Professional Documents

Culture Documents

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Uploaded by

Subash KrishnanCopyright:

Available Formats

You might also like

- Veolia's Case Studies For Small Wastewater Treatment PlantsDocument15 pagesVeolia's Case Studies For Small Wastewater Treatment PlantsOswar MungkasaNo ratings yet

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- 9 - Design of A Fermenter PDFDocument51 pages9 - Design of A Fermenter PDFYAUW HANSEN ADITYANo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Solid and Submerged FermentationDocument12 pagesSolid and Submerged FermentationgopnarayansamyakNo ratings yet

- Proces Equipment Design Guide For FermenDocument23 pagesProces Equipment Design Guide For FermenTheodoros AtheridisNo ratings yet

- Lec No 1 Chapeter 4,5,6,7,8,9,10Document41 pagesLec No 1 Chapeter 4,5,6,7,8,9,10PromiseNo ratings yet

- FermentorDocument14 pagesFermentorSanthosh KaranNo ratings yet

- UntitledDocument16 pagesUntitledAman RaiNo ratings yet

- Fermenter and Its Features 1Document14 pagesFermenter and Its Features 1Akhil Suresh (Synthite Biotech)No ratings yet

- Bioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsDocument14 pagesBioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsShahriar ShamimNo ratings yet

- UNIT - III - Design of FermentorDocument19 pagesUNIT - III - Design of FermentorGDNo ratings yet

- Fermenter DesignDocument59 pagesFermenter DesignPratishtha RawatNo ratings yet

- MCB 407 Lecture FourDocument9 pagesMCB 407 Lecture FourPopoola OlakunleNo ratings yet

- Fermentation Technology TEXTDocument18 pagesFermentation Technology TEXTJIBAN JYOTI DASHNo ratings yet

- BIOREACTORDocument38 pagesBIOREACTORijat_No ratings yet

- Lecture 5 Fermenter Types and Microbial Gowth Kinetics 1 1459529119 1489994861Document36 pagesLecture 5 Fermenter Types and Microbial Gowth Kinetics 1 1459529119 1489994861jeevalakshmanan29No ratings yet

- Abbr Biot Lec 3Document5 pagesAbbr Biot Lec 3nareman hassanNo ratings yet

- Design and Performance Test of A Batch System Rotary Vacuum Dryer With A 50-Liter Capacity To Dry Basidiomycota Class MushroomsDocument7 pagesDesign and Performance Test of A Batch System Rotary Vacuum Dryer With A 50-Liter Capacity To Dry Basidiomycota Class MushroomsAREEJ JAVEDNo ratings yet

- Bioreactors (Fermenters) - Function, Designs and TypesDocument28 pagesBioreactors (Fermenters) - Function, Designs and TypesDolly Priya100% (2)

- Fermenter TypesDocument23 pagesFermenter TypesPratishtha RawatNo ratings yet

- Renewable Energy Unit-2Document17 pagesRenewable Energy Unit-2Sachin ShrivastavNo ratings yet

- Parts of BioreactorDocument8 pagesParts of BioreactorUlfath SultanaNo ratings yet

- Design and Equipment For The Cell Culture LaboratoryDocument3 pagesDesign and Equipment For The Cell Culture LaboratoryAlejandro NavarroNo ratings yet

- Lectuer 16Document23 pagesLectuer 16deekshupapareddyNo ratings yet

- Design Bioreactor For The Production OF Biopharmaceuticals From Animal CellsDocument38 pagesDesign Bioreactor For The Production OF Biopharmaceuticals From Animal Cellsijat_No ratings yet

- Bioreactors LatestDocument34 pagesBioreactors LatestSyeda KazmiNo ratings yet

- Scale-Up, Upstream and Downstream ProcessingDocument106 pagesScale-Up, Upstream and Downstream ProcessingAlbert KuufamNo ratings yet

- Assignment ATFDocument2 pagesAssignment ATFduafareed711No ratings yet

- Bioreactor Types (Industrial Notes)Document23 pagesBioreactor Types (Industrial Notes)anjali100% (1)

- Fermentors Types and Design 2015Document23 pagesFermentors Types and Design 2015NJOKU VERONICA CHIZOBANo ratings yet

- 17 - Chapter 7Document28 pages17 - Chapter 7Franklin Villegas PálizNo ratings yet

- Impacts of Biochemical Engineering in Biotechnology: Kaushik Nath and Debabrata DasDocument4 pagesImpacts of Biochemical Engineering in Biotechnology: Kaushik Nath and Debabrata DasSambeet SatapathyNo ratings yet

- Unit 2Document87 pagesUnit 2SavitaNo ratings yet

- Harmonization of HATCHERY PRODUCTION OF Penaeus Monodon in Asean CountriesDocument20 pagesHarmonization of HATCHERY PRODUCTION OF Penaeus Monodon in Asean CountriesCharles FigueroaNo ratings yet

- InTech-Biogas Plant constructionsPublishedVersionDocument27 pagesInTech-Biogas Plant constructionsPublishedVersionSuraj Kumar SamalNo ratings yet

- Bichemical Eng Chapter 1Document31 pagesBichemical Eng Chapter 1mikialeNo ratings yet

- Chapter # 4 Insight Into FermentationDocument1 pageChapter # 4 Insight Into FermentationWaqas MinhasNo ratings yet

- Mechanical Engineering:Production Engineering: Design and Manufacture O F Incubator MachineDocument75 pagesMechanical Engineering:Production Engineering: Design and Manufacture O F Incubator MachineProsper MahlengezanaNo ratings yet

- Mahatma Gandhi Institute of Pharmacy, Lucknow: BioreactorsDocument19 pagesMahatma Gandhi Institute of Pharmacy, Lucknow: BioreactorsJunior MishraNo ratings yet

- Fermentation SystemsDocument40 pagesFermentation SystemsLolly AntillonNo ratings yet

- InTech-Biogas Plant constructionsPublishedVersionDocument27 pagesInTech-Biogas Plant constructionsPublishedVersionMunkhnasan PurevsurenNo ratings yet

- Presentation On BioreactorsDocument4 pagesPresentation On BioreactorsChukwudi Victor TagboNo ratings yet

- Eid Guidlines For FoodDocument9 pagesEid Guidlines For FoodJohn Nen BiniNo ratings yet

- 8 A BIOREACTORSAComplete ReviewDocument39 pages8 A BIOREACTORSAComplete ReviewSomya SomuNo ratings yet

- Design and Operation of Conventional BioreactorDocument25 pagesDesign and Operation of Conventional BioreactorMahesh RamNo ratings yet

- Safety Issues On DryerDocument5 pagesSafety Issues On Dryerareej athirahNo ratings yet

- Fermenter-Guhan K ADocument4 pagesFermenter-Guhan K AGuhan KANo ratings yet

- Different Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitesDocument11 pagesDifferent Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitespavithraNo ratings yet

- Types of FermentersDocument6 pagesTypes of FermentersSajjad Hossain ShuvoNo ratings yet

- Bacteria As A Filtration Loss Reducing Agent During DrillingDocument4 pagesBacteria As A Filtration Loss Reducing Agent During DrillingJessica KingNo ratings yet

- SWM Practical No. 8Document8 pagesSWM Practical No. 8balrajgholap847No ratings yet

- Design and Fabrication of Bench-Scale Ash Pyrolysis Reactor For Bio-Fuel ProductionDocument7 pagesDesign and Fabrication of Bench-Scale Ash Pyrolysis Reactor For Bio-Fuel ProductionfadyahNo ratings yet

- Lect 2 Fermentation TechnologyDocument42 pagesLect 2 Fermentation TechnologyFadhil HelmiNo ratings yet

- Mode of OperationDocument4 pagesMode of OperationttNo ratings yet

- Irjet V6i2264Document4 pagesIrjet V6i2264Broken AngelNo ratings yet

- 608 208 PDFDocument10 pages608 208 PDF11751175No ratings yet

- Design and Simulation of Hydrogen Peroxide Plant: April 2018Document5 pagesDesign and Simulation of Hydrogen Peroxide Plant: April 2018Fahad AhmedNo ratings yet

- Fermentation Technology CBB 20203: ASSIGNMENT 2: The Functions and Specification of Agitation SystemDocument6 pagesFermentation Technology CBB 20203: ASSIGNMENT 2: The Functions and Specification of Agitation SystemIzzat EmranNo ratings yet

- Biogas PowerplantDocument7 pagesBiogas PowerplantAndrei BarbazaNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- An Initio Method8 PDFDocument23 pagesAn Initio Method8 PDFSubash KrishnanNo ratings yet

- Scop DatabaseDocument29 pagesScop DatabaseSubash KrishnanNo ratings yet

- Abinitio Protein Structure Prediction: Vamsi Krishna Kosaraju, Xue FengDocument6 pagesAbinitio Protein Structure Prediction: Vamsi Krishna Kosaraju, Xue FengSubash KrishnanNo ratings yet

- Ther Maldest R Uct I Onofmi CR Oor Gani SmsDocument8 pagesTher Maldest R Uct I Onofmi CR Oor Gani SmsSubash KrishnanNo ratings yet

- Animal Diseases PDFDocument8 pagesAnimal Diseases PDFSubash KrishnanNo ratings yet

- InTech-Thermal Plasma Gasification of Municipal Solid Waste MSWDocument29 pagesInTech-Thermal Plasma Gasification of Municipal Solid Waste MSWWangunNo ratings yet

- Oxalic Acid Content of Carambola and Bilimbi SCIENTIFIC NAME: Averrhoa Carambola, A. Bilimbi FAMILY: OxalidaceaeDocument19 pagesOxalic Acid Content of Carambola and Bilimbi SCIENTIFIC NAME: Averrhoa Carambola, A. Bilimbi FAMILY: OxalidaceaedoraemonNo ratings yet

- Section A: Choose The Best AnswerDocument15 pagesSection A: Choose The Best Answerhisham abdoNo ratings yet

- Electroplating PowerpointDocument18 pagesElectroplating PowerpointAkhlis Rahman Sari NurhidayatNo ratings yet

- Chortis Tzivakos Kavvadas Full Paper EETC 2014 PDFDocument10 pagesChortis Tzivakos Kavvadas Full Paper EETC 2014 PDFSenthil NathNo ratings yet

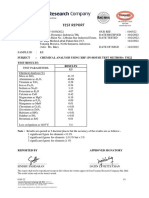

- Subject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: ResultsDocument2 pagesSubject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: Resultstri yuda khalidNo ratings yet

- Etd4264 PDFDocument163 pagesEtd4264 PDFrahma rahmaNo ratings yet

- US3054804Document2 pagesUS3054804rocioNo ratings yet

- Dendrimers in Medicine and BiotechnologyDocument190 pagesDendrimers in Medicine and BiotechnologyBill Ganus100% (1)

- EPRPDocument88 pagesEPRPmanoj0% (1)

- Fire FloodingDocument11 pagesFire FloodinghkaqlqNo ratings yet

- The Solubility of Aluminum Hydroxide in Acidic and Basic Media at CL,?Document4 pagesThe Solubility of Aluminum Hydroxide in Acidic and Basic Media at CL,?Vasant HiremathNo ratings yet

- Date of Submission: 5 MAY 2022Document11 pagesDate of Submission: 5 MAY 2022RUANGLADDA LIMPONGSAWATNo ratings yet

- Elisa & RiaDocument4 pagesElisa & Riadihajum3100% (1)

- BISFA Terminology2009 (Final Version)Document109 pagesBISFA Terminology2009 (Final Version)Afrim TahirajNo ratings yet

- Universities in Germany With Chemistry FacultiesDocument15 pagesUniversities in Germany With Chemistry FacultiesRajat SrivastavaNo ratings yet

- Chemistry Project Class12: TOPIC:Electrochemical CellsDocument11 pagesChemistry Project Class12: TOPIC:Electrochemical CellsÃñs HūlNo ratings yet

- Chapter 11 AlcoholDocument6 pagesChapter 11 AlcoholParam SoniNo ratings yet

- Safety Precautions For Handling ChemicalsDocument68 pagesSafety Precautions For Handling ChemicalsRaul FenrandezNo ratings yet

- Akson College of Pharmacy: Subject Quality Management Topic Submitted by Roll No Submitted To Submission DateDocument14 pagesAkson College of Pharmacy: Subject Quality Management Topic Submitted by Roll No Submitted To Submission DateJaved IqbalNo ratings yet

- List of AWSDocument5 pagesList of AWSkoneidinNo ratings yet

- Angélica García-Quintero - 2021Document22 pagesAngélica García-Quintero - 2021sorinamotocNo ratings yet

- Lab Report SampleDocument2 pagesLab Report SampleG03 Alfonso, Rochelle ElaineNo ratings yet

- RP F110 PDFDocument64 pagesRP F110 PDFallouche_abdNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- U-3, Medicinal Chemistry-I, Carewell PharmaDocument27 pagesU-3, Medicinal Chemistry-I, Carewell PharmaSK Imran RahmanNo ratings yet

- CalciumCarbide CASNO 75 20 7 MSDS PDFDocument7 pagesCalciumCarbide CASNO 75 20 7 MSDS PDFAnuradhaPatraNo ratings yet

- Sample1 QPDocument62 pagesSample1 QPramesh kumar guptaNo ratings yet

- Computational Physics of Carbon NanotubesDocument507 pagesComputational Physics of Carbon NanotubesBanerjee AnirbanNo ratings yet

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Uploaded by

Subash KrishnanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Module-22 (Theory) An Ideal Fermenter Parameters & Basic Functions

Uploaded by

Subash KrishnanCopyright:

Available Formats

NMEICT-MHRD (Govt.

of India) Project on - Creation of e-Contents on Fermentation Technology

Module-22: An Ideal Fermenter Parameters & Basic Functions

What is Fermenter?

A fermenter is an apparatus that maintains required optimal environmental conditions

for the growth of industrially important microorganisms, used in large scale

fermentation process and in the commercial production of a range of fermentation

products like Antibiotics, Enzymes, Organic acids, Alcoholic beverages etc.

To provide a controlled physico-chemical environment for the growth of a pure

culture or a well-defined mixed culture of microorganisms is the key function of an

ideal fermenter to obtain the desired fermentation products

An ideal fermenter maintains optimal environmental conditions throughout the

process for the process organisms, added substrates and additives for a quality end

product

Saving of energy and cost effective operation is very important concern as far as

fermentation economics is concern

Many times, the terms “Bioreactor” and “Fermenter” are used synonymously. There

is a very minor difference between these two

The bioreactor is used for the mass culture of plant and animal cells, while fermenter

is mainly used for microbial culture

The operational parameters and design engineering of fermenters and bioreactors are

identical.

Parameters of an ideal fermenter

A fermenter should……..

Facilitate the growth of a wide range of organisms capable of producing a varieties of

fermentation products

Do not allow entry to any sort of unwanted microorganisms thus to provide operation

free from contamination

Maintain a specific required temperature

Provide adequate aeration and agitation to meet the metabolic requirements of the

organisms during the process to attain mass and heat transfer within the system

without damaging the process organisms

Control the pH of the culture throughout the process

Have provision of constant monitoring and control of level of dissolved oxygen

Allow feeding of nutrient solutions and other supplementary requirements

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

Provide access points for seed culture inoculation and sampling during the process

Reduce liquid loss from the vessel during process by cooling system

Be capable of being operated aseptically during the tenure of the process thus

fulfilling the requirements of containment regulations

Ensure that overall process period should have power consumption, as low as possible

Be designed in such a way that it require the minimal use of labours during

production process and downstream operations (i.e. harvesting, cleaning and

maintenance)

Should be suitable for a range of processes along with the containment regulations

Be constructed in such a way that it ensure even internal surfaces, using welds

instead of flange joints whenever possible

Should have identical geometry at different operational level (i.e. both smaller and

larger vessels in the pilot or scale-up plant)

The material from which the fermenter is made up of should be inert and capable to

withstand repeated stem sterilization conditions

Apart from all these parameters, it is very imperative to have adequate service

provisions for individual plants. The important service provisions are listed below.

Provision of compressed as well as sterile compressed air

Provision of chilled water, cold water and hot water

Facility to supply steam (high pressure) and steam condensate

Provision of continuous electricity and stand-by generator

Confine and well protected storage facilities for media components

Availability of control and monitoring equipment for fermenters

Provision of instrument maintenance facilities

Facilities for extraction and recovery equipment

Arrangement of convenience and easy excess delivery of materials

Appropriate containment facilities

Facility for appropriate effluents treatment of generated from the production unit

A well-equipped workshop for minor mechanical and electrical repair under urgent

situation

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

Functions of different parts of a fermenter

Vessel: Size and Material

Function of a fermenter is to carryout process under appropriate aseptic and pre-

defined environmental conditions

A fermentation vessel is designed in such a way that it requires minimal labour

operation and maintenance

It should have even internal surfaces with a similar geometry

The volume capacity of the fermenter vary at different stages

From laboratory experimental models with volume capacity of one or two litres, pilot

scale fermenter up to one thousand litres

Industrial scale fermenter are of several hundred litres capacity

There are mainly two types of vessels base on the type fermentation process

1. Small scale fermenter (Laboratory scale fermenter)

a. These are made up of glass

b. The large vessels are made up of borosilicate battery jars

c. They have a round or flat bottom and a top flanged carrying plate

d. They are smooth, non toxic and corrosion free

e. These vessels can be sterilized by autoclaving

f. It is feasible to examine the interior of the glass vessels

g. The diameter of the vessel is usually more than 50 cm

2. Large scale fermenter (Industrial scale fermenter)

a. As, stainless steel is the most satisfactory material, it is used to manufacture

vessels of high volume

b. These vessels can be sterilized in situ

c. They can withstand high pressure and corrosion

d. Corrosion resistance property is due to the thin hydrous film on the surface of

the metal

e. This film is stabilized by chromium

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

f. This film is continuous, non-porous, insoluble and self-heating

g. The corrosion resistance property of the vessel can be improved by mixing

tungsten, silicone and other elements at the time of manufacturing

Impeller (Agitator)

This device is use for agitation (mixing up) of the medium

Agitation creates a uniform environment in which all organisms remain in continuous

contact with medium resulting in maximum up take of the nutrient.

It also increase the air bubble path generated from the sparger (aeration device) hence

more time to dissolve oxygen in the medium

The impeller achieves a number of mixing objectives like suspension of solid

particles, bulk fluid and gas phase mixing

There are various types of impellers

1. Disc turbine

2. Vaned disc

3. Open turbine

4. Marine propeller

Sparger

This device is used for aeration

Aerobic fermentation process require sufficient oxygen to the microorganisms for

metabolic requirements

Depending on volume of medium in the fermentation vessel, different types of

spargers are installed in the fermenter.

1. Porous sparger

a. It is made up of sintered glass or ceramics

b. It is used on the laboratory scale in non-agitated vessel

2. Nozzle sparger

a. It is a partially closed or single open pipe which provides stem to the air bubbles

b. As nozzle sparger causes a lower pressure and does not get blocked, they are used

as a single nozzle

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

3. Combined sparger – agitator

a. It introduced air through a hollow agitator shaft

b. The holes are drilled in the disc, which remains connected to the base of the main

shaft from where it is emitting the air bubbles

c. It provide excellent aeration in a baffled vessel

The efficiency of aeration depends on operation of agitator at a range of Revolution

Per Minutes (RPM)

Baffels

This device is used to avoid the vortex formation generated during the agitation of the

medium

Baffles are made up of metal strips attached 900 to the wall of fermentation vessel

The diameter of the baffles is nearly one tenth of the vessel diameter

The gap between the vessel wall and the baffles strips should be maintain in such a

way that scouring action of the minimise microbial growth on the walls of the

fermenter

Foam control

A medium rich in protein when subjected to agitation, it generate foam

If the excessive foaming is not prevented, it results in the leakage of the medium from

the lid of the fermentation vessel and hence lead to the contamination of the

fermentation medium

A foam sensing devised is usually installed from the lid in the fermenter, set at a

definite level above the broth surface

When the foam rises and touches the probe tip, a signal is generated in form current

and pass through the circuit of the probe and gives a signal

If the fermentation operation is automatic, then the signal triggers the pump and

antifoam agent is released within seconds mechanically or robotically

It is also possible to add antifoam manually in case the process is not automatic

Temperature controlling (heating and cooling) devices

Mechanical agitation and exothermic microbial metabolic activity generates heat

during the fermentation process

Endothermic microbial metabolic activity lower down the temperature of the

fermentation medium

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

To maintain this temperature, heat is to be either added to or removed from the system

The cooling system is used to remove excess heat from the system

Internal heating coils are used for providing heat (Note: In case of lab scale process,

the fermenter is placed in thermostatically controlled bath)

Feed ports

Feed ports are the tubes ( for Lab scale fermenter) and pipelines (for large scale

fermenter) connected to the nutrient reservoir

These tubes or pipelines are used to add nutrients and acid/alkali in the fermenter

before and during the fermentation process

They are heat sterilized in situ and /or ex situ with stem

It is advisable to sterilize after connection has been done and before any additions are

made

Flow regulation and controlling devices (i.e. Valves)

Five types of valves are used.

1. Safety valves

a. Any pipe layout which work under pressure are incorporated with these safety valves

to

b. These valves protect the pipe layout and ensures that the pressure never go beyond the

upper limit of the specified value

2. Globe valves

a. These valves do not regulate the flow of steam or water

b. They are suitable for general purposes use like completely opened or completely

closed

3. Butterfly valves

a. When the diameter of the pipes is large and there is low or no pressure butterfly vales

are ideal choice

b. These valves do not ensure aseptic operation

4. Ball valves

a. These valves are appropriate when aseptic condition is required

b. These valves can also be operated under high temperature

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

c. Ball valves can handle mycelia broths

5. Diaphragm valves

a. They are used for flow regulation

Sealing assembly

Stirrer shaft, a device providing agitation must be sealed properly ensuring long term

aseptic operation

There are various types of sealing assembly available in the market, of which three

are mainly used

1. Mechanical seal

a. Made up of a stationary part in the bearing and the rotating part on the shaft

b. A spring is used to press these two components together

c. A suitable lubricant should be apply to ensure friction free smooth rotation

and control the heat generation at the point of stationary and moving parts of

the seal

2. Packed gland seal

a. Several layers of rings made up of asbestos are used to seal the shaft

b. Periodical monitoring and replacement of these rings advisable to prevent the

penetration of heat

3. Magnetic drives

a. This assembly is made up of two magnets

b. The driving magnet is held in bearing on the outside of head plate and

connected to the drive shaft

c. The driven magnet is placed on one end of the impeller shaft and held in

bearings on the inner surface of the top plate

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

Summary: Functions of various parts of a fermenter

Sr. Parts of fermenter Function

To stir the media continuously and hence prevent

1 Impellor (agitator) cells from settling down, and distribute oxygen

throughout the medium

Introduce sterile oxygen to the media in case of

2 Sparger (Aerator)

aerobic fermentation process

3 Baffles (vortex breaker) Disrupt vortex and provide better mixing

4 Inlet Air filter Filter air before it enter the fermenter

5 Exhaust Air filter Trap and prevent contaminants from escaping

6 Rotameter Measure flow rate of Air or liquid

7 Pressure gauge Measure pressure inside the fermenter

Measure and monitor change in temperature of

8 Temperature probe

the medium during the process

To maintain the temperature of the medium

9 Cooling Jacket

throughout the process

10 pH probe Measure and monitor pH of the medium

11 Dissolve Oxygen Probe Measure dissolve oxygen in the fermenter

12 Level probe Measure the level of medium

13 Foam probe Detect the presence of the foam

Maintain the required pH of the medium by

14 Acid

neutralizing the basic environment

Maintain the required pH of the medium by

15 Base

neutralizing the acidic environment

16 Antifoam Breakdown and prevent foams

17 Sampling pint To obtain samples during the process

18 Valves Regulation and control the flow liquids and gases

19 Control panel Monitor over all parameters

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

References

Principles of Fermentation Technology: (2nd edition, by Peter F. Stanbury, Allan

Whitaker and Stephen J. Hall, Butterworth-Heinemann, An imprint of Elsevier Science.)

Industrial Microbiology: (By Casida L. E.New Age international (P) ltd publications)

A Text Book of Industrial Microbiology: (2nd edition By Wulf Crueger & Anneliese

Crueger)

Biotechnology: Food Fermentation Microbiology, Biochemistry & Technology Vol. 1

& 2:(By V.K. Joshi & Ashok Pandey)

Manual of Industrial Microbiology and Biotechnology: (2nd Edition by Arnold L.

Demain and Julian E. Davies, Ronald M. Atlas, Gerald Cohen, Charles L. Hershberger,

Wei-Shou Hu, David H. Sherman, Richard C. Willson and J. H. David Wu)

Industrial Microbiology-An introduction: By Michael J. Waites, Neil L. Morgan,

John S. Rockey and Gary Higton)

Comprehensive Biotechnology-The Principles, Applications and Rugulations of

Biotechnology in Industry, Agriculture and Medicine: (By Mrray Moo Young)

Fermentation Technology : Up Stream Fermentation Technology- Vol-I: (By H. A.

Modi-Pointer Publications)

Fermentation Technology : Down Stream Fermentation Technology- Vol-II: (By H. A.

Modi-Pointer Publications)

Industrial Microbiology by Prescott and Dunn's: (4th edition, edited by Gerald Reed,

CBR publications)

Fermentation Technology: (By M.L. Srivastava, NAROSA publications)

Industrial Microbiology: (By A.H. Patel)

International student edition: Microbiology- A laboratory Manual: (4th edition. By

James G. Chappuccino & Natalie Sherman)

Bacteriological Techniques: (By F.J. Baker)

Introduction to Microbial Techniques: (By Gunasekaran)

Mannual of Industrial Microbiology and Biotechnology: (2nd Edition by Arnold L.

Demain and Julian E. Davies, Ronald M. Atlas, Gerald Cohen, Charles L. Hershberger,

Wei-Shou Hu, David H. Sherman, Richard C. Willson and J. H. David Wu)

Web references

http://www.homebrew.net/ferment/

http://www.soyinfocenter.com/HSS/fermentation.php

http://www.ensymm.com/pdf/ensymm_fermentation_abstract.pdf

http://scialert.net/fulltext/?doi=jm.2007.201.208

http://aem.asm.org/content/7/1/57.full.pdf

http://www.slideshare.net/yongkangbirdnest/lecture-4-sterilization

http://www.ars.usda.gov/research/publications/publications.htm?seq_no_115=140721

http://www.scribd.com/doc/30706834/Fermentation-Design

http://www.wiley-vch.de/books/sample/3527318194_c01.pdf

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

NMEICT-MHRD (Govt. of India) Project on - Creation of e-Contents on Fermentation Technology

http://www.engineersirelandcork.ie/downloads/Biopharmaceuticals%2020Jan09%20-

%202%20-%20Ian%20Marison%20DCU.pdf

www.yobrew.co.uk/fermentation.php

http://bioscipub.com/journals/bbb/pdf/19-24.pdf

http://gertrude-old.case.edu/276/materials/web/immobilizedenzymereview.pdf

http://download.bioon.com.cn/upload/month_0902/20090223_b809d1c59ba2a6e2abfdJt

WiJOiFDm02.attach.pdf

http://bioprocess-maulik.blogspot.in/2007/07/design-of-industrial-fermentation.html

http://hsc.csu.edu.au/biology/options/biotechnology/3051/biotechnologyPart3.html

http://www.rsc.org/ebooks/archive/free/BK9780854046065/BK9780854046065-

00001.pdf

http://www.biotech.upm.edu.my/academics/On%20Line%20Note/Bioprocess/BTK%205

301/Lect6%28Inoculum%20Preparation%20and%20Development%29.pdf

http://www.biotechresources.com/services-strain.shtml

http://www.idosi.org/wjc/4%281%2909/14.pdf

http://cheserver.ent.ohiou.edu/Paper-gu/DualFeed.pdf

Project control No: RE-02091011297, Christ College, Rajkot, Gujarat, India

You might also like

- Veolia's Case Studies For Small Wastewater Treatment PlantsDocument15 pagesVeolia's Case Studies For Small Wastewater Treatment PlantsOswar MungkasaNo ratings yet

- MBBR OM Manual-250Document42 pagesMBBR OM Manual-250senthil2002100% (3)

- 9 - Design of A Fermenter PDFDocument51 pages9 - Design of A Fermenter PDFYAUW HANSEN ADITYANo ratings yet

- Galvanizing AHSSDocument3 pagesGalvanizing AHSSTrial_TNo ratings yet

- Solid and Submerged FermentationDocument12 pagesSolid and Submerged FermentationgopnarayansamyakNo ratings yet

- Proces Equipment Design Guide For FermenDocument23 pagesProces Equipment Design Guide For FermenTheodoros AtheridisNo ratings yet

- Lec No 1 Chapeter 4,5,6,7,8,9,10Document41 pagesLec No 1 Chapeter 4,5,6,7,8,9,10PromiseNo ratings yet

- FermentorDocument14 pagesFermentorSanthosh KaranNo ratings yet

- UntitledDocument16 pagesUntitledAman RaiNo ratings yet

- Fermenter and Its Features 1Document14 pagesFermenter and Its Features 1Akhil Suresh (Synthite Biotech)No ratings yet

- Bioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsDocument14 pagesBioreactor-Definition, Design, Principle, Parts, Types, Applications, LimitationsShahriar ShamimNo ratings yet

- UNIT - III - Design of FermentorDocument19 pagesUNIT - III - Design of FermentorGDNo ratings yet

- Fermenter DesignDocument59 pagesFermenter DesignPratishtha RawatNo ratings yet

- MCB 407 Lecture FourDocument9 pagesMCB 407 Lecture FourPopoola OlakunleNo ratings yet

- Fermentation Technology TEXTDocument18 pagesFermentation Technology TEXTJIBAN JYOTI DASHNo ratings yet

- BIOREACTORDocument38 pagesBIOREACTORijat_No ratings yet

- Lecture 5 Fermenter Types and Microbial Gowth Kinetics 1 1459529119 1489994861Document36 pagesLecture 5 Fermenter Types and Microbial Gowth Kinetics 1 1459529119 1489994861jeevalakshmanan29No ratings yet

- Abbr Biot Lec 3Document5 pagesAbbr Biot Lec 3nareman hassanNo ratings yet

- Design and Performance Test of A Batch System Rotary Vacuum Dryer With A 50-Liter Capacity To Dry Basidiomycota Class MushroomsDocument7 pagesDesign and Performance Test of A Batch System Rotary Vacuum Dryer With A 50-Liter Capacity To Dry Basidiomycota Class MushroomsAREEJ JAVEDNo ratings yet

- Bioreactors (Fermenters) - Function, Designs and TypesDocument28 pagesBioreactors (Fermenters) - Function, Designs and TypesDolly Priya100% (2)

- Fermenter TypesDocument23 pagesFermenter TypesPratishtha RawatNo ratings yet

- Renewable Energy Unit-2Document17 pagesRenewable Energy Unit-2Sachin ShrivastavNo ratings yet

- Parts of BioreactorDocument8 pagesParts of BioreactorUlfath SultanaNo ratings yet

- Design and Equipment For The Cell Culture LaboratoryDocument3 pagesDesign and Equipment For The Cell Culture LaboratoryAlejandro NavarroNo ratings yet

- Lectuer 16Document23 pagesLectuer 16deekshupapareddyNo ratings yet

- Design Bioreactor For The Production OF Biopharmaceuticals From Animal CellsDocument38 pagesDesign Bioreactor For The Production OF Biopharmaceuticals From Animal Cellsijat_No ratings yet

- Bioreactors LatestDocument34 pagesBioreactors LatestSyeda KazmiNo ratings yet

- Scale-Up, Upstream and Downstream ProcessingDocument106 pagesScale-Up, Upstream and Downstream ProcessingAlbert KuufamNo ratings yet

- Assignment ATFDocument2 pagesAssignment ATFduafareed711No ratings yet

- Bioreactor Types (Industrial Notes)Document23 pagesBioreactor Types (Industrial Notes)anjali100% (1)

- Fermentors Types and Design 2015Document23 pagesFermentors Types and Design 2015NJOKU VERONICA CHIZOBANo ratings yet

- 17 - Chapter 7Document28 pages17 - Chapter 7Franklin Villegas PálizNo ratings yet

- Impacts of Biochemical Engineering in Biotechnology: Kaushik Nath and Debabrata DasDocument4 pagesImpacts of Biochemical Engineering in Biotechnology: Kaushik Nath and Debabrata DasSambeet SatapathyNo ratings yet

- Unit 2Document87 pagesUnit 2SavitaNo ratings yet

- Harmonization of HATCHERY PRODUCTION OF Penaeus Monodon in Asean CountriesDocument20 pagesHarmonization of HATCHERY PRODUCTION OF Penaeus Monodon in Asean CountriesCharles FigueroaNo ratings yet

- InTech-Biogas Plant constructionsPublishedVersionDocument27 pagesInTech-Biogas Plant constructionsPublishedVersionSuraj Kumar SamalNo ratings yet

- Bichemical Eng Chapter 1Document31 pagesBichemical Eng Chapter 1mikialeNo ratings yet

- Chapter # 4 Insight Into FermentationDocument1 pageChapter # 4 Insight Into FermentationWaqas MinhasNo ratings yet

- Mechanical Engineering:Production Engineering: Design and Manufacture O F Incubator MachineDocument75 pagesMechanical Engineering:Production Engineering: Design and Manufacture O F Incubator MachineProsper MahlengezanaNo ratings yet

- Mahatma Gandhi Institute of Pharmacy, Lucknow: BioreactorsDocument19 pagesMahatma Gandhi Institute of Pharmacy, Lucknow: BioreactorsJunior MishraNo ratings yet

- Fermentation SystemsDocument40 pagesFermentation SystemsLolly AntillonNo ratings yet

- InTech-Biogas Plant constructionsPublishedVersionDocument27 pagesInTech-Biogas Plant constructionsPublishedVersionMunkhnasan PurevsurenNo ratings yet

- Presentation On BioreactorsDocument4 pagesPresentation On BioreactorsChukwudi Victor TagboNo ratings yet

- Eid Guidlines For FoodDocument9 pagesEid Guidlines For FoodJohn Nen BiniNo ratings yet

- 8 A BIOREACTORSAComplete ReviewDocument39 pages8 A BIOREACTORSAComplete ReviewSomya SomuNo ratings yet

- Design and Operation of Conventional BioreactorDocument25 pagesDesign and Operation of Conventional BioreactorMahesh RamNo ratings yet

- Safety Issues On DryerDocument5 pagesSafety Issues On Dryerareej athirahNo ratings yet

- Fermenter-Guhan K ADocument4 pagesFermenter-Guhan K AGuhan KANo ratings yet

- Different Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitesDocument11 pagesDifferent Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitespavithraNo ratings yet

- Types of FermentersDocument6 pagesTypes of FermentersSajjad Hossain ShuvoNo ratings yet

- Bacteria As A Filtration Loss Reducing Agent During DrillingDocument4 pagesBacteria As A Filtration Loss Reducing Agent During DrillingJessica KingNo ratings yet

- SWM Practical No. 8Document8 pagesSWM Practical No. 8balrajgholap847No ratings yet

- Design and Fabrication of Bench-Scale Ash Pyrolysis Reactor For Bio-Fuel ProductionDocument7 pagesDesign and Fabrication of Bench-Scale Ash Pyrolysis Reactor For Bio-Fuel ProductionfadyahNo ratings yet

- Lect 2 Fermentation TechnologyDocument42 pagesLect 2 Fermentation TechnologyFadhil HelmiNo ratings yet

- Mode of OperationDocument4 pagesMode of OperationttNo ratings yet

- Irjet V6i2264Document4 pagesIrjet V6i2264Broken AngelNo ratings yet

- 608 208 PDFDocument10 pages608 208 PDF11751175No ratings yet

- Design and Simulation of Hydrogen Peroxide Plant: April 2018Document5 pagesDesign and Simulation of Hydrogen Peroxide Plant: April 2018Fahad AhmedNo ratings yet

- Fermentation Technology CBB 20203: ASSIGNMENT 2: The Functions and Specification of Agitation SystemDocument6 pagesFermentation Technology CBB 20203: ASSIGNMENT 2: The Functions and Specification of Agitation SystemIzzat EmranNo ratings yet

- Biogas PowerplantDocument7 pagesBiogas PowerplantAndrei BarbazaNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- An Initio Method8 PDFDocument23 pagesAn Initio Method8 PDFSubash KrishnanNo ratings yet

- Scop DatabaseDocument29 pagesScop DatabaseSubash KrishnanNo ratings yet

- Abinitio Protein Structure Prediction: Vamsi Krishna Kosaraju, Xue FengDocument6 pagesAbinitio Protein Structure Prediction: Vamsi Krishna Kosaraju, Xue FengSubash KrishnanNo ratings yet

- Ther Maldest R Uct I Onofmi CR Oor Gani SmsDocument8 pagesTher Maldest R Uct I Onofmi CR Oor Gani SmsSubash KrishnanNo ratings yet

- Animal Diseases PDFDocument8 pagesAnimal Diseases PDFSubash KrishnanNo ratings yet

- InTech-Thermal Plasma Gasification of Municipal Solid Waste MSWDocument29 pagesInTech-Thermal Plasma Gasification of Municipal Solid Waste MSWWangunNo ratings yet

- Oxalic Acid Content of Carambola and Bilimbi SCIENTIFIC NAME: Averrhoa Carambola, A. Bilimbi FAMILY: OxalidaceaeDocument19 pagesOxalic Acid Content of Carambola and Bilimbi SCIENTIFIC NAME: Averrhoa Carambola, A. Bilimbi FAMILY: OxalidaceaedoraemonNo ratings yet

- Section A: Choose The Best AnswerDocument15 pagesSection A: Choose The Best Answerhisham abdoNo ratings yet

- Electroplating PowerpointDocument18 pagesElectroplating PowerpointAkhlis Rahman Sari NurhidayatNo ratings yet

- Chortis Tzivakos Kavvadas Full Paper EETC 2014 PDFDocument10 pagesChortis Tzivakos Kavvadas Full Paper EETC 2014 PDFSenthil NathNo ratings yet

- Subject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: ResultsDocument2 pagesSubject: Chemical Analysis Using XRF (In-House Test Method) : Tm22 Test Results: Resultstri yuda khalidNo ratings yet

- Etd4264 PDFDocument163 pagesEtd4264 PDFrahma rahmaNo ratings yet

- US3054804Document2 pagesUS3054804rocioNo ratings yet

- Dendrimers in Medicine and BiotechnologyDocument190 pagesDendrimers in Medicine and BiotechnologyBill Ganus100% (1)

- EPRPDocument88 pagesEPRPmanoj0% (1)

- Fire FloodingDocument11 pagesFire FloodinghkaqlqNo ratings yet

- The Solubility of Aluminum Hydroxide in Acidic and Basic Media at CL,?Document4 pagesThe Solubility of Aluminum Hydroxide in Acidic and Basic Media at CL,?Vasant HiremathNo ratings yet

- Date of Submission: 5 MAY 2022Document11 pagesDate of Submission: 5 MAY 2022RUANGLADDA LIMPONGSAWATNo ratings yet

- Elisa & RiaDocument4 pagesElisa & Riadihajum3100% (1)

- BISFA Terminology2009 (Final Version)Document109 pagesBISFA Terminology2009 (Final Version)Afrim TahirajNo ratings yet

- Universities in Germany With Chemistry FacultiesDocument15 pagesUniversities in Germany With Chemistry FacultiesRajat SrivastavaNo ratings yet

- Chemistry Project Class12: TOPIC:Electrochemical CellsDocument11 pagesChemistry Project Class12: TOPIC:Electrochemical CellsÃñs HūlNo ratings yet

- Chapter 11 AlcoholDocument6 pagesChapter 11 AlcoholParam SoniNo ratings yet

- Safety Precautions For Handling ChemicalsDocument68 pagesSafety Precautions For Handling ChemicalsRaul FenrandezNo ratings yet

- Akson College of Pharmacy: Subject Quality Management Topic Submitted by Roll No Submitted To Submission DateDocument14 pagesAkson College of Pharmacy: Subject Quality Management Topic Submitted by Roll No Submitted To Submission DateJaved IqbalNo ratings yet

- List of AWSDocument5 pagesList of AWSkoneidinNo ratings yet

- Angélica García-Quintero - 2021Document22 pagesAngélica García-Quintero - 2021sorinamotocNo ratings yet

- Lab Report SampleDocument2 pagesLab Report SampleG03 Alfonso, Rochelle ElaineNo ratings yet

- RP F110 PDFDocument64 pagesRP F110 PDFallouche_abdNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- U-3, Medicinal Chemistry-I, Carewell PharmaDocument27 pagesU-3, Medicinal Chemistry-I, Carewell PharmaSK Imran RahmanNo ratings yet

- CalciumCarbide CASNO 75 20 7 MSDS PDFDocument7 pagesCalciumCarbide CASNO 75 20 7 MSDS PDFAnuradhaPatraNo ratings yet

- Sample1 QPDocument62 pagesSample1 QPramesh kumar guptaNo ratings yet

- Computational Physics of Carbon NanotubesDocument507 pagesComputational Physics of Carbon NanotubesBanerjee AnirbanNo ratings yet