Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

139 viewsFurmanite Composite Wrap

Furmanite Composite Wrap

Uploaded by

anwarhas05Furmanite Composite Wrap

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Piping Field Inspection ChecklistDocument2 pagesPiping Field Inspection Checklistanwarhas0586% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Online Leak Repair PDFDocument3 pagesOnline Leak Repair PDFanwarhas05100% (2)

- Handbook-Riser-Design - Clamps PDFDocument46 pagesHandbook-Riser-Design - Clamps PDFanwarhas050% (1)

- CEDA OnLine Leak RepairDocument6 pagesCEDA OnLine Leak Repairanwarhas05No ratings yet

- Tube BundleDocument6 pagesTube Bundleanwarhas05No ratings yet

- Exova TestingDocument13 pagesExova Testinganwarhas05No ratings yet

- Injection Safety PresentationDocument20 pagesInjection Safety Presentationanwarhas05100% (1)

- RCM PDFDocument46 pagesRCM PDFanwarhas05No ratings yet

- Safety Programs Life CycleDocument9 pagesSafety Programs Life Cycleanwarhas05No ratings yet

- Technical Manual Adjustable Choke MANUAL006-1 PDFDocument51 pagesTechnical Manual Adjustable Choke MANUAL006-1 PDFanwarhas05No ratings yet

- B.W.G. ChartDocument1 pageB.W.G. Chartanwarhas05No ratings yet

- Presentation Duxvalves B.VDocument25 pagesPresentation Duxvalves B.Vanwarhas05No ratings yet

- Belzona Offshore RepairsDocument4 pagesBelzona Offshore Repairsanwarhas05No ratings yet

- Pressure Point HSB - 2007-06Document4 pagesPressure Point HSB - 2007-06anwarhas05No ratings yet

- HE Tube Plug SizeDocument5 pagesHE Tube Plug Sizeanwarhas05No ratings yet

- Plastic Collapse - Beam in Bending: M Px/2 V P/2Document21 pagesPlastic Collapse - Beam in Bending: M Px/2 V P/2anwarhas05No ratings yet

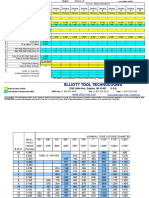

- Elliott Tool Technologies: 1760 Tuttle Ave., Dayton, OH 45403 U.S.ADocument5 pagesElliott Tool Technologies: 1760 Tuttle Ave., Dayton, OH 45403 U.S.Aanwarhas05No ratings yet

- AWS CWI Inspector ResponsibilitiesDocument3 pagesAWS CWI Inspector Responsibilitiesanwarhas05No ratings yet

- Trunnion Mounted Ball Valves TMBVDocument32 pagesTrunnion Mounted Ball Valves TMBVanwarhas05100% (1)

Furmanite Composite Wrap

Furmanite Composite Wrap

Uploaded by

anwarhas050 ratings0% found this document useful (0 votes)

139 views2 pagesFurmanite Composite Wrap

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFurmanite Composite Wrap

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

139 views2 pagesFurmanite Composite Wrap

Furmanite Composite Wrap

Uploaded by

anwarhas05Furmanite Composite Wrap

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

Core ey

Pees Tat

On-line Repairs. Permanent Results.

The very latest composites meterial

technology was successfully applied at

the Shell Mossmorran gas. processing

plant whon Furmanito was called in to

fepair 2 butane tank vapour cetua,

{A planned inspection identified external

corrosion on an TB-inch flange and the

connection between the TB-inch line and

25:inch butane tank nozzle. Shell wanted

8 repair option that could be carried out

online withoutincreesing the possibilty of

aleak

Fast, flexible and permanent

The answer was a composites-based

solution, It would be @ strang permanent

repair. And because it can be taliored on-

sito with no pro-fabricaton, is fast and

costeffactiva. There are minimal life

‘maintenance requirements,

The repair was caried out at pressures of

up to 18 bar g and temperatures of 40°C.

Composites can be used typically up to 50

bar g and at tomperatures from -80°C to

+100°C and, with due design

Consideration, are not limited to these

perameters,

The result is self-evident. A sound,

ormanent repair that uses tho latost

‘composites technology to minimise cost

Dem

technology combines

RUT UTE

ee ae

eae Led

era)

Strong, lightweight, and non-corroding. The benefits of Furmanite

Composites technology are significant.

Furmanite has broadened its on-site and

online services to include composites

material, for highly effective permanent

Furmanite offers the very latest composites,

material technology available. Typically

based on carbon fibre and epoxy resin, the

‘materials are up to ten times as strong and

twice as stiff as steel, have 20-25% the

density of steel, and do not corrode. What's

more, they're easy to handle, require

minimal access for installation, and are

flexible so they can cope with tees, elbows,

reducers, bends and other complex

geometries.

Most importantly, composites technology

from Furmanite will restore pressure

containment and provide multidirectional

structural strength, including axial load,

providing the next generation of on-line

repair and structural strengthening solutions

for pipes, pipelines and vess

Effective. Flexible. Versatile.

A typical repair can incorporate the

following stages:

-

Suber elce i prepared rit bled)

‘erin 3425)

Aisin ingregnated ayes of carbon fre are oplie

Resulting in a strong, effective, permanent

repair, restoring pipe integrity and

structural strength.

CLIDRAAAITO

Carbon fibre keeps the oil flowing

When an NOT inspection revealed

significant extemal. corrosion over an

extensive section of pioework on the

Shell Expro.Ounlin. Alpha platform, it

Ssaemed shutdown and replacamant was

the only option. The composites or-line

repair solution from Furmanite’s

composites division, however, avoided

this, saving up to. threo weoks’ lost

production and significant costs

Over 50 metres of strengthening was

carried out using composits (in most

(¢3508 10a thickness of just Smm) on two.

2inch steel service water lings and a

Winch fire water line as they passed

through the corrosive environment of a

chemical madule, Numerous flanges,

valves and teo-sections were also

‘verwrapped using composites. Much of

the damage was in severely restricted

accpss areas, so that traditional repair

mathods such as conventional soeling

clamps were not viable, The result was

fan overall structural strengthening ofthe

pieline, restoring full design pressure

Containment capability, yet without

adding significant weight

A temporary steel clamp over a weld

defect on a 16-inch hydrocarbon ine

provided a particular challongo. This was

faired in to give a smooth profile, and

composites-wrapped to a thickness of

38mm, restoring full design pressure and

containing a Imm crack eround the

circumference of tho pips.

Five technicians working over a period of

38 days (including mobilisation time)

Carried out the repair with no disruption

to production,

Sha xp Dain ipower

Versatile. On-line. Permanent

‘These are the terms that best describe the application of comp

(es ~ providing a new

generation of structural repairs. The range of situations in which composites can be

used is constantly growing; as one of the leaders in the field, Furmanite’s composites

repair division is well placed to advise on the suitabi

circumstances.

Permanent Pipe Repair

Restoring both axial strength and hoop

sirength to damaged pipelines, composites

provide a rapid-response solution.

Pipe Rehabilitation

Being lightweight, composites impose very

litte additional loading on. pipes. This

makes them ideal for extensive

rehabilitation projects - where corrosion has

set in, for example.

Caisson Rehabilitation

Avoiding the need for costly and disruptive

hotwork, composites offer a costeffective

and long-lasting method of caisson

rehabilitation

Flare Line Repair and Strengthening

Furmanite has engineers with every

necessary skill - including abselling,

enabling even complex repairs to be

undertaken with very litle disruption.

opis to seawater coolio stent

Complex Geometry

Feexibiliy and the abil t form a repair in

situ =the two properties that make composites

ideal for use on complex installations. They

can be easily wrapped around pieces,

K pieces, elbows and flanges without the need

for expensive pre-fabrication.

Small-bore Pipe Repairs

Smalhbore pipes often donot possess the

Structural integrity of larger pipelines.

Furmanite International Limited

Furman Hous, Shap Road, Kenda, Cumbria,

United Kingdom LAG BRU

Tk +44 (0) 153872808

6 (0) 1598 728059

E-mail salessupporwkifurmanite.com

of the materials for particular

Conventional steel clamp solutions may be

too heavy. Again, composites” lightweight

properties provide a viable alternative,

Nozzle Repair

Repairs using composites are specially

designed to ignore the original strength

contribution ofthe existing structure. “Thus

although the repair becomes a part of the

structure, its strengths independent of it

‘or potentially weak points, therefore, such.

a8 a nozzle junction, composites ae ideal

A strong heritage

Composites are ideally suited to

strengthening and permanent repair work.

Originally used in the aerospace industry,

they have now been widely applied in the

marine, civil and offshore engineering

sectors. More than 200 civil structures

including bridges, buildings and tunnels as

well as more than 20 offshore structures

have been strengthened using composite

materials

Quality assurance with Furmanite’s

trained technicians.

Furmanite’s unrivalled highly trained

technicians are fully certified and

externally accredited and work within

the ISO 9000 remit to ensure that

customers achieve maximum process

efficiency and effective asset

management ~ by avoiding unscheduled

shutdown,

1 branch na 2 Go Line Ageia.

FURMANITE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Piping Field Inspection ChecklistDocument2 pagesPiping Field Inspection Checklistanwarhas0586% (7)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Online Leak Repair PDFDocument3 pagesOnline Leak Repair PDFanwarhas05100% (2)

- Handbook-Riser-Design - Clamps PDFDocument46 pagesHandbook-Riser-Design - Clamps PDFanwarhas050% (1)

- CEDA OnLine Leak RepairDocument6 pagesCEDA OnLine Leak Repairanwarhas05No ratings yet

- Tube BundleDocument6 pagesTube Bundleanwarhas05No ratings yet

- Exova TestingDocument13 pagesExova Testinganwarhas05No ratings yet

- Injection Safety PresentationDocument20 pagesInjection Safety Presentationanwarhas05100% (1)

- RCM PDFDocument46 pagesRCM PDFanwarhas05No ratings yet

- Safety Programs Life CycleDocument9 pagesSafety Programs Life Cycleanwarhas05No ratings yet

- Technical Manual Adjustable Choke MANUAL006-1 PDFDocument51 pagesTechnical Manual Adjustable Choke MANUAL006-1 PDFanwarhas05No ratings yet

- B.W.G. ChartDocument1 pageB.W.G. Chartanwarhas05No ratings yet

- Presentation Duxvalves B.VDocument25 pagesPresentation Duxvalves B.Vanwarhas05No ratings yet

- Belzona Offshore RepairsDocument4 pagesBelzona Offshore Repairsanwarhas05No ratings yet

- Pressure Point HSB - 2007-06Document4 pagesPressure Point HSB - 2007-06anwarhas05No ratings yet

- HE Tube Plug SizeDocument5 pagesHE Tube Plug Sizeanwarhas05No ratings yet

- Plastic Collapse - Beam in Bending: M Px/2 V P/2Document21 pagesPlastic Collapse - Beam in Bending: M Px/2 V P/2anwarhas05No ratings yet

- Elliott Tool Technologies: 1760 Tuttle Ave., Dayton, OH 45403 U.S.ADocument5 pagesElliott Tool Technologies: 1760 Tuttle Ave., Dayton, OH 45403 U.S.Aanwarhas05No ratings yet

- AWS CWI Inspector ResponsibilitiesDocument3 pagesAWS CWI Inspector Responsibilitiesanwarhas05No ratings yet

- Trunnion Mounted Ball Valves TMBVDocument32 pagesTrunnion Mounted Ball Valves TMBVanwarhas05100% (1)