 137 137 46.8 455

in italics are generated by 42 412 390 71.5 1340 74 135 135 46.3 450

the passage from table 2 41 402 381 70.9 1300 73 132 132 45.8 440

to table 3 of the ASTM 40 392 371 70.4 1250 72 130 130 45.3 435

A370 norm.

39 382 362 69.9 1220 71 127 127 44.8 425

Rockwell Hardness 38 372 353 69.4 1180 70 125 125 44.3 420

HRC Diamond cone 120°;

37 363 344 68.9 1140 69 123 123 43.8 415

Load 1470 N (150 kgf),

36 354 336 68.4 1110 68 121 121 43.3 405

Duration 30’’

35 345 327 67.9 1080 67 119 119 42.8 400

HRA Diamond cone;

Load 588 N (60 kgf);

34 336 319 67.4 1050 66 117 117 42.3 395

Duration 30’’ 33 327 311 66.8 1030 65 116 116 41.8 385

HRB 1/16’’ sphere;

32 318 301 66.3 1010 64 114 114 41.4 —

Load 980 N (100 kgf); 31 310 294 65.8 970 63 112 112 40.9 —

Duration 30’’

30 302 286 65.3 950 62 110 110 40.4 370

Vickers Hardness 29 294 279 64.6 930 61 108 108 40.0 —

HV Diamond pyramid 136°;

28 286 271 64.3 900 60 107 107 39.5 —

Load 294 N (30 kgf);

27 279 264 63.8 880 59 106 106 39.0 360

Duration 15’’

26 272 258 63.3 860 58 104 104 38.6 —

Brinell Hardness 25 266 253 62.8 850 57 103 103 38.1 350

HB 10 mm sphere;

24 260 247 62.4 820 56 101 101 37.7 —

Load 29.400 N (3000 kgf);

23 254 243 62.0 810 55 100 100 37.2 340

Duration 15’’ 22 248 237 61.5 790 54 — — 36.8 —

Tensile resistence 21 243 231 61.0 770 51 — 94 35.5 330

Rm N/mm2 (MPa) 20 238 226 60.5 760 49 — 92 34.6 320

WWW.PASELLO.COM - Telephone: 051.728778 - The above information are provided by Pasello Trattamenti Termici Srl exclusively for personal use

and for information purposes and are subject to change without notice. Pasello Trattamenti Termici Srl makes no representation that the information

and opinions expressed are accurate, complete or current. Pasello Trattamenti Termici Srl will not be obliged to remove any outdated information or

clearly mark it as obsolete. Nothing herein constitutes consultation of any kind including financial, legal and tax related, nor any decisions about

investments or any other nature will be made based solely on the contents of this document.

page 1 of 1

You might also like

- JIS G 3106-2020 - Rolled Steels For Welded StructureDocument29 pagesJIS G 3106-2020 - Rolled Steels For Welded Structurehải hoàng đôngNo ratings yet

- Is Iso 7452 2002Document20 pagesIs Iso 7452 2002Ketan ValaNo ratings yet

- HighTens EN25Document2 pagesHighTens EN25Annamali Thiayagarajan0% (1)

- DIN 28091-2 GasketDocument20 pagesDIN 28091-2 Gasketengfaridmalk100% (1)

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDocument5 pagesNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliNo ratings yet

- English II Merchant of Venice Notes Compiled by Nilay Kumar Das PDFDocument2 pagesEnglish II Merchant of Venice Notes Compiled by Nilay Kumar Das PDFSubhadip RoyNo ratings yet

- According To DIN 50150: Hardness Comparison TableDocument1 pageAccording To DIN 50150: Hardness Comparison Tablerbagri100% (1)

- Astm A325m InnerDocument7 pagesAstm A325m InnerNgiuyen Viet TienNo ratings yet

- Studbolt Weight Chart MetricDocument1 pageStudbolt Weight Chart MetricselvakumarNo ratings yet

- Resume Standart Uic 800-50,800-51, Aws.a2.4, Iso1302Document7 pagesResume Standart Uic 800-50,800-51, Aws.a2.4, Iso1302isrowelding265No ratings yet

- Mode of Metal Transfer-Gas Metal Arc Wel PDFDocument5 pagesMode of Metal Transfer-Gas Metal Arc Wel PDFRamesh RNo ratings yet

- Mild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603Document2 pagesMild Steel: Mushroom Head Square Neck Bolts (Cup Square) DIN 603MantasNo ratings yet

- Din En1563-2018Document2 pagesDin En1563-2018FAPEMA SGQNo ratings yet

- GB T 3077 - 1999 Specification of 40Cr Alloy SteelDocument1 pageGB T 3077 - 1999 Specification of 40Cr Alloy SteelĐình Sỹ TTPNo ratings yet

- Astm A242-04Document1 pageAstm A242-04truongdinhbkNo ratings yet

- ShapeCUT Steel Hardness Conversion TableDocument2 pagesShapeCUT Steel Hardness Conversion TableVicente GarcíaNo ratings yet

- Tabel AISI ASTM (Selected)Document5 pagesTabel AISI ASTM (Selected)Dini Adilah PrabowoNo ratings yet

- Din 6798 ADocument3 pagesDin 6798 ADuong Bach100% (1)

- DIN 17100 ST 60-2 Steel Plate/sheetDocument1 pageDIN 17100 ST 60-2 Steel Plate/sheetRAMAKRISHNAN R100% (1)

- Astm EDocument32 pagesAstm EE Hammam El MissiryNo ratings yet

- As 3635-1990 Unified (ISO Inch) Screw Threads Associated Gauges and Gauging PracticeDocument8 pagesAs 3635-1990 Unified (ISO Inch) Screw Threads Associated Gauges and Gauging PracticeSAI Global - APACNo ratings yet

- Techincal Data For PCD Dia & Torque ChartDocument1 pageTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- ISO Nominal Diameter of Tool (MM) Tolerance Designation 3-6 6-10 10-18 18-30 30-50 50-80 80-120 120-180 Tolerance (Unit 0.001 MM)Document1 pageISO Nominal Diameter of Tool (MM) Tolerance Designation 3-6 6-10 10-18 18-30 30-50 50-80 80-120 120-180 Tolerance (Unit 0.001 MM)Ahmad Shuja100% (1)

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- Equivalent MaterialDocument28 pagesEquivalent MaterialAnonymous B3I6zYNhqdNo ratings yet

- Porca Din 439 BDocument7 pagesPorca Din 439 BFrank NunesNo ratings yet

- Bs 3100Document20 pagesBs 3100Sintha AidroosNo ratings yet

- Company Profil KS Dan Data Dukungnya PDFDocument107 pagesCompany Profil KS Dan Data Dukungnya PDFRidwanda HimawanNo ratings yet

- Jis G4052-08Document38 pagesJis G4052-08Sinan ChenNo ratings yet

- BS en 10084-2008Document40 pagesBS en 10084-2008Martijn Groot100% (1)

- JIS-G4105-1979-Chromium-Molybdenum-scm 45Document2 pagesJIS-G4105-1979-Chromium-Molybdenum-scm 45avinashchauhan2695No ratings yet

- Surcharges Alloys 2018Document21 pagesSurcharges Alloys 2018S Wa Sachin0% (1)

- Jis 3192Document2 pagesJis 3192Angga KurniawanNo ratings yet

- Calculating Springs According To DIN EN 13906 - 2Document3 pagesCalculating Springs According To DIN EN 13906 - 2romuloacNo ratings yet

- BS 3100 Spec, Steel Castings For General Eng PurposesDocument21 pagesBS 3100 Spec, Steel Castings For General Eng PurposesErol BurnsNo ratings yet

- QU AL ITY: Material Data SheetDocument5 pagesQU AL ITY: Material Data SheetAlex007No ratings yet

- Metric DIN 439 Spec PDFDocument4 pagesMetric DIN 439 Spec PDFHasib SejdinovicNo ratings yet

- Properties of Grade 8.8 Bolt & Nut (Iso)Document1 pageProperties of Grade 8.8 Bolt & Nut (Iso)Didik RahmadNo ratings yet

- S355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateDocument2 pagesS355J2 N, S355J2+N, En10025-2 s355j2n Steel PlateEswaranNo ratings yet

- Iso 4017Document1 pageIso 4017Nuno Miguel TorcatoNo ratings yet

- Alloy EquivalentsDocument3 pagesAlloy EquivalentsRajivharolikarNo ratings yet

- Tie Rod BrochureDocument20 pagesTie Rod Brochuremech_abhiNo ratings yet

- IS 4218 (Part 3) 1999Document17 pagesIS 4218 (Part 3) 1999Soma SundaramNo ratings yet

- Atlantic Catalogue 2016Document34 pagesAtlantic Catalogue 2016caswel14100% (2)

- FW F436 P PDFDocument2 pagesFW F436 P PDFLuis CarlosNo ratings yet

- GB T 699 1988 Quality Carbon Structural SteelsDocument17 pagesGB T 699 1988 Quality Carbon Structural SteelsPHUONGNo ratings yet

- Brinell Scale HBW 10/3000 ChartDocument1 pageBrinell Scale HBW 10/3000 ChartMark BrailsfordNo ratings yet

- Appendix 1 - ASTM Materials EquivalentDocument1 pageAppendix 1 - ASTM Materials EquivalentRAMILNo ratings yet

- Cylindrical Pins Is-2393Document2 pagesCylindrical Pins Is-2393Rajasekaran MuruganNo ratings yet

- Specifications For Design of Hot Metal Ladles AISE Standard No PDFDocument17 pagesSpecifications For Design of Hot Metal Ladles AISE Standard No PDFBuda PesteNo ratings yet

- Fastener Screw Thread Rolling DiametersDocument5 pagesFastener Screw Thread Rolling Diametersn1ghtfallNo ratings yet

- Iso 4162Document2 pagesIso 4162Guillermo TorresNo ratings yet

- BS EN 10028 3 2009, Flat ProductsDocument20 pagesBS EN 10028 3 2009, Flat ProductsgopalvivekNo ratings yet

- Din 126-2Document1 pageDin 126-2Safi Zabihullah SafiNo ratings yet

- Thread Standard BSPDocument7 pagesThread Standard BSPĐạt TrầnNo ratings yet

- Steel Section TablesDocument5 pagesSteel Section TablespudenaliNo ratings yet

- Hardness Conversion Tables: ASTM A370Document1 pageHardness Conversion Tables: ASTM A370Febri Ramdani NugrahaNo ratings yet

- Tabel Conversi HardnessDocument1 pageTabel Conversi HardnesskangenNo ratings yet

- Hardness (A370)Document2 pagesHardness (A370)pramodNo ratings yet

- ASME Sec. II SA370 Table 2 Dan 3 (1)Document2 pagesASME Sec. II SA370 Table 2 Dan 3 (1)Ganda Tua Leonardus L. GaolNo ratings yet

- TOR - Design & Supervision of Windalco-Kirkvine Cold Storage Facility Project - 0Document57 pagesTOR - Design & Supervision of Windalco-Kirkvine Cold Storage Facility Project - 0jawidNo ratings yet

- People CodeDocument44 pagesPeople CodehardanuNo ratings yet

- Cambridge Large1 Template Aog and JogDocument3 pagesCambridge Large1 Template Aog and JogFresh Prince Of NigeriaNo ratings yet

- Impact of Leadership Styles On Employee Performance Case Study of A Non Profit Organization NGO in CambodiaDocument7 pagesImpact of Leadership Styles On Employee Performance Case Study of A Non Profit Organization NGO in CambodiaEditor IJTSRDNo ratings yet

- Revision - Final ExamDocument5 pagesRevision - Final ExamminhadcarryNo ratings yet

- Elastomeric Bearing Design Calculation - 70 MT (400 X 200 X 39) MMDocument1 pageElastomeric Bearing Design Calculation - 70 MT (400 X 200 X 39) MMNamrataNo ratings yet

- Serva Cementing 113015 LR Pages PDFDocument16 pagesServa Cementing 113015 LR Pages PDFAnonymous uKoNmLxkNo ratings yet

- Genexpert Sars-Cov-2 (Covid-19) Vs Genexpert Mdr/Rif (TB) Test. Keep Moving Forward!Document4 pagesGenexpert Sars-Cov-2 (Covid-19) Vs Genexpert Mdr/Rif (TB) Test. Keep Moving Forward!Bashir MtwaklNo ratings yet

- Mental Health and Physical Activity: SciencedirectDocument8 pagesMental Health and Physical Activity: SciencedirectKAMYA SRIDHARAN 20214044No ratings yet

- Escuela Superior Politécnica de Chimborazo Facultad de Ciencias Pecuarias Carrera de Zootecnia NombreDocument15 pagesEscuela Superior Politécnica de Chimborazo Facultad de Ciencias Pecuarias Carrera de Zootecnia NombreJoselyn Vallejo PizanánNo ratings yet

- MassDocument2 pagesMassapi-222745762No ratings yet

- Lab 0: MTS-86C Equipment Familiarization: 1. ObjectivesDocument3 pagesLab 0: MTS-86C Equipment Familiarization: 1. ObjectivesLahcen MediniNo ratings yet

- YuYuYu Bonus Chapter - Sonoko AfterDocument14 pagesYuYuYu Bonus Chapter - Sonoko AfterAaron ParkerNo ratings yet

- Sorcerer's GardenDocument63 pagesSorcerer's Gardenswierck100% (2)

- (J25) Joomla! 2.5 - Beginner's Guide PDFDocument259 pages(J25) Joomla! 2.5 - Beginner's Guide PDFPaco FernándezNo ratings yet

- Cost Accounting Foundations and EvolutionsDocument49 pagesCost Accounting Foundations and EvolutionsTina LlorcaNo ratings yet

- 2023 Physics Study NotesDocument2 pages2023 Physics Study NotesPrapti SharmaNo ratings yet

- Coal Blending Model Developed To Prepare Feed To RINL With Cost Optimization - IPRDocument41 pagesCoal Blending Model Developed To Prepare Feed To RINL With Cost Optimization - IPRbhujakhia_748657110100% (1)

- C S E T: Test GuideDocument16 pagesC S E T: Test GuideShantamNo ratings yet

- Cathay Pacific Research PaperDocument4 pagesCathay Pacific Research Paperafeawfxlb100% (1)

- 2019 ASMPH Baccalaureate Mass and Commencement ExercisesDocument4 pages2019 ASMPH Baccalaureate Mass and Commencement Exercisesashchua21No ratings yet

- (PDF) Autonomous Continuing Professional Development For Algerian University Teachers of English (MISSOUM) Maamar Missoum - Academia - EduDocument12 pages(PDF) Autonomous Continuing Professional Development For Algerian University Teachers of English (MISSOUM) Maamar Missoum - Academia - EduMozadded HassanNo ratings yet

- Specifications: Shenzhen Sunlord Electronics Co., LTDDocument38 pagesSpecifications: Shenzhen Sunlord Electronics Co., LTDdabajiNo ratings yet

- During Compaction: Void SpacesDocument21 pagesDuring Compaction: Void SpacesMinilik Tikur SewNo ratings yet

- Tekradius LT Version 4.9 Readme FileDocument4 pagesTekradius LT Version 4.9 Readme FileAngel MaldonadoNo ratings yet

- Parameters For IPG-83H40PL-BDocument5 pagesParameters For IPG-83H40PL-BJack DanielsNo ratings yet

- Powerpoint presentation-WEEK 6Document35 pagesPowerpoint presentation-WEEK 6Mercy BonggoNo ratings yet

- Balanced Literacy Strategies For TeachersDocument19 pagesBalanced Literacy Strategies For TeachersJonette Cano LandayanNo ratings yet

- Good Thesis Statement For The Lottery by Shirley JacksonDocument7 pagesGood Thesis Statement For The Lottery by Shirley Jacksonbspq3gma100% (1)