Professional Documents

Culture Documents

Darria Carter Resume 2

Darria Carter Resume 2

Uploaded by

api-444711411Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Darria Carter Resume 2

Darria Carter Resume 2

Uploaded by

api-444711411Copyright:

Available Formats

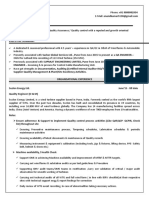

Darria M.

Carter

linkedin.com/in/darriacarter

Phone: 504-909-1441 Email: dcart24@lsu.edu

Profile

A hard-working individual with experience in automotive quality and manufacturing. Completed 3 internships with a tier 1

supplier and an original equipment manufacturer (OEM).

Education

Louisiana State University (LSU) —Baton Rouge, Louisiana

Bachelor of Science in Mechanical Engineering Graduation: May 2019

Minor: Chemistry

Work Experience

Mercedes-Benz Vans, LLC, (Charleston, SC) May 2018-August 2018

Quality Manufacturing Intern

Performed data analysis on 140 vehicles to prevent over 170 defects from reoccurring via process audits and root cause

analyses

Created a process flow outline for the quality manufacturing problem solving process to be used by 2500 employees

Facilitated daily meetings with Quality Coordinator, Process Auditors, and Group Leaders to address defects found in

Customer Product Audits (CPA)

Improved CPA checklist for experienced Quality Auditors to ensure product defects are detected during auditing process,

increasing accuracy of audits by 10%

Röchling Automotive USA LLP, (Troy, MI/Duncan, SC/Laives, IT) June-August 2016/May-August 2017

Failure Modes and Effects Analysis (FMEA) Intern

FMEA

Facilitated a global FMEA meeting in Laives, Italy to develop FMEA Quality Management System (QMS) including 12

work instructions, 10 design and process FMEA templates, and design and process FMEA guidelines

Provided technical input during cross-functional meetings with 15 Design and Quality Engineers for risk analysis

Enforced proper assignment of Risk Priority Numbers (RPN) and suggested preventive and detection actions for BMW

underbody panel and Ford/Honda Active Grille Shutter (AGS) programs

Trained 4 Industrial Engineers in Machinery FMEA to implement on AGS programs

Administered FMEA Survey to Quality Auditors, Process Technicians, and Operators to benchmark a revised FMEA

knowledge base

Quality Engineering

Analyzed Quality Notification (QN), Quick Response Quality Control (QRQC), and warranty data through traveling to

Röchling manufacturing plants in Akron, OH and Duncan, SC

Created an operator work instruction for Daimler halter assembly and gage instruction for Daimler selective catalytic

reduction (SCR) tank

Performed capability studies on 600 Daimler air duct components and updated balloon drawing

Conducted quality inspection on Daimler air ducts to verify product hardware and actuator software

Performed gage R&R study on 10 Tesla wheel arch liners

Materials Engineering

Created test samples of talc reinforced polypropylene to be used for tensile, impact, and ash tests to improve material

characteristics of components produced at Röchling

Performed water absorption, chemical resistance, and tensile tests on light weight reinforced thermoplastic (LWRT)

material to verify material characteristics

Leadership

National Society of Black Engineers (NSBE) Chapter Treasurer & Conference Planning Chair, Engineering Diversity

Ambassador

Specialty Coursework

Internal Combustion Engines, Introduction to Combustion, Corrosion Science & Engineering, Advanced Materials Analysis,

Kinetics in Materials Processes, Deformation & Fracture Mechanics

You might also like

- Meta M357Tv2 FittingDocument3 pagesMeta M357Tv2 Fittings12original100% (4)

- Michael Zhiguo Shen: Troy, MIDocument2 pagesMichael Zhiguo Shen: Troy, MIShiraz KhanNo ratings yet

- Chinese ATS YsuyangDocument16 pagesChinese ATS YsuyangLeo Burns100% (8)

- Remove Malware - Free: Quick Malware Removal in 2 Minutes. Free Download (Highly Recommended)Document9 pagesRemove Malware - Free: Quick Malware Removal in 2 Minutes. Free Download (Highly Recommended)Mainak SasmalNo ratings yet

- TX RVR Tex 300 LCDDocument30 pagesTX RVR Tex 300 LCDJose Magui Maita100% (1)

- Amerta Roopani ResumeDocument2 pagesAmerta Roopani ResumeIccar ConstructionNo ratings yet

- Tushar Padave Resume - 0912Document4 pagesTushar Padave Resume - 0912tusharpadaveNo ratings yet

- Sample ResumesDocument3 pagesSample ResumesinboxsweetsNo ratings yet

- Quality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanDocument4 pagesQuality Manager Senior Engineer in Los Angeles CA Resume Joannes HsueanJoannesHuseanNo ratings yet

- Shubailat - Omar - Quality and MBA Leadership Resume (June 09)Document3 pagesShubailat - Omar - Quality and MBA Leadership Resume (June 09)Omar ShubailatNo ratings yet

- Resume Supplier Quality Engineer 3 Yrs Exp Auto OEM Vinoth KumarDocument2 pagesResume Supplier Quality Engineer 3 Yrs Exp Auto OEM Vinoth KumarVinothKumarDhananjayanNo ratings yet

- CV - Deepankar - SharmaDocument3 pagesCV - Deepankar - SharmaGargi PantNo ratings yet

- Consultant Auditor ProfileDocument2 pagesConsultant Auditor ProfileAnonymous qRbPsLpuNNo ratings yet

- HughStaton 3PDocument3 pagesHughStaton 3PManas RanjanNo ratings yet

- V G Barani: E-MailDocument4 pagesV G Barani: E-MailMagesh ChanderNo ratings yet

- Resume - Myller de Sousa LimaDocument1 pageResume - Myller de Sousa LimaLeonel MiguelNo ratings yet

- Quality Assurance Engineer Production in Frederick MD Resume Terry StineDocument2 pagesQuality Assurance Engineer Production in Frederick MD Resume Terry StineTerryStineNo ratings yet

- Senior Quality Engineer in Houston TX Resume Frank MedranoDocument2 pagesSenior Quality Engineer in Houston TX Resume Frank MedranoFrankMedranoNo ratings yet

- Abdurrahman M Syed: Professional SummaryDocument3 pagesAbdurrahman M Syed: Professional SummaryRamesh AmuluruNo ratings yet

- Curriculam Vitae BXXXXX.RDocument3 pagesCurriculam Vitae BXXXXX.Rsun_sunilNo ratings yet

- Akhil Maurya: An Enthusiastic & Energy-Driven Professional Pursuing Entry-Level Assignment As ProductionDocument2 pagesAkhil Maurya: An Enthusiastic & Energy-Driven Professional Pursuing Entry-Level Assignment As ProductionAkhil MauryaNo ratings yet

- Project Engineering Manager in Dayton OH Resume Rick PelfreyDocument2 pagesProject Engineering Manager in Dayton OH Resume Rick PelfreyRickPelfreyNo ratings yet

- Director Manufacturing Supply Chain Quality in Roanoke VA Resume Laurence GilDocument2 pagesDirector Manufacturing Supply Chain Quality in Roanoke VA Resume Laurence GilLaurenceGilNo ratings yet

- Mechanical Engineer: Mukesh Kumar NagarDocument4 pagesMechanical Engineer: Mukesh Kumar NagarMukesh NagarNo ratings yet

- Navneet (3 0)Document2 pagesNavneet (3 0)BaljeetNo ratings yet

- Business Analyst Project Manager in Denver CO Resume Cheryl PalmerDocument2 pagesBusiness Analyst Project Manager in Denver CO Resume Cheryl PalmerCherylPalmerNo ratings yet

- Bluem Resume Spring17Document1 pageBluem Resume Spring17api-338394754No ratings yet

- Chaitanya321 - Engg@yahoo - Co.in: (Mechanical Engineering)Document6 pagesChaitanya321 - Engg@yahoo - Co.in: (Mechanical Engineering)Hudson George ThomasNo ratings yet

- NIKHILbhadane ResumdDocument2 pagesNIKHILbhadane Resumdaishwaryawrites7No ratings yet

- Manufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczDocument2 pagesManufacturing Quality Process Engineer in Boston MA Resume Joseph MarkowiczJosephMarkowiczNo ratings yet

- Senior Statistician Data Scientist in Dallas FT Worth TX Resume Brian GilsonDocument3 pagesSenior Statistician Data Scientist in Dallas FT Worth TX Resume Brian GilsonBrianGilsonNo ratings yet

- Machining OperatorDocument4 pagesMachining OperatorSwapnil SawantNo ratings yet

- Minor Project (Research Report)Document50 pagesMinor Project (Research Report)Atul DahiyaNo ratings yet

- Michael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Document3 pagesMichael D. Inskeep: 2280 Indian Creek Trails Hamilton, Ohio 45013 513.893.2689Jeremy WilliamsNo ratings yet

- Director VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuDocument3 pagesDirector VP Quality Manufacturing in Los Angeles CA Resume Thomas ZhuThomasZhu2No ratings yet

- Director Product Development Engineering in Detroit MI Resume Brian ThompsonDocument2 pagesDirector Product Development Engineering in Detroit MI Resume Brian ThompsonBrianThompson2No ratings yet

- Resume 2Document2 pagesResume 2anvitistiwariNo ratings yet

- ATS Resume Template PDFDocument1 pageATS Resume Template PDFVamsi ManojNo ratings yet

- Morrison ResumeDocument1 pageMorrison Resumeapi-306413976No ratings yet

- Mechanical Engineer ResumeDocument1 pageMechanical Engineer ResumeDarwin M SalazarNo ratings yet

- Ample Esume: BjectiveDocument1 pageAmple Esume: BjectiveJoy JohnNo ratings yet

- Failure Mode and Effective AnalysisDocument197 pagesFailure Mode and Effective AnalysisHarsha MPNo ratings yet

- Steven F. Thorn: 1800 Preserve Avenue West #1836 Port Royal, SC 29935 Cell# (803) 387-2855Document3 pagesSteven F. Thorn: 1800 Preserve Avenue West #1836 Port Royal, SC 29935 Cell# (803) 387-2855Steve ThornNo ratings yet

- MD Shahnewaz: Manufacturing EngineerDocument4 pagesMD Shahnewaz: Manufacturing Engineerkiran2710No ratings yet

- Juan Fadrique Molina Naranjo RESUME Rev9Document6 pagesJuan Fadrique Molina Naranjo RESUME Rev9juan molinaNo ratings yet

- SandeepDubey (2,4)Document5 pagesSandeepDubey (2,4)ujwalbabarNo ratings yet

- SA - Resume - SAP GRC Consultant - 10 - 2015Document3 pagesSA - Resume - SAP GRC Consultant - 10 - 2015spicychaituNo ratings yet

- G.Dinakaran-Quality Assurance ManagerDocument4 pagesG.Dinakaran-Quality Assurance ManagerSoundhara Pandian SamuvelNo ratings yet

- Production Line Resume SampleDocument2 pagesProduction Line Resume SampleadityadhimanNo ratings yet

- Sandipkumar Arjun ShindeDocument3 pagesSandipkumar Arjun ShindeAditya NaikNo ratings yet

- Mechanical Engineering Student: EducationDocument1 pageMechanical Engineering Student: EducationChandra SinghNo ratings yet

- Tarhe J OsiebeDocument3 pagesTarhe J Osiebezakir itrecruitNo ratings yet

- Sample Resume Process Engineer Economic RecoveryDocument10 pagesSample Resume Process Engineer Economic RecoveryVijay RajaindranNo ratings yet

- Bilal Ahsan: Career ObjectiveDocument3 pagesBilal Ahsan: Career ObjectiveGohar IslamNo ratings yet

- Mechanical Engineer CV Template, Engineering Jobs, Machinery, Quality Assurance, AutocadDocument3 pagesMechanical Engineer CV Template, Engineering Jobs, Machinery, Quality Assurance, AutocadaashroffNo ratings yet

- Ass Dev Eng PWRTRN NavistarDocument3 pagesAss Dev Eng PWRTRN NavistarMike CurranNo ratings yet

- CV-Jose George Alex-EngineeringDocument2 pagesCV-Jose George Alex-EngineeringAnilkumar GNo ratings yet

- Jessica Shorter ResumeDocument1 pageJessica Shorter Resumeapi-417149000No ratings yet

- Career Objective: Page 1 of 6Document6 pagesCareer Objective: Page 1 of 6Vasudevan GovindarajNo ratings yet

- Curriculam Vitae Bharath.RDocument3 pagesCurriculam Vitae Bharath.Rsun_sunilNo ratings yet

- Anand Kumar ResumeDocument3 pagesAnand Kumar ResumeArun ShishodiaNo ratings yet

- Gautam C.V.Document4 pagesGautam C.V.Gautam GuptaNo ratings yet

- GLADIS User Guide May2023Document7 pagesGLADIS User Guide May2023D ardikaNo ratings yet

- Seminar TopicDocument36 pagesSeminar TopicNarasing ManeNo ratings yet

- Microwave Test Bench ComponentsDocument6 pagesMicrowave Test Bench ComponentsRam Singh0% (1)

- Tle Css 9 Las 2nd Quarter 1Document87 pagesTle Css 9 Las 2nd Quarter 1Sheryl UncianoNo ratings yet

- Manipulating Routing Updates: CCNP ROUTE: Implementing IP RoutingDocument104 pagesManipulating Routing Updates: CCNP ROUTE: Implementing IP RoutingAlejandro Cordero OrdoñezNo ratings yet

- Achieveing Superior EfficiencyDocument32 pagesAchieveing Superior Efficiencyrahul krishnaNo ratings yet

- AERO Q307 Article4Document6 pagesAERO Q307 Article4AhmddhbNo ratings yet

- VW NBD Tiguan Allspace R Line Service Pricing GuideDocument1 pageVW NBD Tiguan Allspace R Line Service Pricing GuideNizamNo ratings yet

- Marketing Research Proposal For VERTUDocument16 pagesMarketing Research Proposal For VERTUMikail GasanovNo ratings yet

- Quick Configuration Guide For The ILM Store: Version For SAP IQDocument20 pagesQuick Configuration Guide For The ILM Store: Version For SAP IQandresNo ratings yet

- 11 Secret Meanings Behind Punctuation in Text Messages WIRED-1Document6 pages11 Secret Meanings Behind Punctuation in Text Messages WIRED-1RMNo ratings yet

- C Programming Bit Bank U-1, U-2Document17 pagesC Programming Bit Bank U-1, U-2HariahNo ratings yet

- Common Business Analyst Interview Questions PDFDocument4 pagesCommon Business Analyst Interview Questions PDFAnurag MalhotraNo ratings yet

- 5-CRC CardsDocument18 pages5-CRC Cardsyordy Jeremías matos volquezNo ratings yet

- Bash Shell ScriptingDocument5 pagesBash Shell ScriptingSevenMentorNo ratings yet

- The Hydraulic Machinery of Obervermuntwerk IIDocument8 pagesThe Hydraulic Machinery of Obervermuntwerk IIPeter MeusburgerNo ratings yet

- DCRP Apprd Solar Installer List Jan-2024Document10 pagesDCRP Apprd Solar Installer List Jan-2024Muthukumaran TNo ratings yet

- NOJA-520-05 SCADA Interface DescriptionDocument24 pagesNOJA-520-05 SCADA Interface Descriptionpatricio2015No ratings yet

- Synergy (Company Profile)Document16 pagesSynergy (Company Profile)fairmaytechnicalNo ratings yet

- Smart ParkingDocument9 pagesSmart ParkingSandeep DhimanNo ratings yet

- SW3205 Samwin: FeaturesDocument7 pagesSW3205 Samwin: FeaturesYousef KassimNo ratings yet

- Course Design in CssDocument15 pagesCourse Design in CssTonypet PaclebNo ratings yet

- 4.2.2.5 Common Problems and Solutions For CPUs and MemoryDocument2 pages4.2.2.5 Common Problems and Solutions For CPUs and MemoryBuuh SA100% (2)

- SPAD346Document178 pagesSPAD346ysohail78No ratings yet

- Technical Manual For Float Cum Boost Battery Charger (S1A02)Document8 pagesTechnical Manual For Float Cum Boost Battery Charger (S1A02)DEEPAKNo ratings yet

- AKTA+Process Operating+InstructionsDocument180 pagesAKTA+Process Operating+InstructionsCarlos Alberto Ramirez GarciaNo ratings yet