Professional Documents

Culture Documents

4 OTG Chemical Cleaning of Plate Heat Exchangers Rev1

4 OTG Chemical Cleaning of Plate Heat Exchangers Rev1

Uploaded by

aliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 OTG Chemical Cleaning of Plate Heat Exchangers Rev1

4 OTG Chemical Cleaning of Plate Heat Exchangers Rev1

Uploaded by

aliCopyright:

Available Formats

www.oceanteam.

eu

I

03.2016 Rev 1

CASE:

Chemical Cleaning of Plate Heat Exchangers

- Effective cleaning took only 1 day of work

Ocean Team helps customers saving time Mussels blocked the system

and money by using chemical cleaning of At Asnæsværket the plate heat exchangers use seawater for

cooling of the process water used for the production.

plate heat exchangers instead of ordinary

mechanical cleaning methods. The low efficiency of the exchangers were found to be

At Asnæsværket DONG Energy A/S was challenged by low caused by extensive occurrence of mussels, snails and other

efficiency on two of their Alfa Laval plate heat exchangers. types of marine fouling, which had been brought into the

The temperature of the process water from the two exchang- system with the seawater and gradually plugged the seawa-

ers was 30 degrees. The normal temperature should prefer- ter side of the heat exchangers.

ably be between 25-28 degrees and should not exceed 28

degrees. Usual procedure used by Asnæsværket:

High pressure cleaning – Duration: 2-3 working days

This meant that DONG Energy was facing a challenge, which So far the ordinary procedure used by Asnæsværket for

should be solved as soon as possible in order to restore cleaning of plugged seawater heat exchangers has been high

normal production. pressure cleaning.

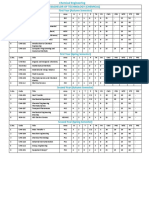

Picture 1 – The two Alfa Laval plate heat exchangers were Manual high pressure cleaning of heat exchangers

obviously strongly affected by mussels, snails and other includes the following procedures:

types of marine fouling. 1. Dismantling of the exchangers

2. Disassembling

3. High pressure cleaning

4. Assembling and sealing

5. Mounting in the process system

6. Tidying up and cleaning of the work area

This process usually takes 2-3 days for each heat exchanger

– a process which is repeated every second month for all the

exchangers at Asnæsværket.

BEFORE CLEANING AFTER CLEANING

Ocean Team Group A/S · otg@oceanteam.eu · www.oceanteam.eu

www.oceanteam.eu

I

03.2016 Rev 1

CASE:

Chemical Cleaning of Plate Heat Exchangers

- Effective cleaning took only 1 day of work

However, disassembling of the heat exchangers have on dismantled and disassembled during the cleaning process, as

several occasions caused problems for Asnæsværket as they are required when using mechanical cleaning methods. The

have experienced problems with making the exchangers tight heat exchangers are shut down in turns and cleaned on the

again after cleaning. This resulted in additional costs for new spot. In this way you avoid additional costs due to problems

gaskets and other kinds of repair. with tightness, cleaning and wear on the working area as

well as other unforeseen repair costs.

Ocean Team’s Solution:

Chemical cleaning – Duration: 1 working day

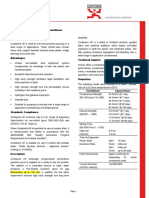

Ocean Team was able to offer Asnæsværket a considerably Picture 2 – Alfa Laval plate heat exchangers at Asnæsværket.

better and quicker solution. By means of chemistry it was

possible to carry out the cleaning in one working day only

for each exchanger. The result was a drop of temperature of

the process water from the high level at 30 degrees to the

normal level at 25 degrees.

The quicker cleaning meant that Asnæsværket could return

to normal production considerably sooner and therefore con-

sequently minimize loss of production.

Apart from the shorter duration chemical cleaning also brings

the advantage, that the heat exchangers should not be

High pressure cleaning carried out by staff from Chemical cleaning carried out by Ocean Team

Asnæsværket + Duration of cleaning: 1 working day for each

÷ Duration of cleaning: 2-3 working days each heat exchanger.

exchanger. + Efficient cleaning – the temperature of the process

÷ The heat exchangers need to be dismantled and water fell from 30 to the normal 25 degrees as a

disassembled. consequence of the chemical cleaning.

÷ After disassembly it can be difficult to make the + The exchangers need not to be disassembled or

exchangers tight again after cleaning, which results dismantled. They are shut down in turns and

in additional costs for new gaskets and other kinds chemically cleaned on the spot which save time as

of repair. well as money compared to mechanical cleaning

÷ The mechanical cleaning requires much space. methods.

High pressure cleaning of coolers for mussels and + No problems with leakages after cleaning and

snails makes a mess; and it takes time to tidy up consequently no additional costs for new gaskets

and clean the working area – this kind of cleaning and other repairs in this connection.

wears down the room as well. + No mess in the working area and consequently no extra

time and costs required for tidying up and cleaning the

working area, which is not subject to wear neither.

= Saving 2-4 working days – as a consequence of quicker cleaning

= Efficient cleaning – the temperature of the process water fell from high 30 degrees to 25 degrees.

= Minimizing loss of production – The first heat exchanger was back in full operation after only 1 day.

= No additional costs – for sealing troubles, cleaning of and wear on the working area.

Ocean Team Group A/S · otg@oceanteam.eu · www.oceanteam.eu

You might also like

- Convection Coils CleaningDocument5 pagesConvection Coils CleaningFaizan AhmedNo ratings yet

- 3.treatment of Toluene Using Wet Scrubber With Sodium Hypochrolite Oxidation ReactionDocument4 pages3.treatment of Toluene Using Wet Scrubber With Sodium Hypochrolite Oxidation ReactionMehul DesaiNo ratings yet

- Maximising Heat Exchanger CleaningDocument4 pagesMaximising Heat Exchanger CleaningAlexNo ratings yet

- MSDS-CSP e - 2131 Roswan QD HBDocument5 pagesMSDS-CSP e - 2131 Roswan QD HBAnkit VyasNo ratings yet

- Cleaning Technology For Heat Exchangers PDFDocument9 pagesCleaning Technology For Heat Exchangers PDFsopian320No ratings yet

- Boiler Cleaning+Procedure+Rev+00Document10 pagesBoiler Cleaning+Procedure+Rev+00Govarthanan Gopalan100% (1)

- Corrosion Inhibitors For Reinforced ConcreteDocument25 pagesCorrosion Inhibitors For Reinforced ConcreteVENKATESHNo ratings yet

- Makalah Convection Section Cleaning 4Document7 pagesMakalah Convection Section Cleaning 4akjayaNo ratings yet

- Maintenance of Distillation Column in An Refinery: By: Asmita Mishra Btech, Chemical Engg Igit SarangDocument24 pagesMaintenance of Distillation Column in An Refinery: By: Asmita Mishra Btech, Chemical Engg Igit SarangJohn RajNo ratings yet

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- Cleaning Plate Heat Exchangers PDFDocument2 pagesCleaning Plate Heat Exchangers PDFukalNo ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionspediNo ratings yet

- Convection Section CleaningDocument10 pagesConvection Section CleaningSuresh RamakrishnanNo ratings yet

- Tank Cleaning Robotic ServicesDocument2 pagesTank Cleaning Robotic ServicesgmitsutaNo ratings yet

- Leak Testing MethodologiesDocument9 pagesLeak Testing MethodologiesElena-Cristina IonitaNo ratings yet

- Rotary Joint Reliability-2014Document24 pagesRotary Joint Reliability-2014Edgar Cordova HerreraNo ratings yet

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- HYDROMILLINGDocument24 pagesHYDROMILLINGJose Omar RodriguezNo ratings yet

- Pollution Control in Oil, Gas and Chemical PlantsDocument15 pagesPollution Control in Oil, Gas and Chemical PlantsPRAFULKUMAR PARMARNo ratings yet

- Catalyst Loading MethodDocument3 pagesCatalyst Loading Methoderwan_exe0% (1)

- Heleium Leak TestDocument20 pagesHeleium Leak TestAkbar Doha100% (1)

- AB-507 Installed Fired Heaters GuidelineDocument36 pagesAB-507 Installed Fired Heaters GuidelineRosa galindo100% (1)

- Industrial Chemical Cleaning MethodsDocument29 pagesIndustrial Chemical Cleaning MethodsTEZ ANALYSIS AND STORIESNo ratings yet

- Flame Arrester Installation and Maintenance Instructions ForDocument3 pagesFlame Arrester Installation and Maintenance Instructions Forhk168No ratings yet

- Passivation of SS Closed SystemDocument9 pagesPassivation of SS Closed SystemSin PoulNo ratings yet

- Heat Exchanger Student HandoutDocument39 pagesHeat Exchanger Student HandoutkotiNo ratings yet

- Catalyst Loading by Dense Method Multi Bed Reactor Inert AtmosphereDocument7 pagesCatalyst Loading by Dense Method Multi Bed Reactor Inert Atmospherevishal bailur100% (1)

- Feroxyle Test Procedur eDocument9 pagesFeroxyle Test Procedur esanrexiNo ratings yet

- 20120502-47 De-Oiling Removal of Flammable Liquids From PipelinesDocument2 pages20120502-47 De-Oiling Removal of Flammable Liquids From Pipelinesnice guyNo ratings yet

- HPCL Material Preservation GuidelinesDocument7 pagesHPCL Material Preservation GuidelinespaimpillyNo ratings yet

- De Scaling Plate Heat ExchangersDocument2 pagesDe Scaling Plate Heat ExchangersKiran DuggarajuNo ratings yet

- Pressure Testing of Pressure VesselDocument3 pagesPressure Testing of Pressure VesselAriq FauzanNo ratings yet

- Guide For Insepction For Installed Fired HeatersDocument35 pagesGuide For Insepction For Installed Fired HeatersColoLatino100% (7)

- Tube Roller ExpansionDocument12 pagesTube Roller ExpansionTejaswiNo ratings yet

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailNo ratings yet

- Spiral Heat Exchanger: By: Anizah AliDocument8 pagesSpiral Heat Exchanger: By: Anizah AliZain Ul AbideenNo ratings yet

- Steam Trap InspectionDocument8 pagesSteam Trap InspectionMurrali Raj JeyagapalNo ratings yet

- Chemical Cleaning of Oil Refinery Heat ExchangersDocument3 pagesChemical Cleaning of Oil Refinery Heat ExchangersAbdul JabbarNo ratings yet

- Boiler Hydrostatic TestingDocument2 pagesBoiler Hydrostatic Testingbonginkosi mathunjwaNo ratings yet

- Chemical CleaningDocument10 pagesChemical CleaningAhmed Khamees ShatlaNo ratings yet

- Column PresentationDocument27 pagesColumn PresentationTaifurNo ratings yet

- CESCO Company Profile 2019Document23 pagesCESCO Company Profile 2019Cheong BianeeNo ratings yet

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- HEATEXDocument34 pagesHEATEXSiddharthNo ratings yet

- Condenser and Heat Exchanger Tube RestorationDocument6 pagesCondenser and Heat Exchanger Tube RestorationspalaniyandiNo ratings yet

- Refractory Dryout by Electrical Coil Heating 2Document1 pageRefractory Dryout by Electrical Coil Heating 2choksNo ratings yet

- 14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFDocument11 pages14.052 Rev. 0 - 9PE122 & 9PE123 - ECOPETROL - Cleaning Supervision, Inspection & Repair PDFVladimir Rodriguez LeonNo ratings yet

- Cortec ProductDocument20 pagesCortec ProductLiu YangtzeNo ratings yet

- Reformer RepairDocument11 pagesReformer RepairNishant Kumar ThakurNo ratings yet

- Sa04c2-Ms-Met-Aag-00012 - MS - Pickling & PassivationDocument7 pagesSa04c2-Ms-Met-Aag-00012 - MS - Pickling & PassivationABAID ULLAHNo ratings yet

- 34 (Distillation Column Info Tray - Bro) PDFDocument16 pages34 (Distillation Column Info Tray - Bro) PDFManish542No ratings yet

- Saes 0001 Chemical Cleaning of BoilersDocument56 pagesSaes 0001 Chemical Cleaning of Boilersqazi12No ratings yet

- Cleaning of Heat ExchangersDocument22 pagesCleaning of Heat ExchangersFareed Alam0% (1)

- 1113 Maintenance of PRVDocument63 pages1113 Maintenance of PRVhardito sussatrioNo ratings yet

- Howto-Recommended Guidelines For Testing of Heat ExchangersDocument1 pageHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_No ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- Corrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesFrom EverandCorrosion and Materials Selection: A Guide for the Chemical and Petroleum IndustriesNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Heat Exchanger: E-3711: Connections Tube Side Shell SideDocument1 pageHeat Exchanger: E-3711: Connections Tube Side Shell SidealiNo ratings yet

- Lightends FoulingDocument2 pagesLightends FoulingaliNo ratings yet

- Heat Exchanger Fouling and Cleaning Fundamentals and ApplicationsDocument9 pagesHeat Exchanger Fouling and Cleaning Fundamentals and ApplicationsaliNo ratings yet

- 4A PresentationDocument19 pages4A PresentationaliNo ratings yet

- Feed Saturator PaperDocument21 pagesFeed Saturator PaperaliNo ratings yet

- Metode de Crestere A SturionilorDocument93 pagesMetode de Crestere A SturionilorMihaila BogdanNo ratings yet

- VDOT Drainage Manual 7-I Chapter 7 - Ditches & ChannelsDocument117 pagesVDOT Drainage Manual 7-I Chapter 7 - Ditches & ChannelsisvicmonNo ratings yet

- Fossil ParksDocument17 pagesFossil ParksSumedha AgarwalNo ratings yet

- BQ MepDocument55 pagesBQ MepKai MatariNo ratings yet

- IIT Roorkee Programme Structure CHeDocument4 pagesIIT Roorkee Programme Structure CHeabcNo ratings yet

- 2-03 - Experiences in Soft Ground Tunnnelling in BangkokDocument11 pages2-03 - Experiences in Soft Ground Tunnnelling in BangkoksonNo ratings yet

- Mankenberg Vacuum ValveDocument10 pagesMankenberg Vacuum ValveAnibal QuezadaNo ratings yet

- Cities, Settlements and Key Infrastructure: This Chapter Should Be Cited AsDocument134 pagesCities, Settlements and Key Infrastructure: This Chapter Should Be Cited AsIgor Francisco Silva GonzalezNo ratings yet

- Datasheet File Conbextra - HFDocument4 pagesDatasheet File Conbextra - HFandikaNo ratings yet

- Health in MapehDocument11 pagesHealth in MapehMary Rose Odtuhan ConejosNo ratings yet

- DIY Worm FarmDocument2 pagesDIY Worm FarmAloysius Dooty Doot SkulltrumpetNo ratings yet

- External AssessmentDocument11 pagesExternal AssessmentEuropez AlaskhaNo ratings yet

- Case Study Infinity BenchmarkDocument27 pagesCase Study Infinity Benchmarkrahulkirtaniya757No ratings yet

- Hy-Pro Gearbox Filtration OverviewDocument4 pagesHy-Pro Gearbox Filtration OverviewlubangjarumNo ratings yet

- IS 670 HS Part.a PDFDocument16 pagesIS 670 HS Part.a PDFMohamed NouzerNo ratings yet

- Pnacs707 2Document173 pagesPnacs707 2mohamed elshemyNo ratings yet

- Earth ScienceDocument41 pagesEarth ScienceOmar EssamNo ratings yet

- Manish (Green Building)Document22 pagesManish (Green Building)Manish kumarNo ratings yet

- Arshad 2017Document17 pagesArshad 2017Arshad AliNo ratings yet

- 02 Aust CE 333 Lecture2 Pit Latrine Options, DesignDocument35 pages02 Aust CE 333 Lecture2 Pit Latrine Options, DesignTanjim IrtizaNo ratings yet

- Evolution of HousingDocument5 pagesEvolution of HousingTejaswini MalajiNo ratings yet

- Fracking PosterDocument1 pageFracking PosterCecil MarianiNo ratings yet

- Instruction Manual For FWGDocument45 pagesInstruction Manual For FWGTotoyNo ratings yet

- Scour Depth & Stone Apron SizingDocument18 pagesScour Depth & Stone Apron SizingguildkeyNo ratings yet

- Sor Bridge 2013Document81 pagesSor Bridge 2013తేజ చొల్లంగిNo ratings yet

- Mid Term Exam March 2021 (CE321)Document1 pageMid Term Exam March 2021 (CE321)Khushi SrivastavNo ratings yet

- Advanced Soil MechDocument199 pagesAdvanced Soil Mechmusiomi2005No ratings yet

- Swas Sample CoolerDocument4 pagesSwas Sample CoolerBhargav ChaudhariNo ratings yet