Professional Documents

Culture Documents

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Uploaded by

KarthickCopyright:

Available Formats

You might also like

- ENA TS 50-18 Issue 4Document39 pagesENA TS 50-18 Issue 4David RothwellNo ratings yet

- Flagship: Visualsmp Users ManualDocument238 pagesFlagship: Visualsmp Users ManualSreekanthNo ratings yet

- G81-Design and Planning Rev 0.5Document25 pagesG81-Design and Planning Rev 0.5radulescuandrei100No ratings yet

- DNV ST E271 Offshore ContainersDocument107 pagesDNV ST E271 Offshore ContainersWantana RattaneeNo ratings yet

- SP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Document94 pagesSP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Rjeb mohamed100% (1)

- DCF Developers GuideDocument231 pagesDCF Developers Guideanon-689453No ratings yet

- RMS Specs 3051 Ed6Document37 pagesRMS Specs 3051 Ed6Luke DigginsNo ratings yet

- Design and Fabrication of Self Centering ViceDocument47 pagesDesign and Fabrication of Self Centering ViceKarthickNo ratings yet

- Metallic Detector Using Ic 555Document7 pagesMetallic Detector Using Ic 555SHRUTI MOON100% (1)

- HVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDocument17 pagesHVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDareyoss NegussieNo ratings yet

- Asr 1005 Aps 900 Ima 09Document43 pagesAsr 1005 Aps 900 Ima 09raulNo ratings yet

- E-500 - Design Criteria - ElectricalDocument45 pagesE-500 - Design Criteria - ElectricalDinesh RajNo ratings yet

- Power and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Document10 pagesPower and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Azhar AliNo ratings yet

- Asr 1005 Aps 900 Ima 08Document21 pagesAsr 1005 Aps 900 Ima 08Anonymous vguPVDzZ7TNo ratings yet

- Spec Hotel Load Conv P4 - Rev 0 - Aug 12Document35 pagesSpec Hotel Load Conv P4 - Rev 0 - Aug 12divisional electrical enggNo ratings yet

- So-0612-W Polaris TechnicalManual Section 5a InstructorsManualDocument534 pagesSo-0612-W Polaris TechnicalManual Section 5a InstructorsManualClarence Pietersz100% (1)

- Programming Standard Specification 7x04Document141 pagesProgramming Standard Specification 7x04Carmen MuñozNo ratings yet

- 3-FRENIC Lift PDFDocument48 pages3-FRENIC Lift PDFMoran Martines100% (1)

- SG FRENIC Lift EN 1 7 0Document42 pagesSG FRENIC Lift EN 1 7 0Mahmoud RobNo ratings yet

- LAZ 5100 Manual EnglishDocument79 pagesLAZ 5100 Manual EnglishMorseNo ratings yet

- CRS Basis For The Design (20210908) - Rev A-ELS Reply 9-9-21Document10 pagesCRS Basis For The Design (20210908) - Rev A-ELS Reply 9-9-21dikiNo ratings yet

- Network Design Manual v7.7Document194 pagesNetwork Design Manual v7.7somchak2000100% (3)

- 165994-BKR-REP-ESG-000001 - Markle LC Renewal Signalling Asset Condition Report - Final - 2 - SPDocument398 pages165994-BKR-REP-ESG-000001 - Markle LC Renewal Signalling Asset Condition Report - Final - 2 - SPShaik SaidabheeNo ratings yet

- Specification - Site DemolitionDocument7 pagesSpecification - Site DemolitionAzhar AliNo ratings yet

- Steel Pipe For Waterworks PurposesDocument25 pagesSteel Pipe For Waterworks PurposesFelipa ShanNo ratings yet

- 202106-Aashto LRFD 8th CA Amendments-A11yDocument403 pages202106-Aashto LRFD 8th CA Amendments-A11yDaniel DugarteNo ratings yet

- Ispo A - 11 0Document24 pagesIspo A - 11 0JaadNo ratings yet

- ESC 420 Track Drainage: Engineering Standard CivilDocument16 pagesESC 420 Track Drainage: Engineering Standard CivilSuciu FlorinNo ratings yet

- Ministry of Railways: Specification For DevelopmentDocument35 pagesMinistry of Railways: Specification For DevelopmentvipinabrolNo ratings yet

- CIV-MS-010-07-Rapid Chloride PermeabilityDocument7 pagesCIV-MS-010-07-Rapid Chloride PermeabilityAdil faridNo ratings yet

- MQ SP M 4004 PDFDocument17 pagesMQ SP M 4004 PDFjaseelNo ratings yet

- Implementation 2011Document1 pageImplementation 2011ahm2011No ratings yet

- FilesDocument54 pagesFilesHussainNo ratings yet

- Cask FsarDocument1,235 pagesCask Fsarvishnew12No ratings yet

- Gic Ispa - Dms Via Ispa Broker v4.0.8Document196 pagesGic Ispa - Dms Via Ispa Broker v4.0.8Antonio NevesNo ratings yet

- 7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications SignedDocument10 pages7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications Signedsibaranjandash2007No ratings yet

- NewDirectionsPostTensioningVol10B PDFDocument66 pagesNewDirectionsPostTensioningVol10B PDFSyed RaziuddinNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsDocument45 pagesTransport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsroshanNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesDocument20 pagesTransport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesHenry HNo ratings yet

- EP2 User InterfaceDocument98 pagesEP2 User InterfacerivershanNo ratings yet

- Changes and Impact - TOC Chapter 1, 2Document9 pagesChanges and Impact - TOC Chapter 1, 2crvillateNo ratings yet

- CPCI PCI Bridge Design Manual PresentationDocument81 pagesCPCI PCI Bridge Design Manual PresentationmikefaraNo ratings yet

- Compass 56030-1Document86 pagesCompass 56030-1Nebyu GetachewNo ratings yet

- 2013-10-17 Seaoc SSDM Series PPT Vol 1 HandoutDocument39 pages2013-10-17 Seaoc SSDM Series PPT Vol 1 HandoutAnonymous 9MDGo2jNo ratings yet

- PPL Su 1051 F.1Document47 pagesPPL Su 1051 F.1resp-ectNo ratings yet

- TS 02164.2 - 0.00 - Design of Reinforced Soil Walls - DCDocument61 pagesTS 02164.2 - 0.00 - Design of Reinforced Soil Walls - DCislamawanNo ratings yet

- DBR Rev.G 26th SeptDocument51 pagesDBR Rev.G 26th Septsudhir12345No ratings yet

- 3-Ken Sabo - Updated Building Codes Are Changing Battery Rack CertificationDocument6 pages3-Ken Sabo - Updated Building Codes Are Changing Battery Rack CertificationBau FroschNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R15 Kerbs and Channels (Gutters)Document20 pagesTransport For NSW (TFNSW) Qa Specification R15 Kerbs and Channels (Gutters)Henry HNo ratings yet

- Crane Fex Guide v0.4Document80 pagesCrane Fex Guide v0.4HugoSilvaNo ratings yet

- 10.0128.F.R OSD 030 Optus Tower Specification Rev 6 5Document45 pages10.0128.F.R OSD 030 Optus Tower Specification Rev 6 5Vinaykumar RaoNo ratings yet

- Newdirectionsposttensioningvol10a PDFDocument95 pagesNewdirectionsposttensioningvol10a PDFNOEL RODRIGUEZNo ratings yet

- JLR Robot Standard Rules For Abb Robots v1.8 Jlr-Mees-Rf-62-009Document43 pagesJLR Robot Standard Rules For Abb Robots v1.8 Jlr-Mees-Rf-62-009Cristian CanalesNo ratings yet

- Specification - Site Preparation, Excavation, and Backfill SpecificationDocument24 pagesSpecification - Site Preparation, Excavation, and Backfill SpecificationAzhar AliNo ratings yet

- Design of An MAV For The 2019 SAE Aero Design Competition PDFDocument209 pagesDesign of An MAV For The 2019 SAE Aero Design Competition PDFShiva KarthikeyaNo ratings yet

- Seagate NAS DriveDocument35 pagesSeagate NAS DriveCristina TudorNo ratings yet

- Guideline SoM in L2 - v1Document22 pagesGuideline SoM in L2 - v1Necdet ÇilingirNo ratings yet

- Design of Highway Bridges: An LRFD ApproachFrom EverandDesign of Highway Bridges: An LRFD ApproachRating: 4.5 out of 5 stars4.5/5 (4)

- The North British Type 2 Bo-Bo Diesel-Electric Classes 21 & 29: Design, Development and DemiseFrom EverandThe North British Type 2 Bo-Bo Diesel-Electric Classes 21 & 29: Design, Development and DemiseNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Building Sustainability in East Asia: Policy, Design and PeopleFrom EverandBuilding Sustainability in East Asia: Policy, Design and PeopleNo ratings yet

- Enzymatic Fuel Cells: From Fundamentals to ApplicationsFrom EverandEnzymatic Fuel Cells: From Fundamentals to ApplicationsHeather R. LuckariftNo ratings yet

- ISRO Scientist Engineer SC MECHANICAL BE002 Result 2020 PDFDocument18 pagesISRO Scientist Engineer SC MECHANICAL BE002 Result 2020 PDFKarthickNo ratings yet

- IJEETC 55f7bcfa91507 PDFDocument5 pagesIJEETC 55f7bcfa91507 PDFKarthickNo ratings yet

- Aptitude PartnershipDocument12 pagesAptitude PartnershipKarthick100% (1)

- Chapter 4Document37 pagesChapter 4KarthickNo ratings yet

- Spotting Errors in EnglishDocument7 pagesSpotting Errors in EnglishKarthickNo ratings yet

- AbstractDocument3 pagesAbstractKarthickNo ratings yet

- Design and Fabrication of Self Centering Vice Ppt-1Document36 pagesDesign and Fabrication of Self Centering Vice Ppt-1KarthickNo ratings yet

- Milling Attachment With 3 FunctionsDocument3 pagesMilling Attachment With 3 FunctionsKarthickNo ratings yet

- Solenoid Valves - : Spare PartsDocument1 pageSolenoid Valves - : Spare PartsJhonny ChoquehuancaNo ratings yet

- Vibraswitch Robertshaw rbs365Document3 pagesVibraswitch Robertshaw rbs365jesus castillejosNo ratings yet

- 2 P 2010 Newcatalog P 2010 CatalogDocument5 pages2 P 2010 Newcatalog P 2010 CatalogNoe Carlos Liviapoma GironNo ratings yet

- Digifas 7200 EDocument70 pagesDigifas 7200 EvinodNo ratings yet

- Electrical Components For The Railway Industry Catalog LV 12 2015 201612161402441410Document112 pagesElectrical Components For The Railway Industry Catalog LV 12 2015 201612161402441410cc_bauNo ratings yet

- Decora Smart™: Dimmer With Z-Wave TechnologyDocument2 pagesDecora Smart™: Dimmer With Z-Wave TechnologypatNo ratings yet

- Simple LED Blinking CircuitsDocument4 pagesSimple LED Blinking CircuitsNoor FazillaNo ratings yet

- H300 Current RelayDocument2 pagesH300 Current RelaySteven WeiNo ratings yet

- Bee Everything - MergedDocument1,973 pagesBee Everything - Mergednakul kamatkarNo ratings yet

- Total Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedDocument1 pageTotal Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedfaberromeroNo ratings yet

- Tut 2Document3 pagesTut 2MOHIT SINGHALNo ratings yet

- Electronic Devices Lab MANUALDocument24 pagesElectronic Devices Lab MANUALna_hariprsadNo ratings yet

- Aurora A5 User Manual (EN) : Operation Instruction: Momentary ON Turn On / Off Primary FeaturesDocument2 pagesAurora A5 User Manual (EN) : Operation Instruction: Momentary ON Turn On / Off Primary FeaturesDamien LockkeNo ratings yet

- IRFZ34N Datasheet - KDocument8 pagesIRFZ34N Datasheet - KNairo FilhoNo ratings yet

- How To Design Capacitor BankDocument5 pagesHow To Design Capacitor BankAbdul AzizNo ratings yet

- Footprint Naming Rule Reference PDFDocument83 pagesFootprint Naming Rule Reference PDFvinh quocNo ratings yet

- 电气设备手册 - Buku Besar Peralatan ElektrikDocument148 pages电气设备手册 - Buku Besar Peralatan ElektriksusitoNo ratings yet

- Ac Motor ProtectionDocument38 pagesAc Motor ProtectionsibtainNo ratings yet

- Ec 238Document2 pagesEc 238Ahmed HasanainNo ratings yet

- Sa Ami 460 Fcon 100702 - 1 1Document1 pageSa Ami 460 Fcon 100702 - 1 1tanyadeasis8No ratings yet

- Lundahl: Amorphous Core Moving Coil Input Transformer LL1931Document1 pageLundahl: Amorphous Core Moving Coil Input Transformer LL1931Giapy Phuc TranNo ratings yet

- LC1D12M7 Schneider Electric Datasheet 21405858Document3 pagesLC1D12M7 Schneider Electric Datasheet 21405858hector diazNo ratings yet

- 300ma L.D.O Voltage Regulator Tj1117GsfDocument14 pages300ma L.D.O Voltage Regulator Tj1117GsfkalanghoNo ratings yet

- Microwave Devices and Circuits - Samuel Y. LiaoDocument101 pagesMicrowave Devices and Circuits - Samuel Y. Liaorkhanna1965No ratings yet

- Product Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyKamilNo ratings yet

- 1vap420001-Tg Abb Utility It Ref Guide 2019Document137 pages1vap420001-Tg Abb Utility It Ref Guide 2019nikodemisNo ratings yet

- Type Coordination Siemens PDFDocument58 pagesType Coordination Siemens PDFvishal.nitham100% (2)

- OBD2 Adapter Cable DatasheetDocument11 pagesOBD2 Adapter Cable DatasheetJay highfieldNo ratings yet

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Uploaded by

KarthickOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Lighting System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor Service

Uploaded by

KarthickCopyright:

Available Formats

Standardized Technical Specification

Bi-Level Passenger Rail Cars

for

Intercity Corridor Service

Chapter 11

Lighting System

Revision K

Copyright 2010 California Department of Transportation All rights reserved

Table of Contents 11-1

Table of Contents

11.0 Lighting System ....................................................................................................... 11-3

11.1 Overview ............................................................................................................. 11-3

11.2 General Requirements ......................................................................................... 11-3

11.3 Lighting Plan Design Review ................................................................................ 11-4

11.4 Interior Lighting Levels ........................................................................................ 11-4

11.4.1 Lighting Color Temperatures ......................................................................... 11-4

11.4.2 Minimum Lighting Illumination ..................................................................... 11-4

11.5 Interior Lighting Modes ....................................................................................... 11-5

11.5.1 Normal Lighting Mode ................................................................................... 11-5

11.5.2 Quiet Car Mode ............................................................................................. 11-5

11.5.3 Standby Lighting Mode .................................................................................. 11-5

11.5.4 Load Shed Lighting Mode .............................................................................. 11-5

11.5.5 Emergency Lighting Mode .............................................................................. 11-6

11.6 Interior Lighting Requirements ............................................................................ 11-6

11.6.1 Passenger Area .............................................................................................. 11-6

11.6.2 Vestibules, Stairways and other Non-Seating Areas ....................................... 11-7

11.6.3 Toilet Rooms.................................................................................................. 11-8

11.6.4 Service and Utility Rooms .............................................................................. 11-9

11.7 Exterior Lighting Requirements ........................................................................... 11-9

11.7.1 Marker Lights ................................................................................................ 11-9

11.7.2 Platform Lights ............................................................................................ 11-10

11.7.3 Exterior Indicator Lights .............................................................................. 11-10

11.7.4 Exterior Door ADA Lights ............................................................................ 11-11

11.7.5 Headlights and Crossing Lights ................................................................... 11-11

11.8 Systems Indicator Panel .................................................................................... 11-11

11.9 Lighting Fixture Requirements .......................................................................... 11-11

11.9.1 Fluorescent Lighting .................................................................................... 11-11

11.9.2 Light Emitting Diode (LED) Lighting ............................................................ 11-12

11.9.3 DC/AC Ballasts ........................................................................................... 11-13

11.9.4 Capacitor-Based Lighting ............................................................................ 11-13

11.10 Housings, Lenses and Diffusers ........................................................................ 11-13

11.11 Controls ............................................................................................................ 11-14

11.12 Testing .............................................................................................................. 11-14

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Revision Status 11-2

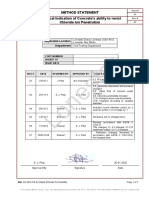

Revision Status

Spec New

Date of

Section Description Revision Author

Revision

# Level

ALL Original Release 5/6/06 A

ALL Additional text added 9/11/06 B Rich F

ALL Edits by SH, LH, BH 11/6/06 C Rich F

ALL Edits by Richard F 11/13/06 D Rich F

ALL Edits by SCH 11/15/06 E SCH

LED LED edits, table 11/16/06 F Rich F

ALL Misc. edits 11/17/06 G SCH

ALL Formatted 02/14/07 H CLC

ALL Complete review of Chapter. 6/22/07 I CLC

ALL Updated Footers 12/10/07 I.1 CLC

ALL Updated formatting & Spec/Vendor paragraphs 3/11/08 I.2 CLC

Incorporated edits and comments agreed upon in

ALL 3/24/08 I.3 CLC

meetings w/ Bob, Leo, and Stan

ALL Incorporated Bobs edits and comments 9/4/08 I.4 CLC

ALL Incorporated Bob’s edits and comments 10/2/08 I.5 CLC

ALL Miscellaneous edits 10/27/08 I.6 sch

ALL Final Formatting 11/6/08 J CLC

Incorporated edits& comments agreed upon in

meeting w/ Bob, Leo, and Stan regarding comments

ALL 11/25/08 J.1 CLC

from Bob Haslam (CCJPA) & Richard Seaton (TDG

Design)

Replaced Language for supplemental reference

11.2 4/25/09 J.2 CLC

paragraph

All Minor edits 4/27/09 J.3 sch

11.2 Updated References 7/9/09 J.4 CLC

All Conformed to Style Guide 9/23/09 J.5 CLC

Spec.

Edited Specified Components per Stan 12/23/09 J.6 CLC

Comp.

Incorporated Stan’s edits/comments w/ tracked

All 2/9/10 J.6 CLC

changes

Incorporated Stan’s response to Interfleet’s, PB’s &

All 3/8/10 J.6 CLC

Amtrak’s comments.

All Accepted all tracked changes and formatted 3/19/10 K CLC

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-3

11.0 Lighting System

11.1 Overview

This chapter describes the interior and exterior lighting system that shall be provided on all car

types. The lighting system as designed shall enhance the appeal of interior furnishings and

create a comfortable and pleasant atmosphere while providing for maximum passenger and

crewmember safety. Normal and emergency lighting shall conform to the requirements of all

applicable APTA standards and FRA regulations.

The lighting system shall provide four modes of interior lighting: normal, quiet car, standby

and emergency. Interior and exterior lighting shall be provided by Light Emitting Diodes

(LEDs) or a combination of LEDs and fluorescent lights. LEDs are the preferred method of

providing interior passenger seating area lighting. Lights in toilet rooms, stairways, vestibules,

passageways, as well as reading lights and indicator lights shall be LED. Incandescent lights

shall not be used except as specified. Halogen lights shall not be used.

For lighting requirements in the lounge and galley areas of the café/lounge car, see Chapter

14. For lighting requirements in the cab control compartment and F-end of the cab/baggage

car, see Chapter 16.

The Contractor shall prepare an interior and exterior lighting plan for Customer review that

describes the type of lighting to be used in all applications, including fixture type, voltage and

color temperature, illumination levels at specified locations for all lighting modes, and

compliance with emergency lighting and signage regulations and standards. This lighting plan

shall be submitted to the Customer during the design review. DR

11.2 General Requirements

Unless otherwise specified in this section, lighting design (both on the exterior and in the

interior of the car) shall meet or exceed the minimum standards defined by APTA Standards

SS-PS-002-98 and SS-PS-004-99 and APTA Recommended Practice RP-E-012-99.

Fixtures installed on the vehicle exterior, and in the interior within 2 ft of a doorway, shall be

watertight, except for interior ceiling lights.

Car interior lighting shall provide adequate and convenient illumination under all ambient

lighting conditions from complete darkness to bright sunlight. Lighting in all locations shall be

arranged to minimize shadows, avoid glare and excessive brightness ratios. Lighting shall be

appropriate for the application, easily maintainable and compliant with all regulations and

standards including this specification.

All lighting lamps and fixtures shall be suitable for rough duty service found in the railroad

environment throughout North America. All lamps shall be commercially available from

multiple sources.

The use of LED and fluorescent lighting is the preferred method for interior and exterior

lighting. Halogen lamps shall not be used. Incandescent lamps shall not be used, except

headlights and crossing lights on cab/baggage cars.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-4

Each type of lamp shall have a distinct fixture design for its specific voltage. Lamps of differing

voltages shall not share the same base design and lamps shall not be interchangeable between

fixtures with differing voltages.

The lighting fixture housing or socket shall not be used as a ground return for any other

electrical circuits.

11.3 Lighting Plan Design Review

The Contractor shall submit their design plan incorporating all requirements listed for review

and approval. Design drawings and calculations showing the complete lighting system

including fixture design, fixture locations, lighting illumination, modes of lighting and electrical

schematics shall be submitted for evaluation during design review. DR

The Contractor shall provide drawings of the lighting arrangement of each car type for

Customer approval during design review. The location of each lighting fixture, circuit breaker

size and location, switch, control, lamp type, color, luminance value (in foot-candles) and

quantity shall be clearly identified. Fixtures providing standby and emergency lighting shall be

identified. Proposed charging light levels for photoluminescent emergency exit signage and Low

Location Exit Pathway Markings (LLEPM) components will be identified.

Examples of each lighting fixture shall be provided for Customer approval at the final design

review.

Lighting fixtures shall not be a source of Electromagnetic Interference (EMI) and shall be

included in the Electromagnetic Compatibility (EMC) plan required by APTA Standard SS-E-

010.98. See chapter 19.

11.4 Interior Lighting Levels

All light level measurements shall be made in accordance with the minimum standards defined

by APTA Recommended Practice RP-E-012-99.

11.4.1 Lighting Color Temperatures

The lighting color for all interior lights and lamps in the passenger rail car shall be

3500° - 4100° Kelvin (K). The Contractor is to provide suggested light color plan for Customer’s

review and approval during the preliminary design review. DR

11.4.2 Minimum Lighting Illumination

The minimum spatial average of illumination shall be at the points listed in Table 11-1, and

shall meet the minimum value(s), measured in foot-candles, with all lights on and at the rated

voltage when the equipment is new.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-5

11.5 Interior Lighting Modes

11.5.1 Normal Lighting Mode

Normal lighting mode is that which is available when the car is is operating from a 480VAC

power source. All lighting fixtures and elements intended for use while the car is in revenue

service shall be available during normal lighting mode. Minimum illumination levels for

normal lighting mode are shown in Table 11-1.

11.5.2 Quiet Car Mode

Normal lighting mode in the car shall be arranged to allow the level of lighting to be reduced for

passenger comfort during early morning and late evening operation, while maintaining

sufficient lighting for passenger and crew safety, and compliance with standards and

regulations. This reduced light level, referred to as “Quiet Car” mode, may use any

combination of lighting elements so long as minimum light levels are maintained at “Standby”

illumination levels throughout the car, and all light fixtures operating during quiet car mode

remain powered at all times, either through the Alternating Current (AC) system or the low-

voltage power supply. Car lighting during quiet car mode shall be adequate to charge the

photoluminescent emergency signage and LLEPM system per the required standards. A

dedicated, clearly labeled switch in the electric locker shall permit operating personnel to easily

select either normal lighting or quiet car mode lighting. Minimum illumination levels for quiet

car mode are shown in Table 11-1 under the “Standby Lighting” column.

11.5.3 Standby Lighting Mode

Standby lighting is that which is available when the car has lost Head End Power (HEP) but

the battery has not yet discharged to load shed. This lighting mode is intended to keep

sufficent lighting operational for a period of at least two hours so that short term loss of

480VAC power will not affect the passengers’ ability to safely move throughout the train. Car

lighting during standby mode shall be adequate to maintain the light charge for the

photoluminescent emergency signage and LLEPM system per the required standards.

Minimum illumination levels for Standby mode are shown in Table 11-1.

11.5.4 Load Shed Lighting Mode

Load shed mode is when the car batteries have discharged sufficiently after HEP loss that non-

essential loads are shed in order to preserve battery power for essential loads. Interior lighting

is reduced to 5 foot-candles in order to maintain charging light levels for High Pressure

Photoluminescent (HPPL) exit signage and pathway markings. Reading lights, equipment room

lights and other Direct Current (DC) loads are shed. Load shed conditions continues for

approximately one hour until the battery voltage drops to roughly 45VDC, at which time the

load drop relay disconnects the batteries from the DC supply circuit, which initiates the

Emergency Lighting mode. See chapter 13 for details regarding load shed.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-6

11.5.5 Emergency Lighting Mode

Emergency lighting mode is that which is available after load drop has occurred when the car's

batteries have reached approximately 45VDC. This lighting provides passenger orientation and

sufficient light levels for passengers to move about safely within the car and if necessary, to

find the nearest safe exit point. It is especially important in stairways, aisles, vestibules and

enclosed spaces, such as toilet rooms. Once the low voltage system reaches a low-voltage

threshold, which occurs at about 45VDC, all standby lighting is extinguished and emergency

lighting shall illuminate. This lighting system may use dedicated fixtures, may provide a

reduced level of illumination from the normal lighting system, or may use some but not all of

the normal lighting fixtures. The emergency lighting system shall be powered by capacitors, or

by batteries if capacitors cannot comply with FRA requirements for emergency lighting, and

shall provide emergency lighting for a minimum of 90 minutes. Emergency lighting shall

comply with APTA Standard SS-E-013-99.

The Contractor shall provide for Customer approval during design review an Emergency

Lighting Plan that describes and illustrates the emergency lighting system, including location,

type and design of all lighting fixtures and the level of illumination that shall be provided at all

points as identified in APTA Standard SS-E-013-99. The Contractor shall demonstrate

compliance with emergency lighting requirements and shall provide to the Customer written

certification of compliance. DR

11.6 Interior Lighting Requirements

11.6.1 Passenger Area

The following describes the individual lighting fixture applications and specifications for all

areas of the car. Lights may be fluorescent or LED unless otherwise specified. Light fixtures in

toilet room ceiling, stairway ceiling, vestibule ceiling and hallway ceiling shall be identical units

if possible.

11.6.1.1 Main Ceiling

Two longitudinal rows of lights shall provide the primary lighting for the seating area in the

revenue seating areas of coaches, cab/baggage and café/lounge cars, and shall be located

adjacent to the center ceiling panels/air diffusers. These fluorescent fixtures provide the main

light source to the car and provide lighting to the aisle as well as general lighting to the seating

areas. The fixtures shall be trough-construction units, mounted end-to-end. They shall be

equipped with terminal blocks wired in parallel fixture-to-fixture, including all bus wiring for

the entire fixture string for normal, quiet car and standby modes. LED units may be used in

place of fluorescent tubes provided that they create an even light output and similar

appearance to fluorescent lights.

11.6.1.2 Passenger Reading Lights

Individual reading lights shall be white LEDs powered by 24VDC. They shall be mounted in an

adjustable gimbal mount that allows for individual directional adjustment. Each reading light

shall have an ON/OFF switch. A reading light shall be provided for each coach seat and the

wheelchair parking location.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-7

Passenger reading lighting shall be mounted in an adjustable track so that the reading light

fixtures can be relocated to match the seat pitch as specified by the Customer. See Chapters 9

and 23.

11.6.2 Vestibules, Stairways and other Non-Seating Areas

11.6.2.1 Flush-Mounted Overhead Light Fixtures

Flush-mounted overhead light fixtures with LED light elements shall be provided in the

following locations for the purposes of commonality and interchangeability:

• Vestibule ceilings

• Toilet room ceilings

• Stairway ceilings

• Hallway ceilings

• Checked baggage room

• Above upper-level luggage racks

11.6.2.2 Diaphragm/End Passageway

The end passageway light shall be a weatherproof, sealed LED unit mounted overhead to the

side of the passageway on the diaphragm side of the end doors on all car types. The unit shall

cast adequate light throughout the diaphragm and passageway area including handholds, door

panel, walkway surface, signage and handbrake.

11.6.2.3 Vestibule Ceiling at Lower Level Side Doors

Flush-mounted light fixtures shall provide overhead light to the areas adjacent to the side entry

doors. The lights shall provide adequate illumination to charge all required emergency signage

on and around door panels and emergency door releases. The same fixture shall be used at all

side entrance locations, including service vestibules in the café/lounge and cab/baggage cars.

11.6.2.4 Stairway Ceiling

Flush-mounted light fixtures shall provide overhead light to the stairways.

11.6.2.5 Stairway Sidewall

Step lights shall be sealed, recessed, wall-mounted LED units. Fixture shall be impact-

resistant and shall not present a tripping hazard. Each light unit may illuminate several steps.

All steps shall be illuminated.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-8

11.6.2.6 Hallway

A flush-mounted fluorescent fixture shall provide light in the ceiling of the hallways. These

lights shall be used in the following locations, at a minimum:

• Hallway at accessible toilet

• Hallway past café galley

• Hallway adjacent to utility lockers, luggage racks and toilet rooms at end doors

11.6.2.7 Luggage Rack/Bike Rack Area

A pair of recessed can-type LED fixtures shall be provided in the ceiling of the luggage

rack/bike rack area in the lower level A-end vestibule of coach cars.

11.6.2.8 Checked Baggage Room

The baggage room shall be equipped with no less than four flush-mounted ceiling fixtures over

the luggage racks, similar to those in the luggage rack/bike rack area in the A-end vestibule of

coach cars. Each fixture shall be equipped with a robust guard to protect the lens from

damage. These fixtures are in addition to those in the vestibule above the side entrance doors.

11.6.3 Toilet Rooms

11.6.3.1 Toilet Ceiling and Mirror

Two light fixtures shall be mounted on the ceiling of each toilet room to provide general lighting

to the toilet room.

The lighting fixtures shall be wired in parallel and shall be provided as part of the toilet

module.

11.6.3.2 Toilet Room Occupied/Out of Service Sign

The toilet OCCUPIED/OUT OF SERVICE light fixture shall be mounted on the toilet room exterior

wall, adjacent to the toilet room door for all toilet rooms. This light shall consist of a two-light

LED fixture with a sign containing text and/or a pictorial symbol which provides indication as

to when the toilet room door is locked (occupied) and a second light that provides indication

that the toilet room is “out of service” (when the toilet system is not functioning). Lights shall

be on when the toilet is occupied or out of service, and shall be extinguished when the toilet is

available for use. These LEDs shall be yellow. Artwork for the labels shall be submitted to the

Customer for approval during the design review. DR

A yellow LED indicator shall be provided inside the toilet room, adjacent to the door, that

illuminates when the door is locked (parallel with the toilet occupied indicator outside the toilet

room). This indicator shall be labeled DOOR LOCKED WHEN LIGHT IS ON.

The LEDs used for these indicators shall be no less than 0.25 in. in diameter for clear visibility

to passengers.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-9

11.6.4 Service and Utility Rooms

11.6.4.1 Electrical Locker

The electrical locker shall be illuminated by at least two overhead lights, controlled by a wall-

mounted manual ON/OFF switch located adjacent to the door. The light fixtures shall be

protected by a clear shatterproof glass or polycarbonate lens, or other suitable protection, and

shall not be vulnerable to damage during normal maintenance activities. Electric locker lights

shall be operable during all lighting modes.

11.6.4.2 Utility Locker

At least one light fixture shall be installed in each interior utility locker, and shall be energized

by means of an automatic light switch that turns the lights on when the door is opened and off

when the door is closed. If necessary to illuminate the space, multiple light fixtures shall be

installed and operated by the single ON/OFF switch. The lights shall be so located as to provide

general illumination within the locker and be readily accessible for replacement.

11.6.4.3 Equipment Rooms

Each equipment room shall be equipped at least four flush-mounted waterproof fixtures to

provide good lighting throughout the equipment rooms for inspecting and servicing the

equipment. The light fixtures shall be protected by a clear shatterproof glass or polycarbonate

lens, or other suitable protection, and shall not be vulnerable to damage during normal

maintenance activities. The lamps shall be LED or DC-based compact fluorescent. The light

design shall provide sufficient light to illuminate the entire room interior and allow all

equipment within it to be serviced in place without the need for additional portable lighting. A

manual, moisture-proof, over-travel type limit switch shall be installed inside the door opening

adjacent to the door.

11.6.4.4 Control Cab

Lighting requirements for the control cab compartment in the cab/baggage cars are described

in Chapter 16.

11.6.4.5 Café/Lounge Galley and Lounge Area

Lighting requirements for the food service galleys (upper and lower) and the lounge seating area

of the café/lounge car are described in Chapter 14, except as noted.

11.7 Exterior Lighting Requirements

11.7.1 Marker Lights

All cars shall be equipped with two red marker lights at each end of the car.

The marker lights shall be an LED matrix and shall meet FRA requirements in 49CFR Part

221.

The marker lights shall be operable during normal, quiet car and standby lighting modes.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-10

The marker lights will be controlled by a 3-position switch in the electric locker, having A-END,

OFF, and B-END positions (the A-END position marking will be replaced by F-END on cab cars).

The marker lights on the F-end of the cab cars shall illuminate when the selector switch in the

electrical locker is placed in the F-END position, except when the headlights and/or crossing

lights are illuminated. Placing the headlight selector switch in any position other than OFF

shall extinguish the marker lights. Returning the headlight selector switch to OFF shall re-

illuminate the marker lights when the marker light selector switch is in the F-END position.

11.7.2 Platform Lights

Each side door opening shall have a platform light that will illuminate the platform area

adjacent to that door opening when those doors are opened. This light shall be mounted flush

into the carshell or the threshold area and not protrude beyond the side of the car. The light

shall be aimed downward so as to not shine directly into the eyes of passengers or crew

standing on the platform or in the vestibule of the car, and shall be mounted in an impact-

resistant and waterproof housing. The platform lights shall illuminate when one or both door

panels in the adjacent door opening is opened, either by command from the door control

system, or by use of the emergency door release. The platform light shall remain off when both

door panels are closed and latched, or locked with a mortise lock.

At a minimum, the Contractor shall meet the requirements of 49CFR Section 38.101.

The platform lights shall also be a part of the emergency lighting system and shall conform to

APTA Standard SS-E-013-99.

11.7.3 Exterior Indicator Lights

Each car shall be equipped with exterior door open indicator lights, four per car. These

indicators shall be red LEDs and shall be located on the exterior of the car adjacent to doors 2,

3, 6 and 7, so that their status is visible to the engineer when viewed down the side of the

train. They shall display a red indication when any door in the adjacent vestibule is open (i.e.,

not closed and latched, or locked with the mortise lock) and shall be dark when all doors in

that vestibule area are closed and latched.

Each car shall be equipped with two exterior brake indicator light units, one on each side of the

car, adjacent to doors 2 and 6. Brake indicators shall be green and yellow LEDs, and shall

display the following indications:

Solid Yellow Air brakes applied (handbrake released)

Flashing Yellow Handbrake applied (air brakes applied or released)

Solid Green Air brakes and handbrake released

The brake indicator unit may be combined with the door open indicator light.

The single-light door indicator units shall be Dialight p/n 566-0001-805.

The three-light door/brake indicator unit shall be Dialight p/n 566-0003-802. This unit shall

be mounted with the indicator lights oriented top to bottom: green/yellow/red.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-11

11.7.4 Exterior Door ADA Lights

A flashing blue LED fixture shall be mounted above or adjacent to each side door opening to

serve as a visual beacon to ADA passengers when the adjacent door is open. This indicator

shall be viewable from all angles on the exterior of the car. The light shall flash at a rate of 1

Hz when the door is open, and 2 Hz for five seconds before the door closes.

11.7.5 Headlights and Crossing Lights

Requirements for cab car headlights and crossing lights are described in Chapter 16.

11.8 Systems Indicator Panel

A multi-LED systems indicator panel shall be located on the B-end vestibule wall adjacent to

the electrical locker door, and shall serve to provide a visual indication of the status of

designated systems. The panel shall be mounted in a location that will prevent tampering or

damage from routine maintenance or cleaning, and will be visible from the vestibule area. The

indicators shall be as follows:

System Indicator

HVAC (one indicator for each unit) Blue (A/F-end and B-end)

Wheel slide control system Green

Toilet system Yellow

Battery charger Red

Communication/public address system White

Door system Yellow

Specific function of the indicator lights is described in the applicable chapter for each

subsystem. Indicator lights shall be flashing on and off at 1 Hz when the system has developed

a fault or is not functioning properly, as defined in each chapter, and shall be on continuously

when the system is functioning as intended. All LEDs shall be appropriately labeled. The

systems indicator panel shall have a lamp test button to verify that the LEDs illuminate when

energized.

11.9 Lighting Fixture Requirements

11.9.1 Fluorescent Lighting

Fluorescent lighting shall use rapid-start, T-8 lamps with a color temperature of 3500°-4100°K.

Where possible, the lighting fixtures shall be arranged with one-rapid start inverter ballast

controlling two lamps in a master and slave arrangement. Stand-alone fixtures shall contain a

ballast configured for efficient, single-lamp operation. The main interior light fixture shall be

arranged for a F32T8 lamp or a F25T8 lamp.

Fixture design shall meet APTA Recommended Practice RP-E-012-99. Lampholder sockets

shall be designed to support the ends of the lamp. Terminal pins shall not be the sole source

of lamp support. Lampholders shall meet or exceed the requirements of UL542. Lamps shall

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-12

be secured in the fixture and be able to withstand rough duty service as found in the railroad

environment. Fixtures shall be dust and moisture resistant.

The main interior light fixture shall consist of a reflector and door joined by an integral,

concealed hinge latched by captive quarter-turn Phillips head fasteners, minimum two per

door. The fixture assemblies shall be positioned to maximize the light output projected

towards the illuminated surface and center of the car.

The master fixture housing shall contain a ballast mounted on an integral hinged ballast plate

retained by captive fasteners designed for repeated use (no self tapping screws allowed). All

wiring shall be accessible by hinging the ballast plate down. The BALLAST ON LED shall be

visible from the bottom of the ballast plate.

Fluorescent lamps shall be designed to use standard, commercially available length bulbs.

Each light fixture shall have a permanent label and/or stamping, visible when the light cover is

removed or swung down, that contains the following information:

• Supplier part number

• Voltage and current or wattage ratings

• Lamp identification, wattage, including color

11.9.2 Light Emitting Diode (LED) Lighting

LED fixtures shall conform to the requirements of the Energy Policy Act of 2005, and shall

utilize white LEDs. The color temperature shall be 3500°-4100°K.

An LED driver designed to ensure proper operation of the LEDs shall be mounted on the LED

assembly. LED assemblies shall be removable without special hardware. Each LED assembly

shall be removable after removing only the hinged lens. LED units shall be connected via

interlocking, self-polarizing and modular connectors accessible when the light fixture is

opened.

All fixtures shall be dust- and moisture-resistant, and shall be arranged to facilitate

replacement of the LED assembly from the passenger compartment after opening the lens.

Fixtures equipped with lenses shall have a one-piece polycarbonate translucent white lens,

uniform in color and smooth on the exposed side, which will provide the specified intensity of

illumination on the reading plane, while diffusing the light to illuminate adjacent wall and

ceiling surfaces, increasing the overall brightness level in the interior of the car. The lens shall

be mounted on a hinged bezel and shall be secured with captive fasteners.

LEDs used in passenger area overhead lighting (in lieu of fluorescent lights) shall be mounted

on replaceable boards installed in the light fixture. Boards shall be connected to the fixture by

screws, and shall be plug-connected electrically for easy replacement. The LEDs shall be sized

and spaced so that the failure of up to two LEDs on an individual board shall not create an

appearance of a dark area on the fixture.

LED lights shall operate on 74VDC, unless specified otherwise. See Chapter 13 for additional

details.

LED lighting shall be sized to provide the level of lighting as outlined in Table 11-1.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-13

Changeable LED lamps are preferred and LED lighting may be dedicated to its fixture where

the design is necessary.

11.9.3 DC/AC Ballasts

The fluorescent lighting fixtures shall contain DC inverter and/or AC electronic ballasts.

Ballasts shall be high performance, rapid start and solid-state.

Ballasts shall incorporate reverse polarity, overload, open circuit, over-temperature, over-

voltage, transient and internal short circuit protection. Inverter ballasts shall withstand

transients of 10 Joules and have an electronic clamp to ground feature. The inverter ballasts

shall be designed to operate normally from a 74VDC supply, with capability for continuous

operation over 45-86VDC supply. Under-voltage protection shall be provided. The ballast shall

automatically restart when voltage within the normal range is again applied, and require no

reset, such as interrupting a circuit breaker under any conditions. Likewise, if a lamp is

changed while the ballast is powered, no action shall be required to restart the ballast.

Ballasts shall be equipped with an LED BALLAST ON indicator that illuminates when the ballast

is functioning normally and power is on.

All ballasts shall have an over temperature protection feature that automatically resets when

the temperature drops to an acceptable level.

The ballasts shall be integral parts of the fixtures, conveniently located and easily removed

from the fixtures without disturbing other components and wiring. The ballast on ceiling

lighting fixtures shall be replaceable with the fixture remaining in position. All ballasts shall

meet the requirements of ANSI C82.

11.9.4 Capacitor-Based Lighting

The capacitors must be rated for a minimum of 500,000 charge cycles. The capacitor based

power source for emergency lighting shall have a label located on the side of the unit exposed

for service that includes the following information:

• OEM name and manufacturer’s address

• OEM part number — revision/modification level and date

• Date of manufacture

• Unit serial number

• Voltage and capacity rating

11.10 Housings, Lenses and Diffusers

The overhead light assembly shall be designed for lamp replacement from below. The hinged

light lens shall swing down allowing easy lamp replacement.

No material shall suffer any loss of performance when exposed to temperatures ranging from

-30ºF to 150ºF or exhibit degradation of properties (including color) under long-term exposure to

ultraviolet light.

Lighting fixtures shall have hinged lenses, which will aid in light distribution, prevent glare and

facilitate easy lamp replacement. The design of the fixture shall permit easy cleaning and easy

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-14

lamp renewal. The lenses shall project light with an even brightness without patterns, and

shall have a smooth surface on all sides and edges that are open to the passenger seating area

to avoid injury. Tamper-proof fasteners shall retain door to the housing. A neoprene foam

gasket around the lens assembly shall make the joining of door and reflector dust-resistant

and rattle free. The hinged lens shall be removable for replacement. The lenses shall be easily

replaceable without having to disassemble the light fixture, and shall be made of an approved

Ultraviolet (UV)-stabilized polycarbonate and meet the Flammability, Smoke Emission and

Toxicity requirements specified in Chapter 18.

11.11 Controls

All lighting shall be circuit breaker protected. Lights identified for ON/OFF control shall have an

ON/OFF switch in addition to the circuit breaker. Controls shall be labeled AC LIGHTS and DC

LIGHTS and also NORMAL and QUIET CAR and housed in the electric locker, except as listed below,

where local controls shall be provided:

• Each reading light shall have a separate ON/OFF switch located adjacent to the reading

light.

• Each reading light at a wheelchair location shall have an ON/OFF switch located in

accordance with the requirements of ADA.

• Electrical lockers and equipment rooms shall have manual light switches located inside

the equipment room adjacent to the entry door.

• Utility lockers shall have automatic light switches located inside the locker adjacent to

the entry door.

• Selected lighting circuits in the food service area shall have ON/OFF switches. See

Chapter 14 for details.

• Selected lighting circuits in the cab control compartment of the cab/baggage car shall

have ON/OFF switches. See Chapter 16 for details.

11.12 Testing

Car lighting shall be tested for compliance with this specification as well as all applicable APTA

standards and FRA regulations regarding minimum illumination requirements and

recommendations during normal, quiet car, standby and emergency modes. This shall include

charging light levels for photoluminescent decals as part of the emergency signage system.

Test reports shall document lighting levels achieved during these modes, test methodology

used during testing, and the standard or regulated light level for all measured locations to

demonstrate compliance.

The Contractor shall provide certification to the Customer that the car's lighting system meets

all standards and regulations. All required material certifications shall be provided to the

Customer.

See chapter 19 for more details.

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

Lighting System 11-15

Table 11-1: Minimum Illumination Levels

Area Measured at: Normal Quiet Car Standby

(See APTA Lighting Lighting Lighting

Recommended (foot- (foot-candles) (foot-candles)

Practice candles)

RP-E-012-99 for

specifics)

General Overhead Table top 30 5 5

Aisle way Lighting Floor 30 5 5

Indirect Lighting Table top 5 5 N/A

Stairway Lighting Stair treads 5 5 5

Vestibules Floor, threshold, side 30 30 5

door panels

General Seating Areas Table top 30 5 5

Reading Lights Table top 20 20 20

End Passageway/ Grab handles 10 10 10

Diaphragm Area Door panel at floor

level.

Bike/ Luggage Rack Area Floor 10 10 5

Luggage Rack Tower Lowest shelf 10 10 5

Toilet Room – ATR Floor 30 30 10

Toilet Room – UTR Sink 30 30 10

Toilet 30 30 10

Mirror 30 30 10

Baby changing 30 30 10

Door handles 30 30 10

Café Car-Lounge Area Floor 30 30 5

Galley Floor 30 30 10

Elevator Floor 30 30 5

Service Counter Area Counter 30 30 10

Food Preparation Area Counter 30 30 10

Electric Locker Floor 30 30 5

Utility Closet Floor 5 5 5

Equipment Rooms Floor 10 10 10

Cab Overhead Floor, cab console 5 5 5

Cab Reading Lamp Table height 20 20 20

* End of Chapter 11 *

C21 Corridor Car Technical Specification Rev. K

Copyright 2010 California Department of Transportation All rights reserved

You might also like

- ENA TS 50-18 Issue 4Document39 pagesENA TS 50-18 Issue 4David RothwellNo ratings yet

- Flagship: Visualsmp Users ManualDocument238 pagesFlagship: Visualsmp Users ManualSreekanthNo ratings yet

- G81-Design and Planning Rev 0.5Document25 pagesG81-Design and Planning Rev 0.5radulescuandrei100No ratings yet

- DNV ST E271 Offshore ContainersDocument107 pagesDNV ST E271 Offshore ContainersWantana RattaneeNo ratings yet

- SP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Document94 pagesSP-1208 - Pipeline Construction Specification (Appendix F) (Formerly PCS-01)Rjeb mohamed100% (1)

- DCF Developers GuideDocument231 pagesDCF Developers Guideanon-689453No ratings yet

- RMS Specs 3051 Ed6Document37 pagesRMS Specs 3051 Ed6Luke DigginsNo ratings yet

- Design and Fabrication of Self Centering ViceDocument47 pagesDesign and Fabrication of Self Centering ViceKarthickNo ratings yet

- Metallic Detector Using Ic 555Document7 pagesMetallic Detector Using Ic 555SHRUTI MOON100% (1)

- HVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDocument17 pagesHVAC System: Standardized Technical Specification Bi-Level Passenger Rail Cars For Intercity Corridor ServiceDareyoss NegussieNo ratings yet

- Asr 1005 Aps 900 Ima 09Document43 pagesAsr 1005 Aps 900 Ima 09raulNo ratings yet

- E-500 - Design Criteria - ElectricalDocument45 pagesE-500 - Design Criteria - ElectricalDinesh RajNo ratings yet

- Power and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Document10 pagesPower and Water Utility Company For Jubail and Yanbu (MARAFIQ) Master Specification MQ-SP-C-2016 Project Name Date: 08 Mar 2011 Contract Number Page 1 of Revision 1Azhar AliNo ratings yet

- Asr 1005 Aps 900 Ima 08Document21 pagesAsr 1005 Aps 900 Ima 08Anonymous vguPVDzZ7TNo ratings yet

- Spec Hotel Load Conv P4 - Rev 0 - Aug 12Document35 pagesSpec Hotel Load Conv P4 - Rev 0 - Aug 12divisional electrical enggNo ratings yet

- So-0612-W Polaris TechnicalManual Section 5a InstructorsManualDocument534 pagesSo-0612-W Polaris TechnicalManual Section 5a InstructorsManualClarence Pietersz100% (1)

- Programming Standard Specification 7x04Document141 pagesProgramming Standard Specification 7x04Carmen MuñozNo ratings yet

- 3-FRENIC Lift PDFDocument48 pages3-FRENIC Lift PDFMoran Martines100% (1)

- SG FRENIC Lift EN 1 7 0Document42 pagesSG FRENIC Lift EN 1 7 0Mahmoud RobNo ratings yet

- LAZ 5100 Manual EnglishDocument79 pagesLAZ 5100 Manual EnglishMorseNo ratings yet

- CRS Basis For The Design (20210908) - Rev A-ELS Reply 9-9-21Document10 pagesCRS Basis For The Design (20210908) - Rev A-ELS Reply 9-9-21dikiNo ratings yet

- Network Design Manual v7.7Document194 pagesNetwork Design Manual v7.7somchak2000100% (3)

- 165994-BKR-REP-ESG-000001 - Markle LC Renewal Signalling Asset Condition Report - Final - 2 - SPDocument398 pages165994-BKR-REP-ESG-000001 - Markle LC Renewal Signalling Asset Condition Report - Final - 2 - SPShaik SaidabheeNo ratings yet

- Specification - Site DemolitionDocument7 pagesSpecification - Site DemolitionAzhar AliNo ratings yet

- Steel Pipe For Waterworks PurposesDocument25 pagesSteel Pipe For Waterworks PurposesFelipa ShanNo ratings yet

- 202106-Aashto LRFD 8th CA Amendments-A11yDocument403 pages202106-Aashto LRFD 8th CA Amendments-A11yDaniel DugarteNo ratings yet

- Ispo A - 11 0Document24 pagesIspo A - 11 0JaadNo ratings yet

- ESC 420 Track Drainage: Engineering Standard CivilDocument16 pagesESC 420 Track Drainage: Engineering Standard CivilSuciu FlorinNo ratings yet

- Ministry of Railways: Specification For DevelopmentDocument35 pagesMinistry of Railways: Specification For DevelopmentvipinabrolNo ratings yet

- CIV-MS-010-07-Rapid Chloride PermeabilityDocument7 pagesCIV-MS-010-07-Rapid Chloride PermeabilityAdil faridNo ratings yet

- MQ SP M 4004 PDFDocument17 pagesMQ SP M 4004 PDFjaseelNo ratings yet

- Implementation 2011Document1 pageImplementation 2011ahm2011No ratings yet

- FilesDocument54 pagesFilesHussainNo ratings yet

- Cask FsarDocument1,235 pagesCask Fsarvishnew12No ratings yet

- Gic Ispa - Dms Via Ispa Broker v4.0.8Document196 pagesGic Ispa - Dms Via Ispa Broker v4.0.8Antonio NevesNo ratings yet

- 7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications SignedDocument10 pages7 2021-02-17 Letter To RDSO For Air Spring and FIBA Modifications Signedsibaranjandash2007No ratings yet

- NewDirectionsPostTensioningVol10B PDFDocument66 pagesNewDirectionsPostTensioningVol10B PDFSyed RaziuddinNo ratings yet

- Transport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsDocument45 pagesTransport For NSW (TFNSW) Qa Specification 3051 Granular Pavement Base and Subbase MaterialsroshanNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesDocument20 pagesTransport For NSW (TFNSW) Qa Specification R23 Plastic Flexible PipesHenry HNo ratings yet

- EP2 User InterfaceDocument98 pagesEP2 User InterfacerivershanNo ratings yet

- Changes and Impact - TOC Chapter 1, 2Document9 pagesChanges and Impact - TOC Chapter 1, 2crvillateNo ratings yet

- CPCI PCI Bridge Design Manual PresentationDocument81 pagesCPCI PCI Bridge Design Manual PresentationmikefaraNo ratings yet

- Compass 56030-1Document86 pagesCompass 56030-1Nebyu GetachewNo ratings yet

- 2013-10-17 Seaoc SSDM Series PPT Vol 1 HandoutDocument39 pages2013-10-17 Seaoc SSDM Series PPT Vol 1 HandoutAnonymous 9MDGo2jNo ratings yet

- PPL Su 1051 F.1Document47 pagesPPL Su 1051 F.1resp-ectNo ratings yet

- TS 02164.2 - 0.00 - Design of Reinforced Soil Walls - DCDocument61 pagesTS 02164.2 - 0.00 - Design of Reinforced Soil Walls - DCislamawanNo ratings yet

- DBR Rev.G 26th SeptDocument51 pagesDBR Rev.G 26th Septsudhir12345No ratings yet

- 3-Ken Sabo - Updated Building Codes Are Changing Battery Rack CertificationDocument6 pages3-Ken Sabo - Updated Building Codes Are Changing Battery Rack CertificationBau FroschNo ratings yet

- Transport For NSW (TFNSW) Qa Specification R15 Kerbs and Channels (Gutters)Document20 pagesTransport For NSW (TFNSW) Qa Specification R15 Kerbs and Channels (Gutters)Henry HNo ratings yet

- Crane Fex Guide v0.4Document80 pagesCrane Fex Guide v0.4HugoSilvaNo ratings yet

- 10.0128.F.R OSD 030 Optus Tower Specification Rev 6 5Document45 pages10.0128.F.R OSD 030 Optus Tower Specification Rev 6 5Vinaykumar RaoNo ratings yet

- Newdirectionsposttensioningvol10a PDFDocument95 pagesNewdirectionsposttensioningvol10a PDFNOEL RODRIGUEZNo ratings yet

- JLR Robot Standard Rules For Abb Robots v1.8 Jlr-Mees-Rf-62-009Document43 pagesJLR Robot Standard Rules For Abb Robots v1.8 Jlr-Mees-Rf-62-009Cristian CanalesNo ratings yet

- Specification - Site Preparation, Excavation, and Backfill SpecificationDocument24 pagesSpecification - Site Preparation, Excavation, and Backfill SpecificationAzhar AliNo ratings yet

- Design of An MAV For The 2019 SAE Aero Design Competition PDFDocument209 pagesDesign of An MAV For The 2019 SAE Aero Design Competition PDFShiva KarthikeyaNo ratings yet

- Seagate NAS DriveDocument35 pagesSeagate NAS DriveCristina TudorNo ratings yet

- Guideline SoM in L2 - v1Document22 pagesGuideline SoM in L2 - v1Necdet ÇilingirNo ratings yet

- Design of Highway Bridges: An LRFD ApproachFrom EverandDesign of Highway Bridges: An LRFD ApproachRating: 4.5 out of 5 stars4.5/5 (4)

- The North British Type 2 Bo-Bo Diesel-Electric Classes 21 & 29: Design, Development and DemiseFrom EverandThe North British Type 2 Bo-Bo Diesel-Electric Classes 21 & 29: Design, Development and DemiseNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Building Sustainability in East Asia: Policy, Design and PeopleFrom EverandBuilding Sustainability in East Asia: Policy, Design and PeopleNo ratings yet

- Enzymatic Fuel Cells: From Fundamentals to ApplicationsFrom EverandEnzymatic Fuel Cells: From Fundamentals to ApplicationsHeather R. LuckariftNo ratings yet

- ISRO Scientist Engineer SC MECHANICAL BE002 Result 2020 PDFDocument18 pagesISRO Scientist Engineer SC MECHANICAL BE002 Result 2020 PDFKarthickNo ratings yet

- IJEETC 55f7bcfa91507 PDFDocument5 pagesIJEETC 55f7bcfa91507 PDFKarthickNo ratings yet

- Aptitude PartnershipDocument12 pagesAptitude PartnershipKarthick100% (1)

- Chapter 4Document37 pagesChapter 4KarthickNo ratings yet

- Spotting Errors in EnglishDocument7 pagesSpotting Errors in EnglishKarthickNo ratings yet

- AbstractDocument3 pagesAbstractKarthickNo ratings yet

- Design and Fabrication of Self Centering Vice Ppt-1Document36 pagesDesign and Fabrication of Self Centering Vice Ppt-1KarthickNo ratings yet

- Milling Attachment With 3 FunctionsDocument3 pagesMilling Attachment With 3 FunctionsKarthickNo ratings yet

- Solenoid Valves - : Spare PartsDocument1 pageSolenoid Valves - : Spare PartsJhonny ChoquehuancaNo ratings yet

- Vibraswitch Robertshaw rbs365Document3 pagesVibraswitch Robertshaw rbs365jesus castillejosNo ratings yet

- 2 P 2010 Newcatalog P 2010 CatalogDocument5 pages2 P 2010 Newcatalog P 2010 CatalogNoe Carlos Liviapoma GironNo ratings yet

- Digifas 7200 EDocument70 pagesDigifas 7200 EvinodNo ratings yet

- Electrical Components For The Railway Industry Catalog LV 12 2015 201612161402441410Document112 pagesElectrical Components For The Railway Industry Catalog LV 12 2015 201612161402441410cc_bauNo ratings yet

- Decora Smart™: Dimmer With Z-Wave TechnologyDocument2 pagesDecora Smart™: Dimmer With Z-Wave TechnologypatNo ratings yet

- Simple LED Blinking CircuitsDocument4 pagesSimple LED Blinking CircuitsNoor FazillaNo ratings yet

- H300 Current RelayDocument2 pagesH300 Current RelaySteven WeiNo ratings yet

- Bee Everything - MergedDocument1,973 pagesBee Everything - Mergednakul kamatkarNo ratings yet

- Total Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedDocument1 pageTotal Clearing Time-Current Characteristic Curves: Positrol Fuse Links-S&C Standard SpeedfaberromeroNo ratings yet

- Tut 2Document3 pagesTut 2MOHIT SINGHALNo ratings yet

- Electronic Devices Lab MANUALDocument24 pagesElectronic Devices Lab MANUALna_hariprsadNo ratings yet

- Aurora A5 User Manual (EN) : Operation Instruction: Momentary ON Turn On / Off Primary FeaturesDocument2 pagesAurora A5 User Manual (EN) : Operation Instruction: Momentary ON Turn On / Off Primary FeaturesDamien LockkeNo ratings yet

- IRFZ34N Datasheet - KDocument8 pagesIRFZ34N Datasheet - KNairo FilhoNo ratings yet

- How To Design Capacitor BankDocument5 pagesHow To Design Capacitor BankAbdul AzizNo ratings yet

- Footprint Naming Rule Reference PDFDocument83 pagesFootprint Naming Rule Reference PDFvinh quocNo ratings yet

- 电气设备手册 - Buku Besar Peralatan ElektrikDocument148 pages电气设备手册 - Buku Besar Peralatan ElektriksusitoNo ratings yet

- Ac Motor ProtectionDocument38 pagesAc Motor ProtectionsibtainNo ratings yet

- Ec 238Document2 pagesEc 238Ahmed HasanainNo ratings yet

- Sa Ami 460 Fcon 100702 - 1 1Document1 pageSa Ami 460 Fcon 100702 - 1 1tanyadeasis8No ratings yet

- Lundahl: Amorphous Core Moving Coil Input Transformer LL1931Document1 pageLundahl: Amorphous Core Moving Coil Input Transformer LL1931Giapy Phuc TranNo ratings yet

- LC1D12M7 Schneider Electric Datasheet 21405858Document3 pagesLC1D12M7 Schneider Electric Datasheet 21405858hector diazNo ratings yet

- 300ma L.D.O Voltage Regulator Tj1117GsfDocument14 pages300ma L.D.O Voltage Regulator Tj1117GsfkalanghoNo ratings yet

- Microwave Devices and Circuits - Samuel Y. LiaoDocument101 pagesMicrowave Devices and Circuits - Samuel Y. Liaorkhanna1965No ratings yet

- Product Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyKamilNo ratings yet

- 1vap420001-Tg Abb Utility It Ref Guide 2019Document137 pages1vap420001-Tg Abb Utility It Ref Guide 2019nikodemisNo ratings yet

- Type Coordination Siemens PDFDocument58 pagesType Coordination Siemens PDFvishal.nitham100% (2)

- OBD2 Adapter Cable DatasheetDocument11 pagesOBD2 Adapter Cable DatasheetJay highfieldNo ratings yet