Professional Documents

Culture Documents

p1475 Misumi

p1475 Misumi

Uploaded by

dmalfazOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p1475 Misumi

p1475 Misumi

Uploaded by

dmalfazCopyright:

Available Formats

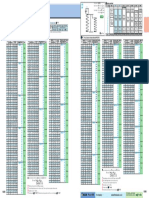

Gas Springs Gas Springs

−Guide− −Free Attachable Type−

CAD Data

Gas Springs

Attaching Portion FGSS G

iAttaching Direction (All Directions 360°)

· High pressure gas (Nitrogen gas: Attaching Portion Ø10 There is no limit on rod direction and attaching

incombustible) is sealed in a cylinder, and No.15050A~No.22300B direction (angle).

Tube

B

the gas reaction force is used as spring. Compression Gas

A

7

7

Because this small gas spring receive Orifice Seal

C C

Usa

ble at any ang

3.2

3.2

le

Piston Rod Guide H

small spring constant from large initial

.

Rod L 360° 360°

Chamber A

load in spite of its size, it can be used for Rod

Oil G Operating Temperature −20~60°C

wide range of applications including Piston

Orifice No.27150A~No.27300B eCylinders : 1.0034/S205G1T(USt.34)

Oil Ø10

machines, furnitures, cars, office Seal Tube (Carbon Steel Pipes for

Rod Guide Chamber B Machine Structural Use)

automation equipments, etc. Rod : 1.1151/C22E(Ck22)

Free Pistons

11

11

B

A

Use within this range. Compression Gas : Nitrogen Gas (N2)

Features 60° 60°

Gas Chamber C

Usable at any angle.

C C

3.2

3.2

360° 360°

· In spite of its size and weight, large spring üThe inside structure Attaching Portion H rCylinders : Baking Finish (Black matt)

of FRGSS is partly Attaching Portion L Rod : Hard Chrome Plating

(reaction) force can be obtained. different from Fig. 1

· Spring (reaction) force is almost constant on the right. üUsable at any angle, only Max. Min. Gas Reaction Force (20°C)

Part Number Applicable Weight Unit Price

throughout its stroke. HFGSS is 360°. Length Length Stroke Max. Length−10mm Max. Length−( )mm A B C G H

(Lmax) (Lmin) Brackets (g)

Fig.1 Gas Spring Fig.2 Gas Spring of Free Attachable Type Type No. (kgf) (kgf) Qty.1~4

· Can be designed as required for wide (GSS · HFGSS · FRGSS) (FGSS · FGSB) 15050A 5 7 (40)

applications. 246 196 50 164 125 17,00

15050B 10 13 (40)

15080A 5 7 (70)

330 250 80 218 150 17,60

15080B 10 13 (70)

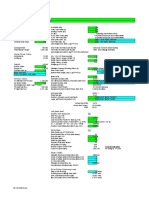

About Selection Gas reaction force at the max. length−10 (5) mm and 15090A 5 7 (80)

15 7

1. Calculate the necessary reaction force(F) through the following formula. the max. length− mm are listed in this catalog. 360 270 90 238 155 17,60

15090B 10 13 (80)

A Since gas reaction force generally changes 15100A 5 7 (90)

F= W×A F : Necessary reaction force (at max. length) proportionately, if the gas reaction force on a certain 386 286 100 254 170 18,40

−−− 15100B 10 13 (90)

B W : Weight of doors, etc. Door stroke is required, connect the 2 points as shown in 18100A 20 26 (90)

A : Horizontal distance between Fig.3 with a straight line and read and conjecture the 386 286 100 253 210 19,30

18100B 30 39 (90)

fulcrum (door hinge, etc.) and centroid W value on the stroke. 18 8

18150A 20 27 (140)

B : Vertical distance between fulcrum 526 376 150 343 280 19,30

Max. Length−10mm (GSS · FGSS · FGSB) 18150B 30 40 (140)

(door hinge, etc.) and the axis F Max. Length−5mm (HFGSS · FRGSS) 22050A 20 27 (40)

of gas spring 19,30

Axis Line 22050B 246 196 50 30 41 (40) 163 215

lid Lin

e 22050C 40 54 (40)

Gas Reaction Force

2. Select Fx1.1 or more for the gas spring reaction force.

ing So 22080A 20 28 (70)

3. If required reaction force (Fx1.1) is larger than the Shrink f

18,20

e 22080B 330 250 80 30 42 (70) 217 270

reaction force at the max. length of gas spring Lin

Theory f 22080C 40 55 (70)

− ( ) mm, use 2 or more springs. B 22090A 20 27 (80)

4. Reaction force is designed at 20°C. Reaction force ine GSSB8A

olid L 22090B 360 270 90 30 41 (80) 237 280 19,30

increases or decreases as the temperature changes. sion S

Expan 22090C 40 54 (80) GSSB8B

22100A 20 28 (90) GSSB8C

24 R9

Max. Length− mm 22100B 386 286 100 30 42 (90) 253 GSSB8D 305 18,40

22100C 40 56 (90) GSSB8E

Max. Length Stroke Min. Length 22120A 20 28 (110) (P.1478)

22120B 440 320 120 30 41 (110) 287 320 19,30

Fig.3 Gas Spring Reaction Force 22120C 40 55 (110)

Precautions for Use (for GSS, FGSS, HFGSS and FRGSS) üf=Internal Sliding Resistance (Theoretical Value x 0.1) FGSS 22130A 20 28 (120)

· When storing, pay attention to temperature of gas springs. 22 10

22130B 470 340 130 30 41 (120) 307 330 19,30

(Product temperature range: GSS · FGSS: −20°C~60°C / HFGSS: −20°C~80°C / FRGSS: −30°C~80°C) 22130C 40 55 (120)

· Gas reaction forces are slightly different among individual products. 22150A 20 28 (140)

· Gas reaction force may change depending on the temperature. 22150B 526 376 150 30 41 (140) 343 400 19,90

· Reaction force may decrease depending on the operating condition and times of use. Please replace it when it cannot reach the necessary reaction force. 22150C 40 55 (140)

· Do not store or use in the environments where the rod rusts or in chemical atmosphere. Furthermore, do not paint the gas spring. 22180A 20 28 (170)

· Do not damage the cylinders and rods. Furthermore, do not apply forces like bending load and torsion etc. 22180B 610 430 180 30 41 (170) 397 420 21,80

· Do not extend gas springs beyond its max. length. Even in the max. stroke (during compression), it must remain about 10 mm away from the stroke end. 22180C 40 55 (170)

Moreover, do not extend and compress at high speed (with 1m / s or more). 22200A 20 27 (190)

· Use GSS with the cylinder side up and the rod side down, so that internal oil will protect the rubber seal. For GSS and FRGSS, do not lean more than 60 degrees. 22200B 666 466 200 30 41 (190) 433 480 21,80

22200C 40 54 (190)

Although there is no restriction in the use angle for the FGSS and HFGSS, rod downward is recommended.

22250A 20 31 (240)

22250B 750 500 250 30 46 (240) 467 540 22,30

Features of Gas Spring of Free Attachable Type (FGSS and FGSB) 22250C 40 61 (240)

· Gas Springs of Free Attachable Type 22300A 20 33 (290)

850 550 300 517 600 25,00

1.Nitrogen gas (incombustible) is sealed in the gas chamber C with free piston intervening, and gas reaction force can be used as spring. 22300B 30 50 (290)

2.Gas chamber C has a constant reaction force in extending direction since it pressurizes oil chamber AB. Therefore the size of reaction force depends on the 27150A 50 67 (140)

27150B 526 376 150 60 80 (140) 351 610 25,50

inner pressure of gas chamber C.

27150C 70 94 (140)

3.When rod moves from the predetermined position, oil in chamber AB moves through orifice hole of the piston.

27200A 50 67 (190)

4.The rod volume change in the cylinder is adjusted by the change of gas chamber C. 27200B 666 466 200 60 80 (190) 441 760 26,20

27200C 70 94 (190) 27.4 12.5 16 R11 −

Example 27250A 50 74 (240)

27250B 750 500 250 60 89 (240) 475 900 27,10

27250C 70 104 (240)

27300A 50 79 (290)

850 550 300 525 1000 28,00

27300B 60 95 (290)

üFor attaching brackets, refer to P.1478.

Fan Facility Equipments OA Equipments Industrial Equipments Board Mounting Equipments Electronic Inspection Devices

Order Part Number Days 8 Days Express A EUR 2,00/

piece o P.92 Price i Volume Discount P.92

Example to Ship Quantity 1~4 5~9 10~14 15~19

1475 üA flat charge of EUR 5,40 for 3 Rate Price List 5% 10% 15% 1476

or more identical pieces.

üFor orders larger than indicated values, please request for quotation.

You might also like

- LRUT ProcedureDocument10 pagesLRUT ProcedureD_D1216No ratings yet

- Construction Material Price Indices: Statistical ReleaseDocument10 pagesConstruction Material Price Indices: Statistical ReleaseMvelo PhungulaNo ratings yet

- Centrifugal Feeder DesignDocument12 pagesCentrifugal Feeder DesignJuan Jose Barrios SanchezNo ratings yet

- FEA Report PDFDocument24 pagesFEA Report PDFDanish JavedNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- CCTVDDocument20 pagesCCTVDSteven SunNo ratings yet

- International StandardDocument20 pagesInternational StandardUdit Kumar SarkarNo ratings yet

- Design Consideration of ShaftDocument6 pagesDesign Consideration of Shaftpriyankar007No ratings yet

- Transmissions Corse MorseDocument87 pagesTransmissions Corse MorseVatsa MolanoNo ratings yet

- Shaft Design1Document4 pagesShaft Design1Gautham RengarajanNo ratings yet

- Binder 1Document6 pagesBinder 1Andy SoxxNo ratings yet

- Brochure 2010Document20 pagesBrochure 2010shankarsreekumarNo ratings yet

- Forbo ConveyorsDocument14 pagesForbo ConveyorsMiguel AngelNo ratings yet

- Misumi Spring Catologue PDFDocument1 pageMisumi Spring Catologue PDFAkshay JagdaleNo ratings yet

- BeltDocument180 pagesBeltHectorHugoRamirezNo ratings yet

- Installation Equipment: Sanitary Fittings and ValvesDocument89 pagesInstallation Equipment: Sanitary Fittings and ValvesSebassde0% (1)

- Shaft DesignDocument7 pagesShaft DesignAhmet GelisliNo ratings yet

- 001Document20 pages001Emad ElhussienyNo ratings yet

- Loads Acting On Crane Structure During TravelDocument11 pagesLoads Acting On Crane Structure During Travelaiyubi2No ratings yet

- M 452 ContentDocument65 pagesM 452 ContentISsa Qafa'itiNo ratings yet

- Counter Weight Drawing MCT85Document14 pagesCounter Weight Drawing MCT85Nirmalya SenNo ratings yet

- 02 Mechanical BasicsDocument29 pages02 Mechanical BasicsVLADIMIR YOLVIS CHOQUEHUANCA GALINDONo ratings yet

- Muff Coupling & Split Muff CouplingDocument19 pagesMuff Coupling & Split Muff CouplingRamanathan DuraiNo ratings yet

- Md-17 Shaft Design StepsDocument12 pagesMd-17 Shaft Design StepsRamji RaoNo ratings yet

- Ansi B1 20 3 17Document1 pageAnsi B1 20 3 17Kristian Raphael BVNo ratings yet

- WC478 PDFDocument1 pageWC478 PDFKasia MazurNo ratings yet

- NX Nastran 8 Design Sensitivity and Optimization User's GuideDocument310 pagesNX Nastran 8 Design Sensitivity and Optimization User's GuideMSC Nastran BeginnerNo ratings yet

- Bevel GearDocument1 pageBevel GearAngielou SialanaNo ratings yet

- Jamesbury Ball Valves PDFDocument20 pagesJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Inventor Project Dynamic Simulation Guide enDocument17 pagesInventor Project Dynamic Simulation Guide enheveton777No ratings yet

- 2.4-p1-p71 VerticalDocument7 pages2.4-p1-p71 VerticalFernando PerdomoNo ratings yet

- Series 450 - JOUCOMATIC Tie Rod Cylinders Type PESDocument2 pagesSeries 450 - JOUCOMATIC Tie Rod Cylinders Type PESIrham Lazuardi100% (1)

- SimMan Tut 01 BackstepDocument20 pagesSimMan Tut 01 BackstepVenkata VasanthaNo ratings yet

- Z M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Document16 pagesZ M B (MM) N H (Hours) : Gear Design (Is-4460) (Spur or Helical)Babu RajamanickamNo ratings yet

- 250 G.P.M. 912 SERIES: Electric Motor DriveDocument64 pages250 G.P.M. 912 SERIES: Electric Motor DriveFerGarciaNo ratings yet

- AD 2000 Tubes Under Intenal PressureDocument1 pageAD 2000 Tubes Under Intenal Pressuremechengg01No ratings yet

- Calculations Per ABS Code Along With ASME Sec. VIII Div.1 XXXXDocument17 pagesCalculations Per ABS Code Along With ASME Sec. VIII Div.1 XXXXordenador90No ratings yet

- Datasheet FXMDocument6 pagesDatasheet FXMSumit ChaurasiaNo ratings yet

- Stresses and Deformations of A Conveyor Power Pulley Shell Under Exponential Belt TensionsDocument9 pagesStresses and Deformations of A Conveyor Power Pulley Shell Under Exponential Belt TensionsShamik ChowdhuryNo ratings yet

- Fea of Splined ShaftDocument6 pagesFea of Splined ShaftrevandifitroNo ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcswidyaditya8No ratings yet

- Gates and RunnersDocument51 pagesGates and RunnersKostas Frantzik100% (1)

- Parametric Study of A Dog Clutch Used in A Transfer Case For TrucksDocument46 pagesParametric Study of A Dog Clutch Used in A Transfer Case For TrucksCesar VasquesNo ratings yet

- FEM9.311 EnglDocument6 pagesFEM9.311 EnglPınar SunNo ratings yet

- Flowserve Air To Open Standard Actuator Valtek 2112 Selection For Korting Thermocompressor ValveDocument1 pageFlowserve Air To Open Standard Actuator Valtek 2112 Selection For Korting Thermocompressor ValvealicardozoNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- Kwsengineering PDFDocument126 pagesKwsengineering PDFargaNo ratings yet

- AGMA Pitting Geometry FactorDocument1 pageAGMA Pitting Geometry FactormgualdiNo ratings yet

- Belt Drive Handout - 05Document3 pagesBelt Drive Handout - 05NkoshiEpaphrasShoopalaNo ratings yet

- Swagelok CatalogueDocument16 pagesSwagelok CatalogueZacharia JohnNo ratings yet

- FEM Analysis Report For Spray HeaderDocument22 pagesFEM Analysis Report For Spray HeaderNithin MathaiNo ratings yet

- 3 WL 00200-5 Ex. 23-41Document30 pages3 WL 00200-5 Ex. 23-41NuM NaNo ratings yet

- Longitudinal Pin For Shaft-Hub ConnectionDocument6 pagesLongitudinal Pin For Shaft-Hub Connectionmet-calcNo ratings yet

- Carbon Steel Tee Rails: Standard Specification ForDocument7 pagesCarbon Steel Tee Rails: Standard Specification ForAAYNo ratings yet

- Guydes: Cable Stiffne Ss Non-Linear RangeDocument3 pagesGuydes: Cable Stiffne Ss Non-Linear RangeAli AlomyNo ratings yet

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocument77 pagesDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoNo ratings yet

- Press Fit Pressure CalculatorDocument4 pagesPress Fit Pressure CalculatorBhadresh ShahNo ratings yet

- Torque AssignmentDocument13 pagesTorque AssignmentMostafa Ahmed ZeinNo ratings yet

- Peract Pi Q23 DW 0004 PDFDocument5 pagesPeract Pi Q23 DW 0004 PDFGNo ratings yet

- ErmetoDocument14 pagesErmetoJavier VespaNo ratings yet

- Gas Springs Gas Springs: Mounting Orientation Free TypeDocument1 pageGas Springs Gas Springs: Mounting Orientation Free TypeTejinder SinghNo ratings yet

- Gas Springs Gas Springs: Mounting Orientation Free TypeDocument1 pageGas Springs Gas Springs: Mounting Orientation Free Typeengineering sssiNo ratings yet

- TCS SH - 387Document9 pagesTCS SH - 387shailendraNo ratings yet

- Hydraulic Swivel Clamps, Double Action: Screw-In Version Operating Pressure Max. 250 BarDocument8 pagesHydraulic Swivel Clamps, Double Action: Screw-In Version Operating Pressure Max. 250 BardmalfazNo ratings yet

- Hydraulic Swivel Clamps, Double ActionDocument8 pagesHydraulic Swivel Clamps, Double ActiondmalfazNo ratings yet

- Bronc EsDocument1 pageBronc EsdmalfazNo ratings yet

- Anticorodal50 Englisch 01Document1 pageAnticorodal50 Englisch 01dmalfazNo ratings yet

- Aluminium Plates - EN AW-7075: ProductsDocument1 pageAluminium Plates - EN AW-7075: ProductsdmalfazNo ratings yet

- Irb 140 PR 10031en - R7 LRDocument2 pagesIrb 140 PR 10031en - R7 LRdmalfazNo ratings yet

- Blockwork Accessories CatalogueDocument53 pagesBlockwork Accessories CatalogueTejinder KumarNo ratings yet

- NCHRP 474 - Service Lyfe of Culverts - TRBDocument145 pagesNCHRP 474 - Service Lyfe of Culverts - TRBWalter PiracocaNo ratings yet

- Sroat 1000-PlusDocument2 pagesSroat 1000-PlusVishnu PatidarNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)Jiso Thomas100% (1)

- Piping DesignDocument4 pagesPiping DesignTerry YongNo ratings yet

- TSFDC Kothagudem WorkDocument42 pagesTSFDC Kothagudem WorkS UDAY KUMARNo ratings yet

- Kapro CatalogDocument72 pagesKapro CatalogIsmael 8877No ratings yet

- Work Based Sapmle CivilDocument7 pagesWork Based Sapmle CivilAchyut TimilsinaNo ratings yet

- CSTI - Solving AIV Problems in The Design Stage (2013) - Design CurveDocument4 pagesCSTI - Solving AIV Problems in The Design Stage (2013) - Design CurveromerobernaNo ratings yet

- Terrace DesignDocument37 pagesTerrace DesignjaffnaNo ratings yet

- IDT Imageprospekt 2012 Web enDocument46 pagesIDT Imageprospekt 2012 Web enjbharghavNo ratings yet

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDocument3 pages1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNo ratings yet

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- HPD 4400 CatalogDocument424 pagesHPD 4400 CatalogMarco Antonio Rivera VázquezNo ratings yet

- Mebs6000 0809 03 Cold and Hot Water Design PDFDocument78 pagesMebs6000 0809 03 Cold and Hot Water Design PDFKamaruz DanialNo ratings yet

- 00calculation Sheet For MMII Compressor Shed1Document31 pages00calculation Sheet For MMII Compressor Shed1clarkgaguiNo ratings yet

- Miltonroy Mroy XT 33005 07 Us PDFDocument16 pagesMiltonroy Mroy XT 33005 07 Us PDFLinaNo ratings yet

- Technical Proposal For AG COMPRESSOR PACKAGE Rev1Document18 pagesTechnical Proposal For AG COMPRESSOR PACKAGE Rev1arper2022No ratings yet

- Sprinkflex Product SubmittalDocument6 pagesSprinkflex Product SubmittalAhmed NabilNo ratings yet

- Flow Metering: "Installation and Set-Up Require A Particular Care"Document18 pagesFlow Metering: "Installation and Set-Up Require A Particular Care"chellahari2922No ratings yet

- WR-PR-015 Pressure VesselDocument20 pagesWR-PR-015 Pressure Vesselarsil5840No ratings yet

- Stainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFDocument8 pagesStainless Steel For Potable Water Treatment Plants PWTP Guidelines PDFAsgard SanchezNo ratings yet

- Galvanizing ProcedureDocument11 pagesGalvanizing ProcedureMcmiltondmordomNo ratings yet

- Nipin CVDocument3 pagesNipin CVAnish PillaiNo ratings yet

- Detailed BOQ: (PART-A) - I. Cement Concrete Pavement (Road Lenght DF 1800 MTR., Wide 2 X 7 MTR.)Document15 pagesDetailed BOQ: (PART-A) - I. Cement Concrete Pavement (Road Lenght DF 1800 MTR., Wide 2 X 7 MTR.)Tapas GoyalNo ratings yet

- Hasbi Asidik - 29120131 - Strategic Decision Making and Negotiation Mid TermDocument15 pagesHasbi Asidik - 29120131 - Strategic Decision Making and Negotiation Mid TermHasbi AsidikNo ratings yet

- Atlas Copco: Stationary Air CompressorsDocument72 pagesAtlas Copco: Stationary Air Compressorsnugrohowijaya37No ratings yet