Professional Documents

Culture Documents

Government Polytechnic, Mumbai Instrumentation Engineering

Government Polytechnic, Mumbai Instrumentation Engineering

Uploaded by

Chaitanya M MundheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Government Polytechnic, Mumbai Instrumentation Engineering

Government Polytechnic, Mumbai Instrumentation Engineering

Uploaded by

Chaitanya M MundheCopyright:

Available Formats

Government Polytechnic, Mumbai Instrumentation Engineering

Programme : Diploma in Instrumentation (IS) Engineering

Course Code: IS 16203 Course Title: Process Measurement - I

Compulsory / Optional: Compulsory

Teaching Scheme and Credits Examination Scheme

TH TU PR Total TH TS PR OR TW Total

3 - 4 7 70(3 Hrs.) 30 50* - - 150

*Indicates assessment by Internal & External Examiners (40% by external examiner, 40 % by internal examiner

and 10 % for journal assessment).

Rationale:

Instrumentation is defined as the art and science of measurement and control of physical variables within

a production or manufacturing area. The physical variables like displacement, force, pH, viscosity,

density etc. are measured in industries to monitor and control the overall operation of plant. For

conversion of these physical quantities into electrical forms, various types of transducers are used. Hence

it is essential to study the conversion/ transduction principles. This course mainly deals with study of

various transduction principles as well as characteristics of measuring instruments.

Course Outcomes:

Upon completion of this course, students should be able to

CO1 Identify, list and classify different of sensors and transducers.

CO2 Draw the diagram/sketches of different transducers and measurement setup.

CO3 Demonstrate and verify the transduction principles of transducers.

CO4 Measure the various process parameters.

CO5 Select the relevant transducers for the given application.

Course Content Details:

Unit No. Topics / Sub-topics

Displacement transducers

1 1.1 Displacement – Definition, types & Units.

1.2 Resistive Displacement Transducers: Potentiometer, Strain gauge, types, Effect of

temperature on strain gauge measurement, Simple Numerical on strain gauge factor.

1.3 Inductive Displacement transducers- Inductance principle, classification of inductive

Transducers: LVDT, RVDT.

1.4 Capacitive Transducers- Capacitance principle, Concept & variable capacitance due to

change in dielectric Media, area of the plate, distance between the plates.

( Diagram, construction, working principle, advantages, Disadvantages, and applications.)

Measurement of Speed & Vibration

2 2.1 Speed and its units, types.

2.2 Contactless Tachometers: Magnetic pickup, Photo pickup, Stroboscope, Digital

Encoder

2.3 Contact Tachometers: D.C. Tachometer, A.C. Tachometer.

2.4 Measurement of vibrations: - Electro mechanical relative vibration pick up, Relative

displacement vibration pick up, Electromagnetic relative vibration pick up.

(Diagram, construction, operation, advantages, applications of above transducers.)

3 Measurement of Force & Torque

3.1 Force and its units, Types , Hydraulic force meter, Pneumatic force meter, Electric

Force meters: Strain gauge Load cell, Pressductor Load cell, Proving ring Load cell.

Piezoelectric Load cell,

3.2 Measurement of Torque:-In line rotating torque sensor, In line stationery torque sensor.

Process Measurement-I IS16203

Government Polytechnic, Mumbai Instrumentation Engineering

(Diagram, construction, operation, advantages and application of above transducers.)

Measurement of Viscosity and Density

4 4.1 Viscosity- Definition, Types -Capillary type, Saybolt, Falling & Rolling ball Type,

Rotameter type Viscometer.

4.2 Density Measurement- Units, Specific gravity, Relative density.

4.3 Types of Densitometer: Hydrometer, Buoyancy type, Radiation type,Ultrasonic

Sludge type, Thermal Conductivity type.

(Diagram, construction, operation, advantages and application of above transducers.)

Electronic Sensors

5 6.1 Sound level meter, Microphone and its types: Condenser type, Electrets type,

piezoelectric crystal type, Electro dynamic type.

6.2 Smoke & gas detector, flame detectors,

6.3 Laser sensors,

6.4 Bar code identification system, position Encoder sensors.

(Diagram, construction, operation, advantages and application of above transducers.)

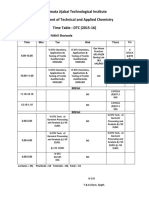

Suggested Specifications Table with Hours and Marks (Theory):

Distribution of Theory Marks

Unit Teaching

Topic Title R U A Total

No Hours

Level Level Level Marks

1 Displacement transducers 10 4 6 6 16

2 Measurement of Speed & Vibration 10 4 4 6 14

3 Measurement of Force & Torque 10 4 4 6 14

Measurement of Viscosity and

4 10 4 4 6 14

Density

5 Electronic sensors 8 2 4 6 12

48 18 28 24 70

Legends: R- Remember; U-Understand; A- Apply and above levels (Bloom’s revised Taxonomy).

Notes: This specification table shall be treated as a general guideline and actual distribution of marks

may slightly vary from table. But the questions from each topic should be asked as per marks weightage.

Numerical questions are to be asked only if specified.

List of Experiments ( Minimum 15 experiments ):

Sr. Approx.

Unit Experiment/Assignment

No. Hours

1 1 Use the potentiometer to measure the linear & angular displacement 4

2 1 Use the LVDT to measure displacement. 4

3 1 Use the strain gauge to measure weights. 4

4 1 Use the capacitive transducer to measure liquid level. 4

5 2 Use the magnetic pickup proximity switch to measure speed of motor. 4

6 2 Use the A.C. tachometer to measure speed of motor. 4

Process Measurement-I IS16203

Government Polytechnic, Mumbai Instrumentation Engineering

7 2 Use the D.C. tachometer to measure speed of motor. 4

8 2 Use the digital tachometer to measure angular speed. 4

9 2 Troubleshoot the given speed transducer. 4

10 2 Use piezoelectric type vibration meter for dynamic measurement. 4

11 3 Use the strain gauge type load cell to measure weights. 4

12 3 Assemble and Dismantle weight measuring system. 4

13 3 Calibrate the weight measuring system using strain gauge type load cell. 4

14 4 To measure the viscosity of fluid using capillary viscometer. 4

15 5 To perform the operation of smoke detector. 4

16 5 Use digital sound level meter to measure intensity of sound. 4

17 5 Use Condenser type microphone to measure sound. 4

18 5 Calibrate Condenser type microphone sound measuring system. 4

Microproject-01

Industrial visit-01

Total 64

References/ Books:

Sr.

Name of Book Author Publisher

No.

1. Instrumentation Measurement and Analysis Nakra, Chaudhari Tata McGraw Hill

2. Transducers and Instrumentation D.V.S. Murthy Prentice Hall India

3. Instrumentation Devices and Systems Rangan ,Mani, Tata McGraw Hill

Sharma

4. Industrial Instrumentation and control S.K.Singh Tata McGraw Hill

5. A Course in Electrical and Electronics A. K. Sawhney Dhanpat Rai & Co

Measurement and Instrumentation

6 Principles of Industrial Instrumentation D. Patranabis Tata McGraw Hill

7 Instrumentation for Process Measurement & Norman A. Anderson ----

Control

8 Instrument Engineers Handbook Bela G.Liptak. Chilton Book Co

Vol . Proecss Measurement U.S.A 1970

ISBN:9780750622547

Course Curriculum Development Committee:

a. Internal Faculty

i. Mr. S. G. Thube, Lecturer-IS

ii. Mr. K.U.Dawane, Lecturer-IS

iii. Mrs. V. K. Pawar, Lecturer-IS

iv. Mrs.S.D.Kapse, Lecturer-IS

b. External Faculty

i. Dr. Shivaji Ghungrad, Principal, St. Xavier’s Technical Institute, Mahim

ii. Mr. B. V. Karhade, Asst. Secretary, RBTE- Mumbai.

iii. Mr. P. V. Kharate, Sr. Manager, RCF, Chembur.

iv. Mr. Ravindra Vyavahare, Manager, Capgemini Technology Services Ltd., Navi Mumbai.

Academic Coordinator Head of Department Principal

(Instrumentation Engg.) Govt. Polytechnic Mumbai

Process Measurement-I IS16203

You might also like

- The Design and Implementation of A SONAR PowerDocument6 pagesThe Design and Implementation of A SONAR PowerKiranNo ratings yet

- 2-V - Waterless Dyeing in India (Elliyas Mohammad)Document30 pages2-V - Waterless Dyeing in India (Elliyas Mohammad)Chaitanya M MundheNo ratings yet

- Arduino ADS1115 Module Getting Started TutorialDocument7 pagesArduino ADS1115 Module Getting Started Tutorialjoeragan 20060% (1)

- Huawei MA5680T/MA5683T/MA5608T GPON Board H805GPFD Hardware DescriptionDocument6 pagesHuawei MA5680T/MA5683T/MA5608T GPON Board H805GPFD Hardware DescriptionHuawei GPON NetworksNo ratings yet

- 21GE1512 SyllabusDocument3 pages21GE1512 SyllabusRobinston Jeyasingh KNo ratings yet

- EDC Diploma SyllabusDocument27 pagesEDC Diploma SyllabusParvinder SinghNo ratings yet

- NBA - 1 - Syllabus Prescribed by WBSCTE - FinalDocument8 pagesNBA - 1 - Syllabus Prescribed by WBSCTE - FinalSo'ham DasNo ratings yet

- 2 Sensors and TransducersDocument83 pages2 Sensors and TransducersJEYAVEL PALANISAMYNo ratings yet

- Tutorial Sheet-5: Kec-057: Electronic Instrumentation & MeasurementsDocument4 pagesTutorial Sheet-5: Kec-057: Electronic Instrumentation & MeasurementsBrahmanand SinghNo ratings yet

- KTU BTech MR 2019scheme 2019Scheme-MinorsDocument49 pagesKTU BTech MR 2019scheme 2019Scheme-Minorsregret0987654321098765No ratings yet

- AE304 INDUSTRIAL INSTRUMENTATION Submodules ModifiedDocument3 pagesAE304 INDUSTRIAL INSTRUMENTATION Submodules ModifiedAnjanaNo ratings yet

- Review of Transducer and SensorDocument113 pagesReview of Transducer and SensorSyedZameerNo ratings yet

- Instrumentation and Measurement: Lesson PlanDocument56 pagesInstrumentation and Measurement: Lesson PlanDanishNo ratings yet

- Keating Sensors and TransducersDocument9 pagesKeating Sensors and TransducersEligiusz PawłowskiNo ratings yet

- Mechanical Engineering VI Sem SyllabusDocument25 pagesMechanical Engineering VI Sem Syllabussaurabh1116No ratings yet

- Position SensorDocument25 pagesPosition Sensoramirul lexNo ratings yet

- ContentDocument4 pagesContentBrundhan B.ANo ratings yet

- Sensors, Actuators and MeasurementDocument3 pagesSensors, Actuators and MeasurementVinayak Dakre100% (1)

- Me 8513 MM Lab 2022 OddDocument63 pagesMe 8513 MM Lab 2022 OddVelan PrintersNo ratings yet

- Transducers and Instrumentation Lab Manual: Mte-317 (L)Document28 pagesTransducers and Instrumentation Lab Manual: Mte-317 (L)Kazekage Tonely FieldNo ratings yet

- Ece5060 Principles-Of-Sensors-And-Signal-Conditioning Eth 1.0 57 Ece5060Document3 pagesEce5060 Principles-Of-Sensors-And-Signal-Conditioning Eth 1.0 57 Ece5060Bharath SrinivasNo ratings yet

- Me3581 Metrology and Dynamics Lab Manual R2021actDocument133 pagesMe3581 Metrology and Dynamics Lab Manual R2021actmarakamadhu800No ratings yet

- ICE VI Sem Syllabus 2021Document15 pagesICE VI Sem Syllabus 2021AshishNo ratings yet

- AE204 Sensors and Transducers PDFDocument2 pagesAE204 Sensors and Transducers PDFReshma SamNo ratings yet

- AE204 Sensors and Transducers PDFDocument2 pagesAE204 Sensors and Transducers PDFReshma SamNo ratings yet

- 22420Document132 pages22420PDNo ratings yet

- EE606-N Industrial InstrumentationDocument4 pagesEE606-N Industrial InstrumentationJohn sonNo ratings yet

- Instrumentation LabDocument26 pagesInstrumentation LabVivek SivaramanNo ratings yet

- Instrumentation & MeasurementDocument7 pagesInstrumentation & MeasurementSadia AhmadNo ratings yet

- AE482 Industrial Instrumentation PDFDocument2 pagesAE482 Industrial Instrumentation PDFShiv GhoradNo ratings yet

- AE482 Industrial Instrumentation (Careeryuga)Document2 pagesAE482 Industrial Instrumentation (Careeryuga)bony bijuNo ratings yet

- MM Lab DetailsDocument2 pagesMM Lab Detailscandiescrusher20No ratings yet

- Industrial Transducers Course Code: 3321701Document6 pagesIndustrial Transducers Course Code: 3321701Rohan MathurNo ratings yet

- Instrumentation and Measurement Techniques: Online Learning Flipped ClassroomDocument19 pagesInstrumentation and Measurement Techniques: Online Learning Flipped ClassroomCalvin KongNo ratings yet

- Eti 17 InCylinderMeasurement PDFDocument121 pagesEti 17 InCylinderMeasurement PDFAlokWardhanSinghNo ratings yet

- 2 Mark Question BankDocument6 pages2 Mark Question BankjeyansanthiNo ratings yet

- Electrical SystemDocument4 pagesElectrical SystemAbhijith TNo ratings yet

- LAB MANUAL S1 - 2023 RBBDocument32 pagesLAB MANUAL S1 - 2023 RBBlionelsebruNo ratings yet

- B P IDocument7 pagesB P IVikram RaoNo ratings yet

- MEM22443 2019 Summer Model Answer PaperDocument15 pagesMEM22443 2019 Summer Model Answer PaperRohit VaityNo ratings yet

- MECHATRONICSDocument71 pagesMECHATRONICSparandaman.mechNo ratings yet

- Mechanical Measurements and Metrology: Topic AnalysisDocument6 pagesMechanical Measurements and Metrology: Topic Analysisسيمو بشيريNo ratings yet

- Revision QuestionsDocument6 pagesRevision QuestionsSooraj KumarNo ratings yet

- DJM3052 Industrial Electronic (UNIT 5) : SensorDocument22 pagesDJM3052 Industrial Electronic (UNIT 5) : SensorShazryl DanielNo ratings yet

- Chapter 1Document21 pagesChapter 1Firaa'ol GizaachooNo ratings yet

- 1152EC142SENSORSANDTRANSDUCERSDocument2 pages1152EC142SENSORSANDTRANSDUCERSswethaNo ratings yet

- Iare Ece Vi-Emi Emi-Lecture Notes-Word NewDocument185 pagesIare Ece Vi-Emi Emi-Lecture Notes-Word NewSiva KumarNo ratings yet

- Measurements & Metrology BasicsDocument208 pagesMeasurements & Metrology BasicsPrabakaran Caleb0% (1)

- EEE355-Industrial Electronics-Course PlanDocument3 pagesEEE355-Industrial Electronics-Course PlanramprabhakarjNo ratings yet

- Dayananda Sagar College of Engineering: Department of Electronics & Instrumentation Engineering (Accredited by NBA)Document5 pagesDayananda Sagar College of Engineering: Department of Electronics & Instrumentation Engineering (Accredited by NBA)krushnasamy subramaniyanNo ratings yet

- Department of Mechanical Engineering Indian Institute of Technology Ropar RUPNAGAR-140001, INDIADocument26 pagesDepartment of Mechanical Engineering Indian Institute of Technology Ropar RUPNAGAR-140001, INDIAPiyush KushwahaNo ratings yet

- An Introduction To Electrical Instrumentation and Measurement SystemsDocument8 pagesAn Introduction To Electrical Instrumentation and Measurement SystemsFarhan AliNo ratings yet

- AnIntroductiontoElectricalInstrumentationandMeasurementSystems 1 PDFDocument455 pagesAnIntroductiontoElectricalInstrumentationandMeasurementSystems 1 PDFPanky Caccam GonzalesNo ratings yet

- Kertas Penerangan 1Document19 pagesKertas Penerangan 1amadNo ratings yet

- Two Marks Questions - Doc-MechatronicsDocument12 pagesTwo Marks Questions - Doc-MechatronicsNagammaieie88% (8)

- Scheme of Courses and Examination: B.Tech IceDocument4 pagesScheme of Courses and Examination: B.Tech IceSahil KhanNo ratings yet

- 3341104Document7 pages3341104Vani YamaniNo ratings yet

- Government Polytechnic, Pune: (An Autonomous Institute of Govt. of Maharashtra)Document4 pagesGovernment Polytechnic, Pune: (An Autonomous Institute of Govt. of Maharashtra)Madhav DeshpandeNo ratings yet

- M&M Lesson Plan and SyllabusDocument5 pagesM&M Lesson Plan and Syllabuschandrasekhar reddyNo ratings yet

- LevelDocument78 pagesLevelvjgeorge100% (1)

- M&i 2m - Opt PDFDocument0 pagesM&i 2m - Opt PDFvjnrkzNo ratings yet

- Chapter 1Document43 pagesChapter 1MohammedNo ratings yet

- 16EI3001-Transducer and Measurements Laboratory - SyllabusDocument1 page16EI3001-Transducer and Measurements Laboratory - Syllabusmadhusudhanan.scholarNo ratings yet

- Web Announcement 15aug2020Document2 pagesWeb Announcement 15aug2020Chaitanya M MundheNo ratings yet

- 1216984412800-Po Ibps Written Test ListDocument8 pages1216984412800-Po Ibps Written Test ListChaitanya M MundheNo ratings yet

- Functionalization of Polymers For Biomedical EngineeringDocument1 pageFunctionalization of Polymers For Biomedical EngineeringChaitanya M MundheNo ratings yet

- ºénùêxéeòé Ê Égòòséò Vééê Þ®Úéié - ¡Äò Éö Éé®Úò 2019 (Ê Égòò Ëeò Éiéòié Ê É Éä É ºéö) Õ Näù Éúxé)Document4 pagesºénùêxéeòé Ê Égòòséò Vééê Þ®Úéié - ¡Äò Éö Éé®Úò 2019 (Ê Égòò Ëeò Éiéòié Ê É Éä É ºéö) Õ Näù Éúxé)Chaitanya M MundheNo ratings yet

- 2nd Announcement SCHEMCON Final PDFDocument2 pages2nd Announcement SCHEMCON Final PDFChaitanya M MundheNo ratings yet

- Antidiabetic Activity of Chandraprabha Vati e A Classical AyurvedicDocument7 pagesAntidiabetic Activity of Chandraprabha Vati e A Classical AyurvedicChaitanya M MundheNo ratings yet

- 190226155747MHADA Nashik Booklet 2019 PDFDocument90 pages190226155747MHADA Nashik Booklet 2019 PDFChaitanya M MundheNo ratings yet

- EVS SyllabusDocument5 pagesEVS SyllabusChaitanya M MundheNo ratings yet

- Application Form For Faculty Recruitment On Tenure BasisDocument4 pagesApplication Form For Faculty Recruitment On Tenure BasisChaitanya M MundheNo ratings yet

- Academic Calender 2017-18Document2 pagesAcademic Calender 2017-18Chaitanya M MundheNo ratings yet

- MPSC 55-2017 00 - Final - Result - 55-2017Document374 pagesMPSC 55-2017 00 - Final - Result - 55-2017Chaitanya M Mundhe0% (1)

- Progress in Organic Coatings: Rasmika H. Patel, Kaushal S. PatelDocument10 pagesProgress in Organic Coatings: Rasmika H. Patel, Kaushal S. PatelChaitanya M MundheNo ratings yet

- Https WWW - Irctc.co - in Eticketing PrintTicketDocument2 pagesHttps WWW - Irctc.co - in Eticketing PrintTicketChaitanya M MundheNo ratings yet

- 5 Polysiloxane Coatings PublicDocument24 pages5 Polysiloxane Coatings PublicChaitanya M MundheNo ratings yet

- TT For Nikhil ShiwaleDocument1 pageTT For Nikhil ShiwaleChaitanya M MundheNo ratings yet

- Unitex Artikel CO2 Dyeing PDFDocument7 pagesUnitex Artikel CO2 Dyeing PDFChaitanya M MundheNo ratings yet

- Ipa Directory (2011 12) (West)Document14 pagesIpa Directory (2011 12) (West)saurs2No ratings yet

- Textile Research Association: Nnual EportDocument7 pagesTextile Research Association: Nnual EportChaitanya M MundheNo ratings yet

- PhpoDocument15 pagesPhpomohitdhingra42No ratings yet

- TE Preferred Fiber Market Report Oct2016 1 PDFDocument56 pagesTE Preferred Fiber Market Report Oct2016 1 PDFChaitanya M MundheNo ratings yet

- Global Supply Chain Summit Brochure-2018Document4 pagesGlobal Supply Chain Summit Brochure-2018Chaitanya M MundheNo ratings yet

- Silane Modified Epoxy ResinsDocument2 pagesSilane Modified Epoxy ResinsChaitanya M Mundhe100% (1)

- Convert Chest Freezer Into A FridgeDocument6 pagesConvert Chest Freezer Into A FridgeelurrakkeroNo ratings yet

- Zida Tomato EX98Document50 pagesZida Tomato EX98EstebanNo ratings yet

- Toward Single Lane 200G Optical Interconnects With Silicon Photonic ModulatorDocument8 pagesToward Single Lane 200G Optical Interconnects With Silicon Photonic ModulatorRaad Sami FyathNo ratings yet

- EV Motors & DriversDocument10 pagesEV Motors & DriversSasindu GayanthaNo ratings yet

- Master Your DSLRDocument29 pagesMaster Your DSLRDarren W. J. Wen100% (3)

- 0625 s07 Ms 3Document7 pages0625 s07 Ms 3Hubbak Khan50% (2)

- The Dell Vostro 1510Document3 pagesThe Dell Vostro 1510vthungNo ratings yet

- QSB33 CM2150 Wiring DiagramDocument2 pagesQSB33 CM2150 Wiring Diagramibrahem100% (2)

- ICT Formatif Exam PapersDocument6 pagesICT Formatif Exam PapersVivasheenie Ramasamy100% (1)

- PSX On PSP Compatibility ListDocument137 pagesPSX On PSP Compatibility Listagi_nopriansyah_22_60% (1)

- Current and Voltage Controls Current Transformer, 1-Phase AC Type TAD 2, TAD 3Document2 pagesCurrent and Voltage Controls Current Transformer, 1-Phase AC Type TAD 2, TAD 3Naeem MemonNo ratings yet

- C Programming and Assembly Language: InstructionsDocument4 pagesC Programming and Assembly Language: InstructionsMohan DalibaniNo ratings yet

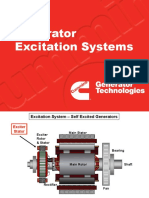

- Npt56 Excitation SystemsDocument13 pagesNpt56 Excitation Systemsengmohsen.ramadanhotmail.comNo ratings yet

- Cook Book Absorção Atômica PDFDocument138 pagesCook Book Absorção Atômica PDFJorgejgNo ratings yet

- 2) General Manual LRP210Document192 pages2) General Manual LRP210Andrei Horhoianu100% (1)

- Prepaid Meter Testing Stds. PM - IS-15884Document8 pagesPrepaid Meter Testing Stds. PM - IS-15884Boson FreelancerNo ratings yet

- Servomax Corporate ProfileDocument81 pagesServomax Corporate ProfileUdayNo ratings yet

- M9220HGA3Document9 pagesM9220HGA3Greg MartinNo ratings yet

- MTX 3g Java ManualDocument109 pagesMTX 3g Java ManualEdson ArandiaNo ratings yet

- Basic Electrical June 2012 NewDocument4 pagesBasic Electrical June 2012 NewPrasad C MNo ratings yet

- Kenwood Kca r71fm SMDocument18 pagesKenwood Kca r71fm SMrobotherNo ratings yet

- DESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemDocument7 pagesDESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemjayxcellNo ratings yet

- Handheld Vacuum Cleaner SAS 7.2 A1: Kompernass GMBH Burgstrasse 21 D-44867 Bochum ID-Nr.: SAS7.2A1-09/10-V1 IAN: 58810Document9 pagesHandheld Vacuum Cleaner SAS 7.2 A1: Kompernass GMBH Burgstrasse 21 D-44867 Bochum ID-Nr.: SAS7.2A1-09/10-V1 IAN: 58810Gabriel SetnicNo ratings yet

- AVM 104-114-105-115S - Actuators With Sauter Universal Technology (SUT)Document7 pagesAVM 104-114-105-115S - Actuators With Sauter Universal Technology (SUT)Setya AgusNo ratings yet

- N2xy PDFDocument5 pagesN2xy PDFArnold StevenNo ratings yet

- KA1M0565R/KA1H0565R: Fairchild Power Switch (FPS)Document10 pagesKA1M0565R/KA1H0565R: Fairchild Power Switch (FPS)Guilherme Ribeiro BarbosaNo ratings yet

- Kurtyna CEDESDocument48 pagesKurtyna CEDESLIFT-POLNo ratings yet