Professional Documents

Culture Documents

EzyJamb SRC Installation Instructions EZ US II WB JAN18

EzyJamb SRC Installation Instructions EZ US II WB JAN18

Uploaded by

Ro KohnCopyright:

Available Formats

You might also like

- NW-BT Escalator Installation Guide Book: NoticeDocument52 pagesNW-BT Escalator Installation Guide Book: NoticeResul Şenay100% (3)

- Progress Tracking Sheet For Piping FabricationDocument1 pageProgress Tracking Sheet For Piping FabricationBrm MaminNo ratings yet

- Ib0600383engc PDFDocument293 pagesIb0600383engc PDFJoshuesito Cruz100% (3)

- (Chemical Injection System) - Operation and Maintenance ManualDocument19 pages(Chemical Injection System) - Operation and Maintenance Manualasri elektronikNo ratings yet

- Easom Product CatalogDocument36 pagesEasom Product Catalogkaniappan sakthivel50% (2)

- Investment Project Management SampleDocument9 pagesInvestment Project Management SampleShaneel PrasadNo ratings yet

- Bca Restart NavigatorDocument1 pageBca Restart NavigatorLoganNo ratings yet

- TX434SDocument2 pagesTX434Sbedjo8No ratings yet

- Gear Shifting: Machine Speed Mode Calculation Evl2775Document1 pageGear Shifting: Machine Speed Mode Calculation Evl2775AlanNo ratings yet

- Dyn Ddtc001 II-r16Document2 pagesDyn Ddtc001 II-r16darshNo ratings yet

- Spears Y Strainer Installation InstructionsDocument2 pagesSpears Y Strainer Installation InstructionsTrEnD SeT vicky rioNo ratings yet

- Dental Implant TorqueDocument2 pagesDental Implant TorqueS. BenzaquenNo ratings yet

- Seal & Seat Matrix-Floating-LatestDocument5 pagesSeal & Seat Matrix-Floating-LatestdennykvgNo ratings yet

- b1722Document1 pageb1722RaziKhanNo ratings yet

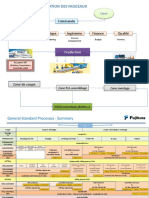

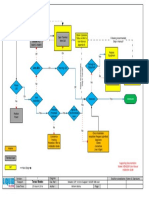

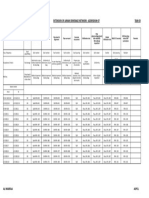

- Processus de Fabrication Des Faisceaux: CommandeDocument4 pagesProcessus de Fabrication Des Faisceaux: CommandeMOUAD BELKHALIFANo ratings yet

- Brochure Wave NG ENGDocument2 pagesBrochure Wave NG ENGSamastha Nair SamajamNo ratings yet

- Is333 - Project Management: Take Home Assignment SEMESTER 1, 2020Document8 pagesIs333 - Project Management: Take Home Assignment SEMESTER 1, 2020Shivani LataNo ratings yet

- Manual de Caja de Control - PORTON AUTOMOTIZADODocument36 pagesManual de Caja de Control - PORTON AUTOMOTIZADOOctavio RojasNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- Adams Rite 4590, 4591 Paddles Installation InstructionsDocument2 pagesAdams Rite 4590, 4591 Paddles Installation Instructionsgi-locksmithNo ratings yet

- E CONNECT 12x18 Folded Instructions PRINT 011 JFDocument2 pagesE CONNECT 12x18 Folded Instructions PRINT 011 JFĐiền Huỳnh Đức TrọngNo ratings yet

- Charla Servomotores SEWDocument17 pagesCharla Servomotores SEWJose RequenaNo ratings yet

- Wireless Keypad-Ic: Teclado Numérico Ic InalambricoDocument2 pagesWireless Keypad-Ic: Teclado Numérico Ic InalambricoshindomoNo ratings yet

- Makalah MGR Promot - Clma Gravity - p2pd TmminDocument27 pagesMakalah MGR Promot - Clma Gravity - p2pd TmminSandi SaputraNo ratings yet

- FTXS60GV1B IM 3P248445-1 en Installation Manuals EnglishDocument14 pagesFTXS60GV1B IM 3P248445-1 en Installation Manuals Englishgogu pompieruNo ratings yet

- Successfully Commenced Crs Inspection For Section-1 (Pa-Shiv)Document2 pagesSuccessfully Commenced Crs Inspection For Section-1 (Pa-Shiv)'Θκ'βύτ-Ίισνέγσύ.No ratings yet

- Microwave Hardware Quality Report: Rtn620 - InstallationDocument3 pagesMicrowave Hardware Quality Report: Rtn620 - InstallationMarco PalaciosNo ratings yet

- Qdoc - Tips 29901b Jake Detroit2Document20 pagesQdoc - Tips 29901b Jake Detroit2Gerald GutierrezNo ratings yet

- Varco Tds 11sa顶驱新图2014年Document261 pagesVarco Tds 11sa顶驱新图2014年Baber824No ratings yet

- JVC GYDV5101 enDocument103 pagesJVC GYDV5101 enEnergy-TVNo ratings yet

- Successfully Commenced Crs Inspection For Section-1 (Pa-Shiv)Document2 pagesSuccessfully Commenced Crs Inspection For Section-1 (Pa-Shiv)'Θκ'βύτ-Ίισνέγσύ.No ratings yet

- Owner'S Manual: ATV Broadcast Seeder - SpreaderDocument12 pagesOwner'S Manual: ATV Broadcast Seeder - SpreaderTemitope SoneyeNo ratings yet

- SWM Rotary PaddleDocument4 pagesSWM Rotary PaddlesydifiaNo ratings yet

- Materials Reliability Program: Tim Wells, ChairmanDocument23 pagesMaterials Reliability Program: Tim Wells, ChairmanLeonardo LimaNo ratings yet

- Phillips Federal - Major ServicesDocument1 pagePhillips Federal - Major ServicesLily DiazNo ratings yet

- Catalogo 4 202210Document8 pagesCatalogo 4 202210DianaCarolinaChimoyPecheNo ratings yet

- 4 Disciplines of ExecutionDocument13 pages4 Disciplines of ExecutioncydeNo ratings yet

- S'curve - Rusun Pik Pulogadung - Revisi 1Document3 pagesS'curve - Rusun Pik Pulogadung - Revisi 1Imran NatsirNo ratings yet

- Shop LayoutDocument1 pageShop LayoutRaphaelle DinaraNo ratings yet

- Tariq Villa - 28.11.2023 - Terrace Floor Ceiling ElectricalDocument1 pageTariq Villa - 28.11.2023 - Terrace Floor Ceiling Electricalosama170595No ratings yet

- CD Infographic PDFDocument1 pageCD Infographic PDFJamey DAVIDSONNo ratings yet

- SAWO Steam-GeneratorDocument24 pagesSAWO Steam-GeneratorPena Park HotelNo ratings yet

- WLAN InstallationDocument29 pagesWLAN Installation4cvnwvf26pNo ratings yet

- KLF Escalator Mechanical Installation ManualDocument35 pagesKLF Escalator Mechanical Installation ManualEmiliano Pugliese0% (1)

- Manual Phobos AC A SeriesDocument16 pagesManual Phobos AC A SeriescarmielsNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- ESG2001C1-W Controller PDFDocument12 pagesESG2001C1-W Controller PDFRenato Matičević100% (1)

- Formwork: Features and BenefitsDocument4 pagesFormwork: Features and BenefitsMilind KharateNo ratings yet

- Daily Report 115 - 23 April 2022 22.04.25Document2 pagesDaily Report 115 - 23 April 2022 22.04.25muis supriyadiNo ratings yet

- Performa (B) Checking Regarding Security of Educational Institutions (Category A)Document1 pagePerforma (B) Checking Regarding Security of Educational Institutions (Category A)ali chahilNo ratings yet

- Hardware Troubleshoot To Obtain Terminal Status: Teraco NewtecDocument1 pageHardware Troubleshoot To Obtain Terminal Status: Teraco NewtecAndrew NkhuwaNo ratings yet

- Instrumentation Upgrade BrochureDocument2 pagesInstrumentation Upgrade BrochurebnzelectricianshopNo ratings yet

- Staged Design ProcessDocument13 pagesStaged Design ProcessWangwen Zhao100% (1)

- Manual BFT IcaroDocument12 pagesManual BFT IcaroRobert Chalhua MonjaNo ratings yet

- MLT03 Wi2Document2 pagesMLT03 Wi2Bami-more AbiolaNo ratings yet

- Progress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepDocument1 pageProgress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepАртем КосовNo ratings yet

- Disassembly AssemblyDocument5 pagesDisassembly AssemblykyawzinkaungNo ratings yet

- CM370 User ManualDocument1 pageCM370 User Manualkovacs știe totNo ratings yet

- Sewer Check List Task-3Document1 pageSewer Check List Task-3csacas sacscNo ratings yet

- 96-0315 English RotaryDocument61 pages96-0315 English RotaryCarlos MendozaNo ratings yet

- Current Status and Future Directions of Cancer ImmunotherapyDocument9 pagesCurrent Status and Future Directions of Cancer ImmunotherapyRo KohnNo ratings yet

- PI 2389 Rev. B Alpha Fetoprotein RMab RUODocument2 pagesPI 2389 Rev. B Alpha Fetoprotein RMab RUORo KohnNo ratings yet

- Ashg Ps August1989Document3 pagesAshg Ps August1989Ro KohnNo ratings yet

- Macbeth Et Al-2016-British Journal of DermatologyDocument13 pagesMacbeth Et Al-2016-British Journal of DermatologyRo KohnNo ratings yet

- ELISA Kit For Fetoprotein Alpha (AFP) E90153BoDocument8 pagesELISA Kit For Fetoprotein Alpha (AFP) E90153BoRo KohnNo ratings yet

- Second-Trimester Maternal Serum Alpha-Fetoprotein Elevation and Its Association With Adverse Maternal/fetal Outcome: Ten Years ExperienceDocument6 pagesSecond-Trimester Maternal Serum Alpha-Fetoprotein Elevation and Its Association With Adverse Maternal/fetal Outcome: Ten Years ExperienceRo KohnNo ratings yet

- Acute Hypercalcemic Hypertension in Man: Role of Hemodynamics, Catecholamines, and ReninDocument5 pagesAcute Hypercalcemic Hypertension in Man: Role of Hemodynamics, Catecholamines, and ReninRo KohnNo ratings yet

- King's Research Portal: Citing This PaperDocument18 pagesKing's Research Portal: Citing This PaperRo KohnNo ratings yet

- Impact of Scalp Cooling On Chemo Induced Alopecia Wig Use and Hair Growth in Patients With CancerDocument5 pagesImpact of Scalp Cooling On Chemo Induced Alopecia Wig Use and Hair Growth in Patients With CancerRo KohnNo ratings yet

- Efficacy of Low Level Laser Therapy in The Treatment of Alopecia AreataDocument6 pagesEfficacy of Low Level Laser Therapy in The Treatment of Alopecia AreataRo KohnNo ratings yet

- 2014 Research SummitDocument8 pages2014 Research SummitRo KohnNo ratings yet

- Changes in Bone Mineral Density in Women With Earlyonset Androgenetik Alopecia and Their Correlations With Hairloss Stages A CrossDocument8 pagesChanges in Bone Mineral Density in Women With Earlyonset Androgenetik Alopecia and Their Correlations With Hairloss Stages A CrossRo KohnNo ratings yet

- Direct Action of The Parathyroid Hormone-Like Human Hypercalcemic FactorDocument5 pagesDirect Action of The Parathyroid Hormone-Like Human Hypercalcemic FactorRo KohnNo ratings yet

- Hypercalcemic Crisis: A Case Study: Loren A. Crown, M.D. Andra Kofahl, EMT-P Robert B. Smith, M.DDocument4 pagesHypercalcemic Crisis: A Case Study: Loren A. Crown, M.D. Andra Kofahl, EMT-P Robert B. Smith, M.DRo KohnNo ratings yet

- 10 11648 J Ajcem 20160404 12Document5 pages10 11648 J Ajcem 20160404 12Ro KohnNo ratings yet

- ISSUE 7 HypercalcemiaDocument1 pageISSUE 7 HypercalcemiaRo KohnNo ratings yet

- Pi Is 1087002416300296Document5 pagesPi Is 1087002416300296Ro KohnNo ratings yet

- Alopecia Areata VOP ReportDocument28 pagesAlopecia Areata VOP ReportRo KohnNo ratings yet

- Hyperthyroidism, An Overlooked Cause of Severe HypercalcaemiaDocument3 pagesHyperthyroidism, An Overlooked Cause of Severe HypercalcaemiaRo KohnNo ratings yet

- Hypercalcemia: Colorado ACP Meeting February 2017 David Tanaka MD FACPDocument33 pagesHypercalcemia: Colorado ACP Meeting February 2017 David Tanaka MD FACPRo KohnNo ratings yet

- Pe 08044Document4 pagesPe 08044Ro KohnNo ratings yet

- 14 CR Hypercalcemia With RenalDocument3 pages14 CR Hypercalcemia With RenalRo KohnNo ratings yet

- Pi Is 0085253815338837Document14 pagesPi Is 0085253815338837Ro KohnNo ratings yet

- Cardiologia: Hypercalcemic Crisis and Primary Hyperparathyroidism: Cause of An Unusual Electrical StormDocument5 pagesCardiologia: Hypercalcemic Crisis and Primary Hyperparathyroidism: Cause of An Unusual Electrical StormRo KohnNo ratings yet

- Entrep 1st PerioDocument5 pagesEntrep 1st PerioMargarette FajardoNo ratings yet

- SSC Teaching QualificationDocument3 pagesSSC Teaching QualificationSasikalaNo ratings yet

- Drinks Menu - Community Food & JuiceDocument1 pageDrinks Menu - Community Food & JuiceDyske SuematsuNo ratings yet

- Uses of RefractoryDocument20 pagesUses of RefractoryRicha Tripathi100% (2)

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Jimmy ReportDocument7 pagesJimmy ReportMaseer SyedNo ratings yet

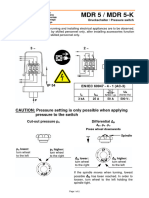

- Pressure Switch MDR5Document4 pagesPressure Switch MDR5Fidelis NdanoNo ratings yet

- Thhv-18 G10 Đề Nâng Cao Tổng Hợp Số 2Document12 pagesThhv-18 G10 Đề Nâng Cao Tổng Hợp Số 2hCby 28No ratings yet

- 19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFDocument110 pages19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFdi TalapaniniNo ratings yet

- ITSDF B56-11-5-2014-Rev-12-2-14Document17 pagesITSDF B56-11-5-2014-Rev-12-2-14Fernando AguilarNo ratings yet

- Proposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaDocument25 pagesProposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaGLOVIS MACNo ratings yet

- Preparation of Paracetamol Post LabDocument5 pagesPreparation of Paracetamol Post Labshmesa_alrNo ratings yet

- Edubba A Composite Text Ver3Document7 pagesEdubba A Composite Text Ver3RicardoNo ratings yet

- Redecon 2022 BrochureDocument4 pagesRedecon 2022 BrochurekarthiksampNo ratings yet

- 04 Vikram Pawar Volume 3 Issue 2Document18 pages04 Vikram Pawar Volume 3 Issue 2Juwan JafferNo ratings yet

- Chemical Technology (CHE1004) : An Overview of CTDocument21 pagesChemical Technology (CHE1004) : An Overview of CTkenziye esmael fetoNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- Private Peaceful EssayDocument7 pagesPrivate Peaceful Essayb6zm3pxh100% (2)

- Tutor Marked Assignment (TMA) SR Secondary 2018 19Document98 pagesTutor Marked Assignment (TMA) SR Secondary 2018 19kanna2750% (1)

- Putra, 003 - 3035 - I Wayan Adi Pranata - GalleyDocument7 pagesPutra, 003 - 3035 - I Wayan Adi Pranata - Galleyeunike jaequelineNo ratings yet

- Dopamine D23 Receptor Antagonism Reduces Activity-Based AnorexiaDocument10 pagesDopamine D23 Receptor Antagonism Reduces Activity-Based AnorexiaJeffery TaylorNo ratings yet

- Information Systems For Sustainable DevelopmentDocument23 pagesInformation Systems For Sustainable DevelopmentnshekhaNo ratings yet

- Catalogue - Nitoproof 600PFDocument2 pagesCatalogue - Nitoproof 600PFkenneth0129aaNo ratings yet

- C Renewables 2023 at Global Status Report Supply-Module. Renewable Energy Policy Network For 21st Century (REN 21 2023) GSR-2023Document127 pagesC Renewables 2023 at Global Status Report Supply-Module. Renewable Energy Policy Network For 21st Century (REN 21 2023) GSR-2023Vicente Correa NetoNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- Hprocedure of Export or ImportDocument96 pagesHprocedure of Export or ImportHiren RatnaniNo ratings yet

- Draftsmangrade II PDFDocument3 pagesDraftsmangrade II PDFakhilaNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet

EzyJamb SRC Installation Instructions EZ US II WB JAN18

EzyJamb SRC Installation Instructions EZ US II WB JAN18

Uploaded by

Ro KohnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EzyJamb SRC Installation Instructions EZ US II WB JAN18

EzyJamb SRC Installation Instructions EZ US II WB JAN18

Uploaded by

Ro KohnCopyright:

Available Formats

EZYJAMB SRC INSTALLATION INSTRUCTIONS

EZYJAMB

EZYJAMB

EZYJAMB

EzyJamb SRC

SRC SRC INS

INS

SRC Installation INS TALLATION

TALLATION

TALLATION

Instructions INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

EZYJAMB SRC

Step 2 INSTALLATION INSTRUCTIONS

Step 2A

A Studco Innovation

Manufactured by STUDCO Building Systems Step Step 2hinge2 StepStep

2A 2A

Stepby 1STUDCO

Manufactured

Manufactured by STUDCO Building

Building SystemsSystems Step

Step 22

Step • Fasten 2 side first, making sure jamb is level and Step2A2A

Head

Step 2A

Step Installation Instructions

Manufactured by STUDCO Building Systems

Manufactured byCODE

STUDCO Building Systems VIDEO

as

• Fasten tight against

• hinge

Fasten hinge

side stud

side

first, opening

first,

making sureas

making possible.

sure

jamb is jamb is level and

level and HeadHead Installation

Installation Instructions

Instructions

SCAN TO VIEW INSTALLATION •asFasten

tight•as hinge

Then side

studfirst,

tightscrew

against 8"making

at stud centers sure

opening upasjamb

stile, is level and

screwing

possible. back Head Installation Instructions

SCAN TO

Ensure that the rough opening is square, level, and is the correct size.

CODE TOINSTALLATION

VIEW INSTALLATION

••Fasten

Fastenhinge

as tight

against

hinge side

against

first,

side first,

stud

opening

making

making

opening

as possible.

sure

sure

as

jambis is

jamb

possible.

level and

level Head Installation

Head Installation Instructions

Instructions

SCAN CODE VIEW VIDEO VIDEO • Then

and

as tight as through

• Then

screw

tight

against

drywall

screw

at 8"

against

stud

atinto

centers

stud

opening

8" stud

centers

asup

opening jamb.

stile,

as up

screwing back back

stile,

possible.

possible.

screwing

SCAN CODE TO VIEW INSTALLATION VIDEO

Important •through

Then •screw

Double

through

drywall atinto

8" centers

screw

drywall

stud all

into up

ends

stud

jamb. stile, screwing

Detail

asjamb. back

D. and beside hinge

SCAN CODEStep

TO VIEW1INSTALLATION VIDEO • Then screw at 8" centers up stile, screwing back 2A

Make sure the rough opening has double studs, the manufacturer • Thenthrough

•

screw

Double •drywall

position

Double

screw -into

at 8” centers

bothstud

screw

all ends

up

above

all

asjamb.

stile,

endsscrewing

andasbelow

Detail DDetail

. and

back

hinge if using

D. and

beside beside

hinge con-

hinge

StepStep

1 1 strongly recommends wood studs or a minimum 18 gauge .030 through

through drywall

drywallintointo

stud jamb.

stud jamb. 2A

•position

Double screw

cealed

position

- both all

hinges ends

- both

above as as

above

and Detail

Detail and

below D

E.hinge. and

below if beside

hinge

using hinge con-

if using

con- 2A 2A

Step 1 1

Step metal studs on both sides of the opening. Studco recommends • Double screw all ends as Detail D. and beside hinge 2A

Insure

double that the rough

studs for thisopening is square,level

installation. and is

When using the correct

concealed size. the

hinges, position

• Double

cealed - both

cealed

screw

hinges above

hinges

all as

ends as and

Detailas

Detail. below

EDetail E.hinge

D. and besideif using

hinge con- 2A

position

position

- both above and below hinge if using con-

stud

Insure

Insure that must

that be

thenotched

rough at each

opening hinge

is location

square,level to

and ensure

is

the rough opening is square,level and is the correct size.the proper

correct fitment.

size. cealed -hinges

both above and below

as Detail E. hinge if using

Important: cealed as Detail

hingeshinges

concealed E. E.

as Detail

Insure that the rough opening is square,level and is the correct size.

Insure Make

that the

Important: roughsure

opening

Important: theis rough opening

square,level and is has double

the correct size.studs,

the

Important:Make manufacturer

sure the strongly

rough opening recommends

has double wood

studs,studs or

Make sure

Important: athe theSCAN

minimum rough opening

20CODE

gauge TO.030 hasmetal

VIEW double studs,

studs onwoodboth studs

sides or

Make sure

the manufacturermanufacturer

the rough strongly

opening has

strongly recommends recommends

double studs,

wood studs or

of the INSTALLATION

opening. VIDEO

Make thesure athe rough

minimum

manufacturer

a minimum 20 gauge opening

20 gauge

strongly has double

.030 metal

recommends

.030 metal studs,

studs

studs onwood onsides orsides

both studs both SCREW

the amanufacturer

of minimumof the

the opening. strongly

20opening.

gauge .030 recommends

metal studs wood studs

on both or

sides DRYWALL

a minimum 20 gauge .030 metal studs on both sides DOUBLE WOOD OR

of the opening. SCREW SCREW

of the opening. DRYWALL DRYWALLSCREW STEEL STUD

DOUBLE

DOUBLE STUD DRYWALL DOUBLE WOOD OR WOOD OR

SCREW

DRYWALL DOUBLE STUDSTEEL

WOOD

STEEL OR STUD

DOUBLE STUD

DOUBLE STUD DOUBLE WOOD

STEELOR

STUD

EZY JAMB

DOUBLE STUD STEEL STUD

DOUBLE STUD JAMB DETAIL DETAIL "D"

EZY JAMB EZY JAMB

EZY JAMB JAMB DETAIL

DRYWALL DRYWALL EZY JAMB

JAMB DETAIL DETAIL "D"DETAIL "D"

1/8” JAMB DETAIL DETAIL "D"

DRYWALL JAMB DETAIL DETAIL "D"

DRYWALL DRYWALL 1/8” 1/8”

DRYWALL

DRYWALL 1/8” DRYWALL "D"

DRYWALL 1/8” DRYWALL

FRAME WIDTH + 1" "D" "D"

FOR ROUGH OPENING "D"

FRAME

FRAME WIDTH + 1"WIDTH + 1" "D"

FRAME FOR

WIDTH

FOR ROUGH +ROUGH

1"

OPENING OPENING "E"

FRAMEFOR

WIDTH + 1"OPENING

ROUGH LEVEL "E"

FOR ROUGH OPENING "E"

LEVEL LEVEL "E"

"E"

LEVEL

LEVEL

DETAIL "E"

FRAME DETAIL "E" DETAIL "E"

SRC Installation Instructions EZ_US_II_WB_JAN18

HEIGHT OPENING

8" DETAIL "E"

FRAME +FRAME

3/4" DETAIL "E"

FRAME FORHEIGHT

HEIGHT OPENING OPENING DETAIL "C" 8"

ROUGH 8"

FRAMEHEIGHT + 3/4"

+ 3/4" OPENING OPENING

OPENING 8"

HEIGHT

FOR 3/4" FOR ROUGH

+ ROUGH DETAIL

DETAIL "C" 8" "C"

+ 3/4"

FOR ROUGH OPENING

OPENING FLOOR LEVEL DETAIL "C" "B"

FOR ROUGH

OPENING DETAIL "C"

FLOOR LEVEL

FLOOR LEVEL "B" "B"

OPENING

FLOOR LEVEL "B"

FLOOR LEVEL "B"

FLOOR

LEVEL

FLOOR FLOOR Elevation

FLOOR

LEVEL LEVEL

FLOORLEVEL Elevation

Elevation

Elevation

LEVEL Elevation

Elevation

Elevation

Elevation

www.ezyjamb.com Elevation

Elevation

Phone 1888 Ezyjamb

www.ezyjamb.com

www.ezyjamb.com

For Sales and Technical Inquiries, please contact EZ Concept USA

www.ezyjamb.com 1888

Phone1888

Phone Ezyjamb

Ezyjamb

www.ezyjamb.com

T: 1 888 399 5262 | F: 585.545.3010 | E: sales@ezconcept.com | W: www.ezconcept.com

Phone 1888 Ezyjamb

Phone 1888 Ezyjamb

EzyJamb SRC Installation Instructions A Studco Innovation

Step

Step 3 3 Step

Step 4 4 SRC

Installation Detail Detail

Step 3

Fasten the final vertical section (strike jamb) below the head

Step 4

Insure the perforated side strips sit flat against the SRC Detail

Fastensection.

the finalInsure

vertical section (strike jamb) below DRYWALL

that the spacing between thethe

twohead

vertical Insure the to

drywall perforated side

enable the strips

jamb sit flat to

sections against the drywall

be easily mudded

Fasten

section.

sections

Step 3

theInsure

final vertical

sections

are

that the section

are

spaced spaced

spacing (strike

evenly

between

evenly

at the at the

jamb)

required

below

the two

required

the head

vertical

distance.

distance.

Insure

into

wall theStep 4

the the

to enable perforated

surface.wall

side strips

jamb sections

surface. All the

sit flatmudded

to be easily

corners

againstinto

must

the the

be DRYWALL

HINGE

SRC Detail HINGE

section. Insure that the spacing between the two vertical drywall to enable the jamb sections to be easily mudded iz e

s

paper taped and mudded in as Detail F. Finish y in

gS

sections are spaced

Fasten the finalevenly at section

vertical the required distance.

(strike jamb) below the head into

AllthetheInsure

the wall surface.

jamb

corners the

with drywall

must Allpaper

perforated

be theside

compound.

corners

taped strips

andsit

Hang

must

flatdoor

the

mudded be

against the F.

ininas Detail Va

r

D OOR

s

DRYWALLiz e

paper taped toand mudded in asfromDetail F.

section. Insure that the spacing between the two vertical

Finish

the jamb

drywall

position leaving

the jambdrywall

intowith

enable

about

with drywall

the

1/8"jamb

compound.compound.

sections

clearance

Hang Hang

to

the betop

the door

the door

Finish

easily

and mudded

in in be

DOUBLE Installation Detail D OORHINGE

gS

Va

r yi

n

Step 3

sections are spaced evenly at the required distance. the

position

position

hinged theside

leaving

leaving

wallusing

Step 4

surface.

about 1/8”

about 1/8"

All Jamb

the

theclearance

Ezy

clearance

corners

Standard

from the toporand

must

Invisible

the WOOD OR

STEEL STUD ze

s

hinged paper

Hinges. side Insuretaped

using that and

the

the EzyJamb rough openingfrom

mudded

Standard is

or the Detail

insquare,

as

Invisibletoplevel,

andand

F. Finish

Hinges. DOUBLE r yi

ng

Si

Fasten the final vertical section (strike jamb) below the head the ishinged

Surfacethe

the correct

mountside

jamb size.

using

the

with

Insure the

striker

drywall

the Ezycompound.

plate

perforatedJamb

intoside Standard

position or

tositalign

Hang

strips the

flat Invisible

with

door in

against the WOOD OR Va D OOR

the latch plate punching. STEEL STUD

section. Insure that the spacing between the two vertical Hinges. Insure

position that

leaving

drywall the rough the

about

to enable opening

1/8" is square,

clearance

jamb sections to level,

from be andand

theeasily

top mudded DOUBLE

sections are spaced evenly at the required distance. is the correct

the hinged size.

into theside using

wall All the

the Ezy

surface. Jamb corners

Standard must be

or Invisible WOOD OR

STEEL STUD

Hinges.paper

Insuretaped and

that the mudded

rough inisas

opening Detail

square, F. Finish

level, and

is the correct

the jambsize.

with drywall compound. Hang the door in

DOUBLE STUD

SCREW FASTEN

ONLY

position leaving about 1/8" clearance from the top and

the hinged side using the Ezy Jamb Standard or Invisible SCREW FASTEN

DOUBLE STUD REINFORCED

Hinges. Surface mount the striker plate into position to ONLY EDGE

ROLLED STEEL JAMB

PERFORATED

align with the latch plate punching. DRYWALL SIDE STRIPS

DRYWALL 1/8” SCREW FASTEN

DOUBLE STUD REINFORCED

ONLY

ROLLED EDGE STEEL JAMB

EZY JAMB

Hinges Available

DOUBLE STUD PERFORATED

EQUAL DISTANCE DRYWALL DOOR 1/8” DRYWALL A range ofREINFORCED

Invisible (Concealed), SOSS,

SIDE STRIPS

STEEL JAMB

1/8” StandardROLLED and Mortised hinges available

EDGE

PERFORATED

EQUAL DISTANCE

DRYWALL

DRYWALL

1/8”

1/8"

DRYWALL

DRYWALL

Hinges Available

SIDE STRIPSinstructions for correct installation

Refer to hinge installation

and rough opening preparation.

1/8”

A range of Invisible (Concealed), SOSS,

EQUAL DISTANCE

DETAIL

"F"

Hinges Available

Standard and Mortised hinges available

EQUAL DISTANCE 1/8”

Refer toAhinge

range of Invisible (Concealed),

correct installationSOSS,

1/8"

installation instructions for

EQUAL DISTANCE

Standard

and rough and Mortised

opening hinges available

preparation.

EQUAL DISTANCE Refer to hinge installation instructions for correct installation

and rough opening preparation.

SET INTO WALL

Installation Instructions EZ_US_II_WB_JAN18

FLOOR LEVEL EQUAL DISTANCE DOOR

SURFACE

EQUAL DISTANCE

EQUAL DISTANCE

FLOOR LEVEL

Elevation

TYPICAL T-STRIKE

FLOOR LEVEL EQUAL DISTANCE

ASSEMBLY

Rocyork have a select range of

Information printed in this document or communicated by the designers, manufacturers, distributors or any agent is functional door furniture that

FLOOR LEVEL EQUAL DISTANCE

Elevation FLOOR LEVEL

subject to change without notice to allow further development in design, manufacture and technology. integrates seamlessly with all facets

EZY_SRC_INST_0616

of the EZYJamb door system.

EQUAL DISTANCE

Elevation

Information printed in this document or communicated by the designers, manufacturers, distributors or any agent is Rocyork have a select range

www.ezyjamb.com Phone 1888 Ezyjamb

subject to change without notice to allow further development in design, manufacture and technology.

Elevation Elevation of functional door furniture that

Y_EZC_INST_0616

For Sales and Technical Inquiries, printed

please contact EZ Concept integrates seamlessly with all facets

Information in this document orUSA

communicated by the designers, manufacturers, distributors or any agent is

SRC

Rocyork have

of the EZYJamb door asystem.

select range

T: 1 888 399 5262 | F: 585.545.3010 | E: sales@ezconcept.com | W: www.ezconcept.com

subject to change without notice to allow further development in design, manufacture and technology. of functional door furniture that

Information printed in this document or communicated by the designers, manufacturers, distributors or any agent is integrates seamlessly with all facets

STRIKE PLATE INSTALLATION DETAIL

subject to change without notice to allow further development in design, manufacture and technology. of the EZYJamb door system.

You might also like

- NW-BT Escalator Installation Guide Book: NoticeDocument52 pagesNW-BT Escalator Installation Guide Book: NoticeResul Şenay100% (3)

- Progress Tracking Sheet For Piping FabricationDocument1 pageProgress Tracking Sheet For Piping FabricationBrm MaminNo ratings yet

- Ib0600383engc PDFDocument293 pagesIb0600383engc PDFJoshuesito Cruz100% (3)

- (Chemical Injection System) - Operation and Maintenance ManualDocument19 pages(Chemical Injection System) - Operation and Maintenance Manualasri elektronikNo ratings yet

- Easom Product CatalogDocument36 pagesEasom Product Catalogkaniappan sakthivel50% (2)

- Investment Project Management SampleDocument9 pagesInvestment Project Management SampleShaneel PrasadNo ratings yet

- Bca Restart NavigatorDocument1 pageBca Restart NavigatorLoganNo ratings yet

- TX434SDocument2 pagesTX434Sbedjo8No ratings yet

- Gear Shifting: Machine Speed Mode Calculation Evl2775Document1 pageGear Shifting: Machine Speed Mode Calculation Evl2775AlanNo ratings yet

- Dyn Ddtc001 II-r16Document2 pagesDyn Ddtc001 II-r16darshNo ratings yet

- Spears Y Strainer Installation InstructionsDocument2 pagesSpears Y Strainer Installation InstructionsTrEnD SeT vicky rioNo ratings yet

- Dental Implant TorqueDocument2 pagesDental Implant TorqueS. BenzaquenNo ratings yet

- Seal & Seat Matrix-Floating-LatestDocument5 pagesSeal & Seat Matrix-Floating-LatestdennykvgNo ratings yet

- b1722Document1 pageb1722RaziKhanNo ratings yet

- Processus de Fabrication Des Faisceaux: CommandeDocument4 pagesProcessus de Fabrication Des Faisceaux: CommandeMOUAD BELKHALIFANo ratings yet

- Brochure Wave NG ENGDocument2 pagesBrochure Wave NG ENGSamastha Nair SamajamNo ratings yet

- Is333 - Project Management: Take Home Assignment SEMESTER 1, 2020Document8 pagesIs333 - Project Management: Take Home Assignment SEMESTER 1, 2020Shivani LataNo ratings yet

- Manual de Caja de Control - PORTON AUTOMOTIZADODocument36 pagesManual de Caja de Control - PORTON AUTOMOTIZADOOctavio RojasNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- Adams Rite 4590, 4591 Paddles Installation InstructionsDocument2 pagesAdams Rite 4590, 4591 Paddles Installation Instructionsgi-locksmithNo ratings yet

- E CONNECT 12x18 Folded Instructions PRINT 011 JFDocument2 pagesE CONNECT 12x18 Folded Instructions PRINT 011 JFĐiền Huỳnh Đức TrọngNo ratings yet

- Charla Servomotores SEWDocument17 pagesCharla Servomotores SEWJose RequenaNo ratings yet

- Wireless Keypad-Ic: Teclado Numérico Ic InalambricoDocument2 pagesWireless Keypad-Ic: Teclado Numérico Ic InalambricoshindomoNo ratings yet

- Makalah MGR Promot - Clma Gravity - p2pd TmminDocument27 pagesMakalah MGR Promot - Clma Gravity - p2pd TmminSandi SaputraNo ratings yet

- FTXS60GV1B IM 3P248445-1 en Installation Manuals EnglishDocument14 pagesFTXS60GV1B IM 3P248445-1 en Installation Manuals Englishgogu pompieruNo ratings yet

- Successfully Commenced Crs Inspection For Section-1 (Pa-Shiv)Document2 pagesSuccessfully Commenced Crs Inspection For Section-1 (Pa-Shiv)'Θκ'βύτ-Ίισνέγσύ.No ratings yet

- Microwave Hardware Quality Report: Rtn620 - InstallationDocument3 pagesMicrowave Hardware Quality Report: Rtn620 - InstallationMarco PalaciosNo ratings yet

- Qdoc - Tips 29901b Jake Detroit2Document20 pagesQdoc - Tips 29901b Jake Detroit2Gerald GutierrezNo ratings yet

- Varco Tds 11sa顶驱新图2014年Document261 pagesVarco Tds 11sa顶驱新图2014年Baber824No ratings yet

- JVC GYDV5101 enDocument103 pagesJVC GYDV5101 enEnergy-TVNo ratings yet

- Successfully Commenced Crs Inspection For Section-1 (Pa-Shiv)Document2 pagesSuccessfully Commenced Crs Inspection For Section-1 (Pa-Shiv)'Θκ'βύτ-Ίισνέγσύ.No ratings yet

- Owner'S Manual: ATV Broadcast Seeder - SpreaderDocument12 pagesOwner'S Manual: ATV Broadcast Seeder - SpreaderTemitope SoneyeNo ratings yet

- SWM Rotary PaddleDocument4 pagesSWM Rotary PaddlesydifiaNo ratings yet

- Materials Reliability Program: Tim Wells, ChairmanDocument23 pagesMaterials Reliability Program: Tim Wells, ChairmanLeonardo LimaNo ratings yet

- Phillips Federal - Major ServicesDocument1 pagePhillips Federal - Major ServicesLily DiazNo ratings yet

- Catalogo 4 202210Document8 pagesCatalogo 4 202210DianaCarolinaChimoyPecheNo ratings yet

- 4 Disciplines of ExecutionDocument13 pages4 Disciplines of ExecutioncydeNo ratings yet

- S'curve - Rusun Pik Pulogadung - Revisi 1Document3 pagesS'curve - Rusun Pik Pulogadung - Revisi 1Imran NatsirNo ratings yet

- Shop LayoutDocument1 pageShop LayoutRaphaelle DinaraNo ratings yet

- Tariq Villa - 28.11.2023 - Terrace Floor Ceiling ElectricalDocument1 pageTariq Villa - 28.11.2023 - Terrace Floor Ceiling Electricalosama170595No ratings yet

- CD Infographic PDFDocument1 pageCD Infographic PDFJamey DAVIDSONNo ratings yet

- SAWO Steam-GeneratorDocument24 pagesSAWO Steam-GeneratorPena Park HotelNo ratings yet

- WLAN InstallationDocument29 pagesWLAN Installation4cvnwvf26pNo ratings yet

- KLF Escalator Mechanical Installation ManualDocument35 pagesKLF Escalator Mechanical Installation ManualEmiliano Pugliese0% (1)

- Manual Phobos AC A SeriesDocument16 pagesManual Phobos AC A SeriescarmielsNo ratings yet

- Site Modification: Bill of MaterialDocument1 pageSite Modification: Bill of MaterialRaziKhanNo ratings yet

- ESG2001C1-W Controller PDFDocument12 pagesESG2001C1-W Controller PDFRenato Matičević100% (1)

- Formwork: Features and BenefitsDocument4 pagesFormwork: Features and BenefitsMilind KharateNo ratings yet

- Daily Report 115 - 23 April 2022 22.04.25Document2 pagesDaily Report 115 - 23 April 2022 22.04.25muis supriyadiNo ratings yet

- Performa (B) Checking Regarding Security of Educational Institutions (Category A)Document1 pagePerforma (B) Checking Regarding Security of Educational Institutions (Category A)ali chahilNo ratings yet

- Hardware Troubleshoot To Obtain Terminal Status: Teraco NewtecDocument1 pageHardware Troubleshoot To Obtain Terminal Status: Teraco NewtecAndrew NkhuwaNo ratings yet

- Instrumentation Upgrade BrochureDocument2 pagesInstrumentation Upgrade BrochurebnzelectricianshopNo ratings yet

- Staged Design ProcessDocument13 pagesStaged Design ProcessWangwen Zhao100% (1)

- Manual BFT IcaroDocument12 pagesManual BFT IcaroRobert Chalhua MonjaNo ratings yet

- MLT03 Wi2Document2 pagesMLT03 Wi2Bami-more AbiolaNo ratings yet

- Progress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepDocument1 pageProgress Tracking Sheet-Piping Fabrication: Enter % Complete For Each Work StepАртем КосовNo ratings yet

- Disassembly AssemblyDocument5 pagesDisassembly AssemblykyawzinkaungNo ratings yet

- CM370 User ManualDocument1 pageCM370 User Manualkovacs știe totNo ratings yet

- Sewer Check List Task-3Document1 pageSewer Check List Task-3csacas sacscNo ratings yet

- 96-0315 English RotaryDocument61 pages96-0315 English RotaryCarlos MendozaNo ratings yet

- Current Status and Future Directions of Cancer ImmunotherapyDocument9 pagesCurrent Status and Future Directions of Cancer ImmunotherapyRo KohnNo ratings yet

- PI 2389 Rev. B Alpha Fetoprotein RMab RUODocument2 pagesPI 2389 Rev. B Alpha Fetoprotein RMab RUORo KohnNo ratings yet

- Ashg Ps August1989Document3 pagesAshg Ps August1989Ro KohnNo ratings yet

- Macbeth Et Al-2016-British Journal of DermatologyDocument13 pagesMacbeth Et Al-2016-British Journal of DermatologyRo KohnNo ratings yet

- ELISA Kit For Fetoprotein Alpha (AFP) E90153BoDocument8 pagesELISA Kit For Fetoprotein Alpha (AFP) E90153BoRo KohnNo ratings yet

- Second-Trimester Maternal Serum Alpha-Fetoprotein Elevation and Its Association With Adverse Maternal/fetal Outcome: Ten Years ExperienceDocument6 pagesSecond-Trimester Maternal Serum Alpha-Fetoprotein Elevation and Its Association With Adverse Maternal/fetal Outcome: Ten Years ExperienceRo KohnNo ratings yet

- Acute Hypercalcemic Hypertension in Man: Role of Hemodynamics, Catecholamines, and ReninDocument5 pagesAcute Hypercalcemic Hypertension in Man: Role of Hemodynamics, Catecholamines, and ReninRo KohnNo ratings yet

- King's Research Portal: Citing This PaperDocument18 pagesKing's Research Portal: Citing This PaperRo KohnNo ratings yet

- Impact of Scalp Cooling On Chemo Induced Alopecia Wig Use and Hair Growth in Patients With CancerDocument5 pagesImpact of Scalp Cooling On Chemo Induced Alopecia Wig Use and Hair Growth in Patients With CancerRo KohnNo ratings yet

- Efficacy of Low Level Laser Therapy in The Treatment of Alopecia AreataDocument6 pagesEfficacy of Low Level Laser Therapy in The Treatment of Alopecia AreataRo KohnNo ratings yet

- 2014 Research SummitDocument8 pages2014 Research SummitRo KohnNo ratings yet

- Changes in Bone Mineral Density in Women With Earlyonset Androgenetik Alopecia and Their Correlations With Hairloss Stages A CrossDocument8 pagesChanges in Bone Mineral Density in Women With Earlyonset Androgenetik Alopecia and Their Correlations With Hairloss Stages A CrossRo KohnNo ratings yet

- Direct Action of The Parathyroid Hormone-Like Human Hypercalcemic FactorDocument5 pagesDirect Action of The Parathyroid Hormone-Like Human Hypercalcemic FactorRo KohnNo ratings yet

- Hypercalcemic Crisis: A Case Study: Loren A. Crown, M.D. Andra Kofahl, EMT-P Robert B. Smith, M.DDocument4 pagesHypercalcemic Crisis: A Case Study: Loren A. Crown, M.D. Andra Kofahl, EMT-P Robert B. Smith, M.DRo KohnNo ratings yet

- 10 11648 J Ajcem 20160404 12Document5 pages10 11648 J Ajcem 20160404 12Ro KohnNo ratings yet

- ISSUE 7 HypercalcemiaDocument1 pageISSUE 7 HypercalcemiaRo KohnNo ratings yet

- Pi Is 1087002416300296Document5 pagesPi Is 1087002416300296Ro KohnNo ratings yet

- Alopecia Areata VOP ReportDocument28 pagesAlopecia Areata VOP ReportRo KohnNo ratings yet

- Hyperthyroidism, An Overlooked Cause of Severe HypercalcaemiaDocument3 pagesHyperthyroidism, An Overlooked Cause of Severe HypercalcaemiaRo KohnNo ratings yet

- Hypercalcemia: Colorado ACP Meeting February 2017 David Tanaka MD FACPDocument33 pagesHypercalcemia: Colorado ACP Meeting February 2017 David Tanaka MD FACPRo KohnNo ratings yet

- Pe 08044Document4 pagesPe 08044Ro KohnNo ratings yet

- 14 CR Hypercalcemia With RenalDocument3 pages14 CR Hypercalcemia With RenalRo KohnNo ratings yet

- Pi Is 0085253815338837Document14 pagesPi Is 0085253815338837Ro KohnNo ratings yet

- Cardiologia: Hypercalcemic Crisis and Primary Hyperparathyroidism: Cause of An Unusual Electrical StormDocument5 pagesCardiologia: Hypercalcemic Crisis and Primary Hyperparathyroidism: Cause of An Unusual Electrical StormRo KohnNo ratings yet

- Entrep 1st PerioDocument5 pagesEntrep 1st PerioMargarette FajardoNo ratings yet

- SSC Teaching QualificationDocument3 pagesSSC Teaching QualificationSasikalaNo ratings yet

- Drinks Menu - Community Food & JuiceDocument1 pageDrinks Menu - Community Food & JuiceDyske SuematsuNo ratings yet

- Uses of RefractoryDocument20 pagesUses of RefractoryRicha Tripathi100% (2)

- RPLL NewDocument74 pagesRPLL NewMeta learnNo ratings yet

- SM - 9 Automatic TransmissionDocument61 pagesSM - 9 Automatic TransmissionJoeNo ratings yet

- Jimmy ReportDocument7 pagesJimmy ReportMaseer SyedNo ratings yet

- Pressure Switch MDR5Document4 pagesPressure Switch MDR5Fidelis NdanoNo ratings yet

- Thhv-18 G10 Đề Nâng Cao Tổng Hợp Số 2Document12 pagesThhv-18 G10 Đề Nâng Cao Tổng Hợp Số 2hCby 28No ratings yet

- 19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFDocument110 pages19 Fingal Development Plan 2017-2023 - Strategic Environmental Assessment Statement PDFdi TalapaniniNo ratings yet

- ITSDF B56-11-5-2014-Rev-12-2-14Document17 pagesITSDF B56-11-5-2014-Rev-12-2-14Fernando AguilarNo ratings yet

- Proposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaDocument25 pagesProposed Residential House To Be Built at Block 00X, Plot 00Y, Kampala UgandaGLOVIS MACNo ratings yet

- Preparation of Paracetamol Post LabDocument5 pagesPreparation of Paracetamol Post Labshmesa_alrNo ratings yet

- Edubba A Composite Text Ver3Document7 pagesEdubba A Composite Text Ver3RicardoNo ratings yet

- Redecon 2022 BrochureDocument4 pagesRedecon 2022 BrochurekarthiksampNo ratings yet

- 04 Vikram Pawar Volume 3 Issue 2Document18 pages04 Vikram Pawar Volume 3 Issue 2Juwan JafferNo ratings yet

- Chemical Technology (CHE1004) : An Overview of CTDocument21 pagesChemical Technology (CHE1004) : An Overview of CTkenziye esmael fetoNo ratings yet

- Composite EbookDocument285 pagesComposite Ebooksunilas218408100% (1)

- Private Peaceful EssayDocument7 pagesPrivate Peaceful Essayb6zm3pxh100% (2)

- Tutor Marked Assignment (TMA) SR Secondary 2018 19Document98 pagesTutor Marked Assignment (TMA) SR Secondary 2018 19kanna2750% (1)

- Putra, 003 - 3035 - I Wayan Adi Pranata - GalleyDocument7 pagesPutra, 003 - 3035 - I Wayan Adi Pranata - Galleyeunike jaequelineNo ratings yet

- Dopamine D23 Receptor Antagonism Reduces Activity-Based AnorexiaDocument10 pagesDopamine D23 Receptor Antagonism Reduces Activity-Based AnorexiaJeffery TaylorNo ratings yet

- Information Systems For Sustainable DevelopmentDocument23 pagesInformation Systems For Sustainable DevelopmentnshekhaNo ratings yet

- Catalogue - Nitoproof 600PFDocument2 pagesCatalogue - Nitoproof 600PFkenneth0129aaNo ratings yet

- C Renewables 2023 at Global Status Report Supply-Module. Renewable Energy Policy Network For 21st Century (REN 21 2023) GSR-2023Document127 pagesC Renewables 2023 at Global Status Report Supply-Module. Renewable Energy Policy Network For 21st Century (REN 21 2023) GSR-2023Vicente Correa NetoNo ratings yet

- Servicio y Reparación GenieDocument268 pagesServicio y Reparación Geniejonny david martinez perezNo ratings yet

- Hprocedure of Export or ImportDocument96 pagesHprocedure of Export or ImportHiren RatnaniNo ratings yet

- Draftsmangrade II PDFDocument3 pagesDraftsmangrade II PDFakhilaNo ratings yet

- Volumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmDocument19 pagesVolumetric Rotary Piston Meter Asm LXH SA1508 15mm, 20mm & 25mmGreen FarmersNo ratings yet