Professional Documents

Culture Documents

Vendor Document Cover Sheet: Project: Ar4 4 Aromatics Plant

Vendor Document Cover Sheet: Project: Ar4 4 Aromatics Plant

Uploaded by

Hyune Boom SheenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vendor Document Cover Sheet: Project: Ar4 4 Aromatics Plant

Vendor Document Cover Sheet: Project: Ar4 4 Aromatics Plant

Uploaded by

Hyune Boom SheenCopyright:

Available Formats

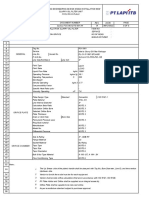

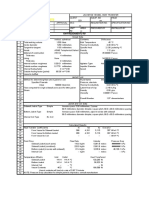

CONSORTIUM OF :

VENDOR

PROJECT : AR4 DOCUMENT

Owner WorkCOVER

No. : E-79/01

TEC

BORZOUYEH PETROCHEMICAL CO.

SAZEH LG E&C 4th AROMATICS PLANTSHEET

Consortium Work No. : BA-0512

TOTAL 43 SHEETS

AR4

REQ. NO. : BXFB001

ITEM NO. : TK-2501

EQUIPMENT NAME : HYDROTREATER FEED

VENDOR DOC. NO. : C3363A-D-01

DOCUMENT TITLE : CALCULATION SHEET

2 Mar. 13. ’02 FINAL T. Yoshii T. Tsukioka T. Ohashi

ISSUED FOR FINAL

1 Jan. 31. ’02 REV. AS MARKED T. Yoshii T. Tsukioka T. Ohashi

0 Oct. 25. ’01 ISSUED FOR APPROVAL Y. Tanaka T. Tsukioka T. Ohashi

REV. DATE DESCRIPTION PREPARED CHECKED APPROVED AUTHORIZED

VENDOR NAME : TOYO KANETSU K.K.

File : /conversion/tmp/scratch/405421796.doc / 521 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 2 OF 43

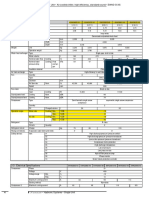

INDEX

(1). TANK DESIGN CONDITION ........................................................................ 3

(2). TANK CAPACITY........................................................................................... 4

(3). SHELL PLATE THICKNESS.......................................................................... 5

(4). TANK SHELL STABILITY AGAINST EARTHQUAKE LOAD................... 6

(5). INTERMEDIATE WIND GIRDER................................................................. 11

(6). TANK STABILITY AGAINST WIND LOAD................................................. 15

(7). ROOF STRUCTURE....................................................................................... 16

(8). THICKNESS OF ROOF PLATE...................................................................... 31

(9). COMPRESSION RING AT ROOF TO SHELL JUNCTURE ........................ 32

(10). BUOYANCY OF FLOATING ROOF ............................................................. 34

(11). DECK POST .................................................................................................... 36

(12). AUTOMATIC BLEEDER VENT ................................................................... 39

(13). BOTTOM AND ANNULAR PLATE .............................................................. 41

(14). WEIGHT LIST ................................................................................................ 43

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 3 OF 43

(1). TANK DESIGN CONDITION

Tank No. TK-2501

Number required 1

Nominal capacity 27,158 m3

Net capacity 25,495 m3

Tank inside diameter 48,500 mm

Tank height 15,100 mm

Design liquid level (D.L.L) 13,800 mm

Max. liquid level (M.L.L) 13,800 mm

Min. liquid level (L.L.L.L) 1,400 mm

Contents Name Hydrotreater Gas Condensate

Flash point Below 38 °C

Max. oper. temp. 47 °C

Specific gravity 0.696

Aromatic Content 40 wt%

Design code API ST’D 650 10TH EDITION NOV. 1998

Operating pressure 0.008 barg

Design temperature 65 / 5 °C

Design pressure 0.02 / -0.005 barg

Pumping In 371 m3/hr

rate Out 371 m3/hr

Corrosion 1st. Shell 3 mm

allowance 2nd. and over 2.5 mm

Bottom 3 mm

Roof 1.5 mm

Floating Wet part 3.0 mm

roof Vapor part 1.5 mm

Roof supp. frame 0.75 mm

(each side)

Shell design API ST’D 650 10TH EDITION NOV. 1998

One foot method (SI unit)

Roof type Dome roof

Bottom slope Cone up 1/100

Earthquake UBC 1997 (Zone4, SC,Ip=1.25)

Design wind velocity UBC 1997 (BWS=125km/h, IF=1.15, Exposure=D)

Snow load 246 N/m2

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 4 OF 43

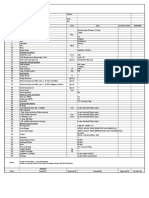

(2). TANK CAPACITY

D D.L.L. H

M.L.L

Hb

L.L.L.L.

1

100

D = 48,500 mm BOTTOM SLOPE = 1 / 100

H = 15,100 mm Hb = 242.5 mm

D.L.L. = 13,800 mm

M.L.L. = 13,800 mm

L.L.L.L. = 1,400 mm

GEOMETRIC CAPACITY : VG

VG = × D2 × H = 27,897 m3

4

NET CAPACITY : VN

VN = × D2 × ( M.L.L) = 25,495 m3

4

MAX. STORAGE CAPACITY : VM

VM = × D2 × ( M.L.L ) - × D2 × Hb = 25,346 m3

4 12

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 5 OF 43

(3). SHELL PLATE THICKNESS

Shell thickness are calculated by One-Foot Method according to API ST’D 650 para. 3.6.3.

4.9 × D × (H’ – 0.3) × G

td = + Sd

C (mm)

4.9 × D × (H’ – 0.3) × G

tt = St (mm)

Where,

td : Design shell thickness, in mm

tt : Hydrostatic test shell thickness, in mm

D : Nominal diameter of tank, in m

D = 48.5 m

H’ : Height from bottom of course under consideration to design liquid level

including design internal pressure. (m)

= H+P/G

H : Height from bottom of course under consideration to the design liquid

level. (m)

P : Design pressure = 0.02 barg = 0.204 mAq.

G : Design specific gravity of the liquid to be stored = 0.696

Gravity of hydrostatic test water = 1.023

c : Corrosion allowance, in mm

c = 3 mm for 1st. shell

c = 2.5 mm for 2nd. and above shell

Sd : Allowable stress for the design condition, in Mpa

St : Allowable stress for the hydrostatic test condition, in Mpa

Allowable stresses Calculated thickness Adopted

No. H’ Sd St td tt thick. Material Width

(m) (Mpa) (Mpa) (mm) (mm) (mm) (mm)

1 14.004 137 154 19.5453 21.6342 21.7 A283M Gr.C 2,450

2 11.554 137 154 16.0874 17.7665 17.8 A283M Gr.C 2,450

3 9.104 137 154 13.1294 13.8987 13.9 A283M Gr.C 2,450

4 6.654 137 154 10.1714 10.0310 10.2 A283M Gr.C 2,450

5 4.204 137 154 7.2135 6.1632 8.0 A283M Gr.C 2,450

6 1.754 137 154 4.2555 2.2954 8.0 A283M Gr.C 2,441

7 0.204 137 154 0.0 0.0 8.0 A283M Gr.C 400

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 6 OF 43

(4). TANK SHELL STABILITY AGAINST EARTHQUAKE LOAD

According to UBC 1997 and API ST’D 650 Appendix E

4.1 Calculation Condition

D : Tank diameter ........................................ 48.5 m

H : Maximum design liquid level ................. 13.8 m

G : Specific gravity of liquid ......................... 0.696

ZIC1 = 0.36 (Refer to doc. no. G3363-D-01)

Z : Zone coefficient ....................................... 0.48

I : Essential facilities factor ........................... 1.25

S : Site amplification factor .......................... 1.2

(Eq. to soil profile type Sc)

4.2 Overturning Moment : M

M = ZI (C1 Ws Xs + C1 Wr Ht + C1 W1 X1 + C2 W2 X2)

Where,

C1 : Lateral earthquake force coefficient ........................ 0.6

C2 : Lateral earthquake force coefficient determined per

API ST’D 650 appendix E para. E.3.3. ................... 0.05940

When T is less than or equal 4.5 : C2 = 0.75 S/T

When T is greater than 4.5 : C2 = 3.375 S/T2

Where, T = Natural period of first mode sloshing, in

seconds. T may be determined from the

following equation.

T = KD1/2 = 8.25769 (sec)

K = Factor obtained from figure E-4 of API st’d

650 app’x E for the ratio D/H .... 3.5145

Ws : Total weight of tank shell 2,590 KN

Xs : Height from bottom of tank shell to center of gravity of shell

6.434 m

Wr : Total weight of tank roof 1,700 KN

Ht : Gravity center of roof 18.349 m

W1 : Weight of effective mass of tank contents which moves in unison with tank

shell 56,918 KN

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 7 OF 43

X1 : Height from bottom of tank shell to centroid of lateral seismic force

applied to W1 5.175 m

W2 : Weight of effective mass of first mode sloshing contents of tank

109,658 KN

X2 : Height from bottom of tank shell to centroid of lateral seismic force

applied to W2 7.465 m

M = 1.5242 × 105 KN-m

4.3 Resistance to Overturning : WL

WL = 99 tb Fby G H .................. except that WL shall not exceed

WL’ (= 196 G H D)

Where,

WL : Maximum weight of tank contents of shell circumference which may be

utilized to resist the shell overturning moment N/m

tb : Thickness of the annular bottom plate after corroded

= 9-3 = 6 mm

Fby : Minimum specified yield strength of annular bottom plate

205 MPa

WL = 99 × 6 × 205 × 0.696 × 13.8

= 2.636 × 104 N/m

WL’ = 196 × 0.696 × 13.8 × 48.5

= 9.130 × 104 N/m

Then,

WL = 2.636 × 104 N/m

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 8 OF 43

4.4 Shell Compression

1) Unanchored tank

The maximum longitudinal compression force at the bottom of the shell may be

determined as follows

M

2

< 0.785

D (Wt + WL)

b 1.273 M

c = = (Wt + ) / 1,000t

1,000t D2

M

0.785 < 2

< 1.5

D (Wt + WL)

b may be computed from the valve of the parameter

b + WL

obtained from figure E-5 (API 650)

Wt + WL

b

c =

1,000t

M

1.5 < 2

< 1.57

D (Wt + WL)

b 1.490 (Wt + WL)

c = = - WL / 1,000t

1,000t 0.637 M 1/2

1- 2

D (Wt + WL)

M

1.57 < 2

D (Wt + WL)

b 1.273 M

c = = (Wt + ) / 1,000t

1,000t D2

Anchor bolts are required.

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 9 OF 43

Where,

c : The maximum longitudinal compressive stress in the shell

N/mm2

b : Maximum longitudinal shell compression force of shell circumference

110.617 KN/m

Wt : Weight of tank shell and portion of roof supported by shell

28.132 KN/m

M

1.57 > 2

= 0.955 > 0.785

D (Wt + WL)

c = 5.92 N/mm2

2) Maximum allowable shell compression

G H D2

> 44

t2

83 t

Fa = < 0.5 Fty

D

G H D2

< 44

t2

83 t

Fa = + 7.5 G H < 0.5 Fty

2.5 D

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 10 OF 43

Where,

Fa : Maximum allowable longitudinal compressive stress in the shell

N/mm2

t :Thickness of the bottom shell course, excluding any corrosion allowance

18.7 mm

Fty : Minimum specific yield strength of the shell

205 MPa

G H D2

= 65 > 44

t2

Fa = 32.86 N/mm2

c < Fa

Therefore, this tank shell is safe.

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 11 OF 43

(5). INTERMEDIATE WIND GIRDER

5.1 The maximum height of unstiffened shell length shall not exceed the following value

according to API ST’D 650 10TH EDITION, 1998 para. 3.9.7.

H1 = 9.47 × t × (t / D)3 × (100 / V)2

= 5.095 m = 5,095 mm

Where,

H1 : Max. height of unstiffened shell, in mm

t : Top shell thickness in height H1, in mm

t = 8 mm

D : Nominal tank diameter, in m

D = 48.5 m

V : Wind velocity, mile/hour

Refer to doc. no. G3363-D-01

V = 44.6 m/sec.

= 99.8 mile/hr

Transposed width of each shell course shall be calculated as follows.

Wtr = W × ( t / t act.) 5

WE = Wtr

Where,

Wtr : Transposed width of each shell, in mm

W : Actual width of each shell, in mm

t act. : Actual shell thickness, in mm

WE : Total transposed width of shell, in mm

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 12 OF 43

Result of Calculation

Course W (mm) t act. (mm) Wtr (mm)

7 th 400 8.0 400

6 th 2,441 8.0 2,441

5 th 2,450 8.0 2,450

4 th 2,450 10.2 1,335

3 rd 2,450 13.9 616

2 nd 2,450 17.8 332

1 st 2,450 21.7 202

WE = 7,776 mm

As WE < H1, intermediate wind girder is not required.

As 1 × H1 < WE < 2 × H1, 1 intermediate wind girder shall be installed.

The location of secondary wind girder is 2,700 mm from compression ring.

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 13 OF 43

5.2 Required section modulus

Applicable Code --- API ST’D 650 10TH EDITION, 1998 Para. 3.9.7

The required minimum section modulus of intermediate wind girder shall be determined

by the following equation.

Zw = (D2 × H1 / 17) × (V / 100)2

= 372 cm3

Where,

Zws : Required min. section modulus, in cm3

D : Nominal tank diameter, in m = 48.5 m

H1 : Vertical distance between the intermediate wind girder and

compression ring, in m = 2.7 m

V : Wind Velocity, in mile per hour = 99.8 MPH

(44.6 m/sec.)

Actual section modulus Zas of intermediate wind girder as drawn below is,

1

263

L175×175×12

2

12

251

8.0

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 14 OF 43

A Y A·Y A·Y2 Io

(cm2) (cm) (cm3) (cm4) (cm4)

1 52.6 17.9 941.5 16,853 4

2 40.52 4.73 191.6 906 1,170

Total 93.12 1,133.1 18,933

Then,

y = (A · Y) / A = 12.16817 cm

I = ( A · Y2 + Io ) - A × y2 = 5,145 cm4

e = 12.16817 cm

Actual section modulus wind girder : Zas

Zas = I / e

= 422 cm3 > Zws = 372 cm3

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 15 OF 43

(6). TANK STABILITY AGAINST WIND LOAD

6.1 Overturning Moment due to Wind Pressure : Mw

Mw = P (As Hs + Ar Hr) / 1,000 KN-m

Where,

As : Shell projectional area

As = H1 D m2

H1 : Shell height m

Ar : Roof projectional area m2

Hs : Center of gravity height for As m

Hr : Center of gravity height for Ar m

P : Wind pressure

(Refer to doc. no G3363-D-01)

6.2 Resistant Moment : Tw

Tw =

2

× Ww D KN-m

3 2

Where,

D : Tank inside dia. m

Ww : Weight of shell (after corroded) and dead weight supported by the

shell (excluding uplift from internal operating pressure) KN

6.3 Calculation Result

P D H1 Hs Hr

(N/m2) (m) (m) (m) (m)

1,214.2 48.5 15.1 7.55 17.71

As Ar Mw Ww Tw

(m2) (m2) (KN-m) (KN) (KN-m)

732 214 11,312 2,607 42,146

Mw < Tw

Therefore, anchor bolt is not required.

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 16 OF 43

(7). ROOF STRUCTURE

7.1 Design Condition

1) Design load (P)

Live load ( Including 0.005 barg vacuum pressure and 246 N/m2 of snow load )

= 1,177 N/m2

Weight of roof plate (6.5mm) = 537 N/m2

P = 1,714 N/m2

2) Corrosion allowance

Roof plate = 1.5 mm

Roof structure = 0.75 mm

(Each side)

7.2 Roof Frame Assembly

72R6 Rafter

72R5 Rafter

72R4 Rafter

2,890 72R3 Rafter

3,280 72R2 Rafter

3,820 36R1 Rafter

3,990

4,110

4,160

R2,000

R6,160

R10,270

R18,080 R14,260

R21,360

72G2 Girder 36G1 Girder Center ring

72G3 Girder

72G4 Girder

72G5 Girder

R24,250

R48,500

48,500

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 17 OF 43

7.3 Intensity of Rafter

LR

Wi = ( r22 p + W’) / N (N)

r1/2

Hi

Where,

h2 Wi p : Design load (N/m2)

h1

Point W’: Weight of center ring, etc. (to r2) (N)

“m”

N : Number of rafter

Hi

q1 = 2 r1p / N (N/m)

q2 = 2 r2p / N + Wg (N/m)

R

Where,

Wg = w × LR / r1 (N/m)

w : Weight of rafter (N/m)

A1 = r1 × q1 / 2 (N)

r1 r2 A2 = r1 × q2 (N)

r0

h1 = R2 - r22 - R2 - r02 (m)

A1

q1 h2 = R2 - r22 - R2 - (r2 + r1 / 2)2 (m)

q2 A2

Horizontal force

r1 Hi = (Wi × r1 + A1 × r1 / 3 + A2 × r1 / 2) / h1

(N)

Maximum bending moment at point “m”

Mmax.= (Wi × r1/2 + q1r12/48 + q2r12/8 - Hi × h2)

Nominal force at point “m” × 100 (N-cm)

Vi = Wi + q1 × r1 / 8 + q2 × r1 / 2 (N)

Point

“m”

Axial force at point “m”

T

Hs = Hi × cos + Vi × sin (N) Hs

Hi

Shearing force at point “m” Vi

T = Hi × sin - Vi × cos (N)

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 18 OF 43

Maximum bending stress

Mmax.

Sb =

z

Axial stress

Hs

Sc = A

Where,

Z : Section modulus of rafter (cm3)

A : Section area of rafter (cm2)

Combined stress (bending & compression)

Sb Sc

b + c < 1

Allowable stress (in accordance with API 650)

b : Allowable bending stress

c : Allowable compressive stress

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 19 OF 43

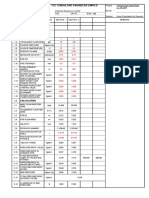

CALCULATION RESULT FOR RAFTER

Zx A LR rgy w

MARK N SIZE

(cm3) (cm2) (cm) (cm) (LR/rgy) (N/m)

R1 36 H148×100×6×9 115.6 21.9 417.6 2.34 178.6 207

R2 72 H148×100×6×9 115.6 21.9 417.2 2.34 178.4 207

R3 72 H148×100×6×9 115.6 21.9 412.6 2.34 176.4 207

R4 72 H148×100×6×9 115.6 21.9 405.3 2.34 173.4 207

R5 72 H148×100×6×9 115.6 21.9 359.1 2.34 153.6 207

R6 72 H148×100×6×9 115.6 21.9 327.6 2.34 140.1 207

W’ r1 r2 Wi Wg q1 q2 A1 A2

MARK

(N) (m) (m) (N) (N/m) (N/m) (N/m) (N) (N)

R1 9,204 4.16 2.0 854 208 1,244 806 2,587 3,352

R2 60,360 4.11 6.16 3,675 210 615 1,131 1,263 4,649

R3 140,329 3.99 10.27 9,835 214 596 1,750 1,191 6,981

R4 223,789 3.82 14.26 18,310 220 571 2,352 1,091 8,983

R5 310,175 3.28 18.08 28,744 227 490 2,929 804 9,610

R6 393,113 2.89 21.36 39,567 235 432 3,429 625 9,907

h1 h2 Hi Mmax. Vi Hs T

MARK

(m) (m) (N) (N-cm) (N) (N) (N)

R1 0.352 0.131 40,143 127,799 3,176 40,269 212

R2 0.707 0.308 37,321 133,872 6,315 37,851 98

R3 1.044 0.477 52,442 169,757 13,622 54,182 83

R4 1.352 0.631 65,441 187,127 23,074 69,389 65

R5 1.461 0.694 75,925 150,712 33,751 83,088 36

R6 1.541 0.739 83,893 117,574 44,677 95,048 17

Sb Sc b c

MARK Sb/b + Sc/c

(Mpa) (Mpa) (Mpa) (Mpa)

R1 11 18 92 45 0.524 < 1

R2 12 17 93 45 0.504 < 1

R3 15 25 91 46 0.700 < 1

R4 16 32 90 46 0.860 < 1

R5 13 38 102 52 0.853 < 1

R6 10 44 113 58 0.837 < 1

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 20 OF 43

7.4 Intensity of Girder

G1 girder Axial force

C

C = 0.5H2 × cot

+ 0.5(H2 - H1) cosec N

H2

H1

L

H2 Bending moment

R L

8 (H2 / cos - W sin )

C Mh = N-cm

W sin

W cos

H2 L

Mv = 8 W cos N-cm

H2/cos

Compressive stress

Sc = C / A Mpa

Bending stress

Sbh = Mh / Zx Mpa

Sbv = Mv / Zy Mpa

Where,

X

A : Cross sectional area of girder cm2

Zx : Section modulus of girder

Y Y

(X - X axis) cm3

Zy : Section modulus of girder

(Y - Y axis) cm3 X

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 21 OF 43

Gi girder Axial force

C

C = 0.5(Hi+1-Hi) × cosec N

H2 Compressive stress

H1

L

Sc = C / A Mpa

R C

Combined stress (bending & compression)

Sc Sbh Sbv

+ + < 1

c bc bt

Allowable stress (In accordance with API 650)

c : Allowable compressive stress

bc : Allowable bending stress (compression side)

bt : Allowable bending stress (tension side)

File : /conversion/tmp/scratch/405421796.doc / 148 kB

TKK JOB NO.

REV.

T01-3363

TOYO KANETSU K.K. SPEC. NO. C3363A-D-01 2

TOKYO, JAPAN SHEET NO. 22 OF 43

CALCULATION RESULT FOR GIRDER

Zx Zy A L rG

MARK N SIZE

(cm )3 3

(cm ) (cm )2

(cm) (cm) (L/rG)

G1 36 H250 × 125 × 6.0 × 9 269.6 38.17 30.43 107.4 2.78 38.6

G2 72 L90 × 90 × 13 --- --- 19.11 89.6 1.71 52.4

G3 72 L90 × 90 × 13 --- --- 19.11 124.4 1.71 72.7

G4 72 L90 × 90 × 13 --- --- 19.11 157.7 1.71 92.2

G5 72 L90 × 90 × 13 --- --- 19.11 186.3 1.71 108.9

H1 H2 W C Mh Mv Sc Sbh Sbv

MARK

(N) (N) (N) (N) (N-cm) (N-cm) (Mpa) (Mpa) (Mpa)

G1 40,143 37,321 3,675 197,094 490,595 112,548 65 19 29

G2 37,321 52,442 --- 173,331 --- --- 91 --- ---

G3 52,442 65,441 --- 148,998 --- --- 78 --- ---

G4 65,441 75,925 --- 120,172 --- --- 63 --- ---

G5 75,925 83,893 --- 91,345 --- --- 48 --- ---

c bc bt

MARK Sc + Sbh + Sbv

(Mpa) (Mpa) (Mpa) c bc bt

G1 122 137 125 0.896 < 1

G2 115 --- --- 0.783 < 1

G3 104 --- --- 0.749 < 1

G4 91 --- --- 0.691 < 1

G5 78 --- --- 0.609 < 1

File : /conversion/tmp/scratch/405421796.doc / 148 kB

You might also like

- Safebuck III Rev C 2015Document237 pagesSafebuck III Rev C 2015Cescyle Costa100% (1)

- Column Data Sheet Distillation Column (T-2010)Document12 pagesColumn Data Sheet Distillation Column (T-2010)John Patrick Sanay NunezNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Rectangular Tank CalculationDocument42 pagesRectangular Tank CalculationSiva baalanNo ratings yet

- Vendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantDocument18 pagesVendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantHyune Boom SheenNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- M24-Plate Heat ExcahngerDocument16 pagesM24-Plate Heat ExcahngerAlexNo ratings yet

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off (Swagelok) ValvesDocument5 pagesTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For On-Off (Swagelok) ValvesMichell TurbayNo ratings yet

- Design Calculation-Oil Cooler MaK-2011Document8 pagesDesign Calculation-Oil Cooler MaK-2011Fauzan Rusmayadi ReharderNo ratings yet

- TK-TF1-001 - Calculation SheetDocument17 pagesTK-TF1-001 - Calculation SheetPhượng NguyễnNo ratings yet

- Heating Coils Calculation P569-INO-RA-0002 - 00 - 004Document16 pagesHeating Coils Calculation P569-INO-RA-0002 - 00 - 004tauqeerNo ratings yet

- Mi - 02 Plate Type Heat ExcangerDocument19 pagesMi - 02 Plate Type Heat ExcangerDaud DamanikNo ratings yet

- Air Conditioning - Airteach - Provision Plant, A.C PlantDocument88 pagesAir Conditioning - Airteach - Provision Plant, A.C PlantGabriel AgafiteiNo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Process Vessel DatasheetDocument2 pagesProcess Vessel Datasheetchat.gpt.irisNo ratings yet

- 4.3 Exhaust Silencer DatasheetDocument4 pages4.3 Exhaust Silencer Datasheetabuya3kubmNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- TD HE S&T v2020.00Document29 pagesTD HE S&T v2020.00Claudia BonocoreNo ratings yet

- Indra: SonatrachDocument9 pagesIndra: Sonatrachmessari mohamedakliNo ratings yet

- 9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankDocument3 pages9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankFikri MakhlufNo ratings yet

- DatasheetDocument1 pageDatasheetDeni HermawanNo ratings yet

- Design Calculation Oil Cooler MaK 2011 v2Document8 pagesDesign Calculation Oil Cooler MaK 2011 v2Fauzan Rusmayadi ReharderNo ratings yet

- KCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Document9 pagesKCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Anonymous bHh1L1No ratings yet

- WH1716-70-B-010-4 S-7004 Storage Tank Specification Datasheet Rev1Document4 pagesWH1716-70-B-010-4 S-7004 Storage Tank Specification Datasheet Rev1Ionut FloricaNo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- Daikin EWAD-DDocument1 pageDaikin EWAD-DsalahcalimeroNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument4 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNo ratings yet

- Indra: Equipment Data Sheet FOR Fire Water / Utility Water Tank 306D-831Document6 pagesIndra: Equipment Data Sheet FOR Fire Water / Utility Water Tank 306D-831senthilkesavanpNo ratings yet

- EHK-PET-MS-INS-DTS-005 Data Sheet For Level Indicator Rev. 1-IFA - OKDocument4 pagesEHK-PET-MS-INS-DTS-005 Data Sheet For Level Indicator Rev. 1-IFA - OKSehargo JunizarNo ratings yet

- Storage Tank Foundation DesignDocument15 pagesStorage Tank Foundation DesignDeny AristyaNo ratings yet

- Directions:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankDocument8 pagesDirections:: T-501 Vertical Fixed Roof Residual Fuel Oil No. 6 Jimmy Peress Newark NJ Outdoor Storage TankAnonymous K3FaYFlNo ratings yet

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 pagesAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyNo ratings yet

- Irkutsk Polymer Plant (IPP) / IPP 650 KTA Ethylene Plant Project Проект установки по производству этилена ИЗП мощностью 650 тыс. т/годDocument1 pageIrkutsk Polymer Plant (IPP) / IPP 650 KTA Ethylene Plant Project Проект установки по производству этилена ИЗП мощностью 650 тыс. т/годJss JssNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- s5113 Mm41 Plate CoolerDocument79 pagess5113 Mm41 Plate CoolerJorge AguilarNo ratings yet

- EPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 ApprovedDocument15 pagesEPN-KSO-LBJ-TBBM-In-DTS-005 Data Sheet For Temperature Relief Valve (TRV) R2 Re-AFC Rev 1 Approvedboy telerNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Accessen Plate Heat Exchanger Specification SheetDocument1 pageAccessen Plate Heat Exchanger Specification Sheetfakir mohammadNo ratings yet

- Ie 101Document14 pagesIe 101raiNo ratings yet

- Quotation Plan For Naz Bangladesh 21-01-15Document4 pagesQuotation Plan For Naz Bangladesh 21-01-15fakir mohammadNo ratings yet

- English Unit Spec SheetDocument3 pagesEnglish Unit Spec SheetDanang PrakosaNo ratings yet

- Strainer DatasheetDocument1 pageStrainer DatasheetdgmprabhakarNo ratings yet

- Data Sheet 65 DS 51.5Document4 pagesData Sheet 65 DS 51.5Gokula Krishnan CNo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Pipeline Cathodic Protection Design - Compress PDFDocument20 pagesPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- Data Sheet Basket Filter-ATF R2Document4 pagesData Sheet Basket Filter-ATF R2Suaib VCSNo ratings yet

- T-707-Calculations Based On Actual Thickness-R2Document25 pagesT-707-Calculations Based On Actual Thickness-R2SachinNo ratings yet

- PHL 1000Document4 pagesPHL 1000kamlesheicNo ratings yet

- Input Data: Tce Consulting Engineers LimitedDocument2 pagesInput Data: Tce Consulting Engineers Limitedsaptarshi samantaNo ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- Data Sheet of Magnetic Level Gauge For Feed Coalescer PackageDocument1 pageData Sheet of Magnetic Level Gauge For Feed Coalescer PackageHemant NimaseNo ratings yet

- VK512 - ESFR Dry Pendent Sprinkler (K25.2)Document8 pagesVK512 - ESFR Dry Pendent Sprinkler (K25.2)DeniNo ratings yet

- 0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXDocument1 page0 1 2 Raffreddamento R9: Jacketed Vessel Heat Transfer 223 XXPhượng NguyễnNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDocument5 pagesTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi Vel100% (1)

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- Seismic Design For Application of LNG Storage TankDocument10 pagesSeismic Design For Application of LNG Storage TankHyune Boom SheenNo ratings yet

- fatigue - knowledge - 14 ソケット溶接継手の疲労に関する既存の知見について PDFDocument23 pagesfatigue - knowledge - 14 ソケット溶接継手の疲労に関する既存の知見について PDFHyune Boom SheenNo ratings yet

- Publication 12 18109 228Document4 pagesPublication 12 18109 228Hyune Boom SheenNo ratings yet

- Assy No. Type of Work Platform Use Test WeightDocument1 pageAssy No. Type of Work Platform Use Test WeightHyune Boom SheenNo ratings yet

- Generation of Residual Stresses in Rotary Swaging ProcessDocument9 pagesGeneration of Residual Stresses in Rotary Swaging ProcessHyune Boom SheenNo ratings yet

- Fracture Mechanics & Material Behaviour: Department of Mechanical Engineering Coursework Assignment Cover SheetDocument1 pageFracture Mechanics & Material Behaviour: Department of Mechanical Engineering Coursework Assignment Cover SheetHyune Boom SheenNo ratings yet

- Vendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantDocument18 pagesVendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantHyune Boom SheenNo ratings yet

- Data / Requisition Sheet For: Eccn Ear99 Design Book No: Contr. Job No: Mesc NoDocument3 pagesData / Requisition Sheet For: Eccn Ear99 Design Book No: Contr. Job No: Mesc NoHyune Boom SheenNo ratings yet

- Equipment: Plant: Consignee:: C OfmDocument1 pageEquipment: Plant: Consignee:: C OfmHyune Boom SheenNo ratings yet

- 3d Measurement and Ffs Assessment For Lta in Pressure Equipment According To Wes2820-2015 PVP2016-63912Document8 pages3d Measurement and Ffs Assessment For Lta in Pressure Equipment According To Wes2820-2015 PVP2016-63912Hyune Boom SheenNo ratings yet

- Ebsco Ebooks: Ebook Petroleum Engineering CollectionDocument1 pageEbsco Ebooks: Ebook Petroleum Engineering CollectionHyune Boom SheenNo ratings yet

- EXAM THERMO (True) 1Document9 pagesEXAM THERMO (True) 1Jojimar JulianNo ratings yet

- May Jun 2022-1Document4 pagesMay Jun 2022-1ARJUNANo ratings yet

- Lec 16 CDocument66 pagesLec 16 CSalman MemonNo ratings yet

- Toaz - Info Atc 24 PDF PRDocument58 pagesToaz - Info Atc 24 PDF PRPooya ArezoomandNo ratings yet

- Critical Reynolds Number in Pipe FlowDocument9 pagesCritical Reynolds Number in Pipe FlowStephen Mirdo100% (3)

- The Math Behind... Solar Cell Design: Apply ItDocument1 pageThe Math Behind... Solar Cell Design: Apply ItKabeed MansurNo ratings yet

- Lab (2) Coefficient of FrictionDocument5 pagesLab (2) Coefficient of FrictionMuhammad HuzaifaNo ratings yet

- Thickness of Pavement PDFDocument7 pagesThickness of Pavement PDFReech Aerol Almendral100% (1)

- Physics - Moving Charges and MagnetismDocument8 pagesPhysics - Moving Charges and MagnetismSAHAJANYA SRIKANTHNo ratings yet

- Metalastik Type Chevron SpringsDocument6 pagesMetalastik Type Chevron SpringsBo WangNo ratings yet

- Prestressed Concrete-Continuous BeamDocument16 pagesPrestressed Concrete-Continuous BeamS PraveenkumarNo ratings yet

- Chapter Assessment Forces in One Dimension Teacher EditableDocument8 pagesChapter Assessment Forces in One Dimension Teacher EditableAriana Jeon100% (1)

- Petrowiki Pressure Drop EquationsDocument14 pagesPetrowiki Pressure Drop Equationsrasnowmah2012No ratings yet

- Short Circuit in High-Voltage Ceramic Station Post InsulatorsDocument7 pagesShort Circuit in High-Voltage Ceramic Station Post InsulatorsJiraya15No ratings yet

- Thiet Ke Cot Composite - EC4. V1.0 (MS03)Document5 pagesThiet Ke Cot Composite - EC4. V1.0 (MS03)luuvandong48xf396No ratings yet

- COMSOL Implementation of A Multiphase Fluid Flow Model in Porous MediaDocument7 pagesCOMSOL Implementation of A Multiphase Fluid Flow Model in Porous MediaDenis GontarevNo ratings yet

- Computational Fluid Dynamics (CFD) : A Seminar Report OnDocument16 pagesComputational Fluid Dynamics (CFD) : A Seminar Report OnAnil GöwđaNo ratings yet

- The Twin Paradox: Jandejongwormer@kpnmail - NLDocument3 pagesThe Twin Paradox: Jandejongwormer@kpnmail - NLSivadev V SathishNo ratings yet

- 유체 정리Document17 pages유체 정리음오아예No ratings yet

- Theory of Lubrication With Ferrofluids: Application To Short BearingsDocument6 pagesTheory of Lubrication With Ferrofluids: Application To Short BearingsKarthik RaoNo ratings yet

- Konsolidasi Tanah Lunak GeoslopeDocument6 pagesKonsolidasi Tanah Lunak GeoslopeFarid MarufNo ratings yet

- Sp015 Nota Fizik Topic 2Document78 pagesSp015 Nota Fizik Topic 2Khairul ImranNo ratings yet

- CS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Document6 pagesCS/B.TECH (CE) /SEM-8/CE-801/4/08: Advanced Foundation Engineering (Semester - 8)Debanjan BanerjeeNo ratings yet

- FortiniSNOWANCHORS3B PDFDocument56 pagesFortiniSNOWANCHORS3B PDFPierre-Frederic VergeNo ratings yet

- Analysis of Statically Determinate Structures: Support ConnectionDocument7 pagesAnalysis of Statically Determinate Structures: Support ConnectionejlNo ratings yet

- Huerre, Monkewitz - Absolute and Convective Instabilities in Free Shear Layers (1985)Document18 pagesHuerre, Monkewitz - Absolute and Convective Instabilities in Free Shear Layers (1985)Aryce_No ratings yet

- SWD TS 500 2000Document63 pagesSWD TS 500 2000mcpayodNo ratings yet

- Theory of SuperconductivityDocument135 pagesTheory of SuperconductivityKonstantinos LadovrechisNo ratings yet

- Corner Peeking AnalysisDocument3 pagesCorner Peeking AnalysisAnonymous 5MO0mkNo ratings yet