Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

34 viewsProduct Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Product Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Uploaded by

amila209This document outlines a 5-step product traceability analysis procedure for Multikem Industries:

1. Analyze product labels and batch numbers in 5 minutes to identify product code, type, manufacturing and expiry dates.

2. Trace storage process in 5 minutes using stock and finished goods transfer notes and loading checklists.

3. Perform quality assurance tests in 5 minutes to estimate batch quality and test parameters.

4. Trace production process in 20 minutes by analyzing raw materials, formulations, production reports and identifying machine operators.

5. Inspect raw materials in 10 minutes to analyze quality, identify suppliers and evaluate test specifications.

The total estimated time for traceability analysis is 45 minutes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- The Cosmic Order Form PDFDocument6 pagesThe Cosmic Order Form PDFamila209No ratings yet

- PalmisrDocument61 pagesPalmisrBineilKcThapaNo ratings yet

- PRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)Document1 pagePRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)ABI Alco QANo ratings yet

- QMS 010 Classification Definition and Approval Matrix of GMP Documents SampleDocument5 pagesQMS 010 Classification Definition and Approval Matrix of GMP Documents SampleRosella Planta100% (1)

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- Standards ManagementDocument3 pagesStandards ManagementGourav SainiNo ratings yet

- AGG-ST-052 Autokiniton Process Approval Sign-Off PPAPDocument19 pagesAGG-ST-052 Autokiniton Process Approval Sign-Off PPAPRamesh DenonNo ratings yet

- Qa003 15Document7 pagesQa003 15Sridhar NandipatiNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- 10 - 1 - QC Plan-Qp-Qc-04-CableDocument6 pages10 - 1 - QC Plan-Qp-Qc-04-CableMagician AMNo ratings yet

- Criticality Ranking Procedure - 7200 039 700 Rev 02Document4 pagesCriticality Ranking Procedure - 7200 039 700 Rev 02Firoz HussainNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- MIDC Buti Bori: Audit Observation SheetDocument1 pageMIDC Buti Bori: Audit Observation SheetAnkush ChourasiaNo ratings yet

- Att. 25 PPAP 21043035500Document9 pagesAtt. 25 PPAP 21043035500Crenguta RaducanuNo ratings yet

- Book 1Document13 pagesBook 1QA HyfreshNo ratings yet

- NAQPDocument9 pagesNAQProhitNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- ASQR09Document14 pagesASQR09Mani Rathinam RajamaniNo ratings yet

- Napino Auto & Electronics LTD.: Initial Production Part TagDocument2 pagesNapino Auto & Electronics LTD.: Initial Production Part TagSACHIN KUMARNo ratings yet

- SOP - EN - 01 Process ChangesDocument2 pagesSOP - EN - 01 Process ChangesHarits As SiddiqNo ratings yet

- Pfmea SopDocument9 pagesPfmea SopAbhijit DasNo ratings yet

- Detailed Requirement SheetDocument53 pagesDetailed Requirement SheetRohit QualityNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi Yadav0% (1)

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- PM-EMS-07 Monitoring & MeasurementDocument3 pagesPM-EMS-07 Monitoring & Measurementkarthiksri41No ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Indentification&Tracability ProcedureDocument3 pagesIndentification&Tracability ProcedureSaad ZiaNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- IAC-HC-HCPR23 Product TracebilityDocument4 pagesIAC-HC-HCPR23 Product TracebilityFaisal RehmanNo ratings yet

- APQPDocument3 pagesAPQPsam1hi5No ratings yet

- Notes Taken During 3 July APQP PPAP ClassDocument2 pagesNotes Taken During 3 July APQP PPAP Classrosemarie tolentinoNo ratings yet

- Incoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012Document3 pagesIncoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012JithuRajNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- Receiving Inspection Checklist Details & Sub-AssemblyDocument7 pagesReceiving Inspection Checklist Details & Sub-AssemblyMohamedNo ratings yet

- 0IATFACTIVITYDEPT23Document1 page0IATFACTIVITYDEPT23Dilshad AliNo ratings yet

- ExecutiveDocument1 pageExecutiveAnbuNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument25 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- P Gen 11Document4 pagesP Gen 11ubraghuNo ratings yet

- MANTU SLIDE KULIAH 2020 Modul-5Document17 pagesMANTU SLIDE KULIAH 2020 Modul-5Siska AprilianiNo ratings yet

- UCA-QMSP-21 Guideline For Accounting and Handling of Rework and RejectionDocument4 pagesUCA-QMSP-21 Guideline For Accounting and Handling of Rework and RejectionVijaya Kumar SNo ratings yet

- PR DV 04 (Facilities Planning & Deployment)Document3 pagesPR DV 04 (Facilities Planning & Deployment)Amit PathakNo ratings yet

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- QP-QA-01-Receiving InspectionDocument2 pagesQP-QA-01-Receiving InspectionDebkanta DasNo ratings yet

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- EEM Recap 20170623Document8 pagesEEM Recap 20170623teseoguerraNo ratings yet

- Materials MGMT and Inventory Control (MMIC) ProgramDocument8 pagesMaterials MGMT and Inventory Control (MMIC) ProgramNithyanandan NagappanNo ratings yet

- 03 LC of Semi Auto Cap Filling Machine 03Document2 pages03 LC of Semi Auto Cap Filling Machine 03Ravi YadavNo ratings yet

- Template Validation Plan For Equipment or ProcessDocument14 pagesTemplate Validation Plan For Equipment or Processkhilifi chaouki100% (1)

- How To Get 100 PP-MEETINGDocument1 pageHow To Get 100 PP-MEETINGAdil NaseerNo ratings yet

- SPTR Audit CSDocument3 pagesSPTR Audit CSRakesh SNo ratings yet

- Internal Audit ReportDocument1 pageInternal Audit ReportDinesh BabuNo ratings yet

- IPQA - QA: Turtle Diagram - Process: Dept.Document1 pageIPQA - QA: Turtle Diagram - Process: Dept.SMTT WORK OFFICIALNo ratings yet

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- 8b Procedure Inprocess QualityDocument2 pages8b Procedure Inprocess QualityniteshNo ratings yet

- (QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Document9 pages(QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Gourav SainiNo ratings yet

- Qp-I&t R05 - OkDocument5 pagesQp-I&t R05 - OkFatin NajehahNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- BL Step1Document1 pageBL Step1amila209No ratings yet

- Corujel JF&IDocument1 pageCorujel JF&Iamila209No ratings yet

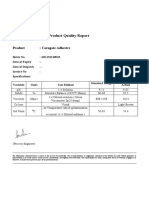

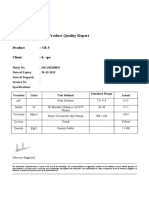

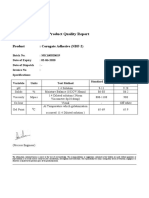

- Product Quality Report: Product: CR-5 Client: K-SpaDocument1 pageProduct Quality Report: Product: CR-5 Client: K-Spaamila209No ratings yet

- Product Quality Report: Product: CR-5 Client: K-SpaDocument1 pageProduct Quality Report: Product: CR-5 Client: K-Spaamila209No ratings yet

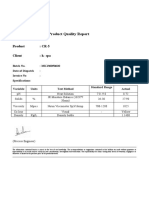

- Product Qualty Report RevisedDocument1 pageProduct Qualty Report Revisedamila209No ratings yet

- Product Quality Report: Product: Corugate Adhesive (NDF-2)Document1 pageProduct Quality Report: Product: Corugate Adhesive (NDF-2)amila209No ratings yet

- BL Step1 RevisedDocument1 pageBL Step1 Revisedamila209No ratings yet

- Multikem Industries (PVT) LimitedDocument1 pageMultikem Industries (PVT) Limitedamila209No ratings yet

- TDS MK CP-WP-02 - 2017Document1 pageTDS MK CP-WP-02 - 2017amila209No ratings yet

- Multikem Industries (PVT) Limited Quality System RecordsDocument3 pagesMultikem Industries (PVT) Limited Quality System Recordsamila209No ratings yet

- MK - Adhesive Used in - Corugate IndustryDocument2 pagesMK - Adhesive Used in - Corugate Industryamila209No ratings yet

- Multikem Industries (PVT) Limited: Product: CR 05 Client:Tunip Lanka (PVT) LTDDocument1 pageMultikem Industries (PVT) Limited: Product: CR 05 Client:Tunip Lanka (PVT) LTDamila209No ratings yet

- Polyvinyl Acetate SAG 10 Formalin Polyvinyl Acetate SAG 10 FormalinDocument4 pagesPolyvinyl Acetate SAG 10 Formalin Polyvinyl Acetate SAG 10 Formalinamila209No ratings yet

- Strength (32 %) Time-1 1/2 HR: Starch (Corn/ Tapioca)Document1 pageStrength (32 %) Time-1 1/2 HR: Starch (Corn/ Tapioca)amila209No ratings yet

- Melting Temperature ( 180 C) Time (45 Min)Document2 pagesMelting Temperature ( 180 C) Time (45 Min)amila209No ratings yet

- Asafoetida Oil: Safety Data SheetDocument15 pagesAsafoetida Oil: Safety Data SheetSaranya DeviNo ratings yet

- Viola DavisDocument1 pageViola DavisGiulia MarmoNo ratings yet

- Water Treatment ChemicalsDocument33 pagesWater Treatment ChemicalsMutasim Hasan MehranNo ratings yet

- Adsorption of Acetic Acid On Charcoal SurfaceDocument3 pagesAdsorption of Acetic Acid On Charcoal SurfaceFrankyFan90% (10)

- Annex 1 Case StudyDocument6 pagesAnnex 1 Case StudyJohn WeakNo ratings yet

- Importance of Psychology in Nursing PracticeDocument6 pagesImportance of Psychology in Nursing PracticeNan Nda Pradipta67% (3)

- 12 Chapter2Document48 pages12 Chapter2Arinta Purwi Suharti100% (1)

- 07017-0014-023-EN-03 - D20003 FAdC MaintenanceDocument13 pages07017-0014-023-EN-03 - D20003 FAdC Maintenancevishu4urNo ratings yet

- Application of Geochemical Methods in Geothermal ExplorationDocument12 pagesApplication of Geochemical Methods in Geothermal ExplorationJuan JoseNo ratings yet

- Activity Worksheet 2 T TestDocument1 pageActivity Worksheet 2 T TestKit Augustine TantoyNo ratings yet

- Brazing, Soldering and Adhesive Bonding - Chapter 32Document40 pagesBrazing, Soldering and Adhesive Bonding - Chapter 32xharpreetx100% (1)

- Electric EquipmentDocument111 pagesElectric EquipmentatertemizNo ratings yet

- Committee Opinion No 664 Refusal of Medically.45Document8 pagesCommittee Opinion No 664 Refusal of Medically.45w yNo ratings yet

- Cabo Brea Catering R 2Document4 pagesCabo Brea Catering R 2Abraham Vega SNo ratings yet

- SC Fact Sheet HP-Oxygen enDocument1 pageSC Fact Sheet HP-Oxygen enTaha OpedNo ratings yet

- Montesano Ness LacartarelacionalenterapiadeparejaDocument23 pagesMontesano Ness LacartarelacionalenterapiadeparejaEncuentros y DiálogosNo ratings yet

- WMF Main Catalog 2019Document96 pagesWMF Main Catalog 2019AntonNo ratings yet

- 7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Document12 pages7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Kiara Ticangan ArgelNo ratings yet

- Administrative Officer (The New India Assurance Co. LTD.) : Assignment - Comprehensive Job Analysis. Job TitleDocument3 pagesAdministrative Officer (The New India Assurance Co. LTD.) : Assignment - Comprehensive Job Analysis. Job TitleAishNo ratings yet

- Web The KAIZEN Handbook 2019 0604Document31 pagesWeb The KAIZEN Handbook 2019 0604MarcoNo ratings yet

- Antonin Artaud - Poetry Madness Self-LibreDocument216 pagesAntonin Artaud - Poetry Madness Self-LibreDouglas Hudson100% (5)

- Mombasa Oil Spill (440895)Document20 pagesMombasa Oil Spill (440895)Ibtisam AbudNo ratings yet

- Main Valve Block, DescriptionDocument13 pagesMain Valve Block, DescriptionWesley MonsaNo ratings yet

- Biology CH 7 Practice TestDocument6 pagesBiology CH 7 Practice Testvaleria100% (2)

- Laurel Dolan 90 Day Business Plan-20106Document5 pagesLaurel Dolan 90 Day Business Plan-20106Robert SweeneyNo ratings yet

- Blue CampaignDocument2 pagesBlue CampaignDavid IbanezNo ratings yet

- VitaminDocument32 pagesVitamingopal jhaNo ratings yet

- Banks On Second-Endorsed Checks Accept or Not?Document3 pagesBanks On Second-Endorsed Checks Accept or Not?Vanessa May GaNo ratings yet

Product Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Product Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Uploaded by

amila2090 ratings0% found this document useful (0 votes)

34 views2 pagesThis document outlines a 5-step product traceability analysis procedure for Multikem Industries:

1. Analyze product labels and batch numbers in 5 minutes to identify product code, type, manufacturing and expiry dates.

2. Trace storage process in 5 minutes using stock and finished goods transfer notes and loading checklists.

3. Perform quality assurance tests in 5 minutes to estimate batch quality and test parameters.

4. Trace production process in 20 minutes by analyzing raw materials, formulations, production reports and identifying machine operators.

5. Inspect raw materials in 10 minutes to analyze quality, identify suppliers and evaluate test specifications.

The total estimated time for traceability analysis is 45 minutes.

Original Description:

Please Review and enjoy

Original Title

MK Tracebility

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines a 5-step product traceability analysis procedure for Multikem Industries:

1. Analyze product labels and batch numbers in 5 minutes to identify product code, type, manufacturing and expiry dates.

2. Trace storage process in 5 minutes using stock and finished goods transfer notes and loading checklists.

3. Perform quality assurance tests in 5 minutes to estimate batch quality and test parameters.

4. Trace production process in 20 minutes by analyzing raw materials, formulations, production reports and identifying machine operators.

5. Inspect raw materials in 10 minutes to analyze quality, identify suppliers and evaluate test specifications.

The total estimated time for traceability analysis is 45 minutes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

34 views2 pagesProduct Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Product Traceability Analysis Procedure: Multikem Industries (PVT) Limited

Uploaded by

amila209This document outlines a 5-step product traceability analysis procedure for Multikem Industries:

1. Analyze product labels and batch numbers in 5 minutes to identify product code, type, manufacturing and expiry dates.

2. Trace storage process in 5 minutes using stock and finished goods transfer notes and loading checklists.

3. Perform quality assurance tests in 5 minutes to estimate batch quality and test parameters.

4. Trace production process in 20 minutes by analyzing raw materials, formulations, production reports and identifying machine operators.

5. Inspect raw materials in 10 minutes to analyze quality, identify suppliers and evaluate test specifications.

The total estimated time for traceability analysis is 45 minutes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

MULTIKEM INDUSTRIES (PVT) LIMITED

No 257, Grandpass Road, Colombo 14. Sri Lanka Tel:11-249998200

Fax: 112472628 Email: sales@multikem.edna.lk

Product Traceability Analysis Procedure

No Process Traceability criteria Estimated Reference & traceable Documents

Step Time

1. Product 1. Identifying 5 Min Working Instruction Production Process

label & Product code and (WI/MK/PR)

Batch No Product type

Analysis 2. Identifying

manufacturing

date

3. Identifying

Product Expiry

date

2. Storage Identifying Dispatch date 5 Min Stock Transfer Note- QF/MK/06

Process and batch quantity

Finished Goods Transfer Note -

QF/MK/08

Loading Check List -QF/MK/17

3. Quality Estimate Batch quality 5 Min Product quality Analysis- QF/MK/01

Assurance and test parameter of

final inspection Specifications for Adhesives-

REC/MK/04

4. Production 1. Recognizing Raw 20 Min Control Diagrams- MP - CD

Process material types and Manufacturing Processes -MP - PP

their batch no

Relevant to Material Requisition Not- QF/MK/02

particular lot Production Report -QR/MK/02

formulated

2. Recognizing Details Daily Production Plan -QF/MK/04

of Product Product Recipe Changes -

formulation and

QF/MK/12

material quantities

used Non-Conformity Report -

3. Estimation of the QR/MK/04

online test

parameter such as Process Verification- REC/MK/12

Processing time,

semi-finished test

parameter results,

Processing

temperature etc

4. Identifying Non

confirming activities

occurred

5. Identifying of

machine operators

and helpers

5. Raw 1. Estimate quality 10 Min Suppliers List - REC/MK/01

material parameters of Raw Material Analysis -

inspection raw material

2. Identifying QF/MK/10

supplier details Raw Material Check List -

and origin

3. Evaluation of test REC/MK/03

specification

given by supplier

Total Time Estimated for trace product 45 Min

You might also like

- The Cosmic Order Form PDFDocument6 pagesThe Cosmic Order Form PDFamila209No ratings yet

- PalmisrDocument61 pagesPalmisrBineilKcThapaNo ratings yet

- PRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)Document1 pagePRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)ABI Alco QANo ratings yet

- QMS 010 Classification Definition and Approval Matrix of GMP Documents SampleDocument5 pagesQMS 010 Classification Definition and Approval Matrix of GMP Documents SampleRosella Planta100% (1)

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Product Part Approval Process: Automotive Quality Management SystemDocument3 pagesProduct Part Approval Process: Automotive Quality Management SystemrajaNo ratings yet

- Standards ManagementDocument3 pagesStandards ManagementGourav SainiNo ratings yet

- AGG-ST-052 Autokiniton Process Approval Sign-Off PPAPDocument19 pagesAGG-ST-052 Autokiniton Process Approval Sign-Off PPAPRamesh DenonNo ratings yet

- Qa003 15Document7 pagesQa003 15Sridhar NandipatiNo ratings yet

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- 10 - 1 - QC Plan-Qp-Qc-04-CableDocument6 pages10 - 1 - QC Plan-Qp-Qc-04-CableMagician AMNo ratings yet

- Criticality Ranking Procedure - 7200 039 700 Rev 02Document4 pagesCriticality Ranking Procedure - 7200 039 700 Rev 02Firoz HussainNo ratings yet

- PUR-PM-06 Initial Flow Control For PCS SupplierDocument4 pagesPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarNo ratings yet

- MIDC Buti Bori: Audit Observation SheetDocument1 pageMIDC Buti Bori: Audit Observation SheetAnkush ChourasiaNo ratings yet

- Att. 25 PPAP 21043035500Document9 pagesAtt. 25 PPAP 21043035500Crenguta RaducanuNo ratings yet

- Book 1Document13 pagesBook 1QA HyfreshNo ratings yet

- NAQPDocument9 pagesNAQProhitNo ratings yet

- 25875-000-V1A-PS02-00004 - Rev.003-With ApprovalDocument11 pages25875-000-V1A-PS02-00004 - Rev.003-With ApprovalKarthikNo ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- ASQR09Document14 pagesASQR09Mani Rathinam RajamaniNo ratings yet

- Napino Auto & Electronics LTD.: Initial Production Part TagDocument2 pagesNapino Auto & Electronics LTD.: Initial Production Part TagSACHIN KUMARNo ratings yet

- SOP - EN - 01 Process ChangesDocument2 pagesSOP - EN - 01 Process ChangesHarits As SiddiqNo ratings yet

- Pfmea SopDocument9 pagesPfmea SopAbhijit DasNo ratings yet

- Detailed Requirement SheetDocument53 pagesDetailed Requirement SheetRohit QualityNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- Quality System Procedure For Change Point ControlDocument3 pagesQuality System Procedure For Change Point Controlrajesh sharmaNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- 02 LC of Double Cone Blender 02Document2 pages02 LC of Double Cone Blender 02Ravi Yadav0% (1)

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- PM-EMS-07 Monitoring & MeasurementDocument3 pagesPM-EMS-07 Monitoring & Measurementkarthiksri41No ratings yet

- MFG Process Audit ReportDocument1 pageMFG Process Audit ReportBASAVA ENGINEERINGNo ratings yet

- Indentification&Tracability ProcedureDocument3 pagesIndentification&Tracability ProcedureSaad ZiaNo ratings yet

- ASP-NPD-04 (Process of Product Safety)Document5 pagesASP-NPD-04 (Process of Product Safety)akash.vd.1603No ratings yet

- IAC-HC-HCPR23 Product TracebilityDocument4 pagesIAC-HC-HCPR23 Product TracebilityFaisal RehmanNo ratings yet

- APQPDocument3 pagesAPQPsam1hi5No ratings yet

- Notes Taken During 3 July APQP PPAP ClassDocument2 pagesNotes Taken During 3 July APQP PPAP Classrosemarie tolentinoNo ratings yet

- Incoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012Document3 pagesIncoming Inspection: QSP-QC-05 Rev.: 4 Date: 8/2/2012JithuRajNo ratings yet

- 01 LC Vibratory Sifter 01Document2 pages01 LC Vibratory Sifter 01Ravi YadavNo ratings yet

- Receiving Inspection Checklist Details & Sub-AssemblyDocument7 pagesReceiving Inspection Checklist Details & Sub-AssemblyMohamedNo ratings yet

- 0IATFACTIVITYDEPT23Document1 page0IATFACTIVITYDEPT23Dilshad AliNo ratings yet

- ExecutiveDocument1 pageExecutiveAnbuNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument25 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- P Gen 11Document4 pagesP Gen 11ubraghuNo ratings yet

- MANTU SLIDE KULIAH 2020 Modul-5Document17 pagesMANTU SLIDE KULIAH 2020 Modul-5Siska AprilianiNo ratings yet

- UCA-QMSP-21 Guideline For Accounting and Handling of Rework and RejectionDocument4 pagesUCA-QMSP-21 Guideline For Accounting and Handling of Rework and RejectionVijaya Kumar SNo ratings yet

- PR DV 04 (Facilities Planning & Deployment)Document3 pagesPR DV 04 (Facilities Planning & Deployment)Amit PathakNo ratings yet

- BMR PraperationDocument9 pagesBMR PraperationwondwossengNo ratings yet

- QP-QA-01-Receiving InspectionDocument2 pagesQP-QA-01-Receiving InspectionDebkanta DasNo ratings yet

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- EEM Recap 20170623Document8 pagesEEM Recap 20170623teseoguerraNo ratings yet

- Materials MGMT and Inventory Control (MMIC) ProgramDocument8 pagesMaterials MGMT and Inventory Control (MMIC) ProgramNithyanandan NagappanNo ratings yet

- 03 LC of Semi Auto Cap Filling Machine 03Document2 pages03 LC of Semi Auto Cap Filling Machine 03Ravi YadavNo ratings yet

- Template Validation Plan For Equipment or ProcessDocument14 pagesTemplate Validation Plan For Equipment or Processkhilifi chaouki100% (1)

- How To Get 100 PP-MEETINGDocument1 pageHow To Get 100 PP-MEETINGAdil NaseerNo ratings yet

- SPTR Audit CSDocument3 pagesSPTR Audit CSRakesh SNo ratings yet

- Internal Audit ReportDocument1 pageInternal Audit ReportDinesh BabuNo ratings yet

- IPQA - QA: Turtle Diagram - Process: Dept.Document1 pageIPQA - QA: Turtle Diagram - Process: Dept.SMTT WORK OFFICIALNo ratings yet

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- 8b Procedure Inprocess QualityDocument2 pages8b Procedure Inprocess QualityniteshNo ratings yet

- (QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Document9 pages(QSP-NPD-01) Process For Advanced Product Quality Planning (APQP)Gourav SainiNo ratings yet

- Qp-I&t R05 - OkDocument5 pagesQp-I&t R05 - OkFatin NajehahNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- Annual Product Quality Review (APQR) in Pharmaceutical ManufacturingFrom EverandAnnual Product Quality Review (APQR) in Pharmaceutical ManufacturingNo ratings yet

- BL Step1Document1 pageBL Step1amila209No ratings yet

- Corujel JF&IDocument1 pageCorujel JF&Iamila209No ratings yet

- Product Quality Report: Product: CR-5 Client: K-SpaDocument1 pageProduct Quality Report: Product: CR-5 Client: K-Spaamila209No ratings yet

- Product Quality Report: Product: CR-5 Client: K-SpaDocument1 pageProduct Quality Report: Product: CR-5 Client: K-Spaamila209No ratings yet

- Product Qualty Report RevisedDocument1 pageProduct Qualty Report Revisedamila209No ratings yet

- Product Quality Report: Product: Corugate Adhesive (NDF-2)Document1 pageProduct Quality Report: Product: Corugate Adhesive (NDF-2)amila209No ratings yet

- BL Step1 RevisedDocument1 pageBL Step1 Revisedamila209No ratings yet

- Multikem Industries (PVT) LimitedDocument1 pageMultikem Industries (PVT) Limitedamila209No ratings yet

- TDS MK CP-WP-02 - 2017Document1 pageTDS MK CP-WP-02 - 2017amila209No ratings yet

- Multikem Industries (PVT) Limited Quality System RecordsDocument3 pagesMultikem Industries (PVT) Limited Quality System Recordsamila209No ratings yet

- MK - Adhesive Used in - Corugate IndustryDocument2 pagesMK - Adhesive Used in - Corugate Industryamila209No ratings yet

- Multikem Industries (PVT) Limited: Product: CR 05 Client:Tunip Lanka (PVT) LTDDocument1 pageMultikem Industries (PVT) Limited: Product: CR 05 Client:Tunip Lanka (PVT) LTDamila209No ratings yet

- Polyvinyl Acetate SAG 10 Formalin Polyvinyl Acetate SAG 10 FormalinDocument4 pagesPolyvinyl Acetate SAG 10 Formalin Polyvinyl Acetate SAG 10 Formalinamila209No ratings yet

- Strength (32 %) Time-1 1/2 HR: Starch (Corn/ Tapioca)Document1 pageStrength (32 %) Time-1 1/2 HR: Starch (Corn/ Tapioca)amila209No ratings yet

- Melting Temperature ( 180 C) Time (45 Min)Document2 pagesMelting Temperature ( 180 C) Time (45 Min)amila209No ratings yet

- Asafoetida Oil: Safety Data SheetDocument15 pagesAsafoetida Oil: Safety Data SheetSaranya DeviNo ratings yet

- Viola DavisDocument1 pageViola DavisGiulia MarmoNo ratings yet

- Water Treatment ChemicalsDocument33 pagesWater Treatment ChemicalsMutasim Hasan MehranNo ratings yet

- Adsorption of Acetic Acid On Charcoal SurfaceDocument3 pagesAdsorption of Acetic Acid On Charcoal SurfaceFrankyFan90% (10)

- Annex 1 Case StudyDocument6 pagesAnnex 1 Case StudyJohn WeakNo ratings yet

- Importance of Psychology in Nursing PracticeDocument6 pagesImportance of Psychology in Nursing PracticeNan Nda Pradipta67% (3)

- 12 Chapter2Document48 pages12 Chapter2Arinta Purwi Suharti100% (1)

- 07017-0014-023-EN-03 - D20003 FAdC MaintenanceDocument13 pages07017-0014-023-EN-03 - D20003 FAdC Maintenancevishu4urNo ratings yet

- Application of Geochemical Methods in Geothermal ExplorationDocument12 pagesApplication of Geochemical Methods in Geothermal ExplorationJuan JoseNo ratings yet

- Activity Worksheet 2 T TestDocument1 pageActivity Worksheet 2 T TestKit Augustine TantoyNo ratings yet

- Brazing, Soldering and Adhesive Bonding - Chapter 32Document40 pagesBrazing, Soldering and Adhesive Bonding - Chapter 32xharpreetx100% (1)

- Electric EquipmentDocument111 pagesElectric EquipmentatertemizNo ratings yet

- Committee Opinion No 664 Refusal of Medically.45Document8 pagesCommittee Opinion No 664 Refusal of Medically.45w yNo ratings yet

- Cabo Brea Catering R 2Document4 pagesCabo Brea Catering R 2Abraham Vega SNo ratings yet

- SC Fact Sheet HP-Oxygen enDocument1 pageSC Fact Sheet HP-Oxygen enTaha OpedNo ratings yet

- Montesano Ness LacartarelacionalenterapiadeparejaDocument23 pagesMontesano Ness LacartarelacionalenterapiadeparejaEncuentros y DiálogosNo ratings yet

- WMF Main Catalog 2019Document96 pagesWMF Main Catalog 2019AntonNo ratings yet

- 7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Document12 pages7.0 Analysis 3: Case Study Concrete Over Pour On Decks Due To Steel Deflection (Structural Breath)Kiara Ticangan ArgelNo ratings yet

- Administrative Officer (The New India Assurance Co. LTD.) : Assignment - Comprehensive Job Analysis. Job TitleDocument3 pagesAdministrative Officer (The New India Assurance Co. LTD.) : Assignment - Comprehensive Job Analysis. Job TitleAishNo ratings yet

- Web The KAIZEN Handbook 2019 0604Document31 pagesWeb The KAIZEN Handbook 2019 0604MarcoNo ratings yet

- Antonin Artaud - Poetry Madness Self-LibreDocument216 pagesAntonin Artaud - Poetry Madness Self-LibreDouglas Hudson100% (5)

- Mombasa Oil Spill (440895)Document20 pagesMombasa Oil Spill (440895)Ibtisam AbudNo ratings yet

- Main Valve Block, DescriptionDocument13 pagesMain Valve Block, DescriptionWesley MonsaNo ratings yet

- Biology CH 7 Practice TestDocument6 pagesBiology CH 7 Practice Testvaleria100% (2)

- Laurel Dolan 90 Day Business Plan-20106Document5 pagesLaurel Dolan 90 Day Business Plan-20106Robert SweeneyNo ratings yet

- Blue CampaignDocument2 pagesBlue CampaignDavid IbanezNo ratings yet

- VitaminDocument32 pagesVitamingopal jhaNo ratings yet

- Banks On Second-Endorsed Checks Accept or Not?Document3 pagesBanks On Second-Endorsed Checks Accept or Not?Vanessa May GaNo ratings yet