Professional Documents

Culture Documents

Nema TC9

Nema TC9

Uploaded by

Tomsy ThomasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nema TC9

Nema TC9

Uploaded by

Tomsy ThomasCopyright:

Available Formats

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

NEMA TC 9

FITTINGS FOR

POLYVINYL CHLORIDE

(PVC) PLASTIC

UTILITIES DUCT FOR

UNDERGROUND

INSTALLATION

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

NEMA Standards Publication TC 9-2004

Fittings for Polyvinyl Chloride (PVC) Plastic Utilities Duct for Underground Installation

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Published by:

National Electrical Manufacturers Association

1300 North 17th Street, Suite 1847

Rosslyn, Virginia 22209

www.nema.org

© Copyright 2004 by the National Electrical Manufacturers Association. All rights including translation into

other languages, reserved under the Universal Copyright Convention, the Berne Convention for the

Protection of Literary and Artistic Works, and the International and Pan American Copyright Conventions.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

NOTICE AND DISCLAIMER

The information in this publication was considered technically sound by the consensus of persons

engaged in the development and approval of the document at the time it was developed.

Consensus does not necessarily mean that there is unanimous agreement among every person

participating in the development of this document.

The National Electrical Manufacturers Association (NEMA) standards and guideline publications, of

which the document contained herein is one, are developed through a voluntary consensus

standards development process. This process brings together volunteers and/or seeks out the

views of persons who have an interest in the topic covered by this publication. While NEMA

administers the process and establishes rules to promote fairness in the development of

consensus, it does not write the document and it does not independently test, evaluate, or verify

the accuracy or completeness of any information or the soundness of any judgments contained in

its standards and guideline publications.

NEMA disclaims liability for any personal injury, property, or other damages of any nature

whatsoever, whether special, indirect, consequential, or compensatory, directly or indirectly

resulting from the publication, use of, application, or reliance on this document. NEMA disclaims

and makes no guaranty or warranty, expressed or implied, as to the accuracy or completeness of

any information published herein, and disclaims and makes no warranty that the information in this

document will fulfill any of your particular purposes or needs. NEMA does not undertake to

guarantee the performance of any individual manufacturer or seller’s products or services by virtue

of this standard or guide.

In publishing and making this document available, NEMA is not undertaking to render professional

or other services for or on behalf of any person or entity, nor is NEMA undertaking to perform any

duty owed by any person or entity to someone else. Anyone using this document should rely on

his or her own independent judgment or, as appropriate, seek the advice of a competent

professional in determining the exercise of reasonable care in any given circumstances.

Information and other standards on the topic covered by this publication may be available from

other sources, which the user may wish to consult for additional views or information not covered

by this publication.

NEMA has no power, nor does it undertake to police or enforce compliance with the contents of

this document. NEMA does not certify, test, or inspect products, designs, or installations for safety

or health purposes. Any certification or other statement of compliance with any health or safety–

related information in this document shall not be attributable to NEMA and is solely the

responsibility of the certifier or maker of the statement.

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page i

CONTENTS

Page

Foreword ....................................................................................................................................ii

Section 1 GENERAL ................................................................................................................................. 1

1.1 Scope......................................................................................................................................... 1

1.2 Referenced Standards .............................................................................................................. 1

Section 2 DEFINITIONS AND ABBREVIATIONS .................................................................................... 2

2.1 Definitions and Abbreviations.................................................................................................... 2

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Section 3 GENERAL REQUIREMENTS................................................................................................... 3

3.1 Materials .................................................................................................................................... 3

3.2 Trade Sizes ............................................................................................................................... 3

3.3 Dimensions................................................................................................................................ 3

3.4 Workmanship............................................................................................................................. 3

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page ii

Foreword

In the preparation of this Standards Publication, input of users and other interested parties has been

sought and evaluated. Inquiries, comments, and proposed or recommended revisions should be

submitted to the concerned NEMA product Subdivision by contacting the:

Vice President, Engineering

National Electrical Manufacturers Association

1300 North 17th Street

Rosslyn, Virginia 22209

AFC Cable Systems—www.afcweb.com—New Bedford, MA

CANTEX, Inc.—www.cantexinc.com—Mineral Wells, TX

Carlon, Lamson & Sessions—www.carlon.com—Cleveland, OH

Champion Fiberglass, Inc.—www.championfiberglass.com—Spring, TX

FRE Composites Corporation—www.frecomposites.com—St. Andre-d'Argenteuil, PQ, Canada

Heyco Products, Inc.—www.heyco.com—Toms River, NJ

Hubbell Incorporated—www.hubbell.com—Orange, CT

IPEX, Inc.—www.ipexinc.com—Mississauga, ON, Canada

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

J-M Manufacturing Company, Inc.—www.jmpipe.com—Livingston, NJ

Panduit Corporation—www.panduit.com—Tinley Park, IL

Picoma Industries—www.beckmfg.com/aboutpic.com—Waynesboro, PA

Southern Pipe, Inc.—www.southern-pipe.com—New London, NC

Thomas & Betts Corporation—www.tnb.com—Memphis, TN

Underground Devices, Inc.—www.udevices.com—Northbrook, IL

Wiremold Corporation—www.wiremold.com—West Hartford, CT

The members of the working group who contributed to the development of this standard are:

CANTEX, Inc.—www.cantexinc.com—Mineral Wells, TX

Carlon, Lamson & Sessions—www.carlon.com—Cleveland, OH

IPEX, Inc.—www.ipexinc.com—Mississauga, ON, Canada

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 1

Section 1

GENERAL

1.1 SCOPE

This standard defines general requirements including materials, trade sizes, dimensions, and

workmanship for the following types of fittings for PVC plastic utilities duct used for the underground

installation of communication and electrical wire and cable:

a. Type EB – Designed for encased burial in concrete when installed in trenches underground.

b. Type DB - Designed for direct burial in trenched underground without a requirement for

encasement in concrete. Type DB may also be encased in concrete.

NOTE—The values stated in U.S. customary units are to be regarded as the standard.

1.2 REFERENCED STANDARDS

In this publication, reference is made to the following ASTM standards. The latest editions shall be used.

Copies are available from the indicated sources.

American Society for Testing and Materials (ASTM)

100 Barr Harbor Drive

West Conshohocken, PA 19428-2959

www.astm.org

D 883 Standards Terminology Relating to Plastics

D 1600 Standard Terminology for Abbreviated Terms Relating to Plastics

D 2749 Standard Symbols for Dimensions of Plastic Pipe Fittings

D 4396 Standard Specification for Rigid Poly (Vinyl Chloride) (PVC) and Related Plastic

Compounds for Non-Pressure Piping Products

F 412 Standard Terminology Relating to Plastic Piping Systems

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 2

Section 2

DEFINITIONS AND ABBREVIATIONS

2.1 DEFINITIONS AND ABBREVIATIONS

Definitions of terms used in this standard shall be in accordance with ASTM F 412 or ASTM D 883, or

both. Abbreviations shall be in accordance with ASTM D 1660. Dimensional symbols shall be in

accordance with ASTM D 2749, unless otherwise specified.

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 3

Section 3

GENERAL REQUIREMENTS

3.1 MATERIALS

Fittings shall be fabricated from extruded stock or shall be molded. Molded fittings shall be made from a

polyvinyl chloride compound that meets cell classification PVC 11232 as defined in ASTM D 4396.

Extruded stock shall meet the requirements of NEMA Standard TC 6&8, Polyvinyl Chloride (PVC) Plastic

Utilities Duct for Underground Installations.

3.2 TRADE SIZES

The trade sizes (metric designators) of fittings shall be 2, 3, 3-1/2, 4, 5, and 6 in. (53, 78, 91, 103, 129,

and 155) per Table 3-1.

3.3 DIMENSIONS

The dimensions of fittings shall be as shown in Tables 3-2 through 3-16 when measured at the point of

manufacture.

3.4 WORKMANSHIP

Plastic dust fittings shall be homogeneous throughout and free from visible cracks, holes, burrs, foreign

inclusions, or other defects at the point of manufacture.

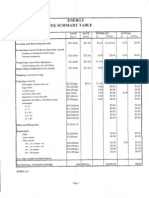

Table 3-1

FITTINGS

Type of Fitting Metric Designators Trade Size

Couplings 53, 78, 91, 103, 129, 155 2, 3, 3-1/2, 4, 5, 6

Caps, plugs

Female and terminal adaptors

End bells

Sweeps and bends, 22°, 30°, 45°, 90°

5-Degree angle couplings 53, 78, 103, 129, 155 2, 3, 4, 5, 6

Adapters to fiber conduit 53, 78, 103 2, 3, 4

Adapters to cement asbestos conduit 53, 78, 103 2, 3, 4

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

No reproduction or networking permitted without license from IHS

Provided by IHS under license with NEMA

Copyright National Electrical Manufacturers Association

TC 9-2004

Page 4

Table 3-2

SOCKETS FOR MOLDED FITTINGS

A B C

Socket Entrance Inside Diameter Socket Bottom Inside Diameter

Out-of- Out-of-

Not for Resale, 04/30/2006 01:20:52 MDT

Licensee=Aramco HQ/9980755100

Metric Roundness Roundness Minimum

Desig- Trade Tolerance On Tolerance on Tolerance Tolerance on Socket

nator Size Average Average Average Average on Average Average Depth

U.S. Customary Units (in.)

53 2 2.393 ±0.006 ±0.012 2.369 ±0.006 ±0.012 1.125

78 3 3.515 ±0.008 ±0.015 3.492 ±0.008 ±0.015 1.594

91 3-1/2 4.015 ±0.008 ±0.050 3.992 ±0.008 ±0.015 1.687

103 4 4.515 ±0.009 ±0.050 4.491 ±0.009 ±0.015 1.750

129 5 5.593 ±0.010 ±0.050 5.553 ±0.010 ±0.030 1.937

155 6 6.658 ±0.011 ±0.050 6.614 ±0.011 ±0.030 2.215

Metric Units (mm)

53 2 60.78 ±0.15 ±0.30 60.17 ±0.15 ±0.30 28.58

78 3 89.78 ±0.20 ±0.38 88.70 ±0.20 ±0.38 40.49

91 3-1/2 101.98 ±0.20 ±1.27 101.40 ±0.20 ±0.38 42.85

103 4 114.68 ±0.23 ±1.27 114.07 ±0.23 ±0.38 44.45

129 5 142.06 ±0.25 ±1.27 141.05 ±0.25 ±0.76 49.20

155 6 169.11 ±0.28 ±1.27 168.00 ±0.28 ±0.76 53.98

NOTE—Metal circular GO/NO-GO plug gauges machined to the minimum and maximum average inside diameters given in the table may be used to check dimensions A and B.

(This note has been approved as Authorized Engineering Information.)

© Copyright 2004 by the National Electrical Manufacturers Association.

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

No reproduction or networking permitted without license from IHS

Provided by IHS under license with NEMA

Copyright National Electrical Manufacturers Association

TC 9-2004

Page 5

Table 3-3

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

SOCKETS FOR THERMOFORMED (FABRICATED) FITTINGS

A B C

Socket Entrance Inside Diameter Socket Bottom Inside Diameter

Out-of- Out-of-

Metric Roundness Roundness Minimum

Not for Resale, 04/30/2006 01:20:52 MDT

Licensee=Aramco HQ/9980755100

Desig- Trade Tolerance on Tolerance on Tolerance Tolerance on Socket

nator Size Average Average Average Average on Average Average Depth

U.S. Customary Units (in.)

53 2 2.400 ±0.006 ±0.030 2.381 ±0.006 ±0.030 1.750

78 3 3.538 ±0.008 ±0.030 3.508 ±0.008 ±0.030 2.875

91 3-1/2 4.041 ±0.008 ±0.050 4.008 ±0.008 ±0.050 3.125

103 4 4.544 ±0.009 ±0.050 4.509 ±0.009 ±0.050 3.375

129 5 5.614 ±0.010 ±0.050 5.573 ±0.010 ±0.050 4.000

155 6 6.687 ±0.011 ±0.050 6.636 ±0.011 ±0.050 5.000

Metric Units (mm)

53 2 60.96 ±0.15 ±0.76 60.48 ±0.15 ±0.76 44.45

78 3 89.87 ±0.20 ±0.76 89.10 ±0.20 ±0.76 73.02

91 3-1/2 102.64 ±0.20 ±1.27 101.80 ±0.20 ±1.27 79.38

103 4 115.42 ±0.23 ±1.27 114.53 ±0.23 ±1.27 85.72

129 5 142.06 ±0.25 ±1.27 141.55 ±0.25 ±1.27 101.60

155 6 169.85 ±0.28 ±1.27 168.55 ±0.28 ±1.27 127.00

NOTE—Metal circular GO/NO-GO plug gauges machined to the minimum and maximum average inside diameters given in the table may be used to check dimensions

A and B. (This note has been approved as Authorized Engineering Information.)

© Copyright 2004 by the National Electrical Manufacturers Association.

TC 9-2004

Page 6

Table 3-4

COUPLINGS

MOLDED

FABRICATED

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size M. Maximum SH. Maximum N. Maximum M. Maximum SH. Maximum N. Minimum

53 2 2-47/64 0.075 3/32 69.5 1.90 2.4

78 3 3-31/32 0.076 7/64 100.8 1.93 2.8

91 3-1/2 4-1/2 0.087 7/64 114.3 2.21 2.8

103 4 5-1/32 0.097 7/64 127.8 2.46 2.8

129 5 6-1/4 0.118 9/64 158.8 3.00 3.6

155 6 7-1/2 0.140 9/64 190.5 3.56 3.6

Table 3-5

TERMINAL ADAPTERS

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size M. Maximum SH. Maximum N. Maximum M. Maximum SH. Maximum N. Minimum

53 2 2-59/64 1.964 5/32 74.2 49.89 4.0

78 3 4-1/16 2.915 15/64 103.2 74.04 6.0

91 3-1/2 4-19/32 3.371 1/4 116.7 85.62 6.4

103 4 5-1/8 3.825 1/4 130.2 97.16 6.4

129 5 6-9/32 4.795 19/64 159.6 121.79 7.5

155 6 7-1/2 5.762 17/64 190.5 146.35 6.7

© Copyright 2004 by the National Electrical Manufacturers Association.

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 7

Table 3-6

FEMALE ADAPTERS

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size M. Maximum SH. Maximum N. Maximum M. Maximum SH. Maximum N. Minimum

53 2 2-27/32 1.964 5/64 72.2 49.89 2.0

78 3 3-31/32 2.915 11/64 100.8 74.04 4.4

91 3-1/2 4-37/64 3.371 11/64 116.3 85.62 4.4

103 4 5-7/64 3.825 11/64 129.8 97.16 4.4

129 5 6-9/32 4.795 15/64 159.6 121.79 6.0

155 6 7-33/64 5.762 15/64 190.9 146.35 6.0

Table 3-7

SOCKET END BELL (MOLDED)

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size M. Maximum SH. Maximum N. Maximum M. Maximum SH. Maximum N. Minimum

53 2 3-7/64 0.075 5/16 79.0 1.90 7.9

78 3 4-1/8 0.076 5/16 104.8 1.93 7.9

91 3-1/2 4-5/8 0.087 5/16 117.5 2.21 7.9

103 4 5-11/32 0.097 7/16 135.7 2.46 11.1

129 5 6-13/32 0.118 7/16 162.7 3.00 11.1

155 6 7-13/32 0.140 7/16 188.1 3.56 11.1

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 8

Table 3-8

SOCKET END BELL (FABRICATED)

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size M. Maximum SH. Maximum N. Maximum M. Maximum SH. Maximum N. Minimum

53 2 4-9/32 2.173 2-25/32 108.7 55.19 70.6

78 3 5-9/32 3.208 2-15/16 134.1 81.48 74.6

91 3-1/2 4-3/4 3.668 3 120.6 93.17 76.2

103 4 5-1/2 4.129 3 139.7 104.88 76.2

129 5 6-1/2 5.195 4-1/4 165.1 131.95 108.0

155 6 7-1/2 6.192 3-1/4 190.5 157.28 82.6

Table 3-9

DOMED CAP

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size W. Maximum M. Maximum W. Maximum M. Minimum

53 2 2-3/32 2-13/16 53.2 71.4

78 3 3 4-3/32 76.2 104.0

91 3-1/2 3-1/8 4-5/8 79.4 117.5

103 4 3-31/64 5-13/64 88.4 137.3

129 5 4-27/64 6-1/4 112.3 158.8

155 6 5-7/32 7-25/64 132.6 187.7

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 9

Tabe 3-10

FLAT CAP

Metric U.S. Customary (in.) Metric Units (mm)

Desig- Trade

nator Size F. Maximum M. Maximum F. Maximum M. Maximum

53 2 1/16 2-35/64 1.5 64.7

78 3 1/16 3-45/64 1.6 94.1

91 3-1/2 5/64 4-7/32 2.0 107.2

103 4 3/32 4-3/4 2.4 120.6

129 5 3/32 5-53/64 2.4 148.0

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

155 6 1/8 6-61/64 3.2 176.6

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 10

Table 3-11

FITTING PLUG

Metric U. S. Customary Units (in.) Metric Units (mm)

Desig- Trade M, F, X, X, M, F, X, X,

nator Size Maximum Minimum Average Tolerance Maximum Minimum Average Tolerance

53 2 2-19/32 23/64 2.375 ±0.006 65.9 9.1 60.32 ±0.15

78 3 3-21/32 23/64 3.000 ±0.008 92.9 9.1 88.90 ±0.20

91 3-1/2 4-9/32 23/64 3.500 ±0.008 108.7 9.1 101.60 ±0.20

103 4 4-25/32 23/64 4.500 ±0.009 121.4 9.1 114.30 ±0.23

129 5 5-21/32 13/64 5.563 ±0.010 143.7 10.3 141.30 ±0.25

155 6 … … … … … … … …

Table 3-12

DUCT PLUG, TAPERED

Metric U. S. Customary Units (in.) Metric Units (mm)

Desig- Trade M, F1, X2, X2, M, X1, X2, F,

nator Size Maximum Minimum Average Tolerance Maximum Minimum Average Tolerance

53 2 3-12/64 2.500 1-7/8 7/64 81.4 63.5 47.6 2.8

78 3 4 3.550 2-7/8 1/8 101.6 90.1 73.0 3.2

91 3-1/2 4-9/16 4.050 3-3/8 7/64 115.9 102.9 85.7 2.8

103 4 5-3/16 4.550 3-27/32 7/64 131.8 115.5 97.6 2.8

129 5 6-9/32 5.750 4-7/8 7/64 159.5 146.0 123.8 2.8

155 6 6-7/8 6.703 5-7/8 5/64 174.6 170.3 149.2 2.0

© Copyright 2004 by the National Electrical Manufacturers Association.

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 11

Table 3-13

FIBER CONDUIT ADAPTER

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

Metric U.S. Customary Units (in.) Metric Units (mm)

Desig- Trade M N CM X1 X2 M N CM X1 X2

nator Size Maximum Minimum Nominal Nominal Nominal Maximum Minimum Nominal Nominal Nominal

53 2 2-3/4 5/64 1-7/16 2.479 2-25/64 69.8 2.0 46.5 62.74 60.7

78 3 4 9/64 1-11/16 3.448 3-11/32 101.6 3.6 42.9 87.58 84.9

103 4 5-3/4 11/64 1-15/16 4.375 4-31/64 146.0 4.4 49.2 120.6 114.12

Table 3-14

CEMENT ASBESTOS CONDUIT ADAPTER

Metric U.S. Customary Units (in.) Metric Units (mm)

Desig- Trade M N CM X1 X2 M N CM X1 X2

nator Size Maximum Minimum Nominal Nominal Nominal Maximum Minimum Nominal Nominal Nominal

53 2 2-3/4 5/64 1-3/4 2.580 2-1/3 69.8 2.0 44.4 65.5 63.5

78 3 4 9/64 1-3/4 3.620 3-17/32 101.6 2.0 44.4 91.9 89.7

103 4 5-3/4 11/64 2 4.620 4-33/64 127.8 4.4 50.8 117.3 114.7

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

Page 12

Table 3-15

BENDS AND SWEEPS

Radii, Degrees of Curvature, and Straight Tangent Lengths at End of Bends and Sweeps

U.S. Customary Units Metric Units

Minimum Minimum

Straight 22.5º, Straight

45º and 22.5º, 30º, Tangents 30º, 45º, Tangents

Metric 90º 22.5º and 45º, 90º Length at End 45º and 90º 22.5º and 90º Length at End

Desig- Trade Bends, 30º Bends, Sweeps, Dimensions Bends, 30º Bends, Sweeps, Dimensions

nator Size Radius Radius Radius CM Radius Radius Radius CM

in. in. ft in. m m m mm

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`---

53 2 18, 24, 36 18, 24, 36 12-1/2 2 0.46, 0.61, 0.46, 0.61, 3.8 50.8

48, 60 48, 60 0.91, 1.22, 0.91, 1.22,

1.52 1.52

78 3 18, 24,30, 18, 24,30, 12-1/2 3-1/8 0.46, 0.61, 0.46, 0.61, 3.8 79.4

36, 48, 60 36, 48, 60 0.76, 0.91, 0.76, 0.91,

1.22, 1.52 1.22, 1.52

91 3-1/2 18, 24, 36 18, 24,30, 12-1/2 3-1/4 0.46, 0.61, 0.46, 0.61, 3.8 82.6

48, 60 36, 48, 60 0.91, 1.22, 0.91, 1.22,

1.52 1.52

103 4 36, 48, 60 18, 24,30, 12-1/2 3-3/8 0.91, 1.22, 0.91, 1.22, 3.8 85.7

36, 48, 60 1.52 1.52

129 5 36, 48, 60 36, 48, 60 12-1/2 3-5/8 0.91, 1.22, 1.22, 1.52 3.8 92.1

1.52

155 6 48, 60 48, 60 12-1/2 3-3/4 1.22, 1.52 1.22, 1.52 3.8 95.2

Alternate Constructions—

a. Bends and sweeps may have a belled socket on one end with socket dimensions conforming to those of Table 3-3; or

b. Bends and sweeps may have a molded coupling on one end with socket dimensions conforming to those of Table 3-2.

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

TC 9-2004

--``,``,`,`,,`,,,,```,``,,,,-`-`,,`,,`,`,,`--- Page 13

Table 3-16

5-DEGREE ANGLE COUPLINGS

Metric Trade U.S. Customary Units (in.) Metric Units (mm)

Desig- Size M Maximum N X X Tolerance M Maximum N Maximum X X Tolerance

nator Maximum Average Average

53 2 2-9/16 3/16 2.375 ±0.006 65.1 4.8 60.32 ±0.15

78 3 3-3/32 7/32 3.500 ±0.008 94.5 5.6 88.90 ±0.20

103 4 4-51/64 14/64 4.500 ±0.009 121.8 6.0 114.30 ±0.23

129 5 5-59/64 15/64 5.563 ±0.010 150.4 10.0 141.30 ±0.25

155 6 7-1/64 9/16 6.625 ±0.011 178.2 14.3 168.21 ±0.28

Thermoformed (Fabricated) Bell by Spigot Thermoformed (Fabricated) Bell by Bell

© Copyright 2004 by the National Electrical Manufacturers Association.

Copyright National Electrical Manufacturers Association

Provided by IHS under license with NEMA Licensee=Aramco HQ/9980755100

No reproduction or networking permitted without license from IHS Not for Resale, 04/30/2006 01:20:52 MDT

You might also like

- Barclays Bank Statement 2Document5 pagesBarclays Bank Statement 2zainabNo ratings yet

- Fence Fittings: Standard Specification ForDocument5 pagesFence Fittings: Standard Specification ForEnriqueVe100% (2)

- Ul 444 PDFDocument32 pagesUl 444 PDFDIPAK50% (2)

- NEMA WC26-2008 - Final PDFDocument7 pagesNEMA WC26-2008 - Final PDFJavier F. Mouriño Roldán0% (2)

- 7.3.2 Cables, Low-Voltage, 600-Volt MaximumDocument2 pages7.3.2 Cables, Low-Voltage, 600-Volt MaximumGlen PolandNo ratings yet

- NitinolDocument20 pagesNitinolTamara PricilaNo ratings yet

- NEMA TCB 2 2017 WatermarkedDocument35 pagesNEMA TCB 2 2017 WatermarkedjovenlouNo ratings yet

- Nema TC 3 PVC ConduitDocument22 pagesNema TC 3 PVC ConduitSureshKumarNo ratings yet

- BS 6004 PDFDocument27 pagesBS 6004 PDFHamood HasanNo ratings yet

- Astm d1248 PDFDocument9 pagesAstm d1248 PDFMayoo Laxman100% (1)

- Tia TSB 140 2004Document28 pagesTia TSB 140 2004k1gabitzu9789No ratings yet

- NEMA 250 - Enclosures For Electrical Equipment (1000 Volts Maximum)Document52 pagesNEMA 250 - Enclosures For Electrical Equipment (1000 Volts Maximum)Teuku Ahmad HaekalNo ratings yet

- Maruti Suzuki Final ProjectDocument63 pagesMaruti Suzuki Final ProjectMilind Singanjude75% (4)

- Northern Research GroupDocument2 pagesNorthern Research GroupTeam GuidoNo ratings yet

- NEMA VE1 2009 - Metal Cable Tray SystemsDocument25 pagesNEMA VE1 2009 - Metal Cable Tray Systemsnovo orderNo ratings yet

- PVC Conduits, Fittings & Accessories PDFDocument70 pagesPVC Conduits, Fittings & Accessories PDFHaytham BafoNo ratings yet

- Contents and Scope NEMA TC 2-2013Document7 pagesContents and Scope NEMA TC 2-2013PVALVERDEANo ratings yet

- Nema TC-8Document17 pagesNema TC-8israrNo ratings yet

- Contents and Scope NEMA TC 6 + 8-2013Document6 pagesContents and Scope NEMA TC 6 + 8-2013cherif yahyaouiNo ratings yet

- NEMA VE 1 2017 Contents and ScopeDocument7 pagesNEMA VE 1 2017 Contents and ScopeShehiryar MuzamalNo ratings yet

- BS 5255 1989 Thermoplastic Waste Pipe - FittingDocument22 pagesBS 5255 1989 Thermoplastic Waste Pipe - FittingFenner ElectromechanicalNo ratings yet

- TIA/EIA-568: HistoryDocument49 pagesTIA/EIA-568: HistoryMerry NunezNo ratings yet

- BICSIDocument4 pagesBICSIJoseph AmalrajNo ratings yet

- C 1047 - 99 QzewndcDocument3 pagesC 1047 - 99 QzewndcGarcia ManuelNo ratings yet

- Hot-Formed Welded and Seamless Carbon Steel Structural TubingDocument6 pagesHot-Formed Welded and Seamless Carbon Steel Structural TubingVenreplast PueblaNo ratings yet

- F1483-15 Standard Specification For Oriented Poly (Vinyl Chloride), PVCO, Pressure PipeDocument5 pagesF1483-15 Standard Specification For Oriented Poly (Vinyl Chloride), PVCO, Pressure PipeMohamedNo ratings yet

- A252Document7 pagesA252Luz DuarteNo ratings yet

- C811-98 (Reapproved 03)Document3 pagesC811-98 (Reapproved 03)diego echagarayNo ratings yet

- Ansinemac29-6-2015 Watermarked PDFDocument17 pagesAnsinemac29-6-2015 Watermarked PDFhendrexNo ratings yet

- Tensile Test UpvcDocument3 pagesTensile Test UpvcAloka KarunarathneNo ratings yet

- Ansi C-136.20Document16 pagesAnsi C-136.20r_surya05100% (1)

- Ul 913 1988Document69 pagesUl 913 1988Jesus OrtizNo ratings yet

- Metallic-Coated Steel Wire For Chain-Link Fence FabricDocument3 pagesMetallic-Coated Steel Wire For Chain-Link Fence FabricDoug WilsonNo ratings yet

- 01 Samss 051 PDFDocument13 pages01 Samss 051 PDFnadeem shaikh100% (1)

- QC PVC 18373Document4 pagesQC PVC 18373Andrei SimionNo ratings yet

- Cable Tray Standards - by LegrandDocument4 pagesCable Tray Standards - by Legrandsuresh babuNo ratings yet

- Standard Specification For Hot Dip GalvanizingDocument4 pagesStandard Specification For Hot Dip GalvanizingNuzul Furqony100% (1)

- Nema TP2 PDFDocument40 pagesNema TP2 PDFwarwarkingNo ratings yet

- Ansi C29.12-1997 PDFDocument16 pagesAnsi C29.12-1997 PDFIvanNo ratings yet

- Associations and Reference StandardsDocument13 pagesAssociations and Reference StandardsgaburrNo ratings yet

- BS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteDocument14 pagesBS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteTom YeeNo ratings yet

- 6 Penetration Fire Stopping PDFDocument2 pages6 Penetration Fire Stopping PDFMMMOH200No ratings yet

- BS 5481Document23 pagesBS 5481Fenner ElectromechanicalNo ratings yet

- PVC Electrical ConduitDocument12 pagesPVC Electrical ConduitIrvan IskandarNo ratings yet

- D 4325 - 02 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesDocument6 pagesD 4325 - 02 Standard Test Methods For Nonmetallic Semi-Conducting and Electrically Insulating Rubber TapesPaulo Heber Alves BrandaoNo ratings yet

- Bsen50525 2-11-2011 Cables For General ApplicationsDocument22 pagesBsen50525 2-11-2011 Cables For General ApplicationssohaibNo ratings yet

- ADM Specs GRP Enclosures and KiosksDocument3 pagesADM Specs GRP Enclosures and KiosksMahiBoumNo ratings yet

- Tr-33 Generic Butt Fusion Joining Gas PipeDocument32 pagesTr-33 Generic Butt Fusion Joining Gas PipeLuis QuinoNo ratings yet

- BS 1722-13 1978 - Chain Link Fences For Tennis Court SurroundsDocument10 pagesBS 1722-13 1978 - Chain Link Fences For Tennis Court SurroundsAnoyNo ratings yet

- Ansi C29.2aDocument22 pagesAnsi C29.2afecasNo ratings yet

- Tia 568 C.0 2009 PDFDocument70 pagesTia 568 C.0 2009 PDFJuan CarlosNo ratings yet

- Tia 568 B 1 5Document28 pagesTia 568 B 1 5John UrdanetaNo ratings yet

- Astm D2729 (2011)Document5 pagesAstm D2729 (2011)khaledaj1977No ratings yet

- Bs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesDocument48 pagesBs5467 2016 Electriccables Thermosetting Insulated Armoured Cable Sofrated VoltagesAfiqul IslamNo ratings yet

- NECA 500 Installation of LightingDocument12 pagesNECA 500 Installation of LightingAlvin Jim VillanuevaNo ratings yet

- Nema Ve1 PDFDocument27 pagesNema Ve1 PDFAlif Anshar100% (1)

- Saes T 887Document15 pagesSaes T 887Eagle SpiritNo ratings yet

- 00 AWWA StandardsDocument3 pages00 AWWA Standardsliviu_dovaNo ratings yet

- Solvent Jointing of CPVC PipesDocument20 pagesSolvent Jointing of CPVC PipesHamza Hashim100% (1)

- BS 6387Document24 pagesBS 6387Ahmed AbidNo ratings yet

- Instrument Cable Test MethodsDocument3 pagesInstrument Cable Test MethodsParesh Ghodasara100% (1)

- Nema Sm23 - 1991pdfDocument64 pagesNema Sm23 - 1991pdfTritis BatikNo ratings yet

- Nema 250Document39 pagesNema 250Tomsy ThomasNo ratings yet

- NEMA C80.3-2005 For Steel Electrical Metallic Tubing (EMT)Document17 pagesNEMA C80.3-2005 For Steel Electrical Metallic Tubing (EMT)Carlos Placeres0% (1)

- Item 22 - RL4 RelayDocument1 pageItem 22 - RL4 RelayTomsy ThomasNo ratings yet

- Item 20 - 5.5abwna FuseDocument1 pageItem 20 - 5.5abwna FuseTomsy ThomasNo ratings yet

- IB 32-253-4A Instr. For Porcel-Line Type DHP Magnetic Air Circuit BreakersDocument77 pagesIB 32-253-4A Instr. For Porcel-Line Type DHP Magnetic Air Circuit BreakersTomsy ThomasNo ratings yet

- Nema 250Document39 pagesNema 250Tomsy ThomasNo ratings yet

- Competency Based LearningDocument9 pagesCompetency Based Learningkarapetyanines08No ratings yet

- SLIM Sparse Linear Methods For Top-N Recommender SystemsDocument10 pagesSLIM Sparse Linear Methods For Top-N Recommender SystemsfcrkudxujdemptrdapNo ratings yet

- BiodiversityR PDFDocument128 pagesBiodiversityR PDFEsteban VegaNo ratings yet

- Irene RAYOS-OMBAC, Complainant, Orlando A. RAYOS, RespondentDocument5 pagesIrene RAYOS-OMBAC, Complainant, Orlando A. RAYOS, RespondentGraceNo ratings yet

- AnswersDocument24 pagesAnswersDeul ErNo ratings yet

- 4 Differently Able Persons ActDocument7 pages4 Differently Able Persons Actumer plays gameNo ratings yet

- Ultra 150 300 Ts FileDocument136 pagesUltra 150 300 Ts FileEmanuel GutierrezNo ratings yet

- MLCC Model enDocument6 pagesMLCC Model enrahmanakberNo ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

- Yoseph ShiferawDocument72 pagesYoseph Shiferawmaheder wegayehuNo ratings yet

- SPP ADC Flightplan UnderstandingDocument25 pagesSPP ADC Flightplan UnderstandingYesid BarraganNo ratings yet

- Service Quality, Customer Satisfaction, and Behavioral Intentions in Fast-Food RestaurantsDocument19 pagesService Quality, Customer Satisfaction, and Behavioral Intentions in Fast-Food RestaurantsFelisitas AgnesNo ratings yet

- NJM072B/082B/072/082: Dual J-Fet Input Operational AmplifierDocument5 pagesNJM072B/082B/072/082: Dual J-Fet Input Operational Amplifieryuni supriatinNo ratings yet

- Adaptable Multi Nut Fastner With Manual Height Adjustment SystemDocument48 pagesAdaptable Multi Nut Fastner With Manual Height Adjustment SystemANAND KRISHNANNo ratings yet

- Data Cleansing Process For Master DataDocument4 pagesData Cleansing Process For Master DataAjay Kumar KhattarNo ratings yet

- Name: Najma Said Salad Faculty: Computer Science Semester: OneDocument2 pagesName: Najma Said Salad Faculty: Computer Science Semester: OneAbdifatah SaidNo ratings yet

- A GMM Approach For Dealing With Missing DataDocument41 pagesA GMM Approach For Dealing With Missing DataraghidkNo ratings yet

- Yongcao 2008Document15 pagesYongcao 2008madebyNo ratings yet

- EE211 Exam S1-09Document8 pagesEE211 Exam S1-09abadialshry_53No ratings yet

- Investment Property - DQDocument3 pagesInvestment Property - DQKryztal TalaveraNo ratings yet

- CursorDocument7 pagesCursorSachin KumarNo ratings yet

- Hotel Administration and Management Network - AbstractDocument3 pagesHotel Administration and Management Network - AbstractMehadi Hasan RoxyNo ratings yet

- SIM7000 Series - AT Command Manual - V1.01Document163 pagesSIM7000 Series - AT Command Manual - V1.01Bill CheimarasNo ratings yet

- Sagarika Sinha: Senior Systems Engineer - Infosys, PuneDocument1 pageSagarika Sinha: Senior Systems Engineer - Infosys, PunePari RastogiNo ratings yet

- Souce Najib LeadershipDocument12 pagesSouce Najib LeadershipSharanya Ramasamy100% (1)