Professional Documents

Culture Documents

3Ph Vert Sep 2010 Weir VerA FPS PDF

3Ph Vert Sep 2010 Weir VerA FPS PDF

Uploaded by

haiderCopyright:

Available Formats

You might also like

- Heater Treater CalculationDocument12 pagesHeater Treater Calculationwahyu100% (1)

- Master - Three Phase Horizontal Separator Rev 0Document6 pagesMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNo ratings yet

- Horizontal Three Phase Separator vap-IPDocument5 pagesHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrNo ratings yet

- 2 Phase Flow Pressure Drop Calc Suresh1Document6 pages2 Phase Flow Pressure Drop Calc Suresh1NKNo ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- MCQ CollectionDocument614 pagesMCQ Collectionanil kumar0% (1)

- 1.pipeline Risk Assessment Definitive Approach and Its Role in Risk ManagementDocument17 pages1.pipeline Risk Assessment Definitive Approach and Its Role in Risk Managementhendry_hdw100% (1)

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- Separator DesignDocument4 pagesSeparator DesignTech ManagerNo ratings yet

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Control Valve Thumb Rule CalculationDocument82 pagesControl Valve Thumb Rule CalculationShubham AgarwalNo ratings yet

- Control Valve Sizing PDFDocument5 pagesControl Valve Sizing PDFsivaNo ratings yet

- G01 20 VD 101 (Sizing Sheet) 3 PhaseDocument6 pagesG01 20 VD 101 (Sizing Sheet) 3 PhaseWickyNo ratings yet

- Line Sizing LiqDocument12 pagesLine Sizing LiqDana GuerreroNo ratings yet

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design Separatorssemarasik_651536604No ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- D-1309 Sizing Calc Sht1Document1 pageD-1309 Sizing Calc Sht1NKNo ratings yet

- Tank Pressure & Vacuum ProtectionDocument4 pagesTank Pressure & Vacuum ProtectionrodrigoperezsimoneNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Separator (1) Sizing Spread SheetsDocument21 pagesSeparator (1) Sizing Spread SheetsSteve WanNo ratings yet

- Gas-Liquid Line SizingDocument1 pageGas-Liquid Line Sizingagusnnn100% (2)

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNo ratings yet

- Separator Sizing SheetDocument8 pagesSeparator Sizing SheetCahyoNo ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Document3 pagesPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweNo ratings yet

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- V-710 CPRP-7Document22 pagesV-710 CPRP-7balajikrishnanNo ratings yet

- Line Sizing - 2PHASEDocument11 pagesLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (2)

- BN-EG-UE109 Guide For Vessel SizingDocument29 pagesBN-EG-UE109 Guide For Vessel SizingSachin ChavanNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDocument15 pages2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNo ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDocument1 pageSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNo ratings yet

- Control Valve Sizing - Gas Rev 2aDocument2 pagesControl Valve Sizing - Gas Rev 2aMahmoud ShaheenNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwNo ratings yet

- Blowdown Calculation Inventory - Subsea FlowlineDocument13 pagesBlowdown Calculation Inventory - Subsea FlowlineNK0% (1)

- Calculation Title: Seagas Pipeline Design - MinervaDocument1 pageCalculation Title: Seagas Pipeline Design - Minerva秦东旺No ratings yet

- Horizontal 3 Phase Separator With Boot SizingDocument16 pagesHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Seperator Sizing v3Document5 pagesSeperator Sizing v3camasa2011No ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 pagesExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- Pemex BA-1071 F. 27898 Bombas Pozo Profundo Tapachula, ChiapasDocument3 pagesPemex BA-1071 F. 27898 Bombas Pozo Profundo Tapachula, ChiapasMarti H JNo ratings yet

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Document2 pagesWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariNo ratings yet

- 3 Phase SizingDocument2 pages3 Phase Sizingc_nghiaNo ratings yet

- Process Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Document15 pagesProcess Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Silas OnyekweNo ratings yet

- Liquid Hold Up Change and Slug Catcher SizingDocument2 pagesLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Sizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)Document14 pagesSizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)JOSE MARTIN MORA RIVEROSNo ratings yet

- Liquid Orifice SizingDocument8 pagesLiquid Orifice SizingrmaganNo ratings yet

- 2 Phase Separator Sizing: Vertical Horizontal OrientationDocument2 pages2 Phase Separator Sizing: Vertical Horizontal Orientationmohideenaliyarjafeer.shanawazNo ratings yet

- Vertical Vessel Adequacy CheckDocument15 pagesVertical Vessel Adequacy CheckTifano KhristiyantoNo ratings yet

- Hojas de Datos Ejercicio ExtraDocument1 pageHojas de Datos Ejercicio ExtraJohnny Ramos DíazNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Design Planning Records Center of The Future 2004-10Document29 pagesDesign Planning Records Center of The Future 2004-10Talam KeladiNo ratings yet

- PGG-EG Governor ActuatorDocument4 pagesPGG-EG Governor Actuatorrodruren010% (1)

- Ironmaking and Steelmaking Theory and PracticeDocument494 pagesIronmaking and Steelmaking Theory and PracticeDrKinnor Chattopadhyay100% (12)

- Research Paper On Building MaterialsDocument7 pagesResearch Paper On Building Materialsafnknlsjcpanrs100% (1)

- Wood Catalog Ver1Document9 pagesWood Catalog Ver1Achmad DimyatiNo ratings yet

- 2003-UFC 3-450-01 - Noise and Vibration ControlDocument152 pages2003-UFC 3-450-01 - Noise and Vibration ControlAndres PalacioNo ratings yet

- Nist Privacy FrameworkDocument43 pagesNist Privacy FrameworkE.G100% (1)

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Topic 6 Fields and Forces and Topic 9 Motion in FieldsDocument30 pagesTopic 6 Fields and Forces and Topic 9 Motion in Fieldsgloria11111No ratings yet

- Failures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityDocument2 pagesFailures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityRajesh KhadkaNo ratings yet

- Manual Conefor 26Document19 pagesManual Conefor 26J. Francisco Lavado ContadorNo ratings yet

- ENMED301055EN - Flite 210 - 042013Document2 pagesENMED301055EN - Flite 210 - 042013Tirthankar DattaNo ratings yet

- WATER FILL UP Procedure - Rev.01Document6 pagesWATER FILL UP Procedure - Rev.01shivanshsovNo ratings yet

- L136T/Tl Marine EngineDocument2 pagesL136T/Tl Marine EngineAhmet GelişliNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- Ekg 6Document2 pagesEkg 6RachitNo ratings yet

- SDI Kit ManualDocument2 pagesSDI Kit ManualMubarak AhmadNo ratings yet

- FCS-8005 User ManualDocument11 pagesFCS-8005 User ManualGustavo EitzenNo ratings yet

- Arson Invest 2Document100 pagesArson Invest 2Harrison sajorNo ratings yet

- Subtopic 6.5-6.7 FORM 4 KSSM 2020Document32 pagesSubtopic 6.5-6.7 FORM 4 KSSM 2020NurulNo ratings yet

- Batch Short Circuit Users ManualDocument64 pagesBatch Short Circuit Users ManualAshleyNo ratings yet

- 2021 May Intake Advert Revised 4Document2 pages2021 May Intake Advert Revised 4douglas0% (1)

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- Pipe Size CalculationDocument42 pagesPipe Size CalculationfelipeNo ratings yet

- 6016 ManualDocument9 pages6016 ManualDoceigenNo ratings yet

- Motion Control With LabviewDocument30 pagesMotion Control With Labviewsocat120013485No ratings yet

- L & T Catalogue 11Document3 pagesL & T Catalogue 11amulya00428No ratings yet

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet

3Ph Vert Sep 2010 Weir VerA FPS PDF

3Ph Vert Sep 2010 Weir VerA FPS PDF

Uploaded by

haiderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3Ph Vert Sep 2010 Weir VerA FPS PDF

3Ph Vert Sep 2010 Weir VerA FPS PDF

Uploaded by

haiderCopyright:

Available Formats

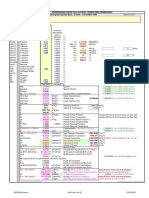

Client: E3 OGPE Datasheet No:

Project: E3 Field Development Rev : A Date: 20-Oct-10

Plant: Gas - Liquid Inlet Separation By: K Chk'd: App'd:

Unit: Inlet Item No: 5V - 100

Service:Production Separator Location:

1 Units FPS Separator Type Vertical Number Required: 1

2 Internals 1 0

3 Feed Inlet Vane/Others Vapour Outlet Mesh Pad Liquid Separation Weir 3 1

4 2 1

5 Process Design Conditions

6 Inlet Pressure psia = 130 * Inlet Temperature °F = 100.0

7 Pressure Drop Allowed psi = * Pressure Drop Calculated psi =

8 Operating & Design Cases Case 1 Case 2 Case 3 Design

9 Vapour Nat Gas Nat Gas

10 Flow Rate MMSCFD = 75.0

11 Flow Rate lb/h = 186,160

12 Flow Surge Factor % = 0%

13 Density lb/ft³ = 0.490

14 Viscosity cP = 0.012

15 Light Liquid = Oil Oil

16 Flow Rate BFPD = 1,000

17 Flow Rate lb/h = 13,158

18 Flow Surge Factor % = 0%

19 Density lb/ft³ = 56.20

20 Viscosity cP = 2

21 Heavy Liquid = Water Water

22 Flow Rate BFPD = 500

23 Flow Rate lb/h = 7,352

24 Flow Surge Factor % = 0%

25 Density lb/ft³ = 62.8

26 Viscosity cP = 1.1

27

28 Contaminants/ Solids Wellmud Sand Proppant Coke Specify

29 Short term operating requirements

30

31 Design Considerations

32 Default

33 Allowable Droplet Size µ = 200 300

34 In horizontal separator, maximum vapour velocity / min area is calculated at LAHH

35 Liquid Residence Time at NLL min = 3

36 Liquid Control Time between LAL and LAH min = 5

37 Liquid Slug Hold up (NLL to LAHH) Water + Oil Sides ft³ = +

38 Inflow Slug duration - all liquid flow at total volume flow rate sec = 2

39 Operator Response Time Reqd between Alarm & Trip min = 1 0.5

40 LALL to consider: outlet SDV closing time Outlet siphon effect

41

42 Nozzle sizing: Inlet Device: Vane Distributor ρmVm² lb/ft.s² = 4,032

43 Vapour Outlet ρgVg² lb/ft.s² = 2,688

44 Horizontal Separator: Inlet Nozzle Top Outlet Nozzle: Top

45

46 Design Notes

47

48

49

50

51

52

53

Client: E3 OGPE Datasheet No:

Project: E3 Field Development Rev : A Date: 20-Oct-10

Plant: Gas - Liquid Inlet Separation By: K Chk'd: App'd:

Unit: Inlet Item No: 5V - 100

Service:Production Separator Location:

1 Vessel Design Conditions

2 Design Pressure psig = Design Temp °F =

3 Vacuum Criteria Min Design Metal Temp °F =

4 Limitations Plot Limitations

5 Shell Diameter, OD/ID ft = 7.0 Length (Tan-Tan) ft = 16.0

6 Design Code = Corrosion Allowance in =

7 Wall thickness = Hydrostatic Test Pressure psig =

8 Material of Construction Shell =

9 Vane Distributor Mesh Pad =

10 Sandjet Nozzles = Coalescer/Calming Baffle =

11

12 External Insulation None Heat Conservation Personnel Protection Fire Protection 1

13 Insulation Thick in = Type/ Material =

14 Anchor = Type/ Material =

15 Post Weld Heat Treatment Yes/ No % Welds fully radiographed

16 Painting Requirements

17 Heating Coil

18 Sand Wash Facility No and Size of Nozzles

19 Water demand = Effluent sand + water flow =

20 Mesh pad/Internal cleaning solvent injection nozzles?

21 Vessel Nozzles

22

23 Mark No Service Dia, in Flange Remarks

24 Inlets & Outlets Minimum Elevation of Bottom of Vessel

25 N1 1 Feed 16 Inlet: No valve or expansion/contraction within 10d

26 N2 1 Vapour Outlet 16 Vapour Outlet: Reducer if any should be 2d away.

27 N3 1 Liquid Outlet 2 Liquid Outlet: SDV if any should at min distance.

28 N4 1 Liquid Outlet 2

29 N5 1 Vent 2 Suggested Levels

30 N6 1 Drain 3 Oil Water

31 N7 1 Relief Valve Level in in

32 N8 1 Utility Connection 2 LAHH 68.0 60.0

33 N9 LAH 24.0 24.0

34 NLL 18.0 18.0

35 Instrumentation LAL 14.0 14.0

36 K1 PG LALL 10.0 10.0

37 K2 TG

38 K3A/B LT

39 K4A/B Not used

40 K5A/B LG

41 K6A/B Not used

42 K7A/B Not used

43 K8A/B LAHH

44 K9A/B LALL

45 K10A/B Not used

46 K10A/B Not used

47

48

49 Manholes

50 M1 1 18

51 H1

52

53

Client: E3 OGPE Calculation No:

Project: E3 Field Development Rev : A Date: 20 Aug 2010

Service:Production Separator 5V - 100 By: K Chk'd: App'd:

Vertical Mesh Pad Weir Type 3 Phase Separator

Vapour & Liquid Flow Rates Vapour Light Liq Heavy Liq Total

Mass Flow Rate lb/s = 51.7 3.7 2.0 57.4

Volume Flow Rate ft³/s = 105.5 0.07 0.03 105.6

Mixture Density lb/ft³ = 0.54

Nozzle Sizing

Number Diameter, in Velocity Criteria

Location off Min Select ID ft/s Parameter Calcul Allowed Remarks

Feed Inlet 1 15 16 1.25 86.08 ρmVm² 4,027 4,032 OK

Vapour Outlet 1 16 16 1.25 86.00 ρgVg² 3,624 2,688 High

Water Outlet 1 1 2 0.16 1.59 Vliquid ft/s 1.6 3.3 OK

Oil Outlet 1 2 2 0.16 3.17 Vliquid ft/s 3.2 3.3 OK

Size, in No Size, in No Size, in No

Miscellaneous Vent 2 1 Manholes 18 1 Utility 2 1

Drain 3 1 Hand holes add check valve on utility nozzle

Vapour Separation

Allowable Droplet Size µ = 200.0 0.001 ft

CRe² = 5,088

Log CRe² = 3.7

C = 1.28

Vt, Liquid droplet free settling velocity ft/s = 1.58

Allowable Vapour Velocity ft/s = 2.84 User K = Default K = 0.27

Design Vapour Flow ft³/s = 105.5 Use 80% for compr, glycol, amine drums

Vessel Diameter - Selected D ft = 7.0

Vapour Flow Area ft² = 38.48

Vapour Velocity ft/s = 2.74 Less than allowable. OK

Liquid Gas Separation

Vessel Height L ft = 16.0

3.0

13.00

Degassing Area Ag ft² = 38.48

Design Oil + Water Flow ft³/s = 0.07 + 0.03

Design Liquid Flow ft³/s = 0.10 Liquid Downward Velocity ft/s = 0.00

Gas Bubble Size - to be removed µ = 200 Gas Rising Velocity ft/s = 0.032

* Gas Separation O.K *

Client: E3 OGPE Calculation No:

Project: E3 Field Development Rev : A Date: 20 Aug 2010

Service:Production Separator 5V - 100 By: K Chk'd: App'd:

Liquid - Liquid Separation

0 Oil Weir Height, H in = 60.0

0 Bucket Base Elevation, b 228.6

4 500.0

0 Water Compt Width, w in = 30.0

Bucket to Weir gap, g 0.0

LAHHNLL

NLL Flooded Weir

NLL Overflow Weir

H NLL2

LALL LALL

w

Liquid Levels - Water - In 1st Compartment

Level Volume IntraVolumeResponse Time, min Remarks

Settings in ft³ ft³ Available Required

Mud Level 6.0 19.3

4.11 126 2.00 sec OK

LALL 10.0 23.4

4.11 2.1 1.0 OK

LAL 14.0 27.5

NLL 18.0 31.6 16.2 3.0 OK

LAH 24.0 37.8

37.02 19.0 1.0 OK

LAHH 60.0 74.8

Control Vol LAL to LAH ft³ 10.3 5.3 5.0 OK

Slug Vol NLL to LAHH ft³ 43.2 0.0 OK

Slug, inflow all liquid ft³/s 105.63 0.4 sec 2.0 sec Slug time not met. Reduce NLL

Liquid Levels - Oil - In 2nd Compartment

Level Volume IntraVolumeResponse Time, min Remarks

Settings in ft³ ft³ Available Required

Mud Level 6.0 88.1

8.72 134 2.00 sec OK

LALL 10.0 96.8

8.72 2.2 1.0 OK

LAL 14.0 105.5

NLL 18.0 114.2 29.3 3.0 OK

LAH 24.0 127.3

95.87 24.6 1.0 OK

LAHH 68.0 223.2

Control Vol LAL to LAH ft³ 21.8 5.6 5.0 OK

Slug Vol NLL to LAHH ft³ 109 0.0 OK

Client: E3 OGPE Calculation No:

Project: E3 Field Development Rev : A Date: 20 Aug 2010

Service:Production Separator 5V - 100 By: K Chk'd: App'd:

Slug, inflow all liquid 0 105.63 1.0 sec 2 sec Slug time not met. Reduce NLL

Oil - Water Droplet Size in Carry-over

Water Velocity ft/s = 0.003 Oil Velocity ft/s = 0.002

Travel Length = NA Travel Length = NA

Water Travel Time sec = NA Oil Travel Time sec = NA

Oil Rising distance = NA Water Settling distance = NA

Oil Terminal Velocity ft/s = 0.003 Water Terminal Velocity ft/s = 0.002

Oil in Water Droplet Size µ = 123.81 Water in Oil in Droplet Size µ = 162.2

A mesh/vane type coalescer may help reduce droplet size/ carry over, rather than a bigger vessel.

Droplets smaller than 150-200 µ generally OK

Sand Droplet Size, µ = Later Sand Accumulation, % =

Sand Accumulation per day ft³ =

Vessel Size

Vessel Diameter D ft = 7.0 Default

LAHH ft = 5.67

Vapour Space below inlet ft = 2.10

0 Inlet Nozzle ft = 1.33

Vapour Space above inlet ft = 4.00

Tan Line to Outlet nozzle ft = 2.83

Minimum Height Required ft = 0.00 15.93

Selected Height L ft = 16.00

L/D Ratio = 2.29 OK

Remarks

Space to explain design features, add comments on caution messages

You might also like

- Heater Treater CalculationDocument12 pagesHeater Treater Calculationwahyu100% (1)

- Master - Three Phase Horizontal Separator Rev 0Document6 pagesMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNo ratings yet

- Horizontal Three Phase Separator vap-IPDocument5 pagesHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrNo ratings yet

- 2 Phase Flow Pressure Drop Calc Suresh1Document6 pages2 Phase Flow Pressure Drop Calc Suresh1NKNo ratings yet

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- MCQ CollectionDocument614 pagesMCQ Collectionanil kumar0% (1)

- 1.pipeline Risk Assessment Definitive Approach and Its Role in Risk ManagementDocument17 pages1.pipeline Risk Assessment Definitive Approach and Its Role in Risk Managementhendry_hdw100% (1)

- Objective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpDocument5 pagesObjective:: 9.) Pump Base Plate Is 0.3 M Above Grade As Per Licensor PDS - Coke Condensate PumpAJAY1381No ratings yet

- Separator DesignDocument4 pagesSeparator DesignTech ManagerNo ratings yet

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Control Valve Thumb Rule CalculationDocument82 pagesControl Valve Thumb Rule CalculationShubham AgarwalNo ratings yet

- Control Valve Sizing PDFDocument5 pagesControl Valve Sizing PDFsivaNo ratings yet

- G01 20 VD 101 (Sizing Sheet) 3 PhaseDocument6 pagesG01 20 VD 101 (Sizing Sheet) 3 PhaseWickyNo ratings yet

- Line Sizing LiqDocument12 pagesLine Sizing LiqDana GuerreroNo ratings yet

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design Separatorssemarasik_651536604No ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- D-1309 Sizing Calc Sht1Document1 pageD-1309 Sizing Calc Sht1NKNo ratings yet

- Tank Pressure & Vacuum ProtectionDocument4 pagesTank Pressure & Vacuum ProtectionrodrigoperezsimoneNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- Section 7Document64 pagesSection 7WlopezaNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Separator (1) Sizing Spread SheetsDocument21 pagesSeparator (1) Sizing Spread SheetsSteve WanNo ratings yet

- Gas-Liquid Line SizingDocument1 pageGas-Liquid Line Sizingagusnnn100% (2)

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocument6 pagesOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNo ratings yet

- Separator Sizing SheetDocument8 pagesSeparator Sizing SheetCahyoNo ratings yet

- ΔP criteria ΔP criteria ρV ρVDocument3 pagesΔP criteria ΔP criteria ρV ρVjenish parekhNo ratings yet

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Document3 pagesPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweNo ratings yet

- All Sep CalcDocument22 pagesAll Sep Calcbharathscds100% (3)

- V-710 CPRP-7Document22 pagesV-710 CPRP-7balajikrishnanNo ratings yet

- Line Sizing - 2PHASEDocument11 pagesLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (2)

- BN-EG-UE109 Guide For Vessel SizingDocument29 pagesBN-EG-UE109 Guide For Vessel SizingSachin ChavanNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document33 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2MaheshNo ratings yet

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDocument15 pages2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNo ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Sizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JDocument1 pageSizing Three Phase (Gas - Oil) Horizontal Separator: As Per API 12JekabudiartiNo ratings yet

- Control Valve Sizing - Gas Rev 2aDocument2 pagesControl Valve Sizing - Gas Rev 2aMahmoud ShaheenNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwNo ratings yet

- Blowdown Calculation Inventory - Subsea FlowlineDocument13 pagesBlowdown Calculation Inventory - Subsea FlowlineNK0% (1)

- Calculation Title: Seagas Pipeline Design - MinervaDocument1 pageCalculation Title: Seagas Pipeline Design - Minerva秦东旺No ratings yet

- Horizontal 3 Phase Separator With Boot SizingDocument16 pagesHorizontal 3 Phase Separator With Boot Sizingzamijaka100% (1)

- Seperator Sizing v3Document5 pagesSeperator Sizing v3camasa2011No ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Example 1: Size A 2-Phase Vertical Separator: Job SpecificationsDocument20 pagesExample 1: Size A 2-Phase Vertical Separator: Job SpecificationsagusnnnNo ratings yet

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Document4 pagesValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNo ratings yet

- Pemex BA-1071 F. 27898 Bombas Pozo Profundo Tapachula, ChiapasDocument3 pagesPemex BA-1071 F. 27898 Bombas Pozo Profundo Tapachula, ChiapasMarti H JNo ratings yet

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Document2 pagesWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariNo ratings yet

- 3 Phase SizingDocument2 pages3 Phase Sizingc_nghiaNo ratings yet

- Process Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Document15 pagesProcess Calculation Cover Page: References: (Include Version No., Date of Publication, Etc.)Silas OnyekweNo ratings yet

- Liquid Hold Up Change and Slug Catcher SizingDocument2 pagesLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Sizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)Document14 pagesSizing of Control Valves For Non-Turbulent Flow (Laminar and Transitional)JOSE MARTIN MORA RIVEROSNo ratings yet

- Liquid Orifice SizingDocument8 pagesLiquid Orifice SizingrmaganNo ratings yet

- 2 Phase Separator Sizing: Vertical Horizontal OrientationDocument2 pages2 Phase Separator Sizing: Vertical Horizontal Orientationmohideenaliyarjafeer.shanawazNo ratings yet

- Vertical Vessel Adequacy CheckDocument15 pagesVertical Vessel Adequacy CheckTifano KhristiyantoNo ratings yet

- Hojas de Datos Ejercicio ExtraDocument1 pageHojas de Datos Ejercicio ExtraJohnny Ramos DíazNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Design Planning Records Center of The Future 2004-10Document29 pagesDesign Planning Records Center of The Future 2004-10Talam KeladiNo ratings yet

- PGG-EG Governor ActuatorDocument4 pagesPGG-EG Governor Actuatorrodruren010% (1)

- Ironmaking and Steelmaking Theory and PracticeDocument494 pagesIronmaking and Steelmaking Theory and PracticeDrKinnor Chattopadhyay100% (12)

- Research Paper On Building MaterialsDocument7 pagesResearch Paper On Building Materialsafnknlsjcpanrs100% (1)

- Wood Catalog Ver1Document9 pagesWood Catalog Ver1Achmad DimyatiNo ratings yet

- 2003-UFC 3-450-01 - Noise and Vibration ControlDocument152 pages2003-UFC 3-450-01 - Noise and Vibration ControlAndres PalacioNo ratings yet

- Nist Privacy FrameworkDocument43 pagesNist Privacy FrameworkE.G100% (1)

- Formal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurDocument23 pagesFormal Language and Automata Theory (CS21004) : Soumyajit Dey CSE, IIT KharagpurManad MishraNo ratings yet

- Topic 6 Fields and Forces and Topic 9 Motion in FieldsDocument30 pagesTopic 6 Fields and Forces and Topic 9 Motion in Fieldsgloria11111No ratings yet

- Failures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityDocument2 pagesFailures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityRajesh KhadkaNo ratings yet

- Manual Conefor 26Document19 pagesManual Conefor 26J. Francisco Lavado ContadorNo ratings yet

- ENMED301055EN - Flite 210 - 042013Document2 pagesENMED301055EN - Flite 210 - 042013Tirthankar DattaNo ratings yet

- WATER FILL UP Procedure - Rev.01Document6 pagesWATER FILL UP Procedure - Rev.01shivanshsovNo ratings yet

- L136T/Tl Marine EngineDocument2 pagesL136T/Tl Marine EngineAhmet GelişliNo ratings yet

- GL1200. .Service - ManualDocument415 pagesGL1200. .Service - ManualIpavec RokNo ratings yet

- Ekg 6Document2 pagesEkg 6RachitNo ratings yet

- SDI Kit ManualDocument2 pagesSDI Kit ManualMubarak AhmadNo ratings yet

- FCS-8005 User ManualDocument11 pagesFCS-8005 User ManualGustavo EitzenNo ratings yet

- Arson Invest 2Document100 pagesArson Invest 2Harrison sajorNo ratings yet

- Subtopic 6.5-6.7 FORM 4 KSSM 2020Document32 pagesSubtopic 6.5-6.7 FORM 4 KSSM 2020NurulNo ratings yet

- Batch Short Circuit Users ManualDocument64 pagesBatch Short Circuit Users ManualAshleyNo ratings yet

- 2021 May Intake Advert Revised 4Document2 pages2021 May Intake Advert Revised 4douglas0% (1)

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- Pipe Size CalculationDocument42 pagesPipe Size CalculationfelipeNo ratings yet

- 6016 ManualDocument9 pages6016 ManualDoceigenNo ratings yet

- Motion Control With LabviewDocument30 pagesMotion Control With Labviewsocat120013485No ratings yet

- L & T Catalogue 11Document3 pagesL & T Catalogue 11amulya00428No ratings yet

- PDF - SYLLABUS B2.new PDFDocument4 pagesPDF - SYLLABUS B2.new PDFSaniya khanNo ratings yet