Professional Documents

Culture Documents

Dominin

Dominin

Uploaded by

Anonymous tvA58EWlRg0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

dominin.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views2 pagesDominin

Dominin

Uploaded by

Anonymous tvA58EWlRgCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

DOMINION MOTORS & CONTROLS LTD

1. IDENTIFICATION OF THE PROBLEM:

In 1984, Dominion Motors was supplying to more than 50% of the available market

for oil well pumping motors in northern Canada. Currently, John Bridges, person-in-

charge of motor testing program in Hamilton is in the process of publishing a report in

which Dominion’s motors are third in line in terms of recommended motors, tested on

the basis of maximum starting torque required to pump at low temperatures and the

horsepower required to lift the fluid. Hamilton is the largest oil company in Canada and

Bridges being a credible expert in the field of electrical motors, claims made by Bridges

will be highly regarded. Considering the third position after Spartan Motor and Universal

Motors, Dominion executives are expecting a sharp decline in their sales in the once the

report reaches the industry. Thus, the core problem is how to combat the negative effects

as a result of the report given by Bridges. Any solution offered should be in compliance

with NEMA standards.

2. ANALYSIS OF THE SITUATION:

According to industry experts, an average of 1000 wells per year would become active

in the next five years The company has four alternatives to go forward with and each has

been evaluated below.

2.1. ALTERNATIVE 1: Reduce the price of DMCs 10HP to that of 7 1/2HP motor. The

only advantage of this option is that it can be immediately implemented but requires a

decrease in price which might send a negative signal in the industry, along with an

obvious decrease in profit. However, this is a short term solution. As of now, companies

are not penalized for using low power factor motors but it may be enforced at a later

stage.

2.2 ALTERNATIVE 2: Re-engineer DMC’s present 7 1/2HP motor to make its starting

torque at least equal to that of the Spartan 7 ½ unit. This option would allow Dominion’s

motor to gain more credibility as per the criteria in Bridge’s report but would violate the

NEMA standards. The first method involves increasing the starting torque with increase

in temperature which violates the temperature standards, which is also a safety concern.

The second method of increasing torque by increasing frame size violates the frame size

standards, which would lead to torque wars in the industry. Adhering to NEMA standards

is an option but this is necessary as the perception of the buyer will be influenced by this.

2.3. ALTERNATIVE 3: A definite purpose 5HP Motor with starting torque of 10HP

motor. This option will allow Dominion to charge the customers a higher price than

Rs.1045 but ideally lesser than Rs.1200. It will also enable the company to capture 60%

of the market. In this option, an investment of Rs. 75,000 is needed and it is difficult to

justify small productions. This motor will only be ready after 4-5months for production.

2.4. ALTERNATIVE 4: Persuade Bridges and Hamilton’s executives to re-consider the

results. If this option is pursued and Dominion is successful in its attempt, then no new

investment has to be made, no discounts to be given and no other changes to be made.

There is a high probability that they will not succeed and Dominion will lose out on their

sales in future.

3. RECOMMENDATION:

After evaluation of all four options, we have come to a decision of investing in a

definite purpose 5HP motor with starting torque of 10HP (Option3).

While the 5HP motor is being developed, we shall engage in talks with Bridges to

convince him that Dominion’s motors are general purpose while his tests are for

definite purpose motors (Option4).

As an additional request, Bridges would be asked to test the new 5HP and include it in

his report.

You might also like

- Carding SetupDocument16 pagesCarding SetupNaeem Islam100% (1)

- How to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsFrom EverandHow to Use and Upgrade to GM Gen III LS-Series Powertrain Control SystemsRating: 3.5 out of 5 stars3.5/5 (4)

- Building Honda K-Series Engine PerformanceFrom EverandBuilding Honda K-Series Engine PerformanceRating: 5 out of 5 stars5/5 (2)

- Berges Level 2 Book PDFDocument80 pagesBerges Level 2 Book PDFYulia Larin100% (1)

- Indonesia Flexible Packaging Market Growth, Trends, COVID 19 ImpactDocument135 pagesIndonesia Flexible Packaging Market Growth, Trends, COVID 19 ImpactIndah YuneNo ratings yet

- Dominion Motors AnalysisDocument4 pagesDominion Motors AnalysisUday Kiran100% (1)

- Dominion Motors & Controls, LTDDocument7 pagesDominion Motors & Controls, LTDMahnoor MaalikNo ratings yet

- Haas School of Business BA 160 Marketing Prof. A. BauerDocument11 pagesHaas School of Business BA 160 Marketing Prof. A. BauerKartik LadNo ratings yet

- PDF Dominion Motors and Controls Case Analysis DDDocument3 pagesPDF Dominion Motors and Controls Case Analysis DDsaifrahmanNo ratings yet

- Cooper Industries Case StudyDocument2 pagesCooper Industries Case StudyShane Mackey50% (2)

- Case Analysis - Dominion MotorsDocument2 pagesCase Analysis - Dominion MotorsNEHA JENA IPM 2018 BatchNo ratings yet

- Dominion Motor CaseDocument3 pagesDominion Motor Caseabhijeet pandeNo ratings yet

- Dominion Case StudyDocument2 pagesDominion Case StudyANKIT AGARWALNo ratings yet

- Dominion Motors and Controls Ltd. - Case AnalysisDocument7 pagesDominion Motors and Controls Ltd. - Case Analysisdhiraj agarwalNo ratings yet

- DMCDocument1 pageDMCKartik LadNo ratings yet

- Dominion Motors & Controls, Ltd. - Case Analysis: Business To Business MarketingDocument6 pagesDominion Motors & Controls, Ltd. - Case Analysis: Business To Business MarketingSayakBiswasNo ratings yet

- Marketing Assingment: Dominion Motors & Controls Case StudyDocument4 pagesMarketing Assingment: Dominion Motors & Controls Case StudyParas JatanaNo ratings yet

- Dominion Motors & Controls LTD.: OCTOBER 7, 2014Document4 pagesDominion Motors & Controls LTD.: OCTOBER 7, 2014ShaunJaiprakash100% (1)

- Sai Charan Perugu Dominion Case AnalysisDocument5 pagesSai Charan Perugu Dominion Case AnalysismmsrajuNo ratings yet

- Dominion Case Study: FactsDocument2 pagesDominion Case Study: FactsSiddhantSethiaNo ratings yet

- Dominion Motors LTDDocument5 pagesDominion Motors LTDutkarshdave100% (1)

- Dominion Motors and Controls Case AnalysisDocument3 pagesDominion Motors and Controls Case AnalysisAshish JaiswalNo ratings yet

- Dominion Motors and Control LTDDocument13 pagesDominion Motors and Control LTDPiyushNo ratings yet

- Dominion Motor Case StudyDocument9 pagesDominion Motor Case StudypranayNo ratings yet

- Dominon MotorsDocument18 pagesDominon MotorspriyaNo ratings yet

- Section B Group 4 DominionDocument8 pagesSection B Group 4 DominiongNo ratings yet

- Dominion Motors CaseDocument12 pagesDominion Motors CaseAgrimGargNo ratings yet

- Dominion Motors & Controls, LTDDocument6 pagesDominion Motors & Controls, LTDdileepNo ratings yet

- Dominion MotorsDocument26 pagesDominion MotorsNikhil BhadNo ratings yet

- Reduce Price of 10 HP Motor To That of 7 HP Motor: SituationDocument3 pagesReduce Price of 10 HP Motor To That of 7 HP Motor: Situation01202No ratings yet

- B2B Assignment: Case Analysis - Group 1Document3 pagesB2B Assignment: Case Analysis - Group 1Subhrodeep DasNo ratings yet

- Dominion Motors & Controls, LTD.: Alhat Devendra Aiswarya Balan Jackson PR Srikant VineetDocument10 pagesDominion Motors & Controls, LTD.: Alhat Devendra Aiswarya Balan Jackson PR Srikant VineetBikramjit ChaudhuryNo ratings yet

- Dominion Motors & Controls LTDDocument15 pagesDominion Motors & Controls LTDAmil BansalNo ratings yet

- Decision Sheet DominionDocument1 pageDecision Sheet DominionDevdatta BhattacharyyaNo ratings yet

- Dominion MotorsDocument5 pagesDominion MotorsavantikaNo ratings yet

- Dominion Motors CaseDocument14 pagesDominion Motors Caseankitkalra198650% (2)

- The Company: Strength WeaknessDocument10 pagesThe Company: Strength Weaknessvky2929No ratings yet

- Dominion Motors LTD Case Analysis BBM, NMP Term Iii: Group 4Document8 pagesDominion Motors LTD Case Analysis BBM, NMP Term Iii: Group 4Sajjad AhmadNo ratings yet

- Dominion Motors & Controls, LTD.: Brief Key ProblemDocument1 pageDominion Motors & Controls, LTD.: Brief Key ProblemAkash PaliwalNo ratings yet

- Presentation 1Document3 pagesPresentation 1renjithkollampuzhaNo ratings yet

- Dominion MotorsDocument9 pagesDominion MotorsSakura2709No ratings yet

- Dominion Motors Controls Ltd.Document4 pagesDominion Motors Controls Ltd.Naveen Chander DharNo ratings yet

- Direct Indirect LaptopDocument3 pagesDirect Indirect LaptopAyushyaNo ratings yet

- Dominion Motor Case: Short Term Plan: Implement Alternative 1 From The Beginning of May WhenDocument1 pageDominion Motor Case: Short Term Plan: Implement Alternative 1 From The Beginning of May WhenAkhilesh KamalNo ratings yet

- Dominion MotorsDocument2 pagesDominion MotorsSimona VasuNo ratings yet

- The Dominion Motor & Controls Case AnalysisDocument2 pagesThe Dominion Motor & Controls Case AnalysispranayNo ratings yet

- Dominion Motors & Controls, LTDDocument8 pagesDominion Motors & Controls, LTDIshan AgrawalNo ratings yet

- Body Configuration Compared To Its Competitors, It Did Not Sacrifice Roominess. The Interiors Offered Almost As Much Space As Competitors' ModelsDocument3 pagesBody Configuration Compared To Its Competitors, It Did Not Sacrifice Roominess. The Interiors Offered Almost As Much Space As Competitors' ModelsRohan SrivastavaNo ratings yet

- Debonair Engineering LTD (Case Study Solution)Document3 pagesDebonair Engineering LTD (Case Study Solution)Muhammad Furqan ZebNo ratings yet

- Product Brand Management Assignments: Submitted To: Prof. Pallavi Mittal Submiited By: Palak Shah Roll No-44 Term-6Document11 pagesProduct Brand Management Assignments: Submitted To: Prof. Pallavi Mittal Submiited By: Palak Shah Roll No-44 Term-6vidhi_136No ratings yet

- Dominion MotorsDocument4 pagesDominion MotorsAnkit MaheshwariNo ratings yet

- Dominion MotorsDocument2 pagesDominion MotorsNarendra PatankarNo ratings yet

- A Case Study On Dominion Motor Company: Presented By: Aniket Harsh Arjun R.K Deepa Sundaram Kumar AbhishekDocument10 pagesA Case Study On Dominion Motor Company: Presented By: Aniket Harsh Arjun R.K Deepa Sundaram Kumar AbhishekPrasenjit DebnathNo ratings yet

- Honda TodayDocument2 pagesHonda Todayashwini patilNo ratings yet

- Group 8: Dominion Motors and Controls LimitedDocument16 pagesGroup 8: Dominion Motors and Controls Limitedanon_116013318No ratings yet

- Dominion Motors and Controls LTDDocument7 pagesDominion Motors and Controls LTDRavinder Kumar100% (1)

- Assignment NAME: Hannan Babar Section: B DATE: 31/03/2020 SUBJECT: Principle of ManagementDocument3 pagesAssignment NAME: Hannan Babar Section: B DATE: 31/03/2020 SUBJECT: Principle of Managementaamna176No ratings yet

- Dominion Motors and Controls: Althaf, Abhay, Harsh, Gayatri, Kanika, LakshyaDocument10 pagesDominion Motors and Controls: Althaf, Abhay, Harsh, Gayatri, Kanika, LakshyaSakura2709No ratings yet

- Dominion MotorsDocument9 pagesDominion MotorsAnimesh BanerjeeNo ratings yet

- DMCs EUDocument2 pagesDMCs EUMaria Eugenia PascualNo ratings yet

- Modul 1: Engineering Economy and The Design Process Engineering Economy BE Class 2020 Dr. Ir. Musthofa Lutfi, MP.,IPMDocument2 pagesModul 1: Engineering Economy and The Design Process Engineering Economy BE Class 2020 Dr. Ir. Musthofa Lutfi, MP.,IPMNiken Ayu PrastiwiNo ratings yet

- Trucking & Fuel Economy/GHG Regulation: Perspectives From Small Business TruckersDocument10 pagesTrucking & Fuel Economy/GHG Regulation: Perspectives From Small Business TruckersOOIDA's DC OfficeNo ratings yet

- Prod RecallDocument5 pagesProd RecallRio joseph (Rio)No ratings yet

- class -9 study materiallDocument77 pagesclass -9 study materiallAnonymous tvA58EWlRgNo ratings yet

- MobilDocument1 pageMobilAnonymous tvA58EWlRgNo ratings yet

- Beta Exhibit 03 - 91 Day Tresury BillDocument1 pageBeta Exhibit 03 - 91 Day Tresury BillAnonymous tvA58EWlRgNo ratings yet

- Hero Motor Corp Vs Nifty500Document2 pagesHero Motor Corp Vs Nifty500Anonymous tvA58EWlRgNo ratings yet

- New Doc 2018-11-30 08.09.00 PDFDocument4 pagesNew Doc 2018-11-30 08.09.00 PDFAnonymous tvA58EWlRgNo ratings yet

- Assignment No.3 Name Roll No: Prepared By: Suresh Kumar 4 Vibhor Mittal 6 Ankit Arora 7 Subir Roy 8 Ramesh. R 9 Ravikumar - M 10Document10 pagesAssignment No.3 Name Roll No: Prepared By: Suresh Kumar 4 Vibhor Mittal 6 Ankit Arora 7 Subir Roy 8 Ramesh. R 9 Ravikumar - M 10Anonymous tvA58EWlRgNo ratings yet

- Demonstrate How An Ethical Culture Can Be Created: (Document Subtitle)Document6 pagesDemonstrate How An Ethical Culture Can Be Created: (Document Subtitle)Anonymous tvA58EWlRgNo ratings yet

- PricingDocument3 pagesPricingAnonymous tvA58EWlRgNo ratings yet

- SwotDocument1 pageSwotAnonymous tvA58EWlRgNo ratings yet

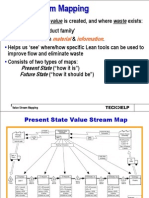

- 4 Slides Value Stream MappingDocument13 pages4 Slides Value Stream MappingRanjan Raj Urs100% (2)

- Servant-Leadership in Higher Education: A Look Through Students' EyesDocument30 pagesServant-Leadership in Higher Education: A Look Through Students' Eyeschrist_wisnuNo ratings yet

- The Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsDocument10 pagesThe Effectiveness of Bilingual Program and Policy in The Academic Performance and Engagement of StudentsJoshua LagonoyNo ratings yet

- Vinayyak - CV - Sap - ExpDocument3 pagesVinayyak - CV - Sap - ExpmanikandanNo ratings yet

- Analysis of Credit Risk Measurement UsinDocument6 pagesAnalysis of Credit Risk Measurement UsinDia-wiNo ratings yet

- Q3 2019 Management Review SHEQ Presentation-1Document23 pagesQ3 2019 Management Review SHEQ Presentation-1Warren KabichiNo ratings yet

- FDI and Corporate StrategyDocument15 pagesFDI and Corporate StrategyKshitij TandonNo ratings yet

- PublicationsDocument8 pagesPublicationssomeshNo ratings yet

- Wire - Declaration of ConformityDocument4 pagesWire - Declaration of ConformityrfandreiNo ratings yet

- TX ComplaintDocument14 pagesTX ComplaintPatchNo ratings yet

- SP 70Document75 pagesSP 70Barbie Turic100% (2)

- Ba311 - Module 5 Capacity ManagementDocument10 pagesBa311 - Module 5 Capacity ManagementShams PeloperoNo ratings yet

- Answers Unit 2 IMK Part 1Document8 pagesAnswers Unit 2 IMK Part 1Vivi SamaniegoNo ratings yet

- Theory, Culture & Society: The AestheticDocument8 pagesTheory, Culture & Society: The AestheticJaime UtrerasNo ratings yet

- Assignment/ Tugasan - Principles of ManagementDocument11 pagesAssignment/ Tugasan - Principles of ManagementSuriya KumaraNo ratings yet

- CH 3Document41 pagesCH 3Diana BaRobNo ratings yet

- Written Test For Innovius ResearchDocument2 pagesWritten Test For Innovius ResearchPrince RoyNo ratings yet

- Ssy R R 2017 Form IDocument3 pagesSsy R R 2017 Form ISoumen Gorai50% (2)

- TED Taiye SelasiDocument4 pagesTED Taiye SelasiMinh ThuNo ratings yet

- Swot PanasonicDocument2 pagesSwot PanasonicXingMei StarszsisNo ratings yet

- Ee NewDocument1 pageEe Newhsbibahmed091No ratings yet

- English Ancestral Homes of Noted Americans (1915)Document386 pagesEnglish Ancestral Homes of Noted Americans (1915)liketoread100% (1)

- Jeopardy SolutionsDocument14 pagesJeopardy SolutionsMirkan OrdeNo ratings yet

- Razon V IAC (De Leon)Document2 pagesRazon V IAC (De Leon)ASGarcia24No ratings yet

- Malankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDocument26 pagesMalankara Catholic Church Sui Iuris: Juridical Status and Power of GovernanceDr. Thomas Kuzhinapurath100% (6)

- Philippine Criminology Profession Act of 2018 (RADocument46 pagesPhilippine Criminology Profession Act of 2018 (RARhem Rick CorpuzNo ratings yet

- Banking Law Syllabus Atty VeraDocument2 pagesBanking Law Syllabus Atty VeraLawrence Villamar100% (1)