Professional Documents

Culture Documents

Engineering Design Guides - Helical Springs PDF

Engineering Design Guides - Helical Springs PDF

Uploaded by

rvpilot0 ratings0% found this document useful (0 votes)

54 views31 pagesOriginal Title

Engineering Design Guides - Helical Springs.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

54 views31 pagesEngineering Design Guides - Helical Springs PDF

Engineering Design Guides - Helical Springs PDF

Uploaded by

rvpilotCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 31

HELICAL SPRINGS

aay armel

he Spring Research Association

ublished for the Design Council,

e British Standards Institution and

e Council of Engineering Institutions

by Oxford University oe

|

ENGINEERING DESIGN GUIDES 08

HELICAL SPRINGS

prepared by

The Spring Research Association on behalf of

the United Kingdom Atomic Energy Authority

Published for the Design Council,

the British Standards Institution, and

the Council of Engineering Institutions,

in conjunction with the United kingdom

‘Atomic Energy Authority by

Oxford University Press

{dtorial Advisory Board

Des Moule Chaimnan CBE.CEng FANE FRACS.

HG, Conway CBEMA HonD Sc Ging FIMeChE FRACS.

De. Castod Cg FICE F1Stact CGS, MGons

MajorGeneral MUL Gavin CB CBE

Copyright (the United Kingdom Atomic Energy Authority 1974

A ighs reserved No part of this publication may be erode

‘Sore aretivalsjtem or transl ev any frm by ary ena

‘dectrnic. mechanical photocopying recorder yor otherwise wit

the per permiscea the Lente King Ate nergy Aut

The Dessn Counct the Beth Stand

Engineer tutions as pansons

ingcom Atomic Energy Authonty hav

accuracy inal responsi 1048

msttution and the Co

Fimset and printed n teat Brita by

BAS Panters Lined, Wallop, Hams

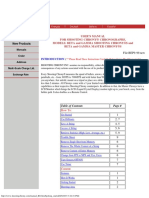

Contents

Introduction

Initial design considerations

Functional classification

Category 1: springs requiring no load

measurements

Category 2: springs requiring one

loadilength measurement

Category 3: springs requiring two or more

load length measurements,

Category 4: springs requiring

measurement of rate

Selection of materials

Carbon steels and alloy steels

Stainless steels (nickel-chromium steels)

Copper and copper alloys

Nickel alloys

Other materials for special applications

ubleation. and the United

tents eae nh the aan

Materials to be used in some common

environments

Corrosive environments

Flevated temperatures

Low temperatures,

Nuclear irradiation

Fatigue conditions

Working stresses

Shot-peening

Vapour-blasting and dry honing

Static conditions

Limiting factors

Dynamic loading of springs

Spring index

Compression springs

Tension springs

Spring ends

Compression springs

Tension spring ends

Appendix 1: Calculations

Notation

Basic formulae

General relationships for use with

compression springs.

Relationships for use with tables (see

‘Appendix 3) when desired spring rate is

known (compression springs)

Natural frequency of vibration

Buckling

Telescopic and nested springs

Example of a design calculation for a

compression spring

General relationships for use with tension

springs

Relationships for use with tables (see

Appendix 3) when desired spring rate is

known (tension springs)

Stresses in end hooks (tension springs)

Example of a design calculation for a

tension spring

‘Appendix 2: Specification

Tolerances

Heat-treatment

Protective finishes

Presentation of data

Appendix 3: Tables

British Standards

Ministry of Defence Specifications

Bibliography

10

10

10

10

n

n

"

"

u

n

R

B

B

B

B

uw

4

5

5

15

B

30

30

Introduction

In order to specify a spring for a particular applica-

tion, the designer will normally be aware of the

approximate forces and the degree of accuracy

required, together with the environmental con-

ditions in which the spring must operate.

From this basic information itis logical to select

a material from which the cheapest spring can be

made to provide a satisfactory performance in

the given environmental conditions. A maximum,

permissible stress can then be determined, which

together with the load requirements will enable

suitable dimensions to be selected. Details of

practical spring calculations and. specifications

are given in Appendixes 1 and 2 and extensive

tables of spring properties in Appendix 3.

Before starting to design a new spring, con-

sideration should be given to standard stock

commercial springs. However, these should not

bbe used where the function is of vital importance

or where a full specification for replacement

purposes is required, since the material specifica-

tions and precise characteristics of commercial

springs may be difficult to establish, Most large

design organizations set up a ‘bank’ of spring,

designs already in production to encourage,

wherever possible, the use of existing items.

Initial design considerations

Where design considerations permit the choice of

using a spring either in compression or in tension.

the former is to be preferred, because the con:

centration of stress which occurs at the ends of

tension springs will result in loss of performance.

It is strongly recommended that, wherever

possible, springs should be designed before the

details of housings or other adjacent parts have

been finally established. This procedure will mini-

mize restrictions on the design of the spring by

ensuring that adequate space is allowed for its

accommodation

Wireshouldbe of circular ratherthan rectangular

section, since the only advantages of rectangular

section springs are that they can be designed to,

give greater volumetric efficiency and that they

have superior resistance to buckling Wire of

Circular section is cheaper, has a superior surface

condition, and is much easier to obtain than that

of rectangular section,

For maximum volumetric efficiency, nested

springs in parallel should be considered. In such

cases the solid length, including end coils of the

outer spring in a nest, should be slightly greater

than that of the inner spring or springs. Adjacent

springs should be wound in opposite directions to

prevent interference

In cases where the deflection is large in relation

to the length of housing available, nested springs

in series (that is, telescopic springs) may be an.

advantage.

Functional classification

The designer should classify every spring according

to its functional requirements into one of the

following four categories, putting as many as

possible into category 1 since these are the easiest

to make, while categories 2, 3, and 4 become

progressively more difficult.

Category 1: springs requiring no load

measurements

These are sufficient where the load exerted by the

spring is not of great importance and is fixed

arbitrarily for design purposes, such as when

operating a simple locking plunger.

Category 2: springs requiring one loadilength

measurement

These are adequate where theload at one operating

length must fall within definite limits, but where

the loads at other deflections are not particularly

important.

Category 3: springs requiring two or more

loadilength measurements

These should be used only when accurate control

of the load at two or more specific points through:

‘out the operating range is necessary.

Category 4: springs requiring measurement ol rate

These should be used only when a definite rate is

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Toyota Tundra A760F TransmissionDocument47 pagesToyota Tundra A760F Transmissionrvpilot100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kenmore Dryer Service Manual PDFDocument80 pagesKenmore Dryer Service Manual PDFrvpilot100% (1)

- ABC's of Spray Painting, DevilbissDocument44 pagesABC's of Spray Painting, Devilbissrvpilot100% (1)

- Honda GX240 Parts List and Diagrams Type QA2X for Serial Numbers GC04-3000000-4399999Document101 pagesHonda GX240 Parts List and Diagrams Type QA2X for Serial Numbers GC04-3000000-4399999rvpilotNo ratings yet

- Maggiore M. A Modern Introduction To Classical Electrodynamics 2023Document466 pagesMaggiore M. A Modern Introduction To Classical Electrodynamics 2023rvpilotNo ratings yet

- 2017 Toyota Tundra Warranty and Maintenance GuideDocument66 pages2017 Toyota Tundra Warranty and Maintenance GuidervpilotNo ratings yet

- Guruji. RC Phase Shift Oscillator Using Opamp IC 741... Electronics 2021Document19 pagesGuruji. RC Phase Shift Oscillator Using Opamp IC 741... Electronics 2021rvpilotNo ratings yet

- H11A817C Optocoupler - FairchildDocument12 pagesH11A817C Optocoupler - FairchildrvpilotNo ratings yet

- Shooting Chrony Users ManualDocument22 pagesShooting Chrony Users Manualrvpilot100% (1)

- Understanding Royer Oscillator For Wireless Power Transfer - Stack-ExchangeDocument3 pagesUnderstanding Royer Oscillator For Wireless Power Transfer - Stack-ExchangervpilotNo ratings yet

- Design of Guidance and Control Systems For Tactical Missles - Zaikang, Qi PDFDocument255 pagesDesign of Guidance and Control Systems For Tactical Missles - Zaikang, Qi PDFrvpilotNo ratings yet

- Stepper Motor BasicsDocument11 pagesStepper Motor BasicsrvpilotNo ratings yet

- Electronic Design Library - Focus On Bob Pease On Analog Vol 1Document10 pagesElectronic Design Library - Focus On Bob Pease On Analog Vol 1rvpilotNo ratings yet

- X-Ray Computed Tomography (CT)Document9 pagesX-Ray Computed Tomography (CT)rvpilotNo ratings yet