Professional Documents

Culture Documents

Welding Procedure Specification: JOINT (QW-402)

Welding Procedure Specification: JOINT (QW-402)

Uploaded by

Lipika GayenCopyright:

Available Formats

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocument4 pagesWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Welding Procedure Specification Pipe 6G PDFDocument3 pagesWelding Procedure Specification Pipe 6G PDFchepurthiNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Wps Ss r0 AdaniDocument2 pagesWps Ss r0 Adanigunasekhar kamireddiNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiAR100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- T-721 For MPTDocument1 pageT-721 For MPTLipika GayenNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VDocument1 pageQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Document4 pagesAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Activity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilDocument1 pageActivity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilLipika GayenNo ratings yet

- Axial Flow For Industry 1Document9 pagesAxial Flow For Industry 1Lipika GayenNo ratings yet

- Field Inspection Report: Facsimile of Name PlateDocument2 pagesField Inspection Report: Facsimile of Name PlateLipika GayenNo ratings yet

- Tank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationDocument1 pageTank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationLipika GayenNo ratings yet

- Joint No: Backing: Yes No Backing Mat: N/ADocument1 pageJoint No: Backing: Yes No Backing Mat: N/ALipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- S.No. Hospital Code Hospital NameDocument20 pagesS.No. Hospital Code Hospital NameLipika GayenNo ratings yet

- Field Inspection Report: Dimension Check of Nozzle & ManholeDocument1 pageField Inspection Report: Dimension Check of Nozzle & ManholeLipika GayenNo ratings yet

- 4 6048613395123405697Document64 pages4 6048613395123405697Lipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- 5 6086791694424998681Document80 pages5 6086791694424998681Lipika GayenNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsLipika GayenNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenNo ratings yet

Welding Procedure Specification: JOINT (QW-402)

Welding Procedure Specification: JOINT (QW-402)

Uploaded by

Lipika GayenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification: JOINT (QW-402)

Welding Procedure Specification: JOINT (QW-402)

Uploaded by

Lipika GayenCopyright:

Available Formats

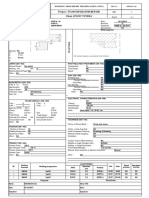

Welding procedure Specification Rev.

Qualificatin code: ASME Sec. IX

Project: SHAZAND ARAK REFINERY EXPANSION & UPGRADING

Client: NIOEC

WPS No. : G2-1/C Welding Process: SMAW

PQR No. : Type: MANUAL

Item : ANNULAR PLAT,NOZZLE TO SHELL Location: site or shop

JOINT(QW-402)

Joint Design : SINGLE or DOUBLE VEE GROOVE

Type of Joint BUTT or CORNER

Backing: YES 60°

Backing Material : C.S. 5mm

30°

5mm

POSITION(QW-405)

Pos. of Groove : all pos. COMPERESSION RING

Welding Progress :up hill

BASE MATERIAL(QW-403) filler(QW-403)

1)Specification: SA283 Gr.C or SA516 Gr.60 or SA106 Gr.B Spec. No.(SFA): 5.1

P-No.: 1 Group No.: 1 AWS No.(Class): E7018 -1

2)Specification: SA283 Gr.C or SA516 Gr.60 F-No.: 4

P-No.: 1 Group No.: 1 A-No.: 1

Thickness(m Groove: 4.8~30 Fillet: Trade Name: 1177F

preheat(QW-406) Manufacturer: AMA

Preheat Temp.(Min): 75°C (see note*) Baking Condition: as per label

Interpass Temp.(Max): 250°C Flux: N/A

Preheat Maintenance: N/A Baking Condition: N/A

tungesten electrode Manufacturer: N/A

Type: N/A Size: N/A Electro-Flux(CLASS): N/A

P.W.H.T.(QW-406)

Heating Rate(°C/Hr) : Temp.(°C): N/A Time(Min): N/A Cooling Rate(°C/Hr) :

TECHNIQUE.(QW-410)

String(S) or Weave(W) BeadWeave Method of Back Gouging : N/A

Orifice Or Gas Cup Size: N/A Oscillation: N/A

Initial Cleaning: BRUSHING Pass Number Per Side: Multi Pass

Interpass Cleaning: BRUSHING Multiple or SingleElctrode: Single

ELECTRICAL CHARACTERISTICS(QW-409)

.

No FILLER METAL CURRENT(A)

IT

Y VOLTAGE(v) TRAVEL SPEED HEAT INPUT

SS AR

PA PROCESS φ(mm) L

CLASS PO Min Max Min Max Min (cm/min) Max KJ/cm(Max)

1 SMAW E7018-1 3.25 DCEP 100 ~ 130 21 ~ 23 10 ~ 15 17.9

2~N SMAW E7018-1 4 DCEP 140 ~ 180 22 ~ 24 15 ~ 25 17.3

Welding Sequence: ROOT (SMAW) & COMPLETE (SMAW)

note: GAS (QW-408)

WEATHERING CONDITION: Gas Mixture Flow(lit/min)

1) All SURFACES SHALL BE CLEAN FROM MOISTUTE, RAIN, ICE, SNOW AND OTHER

POLUTIONS. Shielding Gas (es) N/A N/A N/A

2) IN WINDY CONDITION, WELDING SHALL BE PROCEEDING ONLY IN SHILDED CONDITION.

3) AT TIME OF RAIN/SNOW FALLING, WELDING IS PROHIBITTED. Trailing Gas (es) N/A N/A N/A

4) WELDING OF BASE METAL WITH TEMPERATURE BELOW -18C IS PROHIBITED. Backing Gas (es) N/A N/A N/A

*Remove trace amount of moisture by mean of pre-heating.

IMPACT TEST: Temp. -40°C Energy: 27J

HARDNESS (Max.) : 22 HRC

Prep'd: I.M. App.: H.GH.

20

17.9

17.3

#DIV/0!

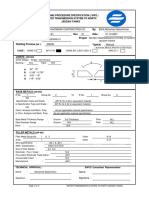

Welding procedure Specification Rev. 2

Qualificatin code: ASME Sec. IX

Project: SHAZAND ARAK REFINERY EXPANSION & UPGRADING

Client: NIOEC

WPS No. : G2-2/C Welding Process: SMAW+GTAW

PQR No. : Type: MANUAL

Item : NOZZLE TO SHELL Location: site or shop

JOINT(QW-402)

Joint Design : SINGLE or DOUBLE VEE GROOVE

Type of Joint BUTT or CORNER

Backing: N/A

Backing Material : N/A

NOZZLE TO SHELL

POSITION(QW-405)

Pos. of Groove : 3G

Welding Progress :up hill

BASE MATERIAL(QW-403) filler(QW-403)

1)Specification: SA283 Gr.C or SA516 Gr.60 or SA106 Gr.B Spec. No.(SFA): 5.1 , 5.18

P-No.: 1 Group No.: 1 AWS No.(Class): E7018-1 , ER70S-6

2)Specification: SA283 Gr.C or SA516 Gr.60 F-No.: 4,6

P-No.: 1 Group No.: 1 A-No.: 1 ,1

Thickness(m Groove: 4.8~30 Fillet: Trade Name: 1177F , 40-16T

preheat(QW-406) Manufacturer: AMA

Preheat Temp.(Min): 75°C (see note*) Baking Condition: as per label

Interpass Temp.(Max): 250°C Flux: N/A

Preheat Maintenance: N/A Baking Condition: N/A

tungesten electrode Manufacturer: N/A

Type: Ewth.2 Size: 2.4 Electro-Flux(CLASS): N/A

P.W.H.T.(QW-406)

Heating Rate(°C/Hr) : Temp.(°C): N/A Time(Min): N/A Cooling Rate(°C/Hr) :

TECHNIQUE.(QW-410)

String(S) or Weave(W) BeadWeave Method of Back Gouging : N/A

Orifice Or Gas Cup Size: 12 mm Oscillation: N/A

Initial Cleaning: BRUSHING Pass Number Per Side: Multi Pass

Interpass Cleaning: BRUSHING Multiple or SingleElctrode: Single

ELECTRICAL CHARACTERISTICS(QW-409)

.

No FILLER METAL CURRENT(A)

IT

Y VOLTAGE(v) TRAVEL SPEED HEAT INPUT

SS AR

PA PROCESS φ(mm) L

CLASS PO Min Max Min Max Min (cm/min) Max KJ/cm(Max)

ROOT GTAW ER70S-6 2.4 DCEN 80 ~ 120 8 ~ 10 11 ~ 12 6.5

2 SMAW E7018-1 3.25 DCEP 100 ~ 130 21 ~ 23 10 ~ 15 17.9

3~N SMAW E7018-1 4 DCEP 140 ~ 180 22 ~ 24 15 ~ 25 17.3

Welding Sequence: ROOT (GTAW) & COMPLETE (SMAW)

note: GAS (QW-408)

Gas Mixture Flow(lit/min)

WEATHERING CONDITION:

1) All SURFACES SHALL BE CLEAN FROM MOISTUTE, RAIN, ICE, SNOW AND OTHER Shielding Gas (es) ARGON 99.9 14

POLUTIONS.

2) IN WINDY CONDITION, WELDING SHALL BE PROCEEDING ONLY IN SHILDED CONDITION. Trailing Gas (es) N/A N/A N/A

3) AT TIME OF RAIN/SNOW FALLING, WELDING IS PROHIBITTED.

4) WELDING OF BASE METAL WITH TEMPERATURE BELOW -18C IS PROHIBITED. Backing Gas (es) N/A N/A N/A

*Remove trace amount of moisture by mean of pre-heating. IMPACT TEST: Temp. -40°C Energy: 27J

HARDNESS (Max.) : 22 HRC

Prep'd: I.M. App.: H.GH.

21

6.5

17.9

17.3

#DIV/0!

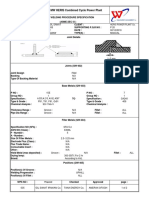

Welding procedure Specification Rev. 2

Qualificatin code: ASME Sec. IX

Project: SHAZAND ARAK REFINERY EXPANSION & UPGRADING

Client: NIOEC

WPS No. : G2-3/C Welding Process: SMAW

PQR No. : Type: MANUAL

Item : NOZZLE TO SHELL or BOTTOM PLAT (if applicable) Location: site or shop

JOINT(QW-402)

Joint Design : SINGLE or DOUBLE VEE GROOVE

Type of Joint BUTT or CORNER

Backing: N/A

Backing Material : N/A

NOZZLE TO SHELL

BOTTOM PLATE

POSITION(QW-405)

Pos. of Groove : all pos.

Welding Progress :up hill

BASE MATERIAL(QW-403) filler(QW-403)

1)Specification: SA283 Gr.C or SA516 Gr.60 or SA106 Gr.B Spec. No.(SFA): 5.1 , 5.18

P-No.: 1 Group No.: 1 AWS No.(Class): E6010 , E7018 -1

2)Specification: SA283 Gr.C or SA516 Gr.60 F-No.: 3,4

P-No.: 1 Group No.: 1 A-No.: 1

Thickness(m Groove: 4.8~30 Fillet: Trade Name: 1047P,11770F

preheat(QW-406) Manufacturer: AMA

Preheat Temp.(Min): 75°C (see note*) Baking Condition: as per label

Interpass Temp.(Max): 250°C Flux: N/A

Preheat Maintenance: N/A Baking Condition: N/A

tungesten electrode Manufacturer: N/A

Type: N/A Size: N/A Electro-Flux(CLASS): N/A

P.W.H.T.(QW-406)

Heating Rate(°C/Hr) : Temp.(°C): N/A Time(Min): N/A Cooling Rate(°C/Hr) :

TECHNIQUE.(QW-410)

String(S) or Weave(W) BeadWeave Method of Back Gouging : N/A

Orifice Or Gas Cup Size: N/A Oscillation: N/A

Initial Cleaning: BRUSHING Pass Number Per Side: Multi Pass

Interpass Cleaning: BRUSHING Multiple or SingleElctrode: Single

ELECTRICAL CHARACTERISTICS(QW-409)

.

No FILLER METAL CURRENT(A)

TY VOLTAGE(v) TRAVEL SPEED HEAT INPUT

SS RI

LA

PA PROCESS CLASS φ(mm) PO Min Max Min Max Min (cm/min) Max KJ/cm(Max)

1 SMAW E6010 3.25 DCEP 90 ~ 120 21 ~ 23 10 ~ 15 16.6

2~N SMAW E7018-1 4 DCEP 140 ~ 180 22 ~ 24 15 ~ 25 17.3

Welding Sequence: ROOT (SMAW) & COMPLETE (SMAW)

note: GAS (QW-408)

Gas Mixture Flow(lit/min)

WEATHERING CONDITION:

1) All SURFACES SHALL BE CLEAN FROM MOISTUTE, RAIN, ICE, SNOW AND OTHER Shielding Gas (es) N/A N/A N/A

POLUTIONS.

2) IN WINDY CONDITION, WELDING SHALL BE PROCEEDING ONLY IN SHILDED CONDITION. Trailing Gas (es) N/A N/A N/A

3) AT TIME OF RAIN/SNOW FALLING, WELDING IS PROHIBITTED.

4) WELDING OF BASE METAL WITH TEMPERATURE BELOW -18C IS PROHIBITED. Backing Gas (es) N/A N/A N/A

*Remove trace amount of moisture by mean of pre-heating. IMPACT TEST: Temp. -40°C Energy: 27J

HARDNESS (Max.) : 22 HRC

Prep'd: I.M. App.: H.GH.

22

16.6

17.3

#DIV/0!

Welding procedure Specification Rev. 2

Qualificatin code: ASME Sec. IX

Project: SHAZAND ARAK REFINERY EXPANSION & UPGRADING

Client: NIOEC

WPS No. : G2-4/C Welding Process: SMAW

PQR No. : Type: MANUAL

Item : NOZZLE TO SHELL Location: site or shop

JOINT(QW-402)

Joint Design : SINGLE or DOUBLE VEE GROOVE

Type of Joint BUTT or CORNER

Backing: YES

Backing Material : C.S.

back-gouge from

INSIDE

back-gouge from

INSIDE

E

m

ID

ro

S

gef

N

o

gu

I

a

bk

c-

SHELL TO SHELL

POSITION(QW-405)

NOZZLE TO SHELL

Pos. of Groove : all pos.

Welding Progress :up hill

BASE MATERIAL(QW-403) filler(QW-403)

1)Specification: SA283 Gr.C or SA516 Gr.60 or SA106 Gr.B Spec. No.(SFA): 5.1

P-No.: 1 Group No.: 1 AWS No.(Class): E7018 -1

2)Specification: SA283 Gr.C or SA516 Gr.60 F-No.: 4

P-No.: 1 Group No.: 1 A-No.: 1

Thickness(m Groove: 4.8~30 Fillet: Trade Name: 1177F

preheat(QW-406) Manufacturer: AMA

Preheat Temp.(Min): 75°C (see note*) Baking Condition: as per label

Interpass Temp.(Max): 250°C Flux: N/A

Preheat Maintenance: N/A Baking Condition: N/A

tungesten electrode Manufacturer: N/A

Type: N/A Size: N/A Electro-Flux(CLASS): N/A

P.W.H.T.(QW-406)

Heating Rate(°C/Hr) : Temp.(°C): N/A Time(Min): N/A Cooling Rate(°C/Hr) :

TECHNIQUE.(QW-410)

String(S) or Weave(W) BeadWeave Method of Back Gouging : N/A

Orifice Or Gas Cup Size: N/A Oscillation: N/A

Initial Cleaning: BRUSHING Pass Number Per Side: Multi Pass

Interpass Cleaning: BRUSHING Multiple or SingleElctrode: Single

ELECTRICAL CHARACTERISTICS(QW-409)

.

No FILLER METAL CURRENT(A)

TY VOLTAGE(v) TRAVEL SPEED HEAT INPUT

SS RI

LA

PA PROCESS CLASS φ(mm) PO Min Max Min Max Min (cm/min) Max KJ/cm(Max)

1 SMAW E7018-1 3.25 DCEP 100 ~ 130 21 ~ 23 10 ~ 15 17.9

2~N SMAW E7018-1 4 DCEP 140 180 22 24 15 ~ 25 17.3

OTHER-SIDE,GOUGING AND P.T. or ATTENTIVE V.T.

R-1 SMAW E7018-1 3.25 DCEP 100 ~ 130 21 ~ 23 10 ~ 15 17.9

2~N SMAW E7018-1 4 DCEP 140 ~ 180 22 ~ 24 15 ~ 25 17.3

Welding Sequence:OUTSIDE THE SHELL: ROOT & COMPLETE (SMAW),INSIDE:GOUGING,& CHECK FOR DELETING OF POLOUTION,COMPLETE(SMAW)

note: GAS (QW-408)

WEATHERING CONDITION:

Gas Mixture Flow(lit/min)

1) All SURFACES SHALL BE CLEAN FROM MOISTUTE, RAIN, ICE, SNOW AND OTHER Shielding Gas (es) N/A N/A N/A

POLUTIONS.

2) IN WINDY CONDITION, WELDING SHALL BE PROCEEDING ONLY IN SHILDED Trailing Gas (es) N/A N/A N/A

CONDITION.

3) AT TIME OF RAIN/SNOW FALLING, WELDING IS PROHIBITTED. Backing Gas (es) N/A N/A N/A

4) WELDING OF BASE METAL WITH TEMPERATURE BELOW -18C IS PROHIBITED .

* Remove trace amount of moisture by mean of pre-heating. IMPACT TEST: Temp. -40°C Energy: 27J

HARDNESS (Max.) : 22 HRC

Prep'd: I.M. App.: H.GH.

23

17.9

17.3

#DIV/0!

17.9

17.3

#DIV/0!

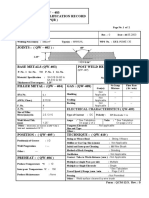

Welding procedure Specification Rev. 2

Qualificatin code: ASME Sec. IX

Project: SHAZAND ARAK REFINERY EXPANSION & UPGRADING

Client: NIOEC

WPS No. : G2-5/C Welding Process: SMAW

PQR No. : Type: MANUAL

Item : ALL FILLET TYPE Location: site or shop

JOINT(QW-402)

Joint Design : FILLET

Type of Joint FILLET or TEE

Backing: YES

Backing Material : BASE METAL SHELL TO BOTTOM / A NNULAR PLAT

FILLET TYPE

ROOF PLATE

POSITION(QW-405) BOTTOM PLATE

Pos. of Groove : all pos.

Welding Progress :up hill

BASE MATERIAL(QW-403) filler(QW-403)

1)Specification: SA283 Gr.C or SA516 Gr.60 or SA106 Gr.B Spec. No.(SFA): 5.1

P-No.: 1 Group No.: 1 AWS No.(Class): E7018-1

2)Specification: SA283 Gr.C or SA516 Gr.60 or SA105 F-No.: 4

P-No.: 1 Group No.: 1 or 2 A-No.: 1

Thickness(m Groove: 4.8~30 Fillet: Trade Name: 1177F

preheat(QW-406) Manufacturer: AMA

Preheat Temp.(Min): 75°C (see note*) Baking Condition: as per label

Interpass Temp.(Max): 250°C Flux: N/A

Preheat Maintenance: N/A Baking Condition: N/A

tungesten electrode Manufacturer: N/A

Type: N/A Size: N/A Electro-Flux(CLASS): N/A

P.W.H.T.(QW-406)

Heating Rate(°C/Hr) : Temp.(°C): N/A Time(Min): N/A Cooling Rate(°C/Hr) :

TECHNIQUE.(QW-410)

String(S) or Weave(W) BeadWeave Method of Back Gouging : N/A

Orifice Or Gas Cup Size: N/A Oscillation: N/A

Initial Cleaning: BRUSHING Pass Number Per Side: Multi Pass

Interpass Cleaning: BRUSHING Multiple or SingleElctrode: Single

ELECTRICAL CHARACTERISTICS(QW-409)

.

No FILLER METAL CURRENT(A)

TY VOLTAGE(v) TRAVEL SPEED HEAT INPUT

SS RI

A LA

P PROCESS CLASS φ(mm) PO Min Max Min Max Min (cm/min) Max KJ/cm(Max)

1 SMAW E7018-1 3.25 DCEP 100 ~ 130 21 ~ 23 10 ~ 15 17.9

2~N SMAW E7018-1 4 DCEP 140 180 22 24 15 ~ 25 17.3

Welding Sequence: FULL (SMAW)

note: GAS (QW-408)

WEATHERING CONDITION: Gas Mixture Flow(lit/min)

1) All SURFACES SHALL BE CLEAN FROM MOISTUTE, RAIN, ICE, SNOW AND OTHER POLUTIONS.

2) IN WINDY CONDITION, WELDING SHALL BE PROCEEDING ONLY IN SHILDED CONDITION. Shielding Gas (es) N/A N/A N/A

3) AT TIME OF RAIN/SNOW FALLING, WELDING IS PROHIBITTED.

Trailing Gas (es) N/A N/A N/A

4) WELDING OF BASE METAL WITH TEMPERATURE BELOW -18C IS PROHIBITED.

*Remove trace amount of moisture by mean of pre-heating. Backing Gas (es) N/A N/A N/A

IMPACT TEST: Temp. -40°C Energy: 27J

HARDNESS (Max.) : 22 HRC

Prep'd: I.M. App.: H.GH.

24

17.9

17.3

#DIV/0!

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobini100% (1)

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocument4 pagesWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Revised PWPS 001Document2 pagesRevised PWPS 001stdshopNo ratings yet

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- Welding Procedure Specification Pipe 6G PDFDocument3 pagesWelding Procedure Specification Pipe 6G PDFchepurthiNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Wps Ss r0 AdaniDocument2 pagesWps Ss r0 Adanigunasekhar kamireddiNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 pagesWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainNo ratings yet

- Procedure Qualification Record PQRDocument3 pagesProcedure Qualification Record PQRNMBaihakiAR100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- T-721 For MPTDocument1 pageT-721 For MPTLipika GayenNo ratings yet

- Table T-233.1 For RTDocument1 pageTable T-233.1 For RTLipika GayenNo ratings yet

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VDocument1 pageQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Document4 pagesAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Activity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilDocument1 pageActivity:: Work Permit No.: Date: Mechanical Chemical I&C Electrical CivilLipika GayenNo ratings yet

- Axial Flow For Industry 1Document9 pagesAxial Flow For Industry 1Lipika GayenNo ratings yet

- Field Inspection Report: Facsimile of Name PlateDocument2 pagesField Inspection Report: Facsimile of Name PlateLipika GayenNo ratings yet

- Tank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationDocument1 pageTank No: Bottom Sketch: Attached Sheet According Api 650 Note 5.3.3 Vacuum Pressure Glass Window Dimentions: Acceptance Creteria:No Leakage LocationLipika GayenNo ratings yet

- Joint No: Backing: Yes No Backing Mat: N/ADocument1 pageJoint No: Backing: Yes No Backing Mat: N/ALipika GayenNo ratings yet

- Test ConditionDocument1 pageTest ConditionLipika GayenNo ratings yet

- S.No. Hospital Code Hospital NameDocument20 pagesS.No. Hospital Code Hospital NameLipika GayenNo ratings yet

- Field Inspection Report: Dimension Check of Nozzle & ManholeDocument1 pageField Inspection Report: Dimension Check of Nozzle & ManholeLipika GayenNo ratings yet

- 4 6048613395123405697Document64 pages4 6048613395123405697Lipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- Weld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersDocument25 pagesWeld Neck Body Flange Design Calculation: HE-CGI, HE-CG, Spiral Wound Gaskets For Heat ExchangersLipika GayenNo ratings yet

- 5 6086791694424998681Document80 pages5 6086791694424998681Lipika GayenNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsLipika GayenNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenNo ratings yet