Professional Documents

Culture Documents

Us6809154 PDF

Us6809154 PDF

Uploaded by

arief0 ratings0% found this document useful (0 votes)

13 views6 pagesOriginal Title

US6809154.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

13 views6 pagesUs6809154 PDF

Us6809154 PDF

Uploaded by

ariefCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 6

USOO6809154B2

(12) United States Patent (10) Patent No.: US 6,809,154 B2

Lindahl et al. (45) Date of Patent: Oct. 26, 2004

(54) HDPE POLYMER COMPOSTION (56) References Cited

(75) Inventors: Ann Kristen Lindahl, Porsgronn (NO); U.S. PATENT DOCUMENTS

Harry Oysaed, Stathelle (NO); Roger 4,588,775 A * 5/1986 McCullough, Jr. ........... 525/88

Goris, Singapore (SG) 5,494.965 A 2/1996 Harlin et al.

5,530,055 A * 6/1996 Needham .................... 524/528

(73) ASSignee: Borealis Technology Oy, Porvoo (FI) 6,221,982 B1 4/2001 Debras et al. ................ 526/64

6.291601 B1 * 9/2001 Debras ................ ... 526/64

(*) Notice: Subject to any disclaimer, the term of this 6,632,896 B1 : 10/2003 Almquist et al. ............. 526/96

patent is extended or adjusted under 35 6,642.323 B1 * 11/2003 Myhre et al. ................. 526/64

U.S.C. 154(b) by 0 days. FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 10/257,498 EP O 423 962 A 4/1991

22) PCT Fied Apr. 5, 2001 GB 2141 719 A 1/1985

(22) CC pr. 5, OTHER PUBLICATIONS

(86) PCT No.: PCT/EPO1/03908 Iroh, J.O. et al., Mechanical Properties of Nucleated

S371 (c)(1), Polypropylene and Short Glass Fiber-Polypropylene Com

(2), (4) Date: Feb. 6, 2003 posites, Eur: Polym. J. vol. 32, No. 12, pp. 1425–1429, 1996.

International Search Reporting corresponding to Interna

(87) PCT Pub. No.: WO01/79344 tional Application No. PCT/EP01/03908.

PCT Pub. Date: Oct. 25, 2001 * cited by examiner

(65) Prior Publication Data Primary Examiner Nathan M. Nutter

(74) Attorney, Agent, or Firm-Fay, Sharpe, Fagan,

US 2003/0153688 A1 Aug. 14, 2003 Minnich & McKee, LLP

(30) Foreign Application Priority Data (57) ABSTRACT

Apr. 13, 2000 (EP) ............................................ OO108174 HDPE compositions comprising a bimodal polymer and a

(51) Int. Cl. ........................... C08L 23/04; CO8L 23/06 nucleating agent, for producing moulded articles with

(52) U.S. Cl. ........................ 525/191; 525/216; 525/240 increased E-modulus and high ESCR, and the use of Such

compositions in the production of moulded articles.

(58) Field of Search ................................. 525/191, 216,

525/240 31 Claims, 1 Drawing Sheet

U.S. Patent Oct. 26, 2004 US 6,809,154 B2

US 6,809,154 B2

1 2

HDPE POLYMER COMPOSTION g/mole. Its polydispersity indeXM/M, is generally between

5 and 75, although for injection moulding applications it is

This invention relates to high density polyethylene preferably between 10 and 20, whilst for blow moulding

(HDPE) compositions and to their use in the production of applications it is preferably between 20 and 60.

moulded articles. The most effective nucleating agents are those containing

Monomodal HDPE, produced by the use of Ziegler-Natta an organic group and a polar group and which are insoluble

or chromium-based catalysts, is a well known material for in the HDPE, such as mono- or polycarboxylic aromatic

the production of articles Such as packaging or containers by acids or Salts thereof A particularly effective nucleating

injection- and blow-moulding. agent is Sodium benzoate. The nucleating agent is usually

It is important that Such articles be resistant to StreSS present in an amount of between 1 and 10,000 ppm, advan

cracking, Since they are frequently used to contain materials tageously between 10 and 5000 ppm; preferably between 50

whose uncontrolled release would be environmentally unde and 2000 ppm, and in certain favoured embodiments

Sirable. The assessing of Such resistance is by the Environ between 400 and 1200 ppm.

mental Stress Crack Resistance test (“ESCR”), the proce The HDPE according to the invention is a bimodal or even

dure for which is laid down in ASTM D 1693. Cond. B. 15 multimodal polymer. By “bimodal” is meant that the poly

It is also important that they possess good Stiffness, So as mer comprises at least two components, one of which has a

not to deform when Stacked during transportation or Storage. relatively low molecular weight and a relatively high density

Stiffness in this context is expressed as Tensile Modulus and another of which has a relatively high molecular weight

(also referred to as "E-modulus), the procedure for assess and a relatively low density. Typically the molecular weight

ing which is laid down in ISO 527-2. distribution (MWD) of a polymer produced in a single

It has not proved possible with existing HDPE formula polymerization Stage using a single monomer mixture, a

tions to achieve both adequate StiffneSS and adequate ESCR Single polymerization catalyst and a single Set of process

in demanding applications Such as manufacture of bottles for conditions will Show a Single maximum, the breadth of

detergents. Increasing the density of the HDPE has been which will depend on catalyst choice, reactor choice, pro

found to increase the Stiffness, but only at the expense of 25 ceSS conditions, etc., i.e. Such a polymer will be monomodal.

decreasing the ESCR. The bimodal (or multimodal) polyethylene is produced by

It has now been found that by using bimodal HDPE in polymerization using conditions which create a bimodal or

Such formulations and adding a nucleating agent to the multimodal polymer product, eg using a catalyst System or

polymer there may be obtained an HDPE moulding com mixture with two or more different catalytic Sites, using two

position of increased stiffness and undiminished ESCR. or more Stage polymerization processes with different pro

According to the present invention, therefore, an HDPE cess conditions in the different stages (eg different

composition for producing moulded articles with increased temperatures, pressures, polymerization media, hydrogen

E-modulus and high ESCR comprises an ethylene partial pressures, etc).

homopolymer or an ethylene alpha-olefin copolymer which Such bimodal (or multimodal) HDPE may be produced

is a bimodal polymer produced in a multistage process and 35 relatively simply by a multistage ethylene polymerization,

comprising eg using a Series of reactors, with comonomer addition in

i) a low molecular weight ethylene polymer and only the reactor(s) used for production of the higher/highest

ii) a high molecular weight ethylene polymer or copoly molecular weight component(s). Examples of bimodal PE

mer and a nucleating agent. production are given in EP-A-778,289 and WO92/12182.

The effectiveness of the nucleation is Surprising, Since 40 If an ethylene homopolymer component is produced by

although nucleation has been widely practised in manufac Slurry polymerization involving use of recycled diluent, that

turing polypropylene-based compositions this has not been diluent may contain Small amounts of higher C-olefins as

the case with polyethylene because it is inherently Such a contaminants. Likewise where an earlier polymerization

rapidly crystallizing polymer. The effect of nucleation on Stage has produced an ethylene copolymer component, Small

bimodal HDPE could therefore not have been foreseen. 45 amounts of comonomer may be carried over to an ethylene

The alpha-olefin of the aforesaid ethylene alpha-olefin homopolymerization Stage. Accordingly, by ethylene

copolymer is Suitably Selected -from propylene, 1-butene, homopolymer is meant herein a polymer preferably contain

1-pentene, 1-hexene, 4-methyl-1-pentene, 1-octene, ing at least 99.9% by weight of ethylene units. Likewise as

1-decene and cyclic olefins, its content being typically in a multistage/multireactor polymerization using more than

between 0.1 and 10 weight %. The density of the compo 50 one catalyst System, the homopolymerization catalysts may

sition is preferably between 910 and 980 kg/m, more be at least partially active during the copolymerization

preferably between 945 and 975 kg/m, while its melt index reaction, any copolymer component making up less than 5%

MFR, measured at 190° C. under 21.6 kg load, is by weight of the total polymer shall not be considered to be

preferably between 1 and 1000 g/10 min. the lowest molecular weight component in an HDPE accord

Different ranges of melt indeX within this range may be 55 ing to the invention.

Selected for particular applications. Thus for manufacture of The polymerization reactions used to produce the HDPE

household and industrial containers MFR is advanta of the invention may involve conventional ethylene

geously between 15 and 50, for injection moulding it should homopolymerization or copolymerization reactions, eggas

be between 120 and 770; and for manufacture of large cans phase, Slurry phase, liquid phase polymerizations, using

an MFR, between 1 and 10 is appropriate. 60 conventional reactors, e.g. loop reactors, gas phase reactors,

The overall composition Suitably comprises 5-95% of the batch reactors etc. (see for example WO97/44371 and

low molecular weight ethylene polymer or copolymer and WO96/18662). The catalyst systems used may likewise be

95-5% of the high molecular weight ethylene polymer, any conventional Systems, e.g. chromium catalysts, Ziegler

preferably 30–70% of the former and 70–30% of the latter. Natta and metallocene or metallocene:aluminoxane

Its number average molecular weight M, is Suitably between 65 catalysts, either homogeneous or more preferably heteroge

1,000 and 20,000 g/mole, while its weight average molecu neous catalysts, eg catalysts Supported on inorganic or

lar weight M, is suitably between 50,000 and 500,000 organic particulates, in particular on magnesium halides or

US 6,809,154 B2

3 4

inorganic oxides Such as Silica, alumina or Silica-alumina. for producing moulded articles with increased E-modulus

For the preparation of the high molecular weight component and high ESCR.

in particular it is especially desirable to use Supported The nucleating agent may be introduced into the polymer

Ziegler-Natta catalyst as the molecular weight can then composition by kneading a mixture of the polymer, usually

conveniently be controlled using hydrogen. It is also poS in powder or pellet form, with the nucleating agent, which

Sible to use Supported metallocene catalysts as it is particu may be utilized alone or in the form of a master batch

larly Straightforward to Select desired molecular weights by containing further additives Such as Stabilizers, pigments,

appropriate Selection of particular metallocenes. The metal antistatics, UV stabilizers and fillers. It should be a material

locenes used will typically be group IVa to VIa metals (in which is wetted or absorbed by the polymer, which is

particular Zr or Hf) complexed by optionally substituted insoluble in the polymer and of melting point higher than

cyclopentadienyl groups, eg groups carrying pendant or that of the polymer, and it should be homogeneously dis

fused Substituents optionally linked together by bridging persible in the polymer melt in as fine a form as possible (1

groupS. Suitable metallocenes and aluminoxane cocatalysts to 10 um).

are widely described in the literature, eg the patent publi Compounds known to have a nucleating capacity for

cations of Borealis, Hoechst, EXXon, etc. 15 polyolefins include Salts of aliphatic monobasic or dibasic

Typically however the HDPE will be prepared using acids or arylalkyl acids, Such as Sodium Succinate or alumi

multistage polymerization using a single catalyst System or num phenylacetate; and alkali metal or aluminum Salts of

a plurality of catalyst Systems, eg two or more metallocenes, aromatic or alicyclic carboxylic acids Such as Sodium

one or more metallocenes and one or more Ziegler-Natta B-naphthoate. Preferred for use in the present invention is

catalysts, two or more chromium catalysts, one or more Sodium benzoate. Effectiveness of nucleation can be moni

chromium catalysts and one or more Ziegler-Natta catalysts, tored microscopically by observation of the degree of reduc

etc.

In a particularly contemplated embodiment the HDPE is tion in size of the Spherulites into which the crystallites are

produced by a proceSS comprising catalytically polymeriz aggregated.

ing or copolymerizing ethylene in the liquid phase in an inert The invention is illustrated by the following Examples.

25

hydrocarbon medium in a loop reactor, passing the polymer EXAMPLE 1.

product from the loop reactor to a gas phase reactor and

there continuing the polymerization in the presence of A bimodal polyethylene was prepared by a two-step

ethylene, optionally with further catalyst, to obtain a bimo process, in which the first Step consisted of a loop polymer

dal product of which Said polymer from the loop reactor ization and the Second Step consisted of a gas phase poly

constitutes 20-90% weight. A prepolymerization step may merization. Ethylene (27 kg/hr) and hydrogen (96 g/hr) were

precede the loop reactor, in which Step ethylene homopoly fed to the loop reactor, ethylene (41 kg/hr), 1-butene (1.2

mer is produced by liquid phase polymerization in the kg/hr) and hydrogen (46 g/hr) were fed to the gas phase

presence of polymerization catalyst, hydrogen and a diluent, reactor. As a catalyst a Ziegler-Natta catalyst was used

the homopolymer produced, amounting to 1 to 5% by weight 35 prepared according to EP-A-688,794 using Al-alkyl as

of final HDPE product, being then passed to the loop reactor cocatalyst. The catalyst was fed only into the loop reactor.

together with Said polymerization catalyst, optionally with The polymerization conditions were the following:

no further addition of catalyst. Typically the polymerization

in the loop reactor is homopolymerization of ethylene and

the polymerization in the gas phase reactor is copolymer 40

ization of ethylene with an alpha-olefin Selected from Loop reactor

propylene, 1-butene, 1-pentene, 1-hexene, 4-methyl-1- Reactor temperature 95° C.

pentene, 1-octene, 1-decene and cyclic olefins. Reactor pressure 65 bar

The low molecular weight ethylene polymer forming one Ethylene feed rate 35-40 kg/h

component of the final bimodal polymer preferably has a 45 Hydrogen feed rate 50-60 g/h

weight average molecular weight of between 5,000 and Medium (diluent) propane

50,000 g/mole, and a melt index MER measured under 2.16 Gas phase reactor

kg load of between 50 and 2,000 g/10 mm, a comonomer Reactor temperature 75° C.

content of less than 2 mole % and a density between 960 and Reactor pressure 20 bar

980 kg/m. 50

Ethylene feed rate

Hydrogen feed rate

50-60 kg/h

15-20 g/h

The high molecular weight ethylene polymer or copoly Comonomer feed rate 2.8 kg/h

mer forming the other component Suitably has a weight

average molecular weight of between 300,000 and 1,000,

000 g/mole and a comonomer content of 0.1-10, preferably The polymer fraction produced in the loop reactor having

0.1-0.3, % wt. 55 a high density (975 kg/m) and a high melt flow (MFR=

A favoured polymerization catalyst for use in the above 300) was introduced into a gas phase reactor in which the

described embodiment comprises an inorganic Support car polymerization was continued for manufacturing bimodal

rying a chlorine compound, a magnesium compound and a product. 1 -Butene was added into gas phase reactor as

titanium compound. Such catalysts and their preparation are comonomer. The ratio between the components produced in

described in detail in EP-A-688,794, the relevant content of 60 the loop reactor and in the gas phase reactor was 45:55. The

which is incorporated herein by reference. bimodal polyethylene obtained had the following properties:

The invention further comprehends the use of a bimodal

HDPE composition comprising

i) a low molecular weight ethylene polymer, MFRs 18

ii) a high molecular weight ethylene polymer or copoly 65 MFR 28

mer; and FFR21.5 19

iii) a nucleating agent;

US 6,809,154 B2

6

copolymer is Selected from propylene, 1-butene, 1-pentene,

-continued 1-hexene, 4-methyl-1-pentene, 1-octene, 1-decene and

cyclic olefins.

Mw 190,000 3. AHDPE composition according to claim 1, character

M/M 2O

Density 958 kg/m ized in that the alpha-olefin comonomer content is between

Comonomer content about 0.2% wt. 0.1 and 10 weight 9%.

4. A HDPE composition according to claim 1, character

ized in that the density is between 910 and 980 kg/m.

This product in powder form was then thoroughly mixed 5. A HDPE composition according to claim 4, character

in an extruder with micronised Sodium benzoate having the ized in that the density is between 945 and 975 kg/m.

particle size distribution: 6. A HDPE composition according to claim 1, character

ized in that the melt index MFR measured at 190° C.

under 21.6 kg load is between 1 and 1000 g/10 min.

7. A HDPE composition according to claim 6 wherein

<htm % MFR is between 15 and 50.

15 8. A HDPE composition according to claim 6 wherein

2 40-70

8 90-95 MFR is between 120 and 770.

2O 99-1OO 9. A HDPE composition according to claim 6 wherein

MFR is between 1 and 10.

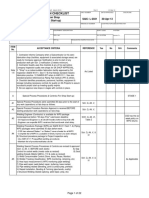

to produce compositions having Sodium benzoate contents 10. A HDPE composition according to claim 1 character

of 500 and 1000 ppm. Samples of these two compositions, ized in that the polymer composition comprises 5-95% of

and of a reference composition containing no Sodium said low molecular weight ethylene polymer and 95-5% of

benzoate, were tested according to ASTM D 1693 for ESCR Said high molecular weight ethylene polymer or copolymer.

(Antarox 10%) and according to ISO 527-2 for Tensile 11. A HDPE composition according to claim 10, charac

Modulus (E-modulus). The results were: terized in that the polymer composition comprises 30–70%

25 of said low molecular weight ethylene polymer and 70-30%

of Said high molecular weight ethylene polymer or copoly

C.

500 ppm 1000 ppm 12. A HDPE composition according to claim 1, charac

Reference Na benzoate Na benzoate terized in that the weight average molecular weight M is

E-modulus 1290 1330 1340 between 50,000 and 20,000 g/mole.

(MPa) 13. A HDPE composition according to claim 1, charac

ESCR (10%) 105 116 106 terized in that the weight average molecular weight M is

F50(h) between 50,000 and 500,000 g/mole.

14. A HDPE composition according to claim 1, charac

EXAMPLE 2

35 terized in that the polydispersity index M/M, is between 5

and 75.

Similar tests run on further batch of the product of 15. A HDPE composition according to claim 14 wherein

Example 1 gave the following results: M/M, is between 10 and 20.

16. AHDPE A composition according to claim 14 wherein

40 M/M, is between 20 and 60.

17. A HDPE composition according to claim 1 wherein

500 ppm 1000 ppm the nucleating agent contains an organic group and a polar

Reference Na benzoate Na benzoate

group and is insoluble in the HDPE.

E-modulus 1250 1250 1290 18. A HDPE composition according to claim 17 where in

(MPa) 45 the nucleating agent is a mono- or polycarboxylic aromatic

ESCR (10%) 87 92 101 acid or a Salt thereof.

F50(h)

19. A HDPE composition according to claim 18 wherein

the nucleating agent is Sodium benzoate.

Photomicrographs of the three Samples tested in Example 1 20. An HDPE composition according to claim 1, charac

at 500x magnification are reproduced in FIGS. 1 (reference), 50 terized in that the nucleating agent is present in an amount

2 (500 ppm Na benzoate) and 3 (1000 ppm Na benzoate). of between 1 and 10,000 ppm.

Comparison of FIGS. 1 and 2 reveals that the addition of 500 21. A HDPE composition according to claim 20 wherein

ppm of Sodium benzoate has caused a slight increase in the the amount of nucleating agent is between 10 and 5000 ppm.

proportion of smaller spherulites, while FIG. 3 reveals the 22. A HDPE composition according to claim 21 wherein

complete elimination of the large spherulites which domi 55 the amount of nucleating agent is between 50 and 2000 ppm.

nate in FIG. 1. 23. AHDPE composition according to claim 22 wherein

What is claimed is: the amount of nucleating agent is between 400 and 1200

1. An HDPE composition comprising an ethylene ppm.

homopolymer or an ethylene alpha-olefin copolymer for 24. A HDPE composition according to claim 1 wherein

producing moulded articles with increased E-modulus and 60 the HDPE has been produced by a process comprising

high ESCR, wherein the polymer is a bimodal polymer catalytically homopolymerizing ethylene in the liquid phase

produced in a multistage process comprising in an inert hydrocarbon medium in a loop reactor, passing

i) a low molecular weight ethylene polymer and the polymer product from the loop reactor to a gas phase

ii) a high molecular weight ethylene polymer or copoly reactor and there continuing the polymerization in the pres

mer and a nucleating agent. 65 ence of ethylene and further catalyst to obtain a bimodal

2. A HDPE composition according to claim 1, character product of which Said polymer from the loop reactor con

ized in that the alpha-olefin of the ethylene alpha-olefin stitutes 20-90% weight.

US 6,809,154 B2

7 8

25. A HDPE composition according to claim 24 wherein 28. A HDPE composition according to claim 1, charac

Said process further comprises a prepolymerization Step terized in that the low molecular weight ethylene polymer

which precedes the loop reactor and in which ethylene has a melt index MFR measured under 2.16 kg load of

homopolymer is produced by liquid phase polymerization in between 50 and 2,000 g/10 min.

the presence of polymerization catalyst, hydrogen and a 29. A composition according to any preceding claim

diluent, the homopolymer produced, amounting to 1 to 5% characterized in that the low molecular weight ethylene

by weight of final HDPE product, being then passed to the

loop reactor together with Said polymerization catalyst. polymer has a density between 960 and 980 kg/m.

26. A HDPE composition according to claim 24 wherein 30. A composition according to claim 1, characterized in

the polymerization in the gas phase reactor is copolymer that the high molecular weight ethylene polymer has a

ization of ethylene with an alpha-olefin Selected from weight average molecular weight of between 300,000 and

propylene, 1-butene, 1-pentene, 1-hexene, 4-methyl-1- 1,000,000 g/mole.

pentene, 1-octene, 1-decene and cyclic olefins. 31. A composition according to claim 1, characterized in

27. A HDPE composition according to claim 1, charac that the high molecular weight ethylene copolymer has a

terized in that the low molecular weight ethylene polymer 15 comonomer content of 0.7 to 7.0 mole%.

has a weight average molecular weight of between 5000 and

50,000 g/mole.

You might also like

- Ste Conchem Q3M4 CFGHSDocument26 pagesSte Conchem Q3M4 CFGHSJazmin Nicole Abanes100% (3)

- Biobase Elisa Microplate Reader BK-EL10C User Manual 202103Document48 pagesBiobase Elisa Microplate Reader BK-EL10C User Manual 202103Victor BlancoNo ratings yet

- Unit 3 & Unit 4Document8 pagesUnit 3 & Unit 4Melania Arliana MeoNo ratings yet

- Landing Capability (Weather) You Need: Fuel Penalty Factor/endurance You HaveDocument1 pageLanding Capability (Weather) You Need: Fuel Penalty Factor/endurance You HaveGeorge Tsolis100% (1)

- Us 558ujdhDocument7 pagesUs 558ujdhLondon MoscowNo ratings yet

- NCO Prepolymers Prepared From Isophorone Diisocyanate and Having A Low Monomer ContentDocument4 pagesNCO Prepolymers Prepared From Isophorone Diisocyanate and Having A Low Monomer ContentQuang VinhNo ratings yet

- Patent US8318835 (FoMoCo)Document6 pagesPatent US8318835 (FoMoCo)LeofodãoNo ratings yet

- US8183190B2Document3 pagesUS8183190B2Risma Dewi SNo ratings yet

- BusaDocument10 pagesBusadewiNo ratings yet

- Balistik Bak 3Document9 pagesBalistik Bak 3KübraNo ratings yet

- Us9873782 PDFDocument11 pagesUs9873782 PDFSyahdillaNo ratings yet

- US8722593 Break FluidDocument5 pagesUS8722593 Break FluidMorkizgaNo ratings yet

- Plastic Bags Bio 2Document4 pagesPlastic Bags Bio 2rida fatimaNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Document7 pagesUnited States Patent: (12) (10) Patent No.: US 7,183,661 B2 Bogner Et Al. (45) Date of Patent: Feb. 27, 2007Vansala GanesanNo ratings yet

- Nat. Gas ReformingDocument6 pagesNat. Gas Reformingabdullah farhanNo ratings yet

- Us 6838499Document7 pagesUs 6838499Pranshu JainNo ratings yet

- Us6391935 PDFDocument10 pagesUs6391935 PDFBilen SeleshiNo ratings yet

- US8236919Document4 pagesUS8236919Billy FowlerNo ratings yet

- US5574124Document6 pagesUS5574124Quang VinhNo ratings yet

- US7950794Document7 pagesUS7950794Hamada HamadaNo ratings yet

- US9505944Document7 pagesUS9505944caronieblesNo ratings yet

- United States Patent: (12) (10) Patent No.: US 9,605,188 B2Document10 pagesUnited States Patent: (12) (10) Patent No.: US 9,605,188 B2peter shiNo ratings yet

- US8475539Document8 pagesUS8475539Nasir UddinNo ratings yet

- Us5844037 PDFDocument12 pagesUs5844037 PDFKelly GuerreroNo ratings yet

- US8796498Document7 pagesUS8796498Muhammad Akbar FahleviNo ratings yet

- United States Patent (10) Patent No.: US 6,818,099 B2: Tienvieri Et Al. (45) Date of Patent: Nov. 16, 2004Document14 pagesUnited States Patent (10) Patent No.: US 6,818,099 B2: Tienvieri Et Al. (45) Date of Patent: Nov. 16, 2004ahmetNo ratings yet

- Lambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónDocument8 pagesLambda + Chlorantraniliprole - Cómo Estabilizar La SuspensiónAlfredo MéndezNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7482.410 B2Document15 pagesUnited States Patent: (12) (10) Patent No.: US 7482.410 B2ariefNo ratings yet

- Rohm and Haas US6300409Document7 pagesRohm and Haas US6300409HermawanRandiNo ratings yet

- United States Patent (10) Patent No.: US 7,939.469 B2Document6 pagesUnited States Patent (10) Patent No.: US 7,939.469 B2live streamNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument7 pagesUnited States Patent: (10) Patent No.: (45) Date of Patentnur mxNo ratings yet

- Plastic Bags BioDocument13 pagesPlastic Bags Biorida fatimaNo ratings yet

- United States Patent: (10) Patent N0.: (45) Date of PatentDocument6 pagesUnited States Patent: (10) Patent N0.: (45) Date of PatentbvritNo ratings yet

- United States Patent: (75) Inventors: Franz-Josef Dietzen, Hassloch (DE)Document8 pagesUnited States Patent: (75) Inventors: Franz-Josef Dietzen, Hassloch (DE)Ghina Fatikah SalimNo ratings yet

- Preparation ProcessDocument5 pagesPreparation ProcessHarshitMittalNo ratings yet

- Paten Produksi Syn Gas BaruDocument6 pagesPaten Produksi Syn Gas BaruFarras HaidaryNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,333,903 B2Document7 pagesUlllted States Patent (10) Patent N0.: US 8,333,903 B2andrew22No ratings yet

- United States Patent: (75) Inventors: Guy Joseph Clamen, Opio (FR)Document5 pagesUnited States Patent: (75) Inventors: Guy Joseph Clamen, Opio (FR)Long An DoNo ratings yet

- United States Patent (19) : Heyke Et Al. Feb. 23, 1993Document4 pagesUnited States Patent (19) : Heyke Et Al. Feb. 23, 1993Vansala GanesanNo ratings yet

- Pigment PasteDocument5 pagesPigment PasteAoronno Hasan AkibNo ratings yet

- Us7084310 PG PDFDocument9 pagesUs7084310 PG PDFmeimeiNo ratings yet

- 12) United States Patent: Krupinski Et ADocument19 pages12) United States Patent: Krupinski Et AVinod Kumar KonagantiNo ratings yet

- III Iii Iihiii: United States PatentDocument5 pagesIII Iii Iihiii: United States PatentThuận LêNo ratings yet

- United States Patent (10) Patent No.: US 8,710,133 B2Document11 pagesUnited States Patent (10) Patent No.: US 8,710,133 B2APEX SONNo ratings yet

- US Patent US6657057Document6 pagesUS Patent US6657057Vandit KhareNo ratings yet

- United States Patent (10) Patent No.: US 8,598,377 B2Document8 pagesUnited States Patent (10) Patent No.: US 8,598,377 B2Vaibhav MoonNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,041,746 B2Document4 pagesUnited States Patent: (12) (10) Patent No.: US 7,041,746 B2รอคนบนฟ้า ส่งใครมาให้ สักคนNo ratings yet

- Biodegradable SADocument12 pagesBiodegradable SAziziNo ratings yet

- Patent 5Document8 pagesPatent 5ALEXANDER FRANCO CASTRILLONNo ratings yet

- US8048970Document10 pagesUS8048970subramanian.sNo ratings yet

- Us7951429 2595Document5 pagesUs7951429 2595WSERNo ratings yet

- EP12722593NWB1Document30 pagesEP12722593NWB1Sy Nguyen VietNo ratings yet

- Proceso de HidrocarburosDocument14 pagesProceso de Hidrocarburosingeniomeca8800No ratings yet

- Us8455685 UseDocument10 pagesUs8455685 UseRefi RahmanNo ratings yet

- United States Patent (10) Patent No.: US 7.442.434 B2Document6 pagesUnited States Patent (10) Patent No.: US 7.442.434 B2Alexander Franco CastrillonNo ratings yet

- Gel SpinningDocument20 pagesGel SpinningRATNA YULYANTINo ratings yet

- United States Patent: Jangbarwala (45) Date of Patent: Dec. 15, 2015Document12 pagesUnited States Patent: Jangbarwala (45) Date of Patent: Dec. 15, 2015Juzer JangbarwalaNo ratings yet

- United States Patent: US 7,084,310 B2 Aug. 1,2006Document9 pagesUnited States Patent: US 7,084,310 B2 Aug. 1,2006Ivander GultomNo ratings yet

- US8322575Document7 pagesUS8322575r3marcosNo ratings yet

- US7387748Document7 pagesUS7387748MaboodNo ratings yet

- US9469775Document8 pagesUS9469775Lucie LeroyNo ratings yet

- SBR LetixDocument6 pagesSBR LetixzaighumNo ratings yet

- United States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Document10 pagesUnited States Patent (10) Patent No.: US 6,455,142 B1: Heberger Et Al. (45) Date of Patent: Sep. 24, 2002Thuận LêNo ratings yet

- Principles of Unit Operations by A S Foust L A Wenzel C W Clump L Maus L B Andersen 0471268976 PDFDocument5 pagesPrinciples of Unit Operations by A S Foust L A Wenzel C W Clump L Maus L B Andersen 0471268976 PDFariefNo ratings yet

- SDocument16 pagesS266870idNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7482.410 B2Document15 pagesUnited States Patent: (12) (10) Patent No.: US 7482.410 B2ariefNo ratings yet

- United States Patent: Crowther Et AlDocument33 pagesUnited States Patent: Crowther Et AlariefNo ratings yet

- (US) Ray Christian, Midland, MI, W 33.33. A 23: United States PatentDocument9 pages(US) Ray Christian, Midland, MI, W 33.33. A 23: United States PatentariefNo ratings yet

- United States Patent Office: Patented Jan. 20, 1959Document2 pagesUnited States Patent Office: Patented Jan. 20, 1959ariefNo ratings yet

- Effect of Titanium-Magnesium Catalyst Morphology On The Properties of Polypropylene Upon Propylene Polymerization in A Liquid MonomerDocument2 pagesEffect of Titanium-Magnesium Catalyst Morphology On The Properties of Polypropylene Upon Propylene Polymerization in A Liquid MonomerariefNo ratings yet

- Polyethylene: K S. W, Formerly ICI Plastics Division, Welwyn Garden City, United KingdomDocument38 pagesPolyethylene: K S. W, Formerly ICI Plastics Division, Welwyn Garden City, United KingdomariefNo ratings yet

- SCHWING Fluidized Bed Process Technique enDocument6 pagesSCHWING Fluidized Bed Process Technique enariefNo ratings yet

- Perrys Chemical Engineering Handbook 6thDocument2 pagesPerrys Chemical Engineering Handbook 6tharief50% (6)

- T CrioDocument2 pagesT CrioTempcoNo ratings yet

- Health Condition1Document22 pagesHealth Condition1Barrack koderaNo ratings yet

- Ground Floor LayoutDocument1 pageGround Floor LayoutDEVEN GEETNo ratings yet

- The New Cairo Mall: DWG-MF0202.03 DWG - MF0202.04Document1 pageThe New Cairo Mall: DWG-MF0202.03 DWG - MF0202.04Mahmud MaherNo ratings yet

- Jealousy As Good: Bad Behavior and JealousyDocument2 pagesJealousy As Good: Bad Behavior and JealousyInesha FebrinaNo ratings yet

- CatalystDocument22 pagesCatalystAdan JavedNo ratings yet

- Silicon NPN Darlington Power Transistor BDW93C: DescriptionDocument2 pagesSilicon NPN Darlington Power Transistor BDW93C: DescriptionSergio Brida100% (1)

- Is 1200Document18 pagesIs 1200Abhishek PawarNo ratings yet

- Diels-Alder ReactionDocument25 pagesDiels-Alder ReactionEsteban ArayaNo ratings yet

- Hu 2018Document11 pagesHu 2018avula43No ratings yet

- Anhedonia Preclinical, Translational, and Clinical Integration (Ch. 1)Document30 pagesAnhedonia Preclinical, Translational, and Clinical Integration (Ch. 1)strillenNo ratings yet

- P2 Ped 030 ReviewerDocument6 pagesP2 Ped 030 ReviewerFrancis DeocaresNo ratings yet

- Amicor InformationDocument5 pagesAmicor InformationcciprainNo ratings yet

- Algae JurnalDocument9 pagesAlgae Jurnalalex kristiantoNo ratings yet

- Directions: Please Read The Following Passage and Answer All of The AccompanyingDocument5 pagesDirections: Please Read The Following Passage and Answer All of The AccompanyingLiseth Mabel Angarita BonillaNo ratings yet

- Case Analysis: ObjectivesDocument8 pagesCase Analysis: ObjectivesJoan BalendrezNo ratings yet

- Component Spec TRIMAX 43C Detector 02162020 (AK0540)Document5 pagesComponent Spec TRIMAX 43C Detector 02162020 (AK0540)RamaNurullarifahNo ratings yet

- Chapter 5 Connective Tissue NotesDocument3 pagesChapter 5 Connective Tissue NotesBinadi JayNo ratings yet

- Saudi Aramco Inspection ChecklistDocument22 pagesSaudi Aramco Inspection Checklistabdulgafoor54100% (2)

- Individual AssignementDocument7 pagesIndividual Assignementgemechu67% (3)

- Force and Pressure MCQDocument6 pagesForce and Pressure MCQnitikaNo ratings yet

- Takayasu S Arter It IsDocument5 pagesTakayasu S Arter It IsButarbutar MelvaNo ratings yet

- School Action Plan (Bridging Primer 2 Output) RevisedDocument3 pagesSchool Action Plan (Bridging Primer 2 Output) RevisedCynthiaNo ratings yet

- Trends in The Use of Marine Ingredients in Anti-Aging CosmeticsDocument11 pagesTrends in The Use of Marine Ingredients in Anti-Aging CosmeticsANGIE TATIANA RUIZ LADINONo ratings yet

- 428 Perioperative Management of Subarachnoid HemorrhageDocument27 pages428 Perioperative Management of Subarachnoid Hemorrhagemuthia yuniarta sinagaNo ratings yet

- Navitron Panel AssemblyDocument23 pagesNavitron Panel AssemblyXe CohNo ratings yet