Professional Documents

Culture Documents

TE4 Example Calculations PDF

TE4 Example Calculations PDF

Uploaded by

estebandidochasconOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TE4 Example Calculations PDF

TE4 Example Calculations PDF

Uploaded by

estebandidochasconCopyright:

Available Formats

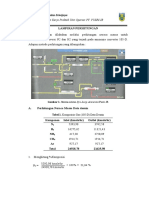

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

Note: the following are examples of the type of calculations you may be asked to

perform in the TE4 narrative paper. This is not a complete exam paper. Calculation

questions typically make up 20 out of 40 marks for a paper.

EXAMPLE CALCULATIONS ASSOCIATED WITH

THE MEASURMENT OF GASES AND VAPOURS

USING INSTRUMENTAL TECHNIQUES

1 To calculate total NOx in mg/m3 at reference conditions given NO and NO2

measurements in ppm

NO concentration = 34 ppm (dry)

NO2 concentration = 15 ppm (dry)

Measured oxygen level = 12%

Reference conditions = STP, 15% O2, dry

Atomic weight of N = 14

Atomic weight of O = 16

Molar volume = 22.4 litres

1.1 To calculate the total NOx concentration in ppm

Total NOx concentration = NO concentration + NO2 concentration

= 34 ppm + 15 ppm

= 49 ppm

1.2 To calculate the molecular weight of NOx as NO2

Molecular weight of NO2 = atomic weight of N + molecular weight of O2

= 14 + (16 x 2)

= 46

1.3 To convert NOx concentrations in ppm to NO2 in mg/m3

NOx concentration= 49 ppm

Molecular weight of NO2 = 46

Molar volume = 22.4 litres

Concentration in mg/m3 = concentration (ppm) x molecular weight of substance

molar volume

= 49 ppm x 46

22.4

= 100.6 mg/m3

April 2014 Sira Certification Service Page 1 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

1.4 To calculate the concentration of NO2 at reference conditions

Measured oxygen level = 12%

Reference oxygen = 15%

Oxygen correction factor = (21 – reference oxygen)

(21 – measured oxygen)

= (21 – 15)

(21 – 12)

= 0.67

Concentration at reference conditions

= Concentration as measured x correction factor for oxygen

= 100.6 mg/m3 x 0.67

= 67.4 mg/m3

2 To calculate concentrations at reference conditions in mg/m3 from analyser

results in ppm

Concentration of substance = 120 ppm

Measured moisture level = 9%

Reference moisture is dry

Measured oxygen level = 12.5% (wet)

Reference oxygen = 11%

Molecular weight of substance = 28

Molar volume = 22.4 litres

(In this example the molecule is CO)

2.1 To convert concentrations in ppm to mg/m3

Concentration of substance = 120 ppm

Molecular weight of substance = 28

Molar volume = 22.4 litres

Concentration in mg/m3 = concentration (ppm) x molecular weight of substance

molar volume

= 120 ppm x 28

22.4

= 150 mg/m3

April 2014 Sira Certification Service Page 2 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

2.2 To calculate the concentration of a substance at reference conditions

Moisture correction factor = _____100_______

(100 – measured moisture)

= 100_

(100 – 9)

= 1.1

(Note that the oxygen was measured on a wet basis and should be corrected to dry

conditions)

Oxygen at reference conditions = measured oxygen x correction factor for moisture

= 12.5% x 1.1

= 13.8% (dry)

Oxygen correction factor = (21 – reference oxygen)

(21 – measured oxygen, dry)

= (21 – 11)

(21 – 13.8)

= 1.4

Concentration of substance at reference conditions

= concentration as measured x correction factor for oxygen x

correction factor for moisture

= 150 mg/m3 x 1.4 x 1.1

= 231 mg/m3

April 2014 Sira Certification Service Page 3 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

3 To express analyser readings in ppm (wet) at reference conditions in mg/m 3

(dry)

NOx concentration = 80 ppm (wet)

Measured moisture level = 10%

Molar volume at STP = 22.4 litres

Atomic weight of N = 14

Atomic weight of O = 16

3.1 To calculate the molecular weight of NO2

Molecular weight of NO2 = atomic weight of N + molecular weight of O2

= 14 + (16 x 2)

= 46

3.2 To convert concentration in ppm to mg/m3

Concentration in mg/m3 = concentration (ppm) x molecular weight of substance

molar volume

= 80 ppm x 46

22.4

= 164 mg/Nm3 (wet)

3.3 To calculate the concentration at reference conditions dry

Moisture correction factor = ____100____

(100 – measured moisture)

= 100

100 – 10

= 1.1

NO2 concentration (dry)

= concentration as measured x correction factor for moisture

= 164 mg/Nm3 x 1.1

= 180 mg/Nm3 (dry)

April 2014 Sira Certification Service Page 4 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

4 To calculate a mass emission rate in kg/h (Example 1)

Volume flow rate at STP (wet) = 43 Nm3/s

NO2 concentration (wet) = 164 mg/m3

Seconds in 1 hour = 3600

4.1 To calculate the volume flow in the stack

Volume flow rate in Nm3/h = volume flow rate in Nm3/s x seconds in 1 hour

= 43 Nm3/s x 3600

= 154,800 Nm3/h

4.2 To calculate the mass emission to atmosphere in kg/h

Mass emission rate in kg/h = volume flow rate m3/h x concentration in mg/m3

1 x 106

= 154,800 Nm3/h x 164 mg/m3

1 x 106

= 25.4 kg/h

(Note dividing by 1 x 106 converts the result from mg to kg)

5 To calculate a mass emission in kg/h (Example 2)

Average stack gas velocity = 10 m/s

Stack diameter = 0.9 m (radius = 0.45 m)

Concentration of substance = 150 mg/m3 (measured wet with no correction for oxygen

or temperature)

5.1 To calculate the cross section area of the stack

Cross sectional area of stack = π r2

= 3.14 x 0.452

= 0.64 m2

5.2 To calculate the volume flow in the stack

Volume flow rate in m3/s = cross section area of stack x average gas velocity

= 0.64 m2 x 10 m/s

= 6.4 m3/s

Volume flow rate in m3/h = volume flow rate in m3/s x seconds in 1 hour

= 6.4 m3/s x 3600

= 23,040 m3/h

April 2014 Sira Certification Service Page 5 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

5.3 To calculate the mass emission in kg/h at stack conditions

Mass emission = volume flow rate x concentration of substance

1 x 106

= 23,040 m3/h x 150 mg/m3

1 x 106

= 3.46 kg/h

(Note dividing by 1 x 106 converts the result from mg to kg)

6 To convert VOC results from a FID analyser to reference conditions

VOC concentration = 23 mgC/m3

Measured moisture level = 9.5%

Reference moisture is dry

Measured oxygen level = 13.2% (dry)

Reference oxygen = 11%

(Note that the FID analyser measures hot and wet)

Oxygen correction factor = (21 – reference oxygen)

(21 – measured oxygen)

= (21 – 11)

(21 – 13.2)

= 1.3

Moisture correction factor = _____100_______

(100 – measured moisture)

= _100_

(100 – 9.5)

= 1.1

Concentration at reference conditions

= Concentration as measured x correction factor for oxygen x correction

factor for moisture

= 23 mgC/m3 x 1.3 x 1.1

= 33 mgC/m3

April 2014 Sira Certification Service Page 6 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

7 To calculate the concentration of VOCs as Carbon (C) as a dry gas and

calculate the mass emissions of carbon and toluene from the results

provided by a FID analyser

VOC concentration = 185 ppm (propane equivalent C3 H8)

Measured moisture level = 6.5%

Atomic weight of C = 12

Atomic weight of H = 1

Molar volume at STP = 22.4 litres

Stack gas flow rate = 0.4 m3/s

7.1 To calculate the molecular weight of propane as carbon

Molecular weight of propane as carbon

= number of carbon atoms in molecule x atomic weight of carbon

= 3 x 12

= 36

7.2 To calculate the concentration of VOC in mgC at STP wet

= concentration in ppm x molecular weight of propane as carbon

molar volume

= 185 ppm x 36

22.4

= 297 mgC/Nm3

7.3 To calculate the concentration of VOC in mgC as a dry gas

Moisture correction factor = ____100____

(100 – measured moisture)

= 100

100 – 6.5

= 1.07

Concentration of VOC(dry) = VOC concentration wet x correction factor for

moisture

= 297 mgC/Nm3 x 1.07

= 318 mgC/Nm3

April 2014 Sira Certification Service Page 7 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

7.4 To calculate the hourly emission rate in gC/h

Stack gas flow rate = 0.4 m3/s

Concentration of VOC = 297 mgC/Nm3 (wet)

Volume flow rate in m3/h = flow rate in m3/s x seconds in 1 hour

= 0.4 m3/s x 3600

= 1440 m3/h

Mass emission rate g/h = volume flow rate m3/h x concentration of substance

1000

= 1440 m3/h x 297 mgC/Nm3

1000

= 428 gC/h

(Note dividing by 1000 converts the result from mg to g)

7.5 To calculate the mass emission as g toluene per hour

Toluene = C7H8

Molecular weight of toluene as mgC

= number of carbon atoms in molecule x atomic weight of carbon

= 7 x 12

= 84

Molecular weight of toluene

= (number of carbon atoms x molecular weight of carbon) +

(number of hydrogen atoms x atomic weight of

hydrogen)

= (7 x 12) + (8 x 1)

= 92

Ratio of molecular weight of toluene to molecular weight of toluene as carbon

= molecular weight of toluene

molecular weight of toluene as carbon

= 92

84

= 1.095

April 2014 Sira Certification Service Page 8 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

Mass emission expressed as gT/h

= mass emission rate gC/h x toluene to carbon mass ratio

= 428 gC/h x 1.095

= 469 gT/h

8 To calculate an uncertainty budget

The performance characteristics of the analyser are as follows:

Type

B Sensitivity to ambient temperature = 1.5% of the certified range per 10K of variation

B Sensitivity to atmospheric pressure = 0.7% of the certified range per kPa

B Uncertainty of calibration gas = 1.5%

A Standard deviation of repeatability at span = 0.9% of the certified range

Certification range of analyser = 0 – 175 mg/m3

Maximum ambient temperature variation during sampling = 8K (± 4K relative to the

temperature value at calibration)*

Ambient pressure range during sampling = 98.8 – 101.2 kPa (± 1.2 kPa relative to a

pressure value of 100 kPa at calibration)*

Calibration gas concentration = 140 mg/m3

* Note : The exams will not require a calculation of an uncertainty where the variation is not symmetrical

about the value at calibration

8.1 To calculate the standard uncertainty in mg/m3 associated with the ambient

temperature variations

Sensitivity of analyser to ambient temperature variations = 1.5% of the certified range

per 10K of variation

Certification range = 0 – 175 mg/m3

Maximum ambient temperature variation during sampling = ± 4 K

8.2 To calculate the sensitivity per degree of ambient temperature change

= certified range x sensitivity

10 K

= 175 mg/m3 x 0.015

10K

= 0.26 mg/m3 per degree

April 2014 Sira Certification Service Page 9 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

8.3 To calculate the standard uncertainty associated with the ambient

temperature variation

Standard uncertainty Utemp

= sensitivity per degree x variation in ambient temperature

√3

= 0.26 mg/m3 x 4 K

√3

= 0.6 mg/m3

8.4 To calculate the standard uncertainty in mg/m3 associated with ambient

pressure changes

Sensitivity of analyser to ambient pressure variations = 0.7% of the certified range per

kPa of pressure change

Certification range = 175 mg/m3

Ambient pressure range during sampling = 98.8 – 101.2 kPa

Variation in ambient pressure = 101.2 – 98.8

2

= ±1.2 kPa

Sensitivity per kPa of pressure change = certification range x sensitivity

= 175 mg/m3 x 0.007

= 1.23 mg/m3 per kPa

Standard uncertainty associated with ambient pressure changes Uapress

= sensivitity x variation in ambient pressure

√3

= 1.23 mg/m3 x 1.2 kPa

√3

= 0.85 mg/m3

8.5 To calculate the standard uncertainty of the calibration gas in mg/m3

Uncertainty of calibration gas = 1.5%

Calibration gas value = 140 mg/m3

Standard uncertainty of calibration gas Ucal

= calibrated gas value x uncertainty of calibration gas

√3

April 2014 Sira Certification Service Page 10 of 11

Form 1330 Issue 2

MCERTS Stack Emission Monitoring Technical Endorsement 4

Personnel Certification Scheme

Example calculations

= 140 mg/m3 x 0.015

√3

= 1.21 mg/m3

8.6 To calculate the standard deviation of repeatability at span level in mg/m3

Standard deviation of repeatability at span level = 0.9% of the certified range (note that

this is a ‘Type A’ uncertainty and does not need to be divided by √3)

Certified range of analyser = 175 mg/m3

Standard deviation of repeatability at span Us,r

= certified range x standard deviation of repeatability at span

= 175 mg/m3 x 0.9%

= 1.58 mg/m3

8.7 To calculate the combined standard uncertainty

________________________

Combined uncertainty = √ Utemp2 + Uapress2 + Ucal2 + Us,r2

______________________

= √ 0.62 + 0.852 + 1.212 + 1.582

____________________

= √ 0.36 + 0.72 + 1.46 + 2.5

= 2.25 mg/m3

Expanded uncertainty = combined uncertainty x 1.96

= 2.05 mg/m3 x 1.96

= 4.4 mg/m3

April 2014 Sira Certification Service Page 11 of 11

Form 1330 Issue 2

You might also like

- Anoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Document4 pagesAnoxic Tank Design & Aeration Requirement-Lanka Hospitals: Wastewater Characteristics Parameter Concentration (G/M)Vaish Kan100% (5)

- TA1179-D-5212-100X-3 - P&ID (Marked-Up)Document40 pagesTA1179-D-5212-100X-3 - P&ID (Marked-Up)Iksan Adityo Mulyo100% (2)

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Calculation and Design of Packed Column For AcidDocument14 pagesCalculation and Design of Packed Column For AcidDavid Lambert100% (1)

- Chem Lab Report 2Document6 pagesChem Lab Report 2api-305324573100% (1)

- DEP Metering For Liquid Hydrocarbon (00000002)Document44 pagesDEP Metering For Liquid Hydrocarbon (00000002)Chijioke Obi100% (1)

- Guide To Selecting A Particle Counter For Cleanroom CertificationDocument2 pagesGuide To Selecting A Particle Counter For Cleanroom CertificationsombatseNo ratings yet

- Form 1325Document7 pagesForm 1325Alex HateganNo ratings yet

- Introduction To Air Pollution - WorkbookDocument10 pagesIntroduction To Air Pollution - Workbookrocky21stNo ratings yet

- Gas Absorption CalculationsDocument5 pagesGas Absorption Calculationschristianbryce70% (10)

- t224 PDFDocument2 pagest224 PDFJulio César ChávezNo ratings yet

- University Questions (Two Marks With Answers)Document17 pagesUniversity Questions (Two Marks With Answers)Uad100% (3)

- Chapter 8 - Mass TranferDocument27 pagesChapter 8 - Mass TranferThanh VânNo ratings yet

- Assignment 1 Cpe420 - Raiss Hakim Bin ZulkarnainDocument14 pagesAssignment 1 Cpe420 - Raiss Hakim Bin Zulkarnainraisshakim02No ratings yet

- PPM To MG - Nm3Document11 pagesPPM To MG - Nm3Chengkc2014100% (1)

- t224 PDFDocument2 pagest224 PDFRodrigo Samuel Huanca PerezNo ratings yet

- ECE Conentration and Unit Problems - T1Document9 pagesECE Conentration and Unit Problems - T1DanialNo ratings yet

- Unitsofconcentration PDFDocument8 pagesUnitsofconcentration PDFMohamedFittriNo ratings yet

- Converting Occupational Exposure Limits From MGDocument6 pagesConverting Occupational Exposure Limits From MGmajedzNo ratings yet

- Example Calculations: Time: Run Number: DateDocument4 pagesExample Calculations: Time: Run Number: DateLong Nguyễn HoàngNo ratings yet

- Experiment-04 Objective: Sampling of Particulate Matter PM2.5 andDocument3 pagesExperiment-04 Objective: Sampling of Particulate Matter PM2.5 andnopimeNo ratings yet

- Lecture3&4 Mass Transfer STDDocument27 pagesLecture3&4 Mass Transfer STDNuria Armenteros MenaNo ratings yet

- Units of Measure: SolidsDocument3 pagesUnits of Measure: SolidsHka Ismail100% (1)

- MiniStack CalculationsDocument12 pagesMiniStack CalculationsAdi Moh RizalNo ratings yet

- Check LIst - V4Document5 pagesCheck LIst - V4Yash DumaswalaNo ratings yet

- Unit 2 Advanced Biological Processes For Wastewater TreatmentDocument75 pagesUnit 2 Advanced Biological Processes For Wastewater TreatmentBadal NayakNo ratings yet

- Carbon BalanceDocument5 pagesCarbon BalanceHelmer AcevedoNo ratings yet

- Venturi Scrubber Design CalculationDocument2 pagesVenturi Scrubber Design CalculationAnil DhamankarNo ratings yet

- Environmental MeasurementsDocument5 pagesEnvironmental MeasurementsVincent OrianaNo ratings yet

- Humidity ConverterDocument2 pagesHumidity ConverterLeonidas IoannouNo ratings yet

- Concentration Units: Chemicals in Liquid SampleDocument9 pagesConcentration Units: Chemicals in Liquid Samplethuaiyaalhinai0% (1)

- Mole ConceptDocument1 pageMole ConceptMalnizah Abdul MalikNo ratings yet

- Process Engineeering CalculationsDocument1 pageProcess Engineeering CalculationskashifwarsiNo ratings yet

- Parts Per Million and ConcnDocument4 pagesParts Per Million and ConcnFreya SawNo ratings yet

- Trickling FilterDocument12 pagesTrickling FilterAditya Rahmat FauziNo ratings yet

- Tutorial 4 SolutionsDocument2 pagesTutorial 4 SolutionsUý Đại100% (1)

- Chapter Three Concentrations and EmissionsDocument39 pagesChapter Three Concentrations and EmissionsBassam RiachiNo ratings yet

- Ta Fe3 Part 1Document3 pagesTa Fe3 Part 1Nhi Trương MẫnNo ratings yet

- Ventury Scrubber Design MethodDocument3 pagesVentury Scrubber Design MethodPukhraj DagaNo ratings yet

- Assignment 4 5Document4 pagesAssignment 4 5maluNo ratings yet

- 4.1 Electrolyzer:: 2H O 2H + O 4H + 4e 2HDocument10 pages4.1 Electrolyzer:: 2H O 2H + O 4H + 4e 2Hrimsha qureshiNo ratings yet

- Question Bank CPCDocument20 pagesQuestion Bank CPCmadhavanssnNo ratings yet

- Lampiran Perhitungan: Laporan Kerja Praktek Unit Operasi PT. PUSRI-IBDocument5 pagesLampiran Perhitungan: Laporan Kerja Praktek Unit Operasi PT. PUSRI-IBRifqiMuhammadNo ratings yet

- Processes and Process VariablesDocument35 pagesProcesses and Process VariablesAndrei Jose GilNo ratings yet

- HW 3 BharatDocument3 pagesHW 3 BharatBharat MahajanNo ratings yet

- Grade 10 Lesson Note 1-1Document15 pagesGrade 10 Lesson Note 1-1Araoye AbdulwaheedNo ratings yet

- Thermo Part BDocument9 pagesThermo Part BSlindile HlambisaNo ratings yet

- Perhitungan Praktikum Uji Emisi Pak Ramli-NataDocument3 pagesPerhitungan Praktikum Uji Emisi Pak Ramli-NataChristian AltasaNo ratings yet

- Concentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Document7 pagesConcentrations and Other Units of Measure: (Nazaroff & Alvarez-Cohen, Section 1.C.1)Vivian SolangonNo ratings yet

- Lecture 7 - CE 433Document37 pagesLecture 7 - CE 433Khalid Bin OmarNo ratings yet

- Units of ConcentrationDocument8 pagesUnits of ConcentrationmadbakingNo ratings yet

- N Removal: CIE4485 Laboratory ExperimentDocument13 pagesN Removal: CIE4485 Laboratory ExperimentAbass MarrakchiNo ratings yet

- Design of Bagasse Dryer To Recover Energy of Water Tube Boiler in A Sugar FactoryDocument3 pagesDesign of Bagasse Dryer To Recover Energy of Water Tube Boiler in A Sugar FactorySolooloo Kebede NemomsaNo ratings yet

- FU 1 Assignment 4Document4 pagesFU 1 Assignment 4Thuỳ TrangNo ratings yet

- Waste Water AssignmentDocument4 pagesWaste Water Assignmentermias100% (2)

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsFrom EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffineNo ratings yet

- Air Quality ManagementFrom EverandAir Quality ManagementSuresh T. NesaratnamNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Global Vegetation Dynamics: Concepts and Applications in the MC1 ModelFrom EverandGlobal Vegetation Dynamics: Concepts and Applications in the MC1 ModelDominique BacheletNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Understanding Modern Dive Computers and Operation: Protocols, Models, Tests, Data, Risk and ApplicationsFrom EverandUnderstanding Modern Dive Computers and Operation: Protocols, Models, Tests, Data, Risk and ApplicationsNo ratings yet

- Environmental Scenario in Indian Mining Industry - an OverviewFrom EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNo ratings yet

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- Flow Meter ptm-01Document4 pagesFlow Meter ptm-01Jani WidodoNo ratings yet

- Wellbore Heat Loss in Production and Injection Wells, JPT Forum, 1979, 3 PGDocument3 pagesWellbore Heat Loss in Production and Injection Wells, JPT Forum, 1979, 3 PGjoselosse desantosNo ratings yet

- Final DRWDocument13 pagesFinal DRWK.l. DhanaNo ratings yet

- LPG Storage TankDocument5 pagesLPG Storage TankDimas PratamaNo ratings yet

- Comparison of Pumped Air Characteristics From A Rotary Atomizer With Different WheelsDocument6 pagesComparison of Pumped Air Characteristics From A Rotary Atomizer With Different WheelssanketNo ratings yet

- 12 Oventrop 60Document6 pages12 Oventrop 60Paolo FerjančićNo ratings yet

- Nozzle Performance Study System: Technical DescriptionDocument2 pagesNozzle Performance Study System: Technical DescriptionSheikh IsmailNo ratings yet

- EN7654 3 06 18 - FAM Economy PDFDocument8 pagesEN7654 3 06 18 - FAM Economy PDFPritesh KoratNo ratings yet

- Intrenship Report 2017 OGDCL PakistanDocument56 pagesIntrenship Report 2017 OGDCL PakistanIsrarAhmadMarwatNo ratings yet

- Factors Affecting Wet Scrubber PerformanceDocument4 pagesFactors Affecting Wet Scrubber PerformanceZee KayNo ratings yet

- An Instruction Manual: HTSR Series BlowersDocument10 pagesAn Instruction Manual: HTSR Series Blowersjmra12No ratings yet

- Sarn 7000Document66 pagesSarn 7000otrupon melliNo ratings yet

- Atrato Instruction Ficha - Just SolcoincoDocument7 pagesAtrato Instruction Ficha - Just SolcoincoJohn Jairo CelisNo ratings yet

- Omega M3704 PDFDocument76 pagesOmega M3704 PDFFathurrahman Yudhi NugrahaNo ratings yet

- Technical Data Sheets - TurbineDocument19 pagesTechnical Data Sheets - Turbinepavankumar001100% (1)

- Ins PDFDocument3 pagesIns PDFOmar Ahmed ElkhalilNo ratings yet

- Villegas Thesis Proposal PaperDocument27 pagesVillegas Thesis Proposal PaperLouie Ludeña VillegasNo ratings yet

- Technical - DOAS-01 - DA1-0710Document4 pagesTechnical - DOAS-01 - DA1-0710Sicologo CimeNo ratings yet

- Course Name: Biomedical Instrumentation Course Code: MC1652: Wednesday, March 30, 2016 1Document214 pagesCourse Name: Biomedical Instrumentation Course Code: MC1652: Wednesday, March 30, 2016 1Sachin GuptaNo ratings yet

- Gear PumpDocument58 pagesGear Pumpsgupta_615796100% (5)

- Biomedical Sensors and InstrumentsDocument9 pagesBiomedical Sensors and InstrumentslillosalesianoNo ratings yet

- As Found Report: Meter IdentificationDocument4 pagesAs Found Report: Meter IdentificationLaskar PejuangNo ratings yet

- Control Valve SizingDocument3 pagesControl Valve Sizingkaveh-bahiraeeNo ratings yet

- Efyxnov 2020Document84 pagesEfyxnov 2020Subhash ThakerNo ratings yet

- Data Sheet VA570 enDocument5 pagesData Sheet VA570 enNguyễn ĐạiNo ratings yet