Professional Documents

Culture Documents

Flo Fusion 4000 SLSH

Flo Fusion 4000 SLSH

Uploaded by

Agustin HaddadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flo Fusion 4000 SLSH

Flo Fusion 4000 SLSH

Uploaded by

Agustin HaddadCopyright:

Available Formats

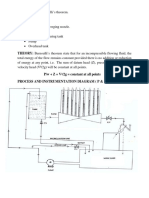

FLO FUSION 4000

Pipeline Booster

Increase pipeline throughput and

reduce frictional pressure loss

Applications Application

• Crude oil barrel of fluid treated [0.378 to 3.78 L per

Baker Hughes, a GE company (BHGE) offers

the FLOTM FUSION 4000 pipeline booster 158 m3]). The treatment level is dependent

to help reduce frictional pressure loss and upon throughput requirements, fluid

Features and benefits increase throughput in crude oil pipelines properties, and pipeline hydraulics.

• Organic based

that are restricted by pump capacity or

–– Mild odor

operating pressure limits. The pipeline

• Higher maximum achievable drag

booster is an organic, carrier-based, slurry

Safety and handling

reduction Before handling, storage or use, review the

drag reducer that is nonflammable

–– Increases pipeline throughput at the Safety Data Sheet (SDS) for guidance.

and non-aqueous.

same operating pressure

–– Reduces pipeline pressure while It features a fast-dissolving, ultrahigh

maintaining flow rate molecular weight copolymer that allows

Typical properties

–– Enables shutdown of intermediate the additive to deliver a high level of drag

pump stations reduction. It dissolves in hydrocarbon fluid Appearance Beige slurry

• Rapid dissolution and maintains robust performance in the

Specific gravity

–– Provides maximum drag reduction pipeline. The active polymer does not coat ~0.87

at 60°F (15.6°C)

benefits in the pipelines treated the pipeline wall and does not adversely

• High activity affect the hydrocarbon fluids being treated. Typical density ~7.36 lbm/US gal

–– Minimizes product consumption and However, it will shear degrade to lower at 60°F (15.5°C) (866.76 kg/m3)

handling molecular weight after passing through

mainline pumps or other regions of Flash Point >155°F (>68°C)

• Handling

–– Provides free-flowing, liquid-like high shear. Freezing Point < -40°F (-40°C)

handling down to -22°F (-30°C) FLO FUSION 4000 pipeline booster is

Boiling Point 336°F (169°C)

–– Good-temperature stability pumped into the pipeline using an injection

–– Does not need a temperature- module consisting of a high-pressure, Viscosity

controlled environment 2600 cP

adjustable rate pump, a flow meter, and at 77°F (25°C)

–– Can be stored outside preferably in other instrumentation. This additive is

covered area out of direct sunlight Vapor Pressure

injected downstream of mainline pumps at 0.14 mmHg (20°C)

at 77°F (25°C)

a typical treatment level of 2 ppm to 20 ppm

(approximately 0.1 to 1.0 gal per 1,000

bhge.com

© 2017 Baker Hughes, a GE company, LLC – All rights reserved.

Baker Hughes, a GE company, LLC and its affiliates (“BHGE”) provides this information on an “as is” basis for general information purposes

and believes it to be accurate as of the date of publication. BHGE does not make any representation as to the accuracy or completeness of

the information and makes no warranties of any kind, specific, implied or oral, to the fullest extent permissible by law, including those of

merchantability and fitness for a particular purpose or use. BHGE hereby disclaims any and all liability for any direct, indirect, consequential

or special damages, claims for lost profits, or third party claims arising from the use of the information, whether a claim is asserted in

contract, tort, or otherwise. The BHGE logo is a trademark of Baker Hughes, a GE company, LLC. GE and the GE monogram are trademarks of

General Electric Company used under trademark license. FLO is a trademark of Baker Hughes, a GE company, LLC.

77485

You might also like

- CET 1 GavhaneDocument609 pagesCET 1 Gavhaneraj kumar86% (7)

- Tetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsDocument2 pagesTetra Pak Homogenizer 300: Homogenizer or High Pressure Pump For Liquid Food ApplicationsFátima RomeroNo ratings yet

- Gear Pump PGP511Document11 pagesGear Pump PGP511Ayman AlhalfawyNo ratings yet

- M 110yDocument2 pagesM 110yjawadNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Tetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsDocument2 pagesTetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsThinura SamarawickramaNo ratings yet

- Relief Valve 5k 6-015-1Document2 pagesRelief Valve 5k 6-015-1francis_15inNo ratings yet

- High Pressure Full Flow Bi-Directional FilterDocument7 pagesHigh Pressure Full Flow Bi-Directional FilterOscar NavarroNo ratings yet

- For Crude Oil: BackgroundDocument2 pagesFor Crude Oil: BackgroundQaiser HafeezNo ratings yet

- LBI 60 HZDocument12 pagesLBI 60 HZPayal Umesh BarotNo ratings yet

- Liquid Ring CompressorsDocument6 pagesLiquid Ring Compressorsmember1000No ratings yet

- Cosmolubric HF-122 Data SheetDocument1 pageCosmolubric HF-122 Data Sheetsiddharth srinivasanNo ratings yet

- Engineering: GREAT SolutionsDocument4 pagesEngineering: GREAT SolutionsLaura ParkaNo ratings yet

- Releif Valve 3k 6-010-1Document2 pagesReleif Valve 3k 6-010-1francis_15inNo ratings yet

- S75-S76 Low Pressure Spin-Ons: Featuring Hy-Pro G8 Dualglass High Performance Filter Element TechnologyDocument4 pagesS75-S76 Low Pressure Spin-Ons: Featuring Hy-Pro G8 Dualglass High Performance Filter Element TechnologyJOHNNo ratings yet

- Adjunct b PdsDocument2 pagesAdjunct b Pdserwinalfonso15No ratings yet

- Filtr Ciśnieniowy ARGO HYTOS HD049 - HD069 - 40.45 - EN - US Karta KatalogowaDocument7 pagesFiltr Ciśnieniowy ARGO HYTOS HD049 - HD069 - 40.45 - EN - US Karta Katalogowatomasz.palaszNo ratings yet

- LSV1 4-260-1 PDFDocument2 pagesLSV1 4-260-1 PDFfrancis_15inNo ratings yet

- Air Conditioning - Scroll Compressor - Global - 20240401 - Split HighDocument20 pagesAir Conditioning - Scroll Compressor - Global - 20240401 - Split Highmr. dossNo ratings yet

- LP111Document2 pagesLP111Joann HowardNo ratings yet

- HF 745 / HF 748 Series: in Line High Pressure FiltersDocument24 pagesHF 745 / HF 748 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- Fuchs - Aquacent LT 68 & LT 100 - Apr08 (UK)Document3 pagesFuchs - Aquacent LT 68 & LT 100 - Apr08 (UK)RiyazNo ratings yet

- RV56-26 Relief, Pilot-Operated, High PressureDocument2 pagesRV56-26 Relief, Pilot-Operated, High PressurecaiNo ratings yet

- BW30HR-440i - MembranaDocument2 pagesBW30HR-440i - Membranaclaudia gonzalesNo ratings yet

- Argo-hyto-filtration-HD040 HD081 HD150 40.05 EN US PDFDocument4 pagesArgo-hyto-filtration-HD040 HD081 HD150 40.05 EN US PDFhydrola 2021No ratings yet

- Interface Value GradesDocument16 pagesInterface Value Gradesvagner boldiNo ratings yet

- DOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsDocument4 pagesDOWSIL™ 744 RTV Adhesive Sealant: Features & BenefitsSami LAHMIDINo ratings yet

- Ion LXZ DsDocument2 pagesIon LXZ Dsmahdi rasoulianNo ratings yet

- Gsov25 HT: ApplicationsDocument4 pagesGsov25 HT: ApplicationsRICARDO ALEXIS LARA GALLEGO STORKNo ratings yet

- HF 735 Series: in Line High Pressure FiltersDocument20 pagesHF 735 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- HE360A Powered Flow-Through Humidifier: FeaturesDocument8 pagesHE360A Powered Flow-Through Humidifier: FeaturesLim TiNo ratings yet

- Advance Plus 1680Document1 pageAdvance Plus 1680Ari WijayaNo ratings yet

- Specifications - ACS 6000 Centrifuge GlacierDocument2 pagesSpecifications - ACS 6000 Centrifuge GlacierzzapiNo ratings yet

- Compressor 27 de OutubroDocument16 pagesCompressor 27 de OutubroOtavio leite pereiraNo ratings yet

- Up-Stream Pumping - Presentation1Document46 pagesUp-Stream Pumping - Presentation1Chozha RajanNo ratings yet

- Hsro 390 FFDocument3 pagesHsro 390 FFAlejandro OdioNo ratings yet

- Ispe Nordic Cop Clean UtilitiesDocument28 pagesIspe Nordic Cop Clean UtilitiesBulent InanNo ratings yet

- AC Compressor 202006 PDFDocument16 pagesAC Compressor 202006 PDFSenthil KumarNo ratings yet

- HF 525 Series: Tank Mounted Return and Suction Line FiltersDocument16 pagesHF 525 Series: Tank Mounted Return and Suction Line FilterssitnikovsNo ratings yet

- HPK03Document4 pagesHPK03Tan CkNo ratings yet

- Admix Datasheet RotosolverDocument2 pagesAdmix Datasheet RotosolverYusuf DabhiyaNo ratings yet

- Pds Halalube FCM 2 PLUS Grease v2019Document1 pagePds Halalube FCM 2 PLUS Grease v2019chandraNo ratings yet

- GuardianDocument8 pagesGuardianAbimael GarayNo ratings yet

- HF 760 - HF 761 Series: in Line High Pressure FiltersDocument28 pagesHF 760 - HF 761 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- PFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateDocument8 pagesPFH High Pressure In-Line Filter: 615 Bar, 8700 Psi Operating Pressure 450 LPM, 120 GPM Max Flow RateOscar NavarroNo ratings yet

- Scheda - Tecnica - DG PED-ITDocument4 pagesScheda - Tecnica - DG PED-ITArgenis VeraNo ratings yet

- HiTEC-580 PDSDocument2 pagesHiTEC-580 PDSTouqeer NasirNo ratings yet

- 1HSH20 SDocument2 pages1HSH20 SIslam ElhabsheNo ratings yet

- High Shear MixersDocument6 pagesHigh Shear Mixershaniif prasetiawanNo ratings yet

- HD 319 HD 419 HD 619: High Pressure Filters - Worldline 300Document8 pagesHD 319 HD 419 HD 619: High Pressure Filters - Worldline 300pavankumarNo ratings yet

- Roto Jet Model 2100 Spec SheetDocument2 pagesRoto Jet Model 2100 Spec SheetHenry Garavito RamirezNo ratings yet

- Tetra Pak High Shear Mixer R200-200Document2 pagesTetra Pak High Shear Mixer R200-200Mưa Bóng MâyNo ratings yet

- Dvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom YazykeDocument6 pagesDvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom Yazykedindin6666No ratings yet

- Centrifuges BrochureDocument16 pagesCentrifuges BrochureVideoKesitNo ratings yet

- Hypro Housing Fa-Mf3Document4 pagesHypro Housing Fa-Mf3Roberto Torres ArancibiaNo ratings yet

- 5718bf9c96b271461239708mto23 Presentation EM Gargoyle SHC 80 POE PDFDocument58 pages5718bf9c96b271461239708mto23 Presentation EM Gargoyle SHC 80 POE PDFChristian CotteNo ratings yet

- Carbothane 134 HB: Selection & Specification DataDocument4 pagesCarbothane 134 HB: Selection & Specification DataAyman JadNo ratings yet

- Ficha Tecnica HYDRON BW-8040Document1 pageFicha Tecnica HYDRON BW-8040Daniel HernándezNo ratings yet

- Performance SheetDocument2 pagesPerformance Sheetrake1981No ratings yet

- G77x - 77xK Valve - CatalogueDocument8 pagesG77x - 77xK Valve - CatalogueEzgi PelitNo ratings yet

- Redox PhotobleachingDocument5 pagesRedox PhotobleachingKapil BambardekarNo ratings yet

- ww21b Y-HedbergDocument10 pagesww21b Y-HedbergKARLNo ratings yet

- PSC Unit (2) - NoRestrictionDocument3 pagesPSC Unit (2) - NoRestrictionAbinayaHemaRajNo ratings yet

- Energetics (Chem For CSEC p248)Document2 pagesEnergetics (Chem For CSEC p248)Laurie-Ann 大丽花 Edwards-MurdockNo ratings yet

- Open Channel DesignDocument46 pagesOpen Channel DesignVijayakumar ChandrasekaranNo ratings yet

- Experiment-5 Biot-SavartsnnnDocument8 pagesExperiment-5 Biot-SavartsnnnORIANA MELISSA CALVO CARRILLONo ratings yet

- Millikan Oil Drop ExperimentDocument6 pagesMillikan Oil Drop ExperimentruleevanNo ratings yet

- The Harmonic Oscillator With Modified DampingDocument5 pagesThe Harmonic Oscillator With Modified Dampingtanha56313955No ratings yet

- Packager Guide: Dedicated To Gas Compression Products & ApplicationsDocument4 pagesPackager Guide: Dedicated To Gas Compression Products & ApplicationsVladimirNo ratings yet

- Barden Bearing Failures Us enDocument31 pagesBarden Bearing Failures Us encakendriNo ratings yet

- JJ 615 Mechanical Components & MaintenanceDocument36 pagesJJ 615 Mechanical Components & Maintenancedaussz60% (5)

- Group1 - A4Conductors and InsulatorsDocument5 pagesGroup1 - A4Conductors and InsulatorsLance CadiangNo ratings yet

- Materi Perpindahan Kalor - BAB 3Document32 pagesMateri Perpindahan Kalor - BAB 3winandaNo ratings yet

- GNL3Z PJ Piping InspectionDocument29 pagesGNL3Z PJ Piping Inspectiondon_romanticko281236No ratings yet

- Drymax Dryers WittmannDocument12 pagesDrymax Dryers WittmannFlorin TarziuNo ratings yet

- Quantum Vampire: Collapse-Free Action at A Distance by The Photon Annihilation OperatorDocument4 pagesQuantum Vampire: Collapse-Free Action at A Distance by The Photon Annihilation Operatorsad100% (1)

- Tutorials For Holistic ExamDocument40 pagesTutorials For Holistic ExamRefisa JiruNo ratings yet

- Materials Characterization: Lab ReportDocument9 pagesMaterials Characterization: Lab ReportGM MalikNo ratings yet

- Chapter 4 - Chemical KineticsDocument7 pagesChapter 4 - Chemical KineticsMADHAVNo ratings yet

- Stone Three Portable Pulp Sensor (Bubble Sizer) Product BrochureDocument1 pageStone Three Portable Pulp Sensor (Bubble Sizer) Product BrochureRafaelNo ratings yet

- Baseplate 4 Bolts For PoleDocument5 pagesBaseplate 4 Bolts For PoleAlma M. LaraNo ratings yet

- FRP Paper PDFDocument6 pagesFRP Paper PDFRikson TandelilinNo ratings yet

- Fatigue Lifetime Prediction For Oil Tube Material Based On Abaqus and Fe-SafeDocument8 pagesFatigue Lifetime Prediction For Oil Tube Material Based On Abaqus and Fe-Safenferreira_245024No ratings yet

- Study Unit 2 First Law BBDocument47 pagesStudy Unit 2 First Law BBLutendo Assurance MadzivhaaNo ratings yet

- Lecture Notes 9.2Document15 pagesLecture Notes 9.2Yip Tuck WaiNo ratings yet

- BERNOULLIS THEOREM PracticalDocument4 pagesBERNOULLIS THEOREM PracticalMandeep PathakNo ratings yet

- Flange Leakage Check by Code Case method-PASSDocument9 pagesFlange Leakage Check by Code Case method-PASSJafer SayedNo ratings yet

- Huckel Molecular Orbital TheoryDocument4 pagesHuckel Molecular Orbital TheoryVijetha AchNo ratings yet

- Optical Kerr Effect NotesDocument9 pagesOptical Kerr Effect NotesNivethaNo ratings yet