Professional Documents

Culture Documents

Claus Sulphur Recovery Options

Claus Sulphur Recovery Options

Uploaded by

ghasem_726990287Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Claus Sulphur Recovery Options

Claus Sulphur Recovery Options

Uploaded by

ghasem_726990287Copyright:

Available Formats

Claus sulphur recovery options

This article examines some Claus modifications which can alleviate operational

difficulties and improve overall sulphur recovery

Gavin McIntyre and Lili Lyddon Bryan Research and Engineering Inc

S

ince its inception, the Claus process has reaction furnace, so some modification to the

been the standard of the sulphur recovery process is required. In addition, acid gas feeds

industry, but limitations and problems may contain undesirable components such as

relating to composition may restrict its effective- ammonia and hydrocarbons, which cause prob-

ness. Numerous modifications have been lems during processing. Again, the traditional

applied to the basic process in an effort to Claus process must be modified to handle these

develop the optimum system for a certain set of contaminants.

conditions. For the purposes of this article, acid gas is

The primary consideration in determining the classified into three different categories based on

optimum sulphur removal process is the compo- composition, and the types of Claus or modified

sition of the acid gas stream to be processed. A Claus processes that may be used to lower

typical rich feed gas stream to a Claus plant sulphur emissions to an acceptable level are

contains at least 50 per cent H2S by volume (50– discussed.

60 per cent is considered marginal). The The first type of feed gas discussed is rich acid

traditional Claus plant may be used for primary gas, or feed containing greater than 50 mole%

sulphur recovery from such a rich acid gas H2S. The second type is lean acid gas, or feed

stream. Unfortunately, the H2S content of acid containing less than 50 mole% H2S. The last type

gas is sometimes very low (5–50 per cent) with of feed to be considered is acid gas containing

CO2 making up the bulk of the feed. ammonia. A process simulator, TSWEET, illus-

This lean feed is not sufficient to sustain trates how effective various processes are for

combustion in the burner of the traditional Claus each of the three acid gas feed types.

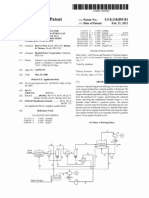

Figure 1 Schematic of the basic Claus process

www.digitalrefining.com/article/1000328 PTQ Q2 1997 1

Rich acid gas inlet conditions and base case results by current industry standards. Upon examina-

tion, there are several areas where small

operational or design changes could improve

Composition (mole %)

Temperature 75°F H2S 93.40

recovery. Some of these changes were simulated

Pressure 16.5psia CO2 5.64 to show how the plant might operate if it were

H2O 0.96 optimised by today’s standards.

The outlet temperature of the waste heat boiler

Base Two-Bed Modified

Two-Bed

was decreased from 840°F to 700°F and a

Data TSWEET TSWEET sulphur condenser was added to remove all the

Reactor furnace temperature 2230°F 2258°F 2221°F sulphur formed in the furnace. The condenser

1st sulphur condenser none none 320°F improves recovery because the presence of

Bed 1 outlet temperature 730°F 727°F 650°F

Bed 1 H2S conversion – 9% 51%

elemental sulphur in the catalyst beds reduces

Bed 2 outlet temperature 581°F 590°F 450°F the efficiency of the Claus reaction. Also, the

Bed 2 H2S conversion – 65% 77% outlet temperature of the first reheater was

H2S : SO2 ratio 1.2:1 1.2:1 2:1 controlled to maintain a bed outlet temperature

Overall recovery 91.8 90.7% 96.1%

of 650°F rather than 727°F.

This lower temperature promotes improved

Table 1 Claus conversion but still ensures destruction of

the COS and CS2 formed in the burner. Similarly,

Case study 1: Rich acid gas feed – H2S content the second reheater was controlled to maintain

above 50 per cent the outlet temperature of the second bed at 30

Several options are available for consideration degrees above the sulphur dew point. The closer

when designing the primary sulphur recovery to the sulphur dew point the bed operates, the

unit to process a rich acid gas feed. Even though higher the equilibrium conversion.

many variations of the standard Claus plant may One final item to note concerning this case is

be suitable, one may have a slight advantage the ratio control of H2S to SO2 in the tail gas.

over the others. The Claus reaction requires two moles of H2S for

Depending on the required sulphur removal, a every one mole of SO2 for optimum conversion

number of configurations could be used for according to the following reactions:

primary sulphur removal, such as a two- or

three-bed Claus plant, with or without a direct H2S + 11/2O2 →SO2 + H2O

oxidation bed or cold (sub dew point) bed. These 2H2S + SO2 ⇔ 3S + 2H2O

and other variations are compared, based on

their ability to effectively process a rich acid gas This plant originally operated at a ratio of

stream. Figure 1 is a schematic of the basic Claus 1.2:1, but in the simulation the ratio was changed

process. Some of the more common process to 2:1 to optimise the performance of the unit.

modifications to the basic Claus, discussed in the The ratio is controlled by manipulating the flow

following sections, are indicated with dashed rate of inlet air from the blower to the furnace.

lines. These seemingly minor changes to operating

A two-bed Claus plant operating in the 1960s conditions increased sulphur recovery from 91.8

with approximately 93 per cent H2S in the feed per cent to 96.1 per cent, a 4.3 per cent improve-

is used as the base case for this discussion. A ment over the original design, as shown in Table

process simulator, TSWEET, was used to obtain 1. These modifications are used as the basis for

an initial model by matching plant data. The comparisons with other process modifications.

model was then modified to show how improve-

ments could be made. Standard three-bed Claus plant

A comparison of plant data to TSWEET predic- There are numerous technical papers available

tions is listed in Table 1 to provide a basis for the on the conventional Claus process and its capa-

accuracy of the program’s predictions for further bilities. Typically, sulphur recoveries in the range

modifications. of 96–97.5 per cent can be expected for a stand-

This particular plant achieved an overall ard three-bed Claus plant with rich acid gas feed.

sulphur recovery of 91.8 per cent, which is low (Emission regulations often necessitate the inclu-

2 PTQ Q2 1997 www.digitalrefining.com/article/1000328

sion of a secondary tail gas cleanup unit to boost Rich acid gas feed process comparison

recovery as high as 99.9+per cent). For this

comparison, a third Claus bed was added to the

Process description Overall sulphur

modified two-bed plant. recovery

A controller maintains a 2:1 H2S:SO2 ratio in Modified 2-Bed Claus 96.1

the tail gas by operating the burner sub-stoichio- Conventional 3-Bed Claus 98.0

metrically. The simulation model assumes a 95 2-Bed with direct oxidation bed 98.8

2-Bed with sub dew point bed 99.0

per cent approach to equilibrium in the Claus 4-Bed Claus 98.5

reactors and 4lb liquid sulphur entrained in the 3-Bed Claus with direct oxidation bed 99.0

sulphur condensers per 100 moles of gas. 3-Bed Claus with sub dew point bed 99.3

The first bed is operated at a temperature of

650°F to ensure destruction of the COS and CS2. Table 2

Subsequent beds are maintained at 30 degrees

above the sulphur dew point to achieve the high- the operation of the traditional Claus process.

est possible conversion. The overall sulphur Instead of maintaining a 2:1 H2S:SO2 ratio

recovery predicted by simulation increased to throughout, the process operates with an excess

98.0 per cent, a 1.9 per cent improvement over of H2S. All sulphur species except H2S pass over

the two-bed case, by adding the third catalyst the special catalyst unreacted. Therefore, prior

bed, as shown in Table 2. (Table 2 recoveries reduction of non-H2S species results in greater

assume the plant is operating under optimum conversion in the direct oxidation bed and

conditions and are for comparison only. Actual greater overall recovery for the plant.

recoveries may be 0.5 to 1 per cent lower than An additional requirement for this process is a

those reported). source of air upstream of the direct oxidation

reactor. The air mixes with the Claus tail gas to

Two-bed Claus with a direct oxidation catalyst bed promote oxidation of the H2S to elemental

For this case, the third reactor of the previous sulphur in the presence of the direct oxidation

three-bed case was replaced by a bed represent- catalyst. The success of this process depends on

ing a direct oxidation process such as Superclaus. the ability to operate with an excess of H2S and

Direct oxidation requires a special catalyst which consume all of the SO2 before entering the direct

converts H2S directly to sulphur. oxidation reactor.

There are two versions of the Superclaus proc- Simulation results indicate that the overall

ess – the Superclaus-99 and the 99.5. The 99 recovery of this process increased to 98.8 per

and 99.5 represent the overall sulphur recoveries cent by replacement of the third bed with a

that can be expected when the Superclaus cata- direct oxidation catalyst bed. This is an increase

lyst is used in the final bed of a Claus plant. To of 0.8 per cent over the original three-bed case

achieve 99 per cent sulphur recovery, the tail gas shown in Table 2.

from the second Claus bed is fed directly to the

reactor bed containing the direct oxidation Two-bed Claus with a cold bed

catalyst. The next option explored in the study of rich

To achieve 99.5 per cent sulphur recovery, the acid gas feed was the use of a cold bed as the

process includes a hydrogenation reactor third and final bed. Since the Claus reaction is

upstream of the direct oxidation bed to convert exothermic, the lower the reaction temperature,

all remaining sulphur species to H2S before pass- the closer the reaction proceeds to completion.

ing over the direct oxidation catalyst, thus The main difference between this process and

yielding a higher overall sulphur recovery. Direct the traditional Claus process is that the sulphur

oxidation without the hydrogenation step has formed in the bed is actually adsorbed on the

been chosen for comparative purposes in this catalyst, since the bed is operated below the

case. A conversion efficiency of 85 per cent was sulphur dew point.

assumed for the direct oxidation bed in the More than one bed is required for this process

simulations. because the beds must be regenerated periodi-

The operation of a process which includes a cally to remove the adsorbed sulphur. Sulphur is

direct oxidation bed is somewhat different from condensing on one bed while the other bed is

www.digitalrefining.com/article/1000328 PTQ Q2 1997 3

Lean acid gas inlet conditions and Base Case results the burner temperature, ensuring

complete combustion of all hydrocar-

bons which might be in the feed, thus

Inlet gas Furnace temp Overall sulphur recovery

Temperature 100°F Data: 1684°F Data: 96.3%

preventing carbon or soot deposition in

Pressure 20psia TSWEET: 1695°F TSWEET 96.3% the catalyst beds.

Composition (mole%) Acid gas + fuel gas WHB outlet Tail gas Case study 2: Lean acid gas feed – H2S

Data Data TSWEET Data TSWEET

Argon 0 0.51 – 0.55 –-

content above 50 per cent

Hydrogen 0 1.22 0.58 1.21 Processing a lean acid gas requires that

0.60

Nitrogen 1.30 42.47 41.99 45.78 special consideration be given to the

44.52

Carbon monoxide 0 0.85 0.84 0.81 0.89

operation of the burner. A Claus

Carbon dioxide 74.41 47.74 49.32 51.20 53.67

Hydrogen sulphide 21.13 3.37 3.38 0.15

furnace feed containing a relatively low

0.10

Carbonyl sulphide 0 1.08 1.10 0.02 concentration (less than 50 per cent) of

0.07

Carbon disulphide 0 0.26 0.25 0.08 H2S may be incapable of producing a

0.01

Sulphur dioxide 0 2.50 2.54 0.20 0.14

stable flame. Also, as discussed previ-

C1+ 3.16 0 0 0 0

ously, incomplete combustion of

Total 100 100 100 100 100 hydrocarbons in the feed can lead to

deterioration of the catalyst in the reac-

tors due to soot or carbon deposition.

Table 3 There are several processes available

to treat lean streams, including some

being regenerated. The gas exiting the third which require only slight modifications to the

condenser is not reheated before entering the conventional Claus plant. The focus of this

cold bed; therefore, the sulphur condenses section is directed at how a certain process

directly onto the catalyst as it is formed. The compensates for low acid gas concentrations

H2S:SO2 ratio is controlled at 2:1 in the same rather than the ability of the process to achieve a

manner as in the conventional Claus. The overall required recovery percentage.

recovery predicted by the simulator for this A comparison of several of these methods

configuration was 99.0 per cent, as shown in follows, including: a four-bed Claus with acid gas

Table 2. If environmental regulations require preheat and fuel gas burner, the all catalytic

greater than 99 per cent recovery of sulphur Selectox process, acid gas bypass around the

species, further processing of the tail gas may be furnace, and oxygen enrichment of the combus-

required. An additional bed with or without tion air feed to the Claus plant.

hydrogenation or a SCOT type tail gas cleanup

unit may be required. Acid gas preheat

In Table 1, we have included expected recover- A four-bed Claus plant with approximately 21

ies for a three-bed Claus with a fourth direct mole% H2S in the feed (Table 3) is used as the

oxidation bed and a three-bed Claus with a base case for the lean acid gas feed discussion.

fourth cold bed. These values represent the opti- In order to achieve a stable flame in the burner,

mum recoveries expected for a plant with feed this plant uses acid gas preheat to 500°F and

conditions as stated in Table 1. For feed streams burning of fuel gas separately using a special

of different compositions, all feasible alternatives burner. TSWEET was used to match plant data,

should be investigated. A process simulator is an and Table 3 provides a comparison of plant data

excellent tool to aid in determining appropriate with TSWEET to provide a basis for the accuracy

design alternatives. of the program’s predictions.

Another option to consider for increasing plant This four-bed plant achieved a 96.3 per cent

capacity or boosting sulphur recovery is the use sulphur recovery with a burner temperature of

of oxygen in a conventional Claus plant. Oxygen 1700°F (94–96 per cent recovery can be expected

enrichment of the air to the combustion chamber for a conventional three-bed Claus unit with lean

can increase capacity of the plant by displacing acid gas feed). The inlet composition and condi-

the amount of inert compounds present in air tions listed in Table 3 are in all of the simulations

such as nitrogen. Oxygen enrichment also raises in this section.

4 PTQ Q2 1997 www.digitalrefining.com/article/1000328

Selectox Lean acid gas feed process comparison

The Selectox process, licensed by UOP,

processes lean acid gas with a catalytic

Process Features Sulphur recovery %

burner which oxidises the H2S to SO2 Feed preheat Acid gas and air preheat 96.3

at a temperature of about 700°F. Two Addition of fuel gas to a

versions are available, the “Straight separate burner

Through Selectox” and the ”Recycle Burner temperature 1700°F

4 Claus beds

Selectox”.

The straight through process is typi- Recycle Selectox Burner replaced by 700°F 96.3

cally used for acid gas streams catalyst bed

containing a maximum of 5 mole% Recycle gas controls

Selectox bed temperature

H2S. The Recycle Selectox is normally 2 Claus beds

used for acid gas streams containing

5–40 mole% H2S but can be utilised Acid gas bypass Burner temperature = 1828°F 96.2

effectively on streams of 65–70 mole% 55% Acid gas bypassed

2 Claus beds

H2S. The Recycle Selectox process is

used for this case since the feed Acid gas bypass with Burner temperature = 1865°F 96.4

contains 21 per cent H2S. oxygen enrichment 50% Acid gas bypassed

The Recycle Selectox is an all-cata- 30% O2 to the burner

2 Claus beds

lytic process meaning there are no

flames at any point in the process. A Acid gas bypass with Burner temperature = 1840°F 96.6

special catalyst bed replaces the acid oxygen enrichment 35% Acid gas bypassed

gas burner in a conventional Claus 100% O2 to the burner

2 Claus beds

plant. The Selectox catalyst occupies

the top few inches of the first bed,

where it promotes the selective oxida- Table 4

tion of H2S to SO2. The remainder of

the bed is filled with Claus catalyst where the burn the entire stream, resulting in an increased

Claus reaction occurs to about 80 per cent flame temperature. Ideally, a flame temperature

completion. The highly exothermic nature of in the range of 1850–2200°F should be

these reactions requires that the feed gas be maintained.

monitored for the concentration of H2S to avoid One consequence of bypassing gas around the

overheating. The Recycle Selectox process uses burner is that any hydrocarbons in the bypassed

a recycle blower to dilute the inlet H2S concen- gas are not combusted, which may lead to prob-

tration to less than 5 vol% by recycling a portion lems in the downstream catalyst beds. Another

of the effluent gases from the Selectox consequence is lower Claus thermal conversion

condenser (Figure 1). This recycle of mainly due to a decrease in furnace residence time and

inert gases limits the outlet temperature of the lower waste heat boiler entrance temperature. At

catalyst bed to a temperature of approximately temperatures below 1200°F, H2S and SO2 will

700°F. The Selectox bed is followed by two not react to form elemental sulphur without a

conventional Claus beds. The simulator predicts suitable catalyst. The sulphur recovery predicted

96.3 per cent sulphur recovery for the Recycle by simulation for this system was 96.2 per cent

Selectox case. (Table 4).

Acid gas bypass Oxygen enrichment

Another way of attacking the problem of insuffi- Increasing the concentration of oxygen in the

cient combustibles in a lean acid gas feed is combustion air to the burner is another option

through bypassing a portion of the feed around to aid in flame stability. The amount of bypass

the furnace. The bypassed gas is mixed with the gas may be reduced by enriching the air with

burner effluent prior to the waste heat boiler. oxygen, as shown in Table 4.

The amount of oxygen fed to the burner is the As discussed previously, other benefits of

same as the amount that would be required to oxygen-enhanced combustion air in both rich

www.digitalrefining.com/article/1000328 PTQ Q2 1997 5

and lean acid gas feed cases include increased Conclusion

plant capacity and sulphur recovery, increased The basic three-bed Claus process can be used

SCOT tail gas cleanup efficiency, and burner for rich acid gas feeds, but current emission

temperatures high enough to prevent carbon or regulations requiring 99+ per cent sulphur

soot formation and resultant poisoning of cata- recovery necessitate a modification to the tradi-

lyst beds. tional Claus process or the addition of a

secondary tail gas cleanup process. This could

Case study 3: Acid gas containing ammonia mean using a cold bed or a direct oxidation bed

Ammonia in the Claus plant feed can usually be as the final bed.

traced to an upstream sour water stripper. The Another type of tail gas cleanup process such

ammonia must be destroyed in the Claus burner as SCOT could be used with a basic three-bed

to avoid deposition of ammonium salts in down- Claus to achieve elevated recoveries.

stream catalyst beds. Most process modifications Lean acid gas feeds require a modification to

designed to destroy ammonia include oxygen the operation of the burner to produce tempera-

enrichment and/or the use of a specialised tures high enough to promote stable combustion.

burner. Other methods such as a catalytic “burner” may

Several examples of process modifications be used in place of the traditional burner in

involving the burner which can be used to some instances.

destroy ammonia are Cope, OxyClaus, and Processing feeds containing ammonia usually

Comprimo. These methods are discussed briefly, requires a higher burner flame temperature to

but comparative simulation results are not destroy the NH3 and avoid ammonium salt depo-

included. sition on the catalyst beds. Either oxygen

The Cope process achieves an elevated burner enrichment and/or a special burner are the usual

temperature with oxygen-enhanced feed. The choices for handling this problem. In all cases

burner temperature is limited to 2700°F and is involving ammonia, the burner is the key to solv-

moderated by a stream of recycle gas originating ing the problem, and much thought should be

as the effluent from the first sulphur condenser given to the burner design to ensure proper

(Figure 1). ammonia destruction.

Up to 100 per cent oxygen may be fed to the To achieve the optimum Claus process design

special burner, which handles acid gas, recycle for any feed composition, all suitable processes

gas, air and oxygen simultaneously. Other simi- should be fully explored with a process simulator

lar processes use SO2 or other streams as the before making design decisions.

quench instead of the recycle stream.

The OxyClaus process requires no recycle gas,

and 80–90 per cent O2 may be fed to the special Gavin D McIntyre is a senior sales engineer with Bryan Research

burner, or it may operate with air only. The & Engineering Inc, Bryan, Texas, and is responsible for promotion

burner may bypass part of the amine acid gas and expansion of the company’s business in the US and Canadian

while burning all of the sour water stripper acid markets. He holds a degree in chemical engineering from Texas

A&M University.

gas. This front/side split system is not usually

Lili G Lyddon has been senior technical support engineer for

required for streams containing less than 5 per

Bryan Research & Engineering for the past five years. She holds a

cent NH3. The Comprimo process is similar to degree in chemical engineering from Texas A&M University.

the OxyClaus in that it requires no recycle gas

to moderate burner temperature. All gas is fed

to the special burner which mixes acid gas, air Links

and oxygen, if desired, so that no front/side

split of the acid gas is required. The typical More articles from: Bryan Research & Engineering

burner temperature range is 2200–2350°F, More articles from the following categories:

which is lower than the Cope burner Design, Engineering & Construction

temperature. Desulphurisation & Sulphur Handling

It should be noted that ammonia can be fed to Process Modelling & Simulation

a conventional Claus plant if the burner temper-

ature remains at 2700°F.

6 PTQ Q2 1997 www.digitalrefining.com/article/1000328

You might also like

- Process Insight:: Selecting The Best Solvent For Gas TreatingDocument1 pageProcess Insight:: Selecting The Best Solvent For Gas Treatingghasem_726990287100% (1)

- UOP Integration of Membranes For CO2 Removal Tech Paper PDFDocument15 pagesUOP Integration of Membranes For CO2 Removal Tech Paper PDFghasem_726990287No ratings yet

- Attachment No.2 CECA Technical Proposal Unit 104ADocument2 pagesAttachment No.2 CECA Technical Proposal Unit 104Aghasem_726990287No ratings yet

- Innovene Pe ProductsDocument25 pagesInnovene Pe Productsghasem_726990287No ratings yet

- Claus Sulphur Recovery OptionsDocument8 pagesClaus Sulphur Recovery Optionsabhisekju2003No ratings yet

- Re-Evaluate Recycling Options For The Claus UnitDocument5 pagesRe-Evaluate Recycling Options For The Claus Unitbakhtiari_afNo ratings yet

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDocument9 pagesDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861100% (1)

- Hermes Claus ProcessDocument3 pagesHermes Claus ProcessShyam YadavNo ratings yet

- Report On Sulphur RecoveryDocument9 pagesReport On Sulphur Recoveryvidit SinghNo ratings yet

- Sulfur Costs Vary With Process SelectionDocument5 pagesSulfur Costs Vary With Process Selectionbakhtiari_afNo ratings yet

- Optimisation of SRUDocument12 pagesOptimisation of SRUHuzefaFDNo ratings yet

- SRU ExplainedDocument5 pagesSRU ExplainedRitu VarshneyNo ratings yet

- Advancements in Sulfur Recovery ProcessesDocument21 pagesAdvancements in Sulfur Recovery Processesprateek kumarNo ratings yet

- Ortloff - Amoco Cold Bed Sulfur AdsorptionDocument3 pagesOrtloff - Amoco Cold Bed Sulfur Adsorptionrieza_fNo ratings yet

- Designing Aselective MDEA Tail-Gas Treating UnitDocument5 pagesDesigning Aselective MDEA Tail-Gas Treating UnitbehnamhfNo ratings yet

- Hydrogen Production by Steam ReformingDocument12 pagesHydrogen Production by Steam ReformingDeepak DubeyNo ratings yet

- Low Quality Natural Gas Sulfur Removal and Recovery CNG Claus Sulfur Recovery Process Pilot Plant Test ProgramDocument32 pagesLow Quality Natural Gas Sulfur Removal and Recovery CNG Claus Sulfur Recovery Process Pilot Plant Test ProgramCHARAN AjmeeraNo ratings yet

- Process Analytics in ClausDocument9 pagesProcess Analytics in ClausMorteza SepehranNo ratings yet

- 39 - 4 - Washington DC - 08-94 - 1131Document5 pages39 - 4 - Washington DC - 08-94 - 1131DHe Vic'zNo ratings yet

- High-Temperature Operation of Hydrodesulfurization Catalyst: J. Richardson and R. DruckerDocument10 pagesHigh-Temperature Operation of Hydrodesulfurization Catalyst: J. Richardson and R. Druckervaratharajan g r100% (1)

- fb030 en COMDocument12 pagesfb030 en COMFaraj AlferjaniNo ratings yet

- Article 1000346 PDFDocument4 pagesArticle 1000346 PDFAnonymous 2p6UltflNo ratings yet

- Eliminating The Claus FurnaceDocument9 pagesEliminating The Claus Furnaceoujda1977No ratings yet

- Large-Scale Sulfur Recovery: AS RocessingDocument3 pagesLarge-Scale Sulfur Recovery: AS RocessingMorteza SepehranNo ratings yet

- HYSYS Training Project 1668937366Document72 pagesHYSYS Training Project 1668937366Sourabha DehadraiNo ratings yet

- Sulphur Recovery Units (SRU) - Conversion ReactorsDocument22 pagesSulphur Recovery Units (SRU) - Conversion ReactorsIffatNo ratings yet

- United States Patent (10) Patent No.: US 8,118,895 B1Document4 pagesUnited States Patent (10) Patent No.: US 8,118,895 B1Heny IsmawatiNo ratings yet

- An Investigation of Reaction Furnace Temperatures and Sulfur RecoveryDocument10 pagesAn Investigation of Reaction Furnace Temperatures and Sulfur RecoveryIffatNo ratings yet

- FTDocument29 pagesFTNitin HansaliaNo ratings yet

- 49 1 Anaheim 03-04 0837Document2 pages49 1 Anaheim 03-04 0837castelo_grandeNo ratings yet

- Morin 1993Document41 pagesMorin 1993muhammad fattah RomdhoniNo ratings yet

- Hydrogen Production by Steam Reforming of HC by TopsoeDocument2 pagesHydrogen Production by Steam Reforming of HC by TopsoeMainak Sarkar100% (1)

- Work PlanDocument1 pageWork PlanrexxmanuNo ratings yet

- Contactor Vol - 12 No - 1 (Sulphur Condenser Turndown)Document2 pagesContactor Vol - 12 No - 1 (Sulphur Condenser Turndown)sepideh asadiNo ratings yet

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Document5 pagesSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957No ratings yet

- Pet Coke PDFDocument6 pagesPet Coke PDFMutyala Satya Vara Prasad100% (1)

- Section 3 Process Description: OM/6000 Rev.1 3/1 September 1997Document30 pagesSection 3 Process Description: OM/6000 Rev.1 3/1 September 1997Kinger Bin KingeeNo ratings yet

- Lecture-10-Clous and Merox ProcessesDocument43 pagesLecture-10-Clous and Merox ProcessesAnilKumar100% (2)

- Fine Tuning A CFBC Boiler PDFDocument12 pagesFine Tuning A CFBC Boiler PDFrikumohanNo ratings yet

- Claus ProcessDocument6 pagesClaus ProcessRafi AlgawiNo ratings yet

- Petroleum Coke Utilization For Cement Kiln FiringDocument8 pagesPetroleum Coke Utilization For Cement Kiln FiringSyeed SofieNo ratings yet

- Sulfur Magazine Ideas For Better Clean Up Jan 09Document0 pagesSulfur Magazine Ideas For Better Clean Up Jan 09Bharat VaajNo ratings yet

- Economic Effects Condenser Backpressure Heat Rate Condensate Subcooling and Feedwater Dissolved OxygDocument9 pagesEconomic Effects Condenser Backpressure Heat Rate Condensate Subcooling and Feedwater Dissolved Oxygsekhar_ntpcNo ratings yet

- Claus Process: From Wikipedia, The Free EncyclopediaDocument5 pagesClaus Process: From Wikipedia, The Free EncyclopediaAshish SutariyaNo ratings yet

- AmmoniaDocument9 pagesAmmoniaAditya Anugerah Putra100% (1)

- Sulfur and Hydrogen Sulfide RecoveryDocument27 pagesSulfur and Hydrogen Sulfide RecoveryChemical.AliNo ratings yet

- Journal of Industrial and Engineering Chemistry: Nader Javanmardi Nabikandi, Shohreh FatemiDocument14 pagesJournal of Industrial and Engineering Chemistry: Nader Javanmardi Nabikandi, Shohreh FatemiiffatNo ratings yet

- COS-Forming Reaction Between CO and Sulfur: A High-Temperature Intrinsic Kinetics StudyDocument8 pagesCOS-Forming Reaction Between CO and Sulfur: A High-Temperature Intrinsic Kinetics StudyMos-ta-fa Man-GalNo ratings yet

- Ammonia The Next StepDocument11 pagesAmmonia The Next StepmuralleroNo ratings yet

- Agroni KokbidoniDocument14 pagesAgroni KokbidoniVisi GjNo ratings yet

- Enhancing Srus With Oxygen-Enriched AirDocument5 pagesEnhancing Srus With Oxygen-Enriched AirIsraelo PueblaNo ratings yet

- Coal P PDocument9 pagesCoal P Papi-19667371No ratings yet

- Solvents Used For Co2 AbsorptionDocument23 pagesSolvents Used For Co2 AbsorptionSanjeev KumarNo ratings yet

- Features Shown in HYSYS Sulsim Example FilesDocument6 pagesFeatures Shown in HYSYS Sulsim Example FilessugaremilioNo ratings yet

- Production of Synthesis GasDocument18 pagesProduction of Synthesis GasGonzalo TitoNo ratings yet

- US2960514Document4 pagesUS2960514PRASSAN SHAHNo ratings yet

- Refinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS SimulationDocument58 pagesRefinery Amine, Sour Water & Sulphur Recovery Unit (SRU) HYSYS Simulationyou kackNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Conventional and Alternative Power Generation: Thermodynamics, Mitigation and SustainabilityFrom EverandConventional and Alternative Power Generation: Thermodynamics, Mitigation and SustainabilityNo ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Mitigating Coke Formation Hydrocarbon Engineering July2014 PDFDocument3 pagesMitigating Coke Formation Hydrocarbon Engineering July2014 PDFghasem_726990287No ratings yet

- Intermediate Pressure: 8 - Temperature Total Compressor PowerDocument1 pageIntermediate Pressure: 8 - Temperature Total Compressor Powerghasem_726990287No ratings yet

- Flare Safe PDFDocument19 pagesFlare Safe PDFghasem_7269902870% (1)

- Coke FormationDocument10 pagesCoke Formationghasem_726990287No ratings yet

- Choosing A Selective Hydrogenation SystemDocument9 pagesChoosing A Selective Hydrogenation Systemghasem_726990287No ratings yet

- Kish Gas Field: General SpecificationsDocument1 pageKish Gas Field: General Specificationsghasem_726990287No ratings yet

- 173772738Document2 pages173772738ghasem_726990287No ratings yet

- Choose The Right Cooling Tower Chemicals - Power EngineeringDocument11 pagesChoose The Right Cooling Tower Chemicals - Power Engineeringghasem_726990287No ratings yet

- Reflux in A Gas Dehydration PlantDocument5 pagesReflux in A Gas Dehydration Plantghasem_726990287No ratings yet

- Power Engineering Jul 1998 102, 7 Proquest CentralDocument5 pagesPower Engineering Jul 1998 102, 7 Proquest Centralghasem_726990287No ratings yet

- Iran Light CrudeDocument1 pageIran Light Crudeghasem_726990287No ratings yet

- The Impact of The Use of International Standards On Projects and Their AssetsDocument25 pagesThe Impact of The Use of International Standards On Projects and Their Assetsghasem_726990287No ratings yet

- Butadiene: Product Data SheetDocument1 pageButadiene: Product Data Sheetghasem_726990287No ratings yet

- Hydrogen Production With PSADocument20 pagesHydrogen Production With PSAghasem_726990287No ratings yet

- Ceca Newsletter April 2012Document1 pageCeca Newsletter April 2012ghasem_726990287No ratings yet

- Axeaxensns P2Document12 pagesAxeaxensns P2ghasem_726990287No ratings yet

- Adhesive Systems Textile Screen PrintingDocument5 pagesAdhesive Systems Textile Screen PrintingrspriyaaNo ratings yet

- SY Bcom SPPU EVS ProjectDocument36 pagesSY Bcom SPPU EVS ProjectniteshNo ratings yet

- Refrigerant R22 - PropertiesDocument6 pagesRefrigerant R22 - PropertiesIndra Pradana0% (1)

- Jurnal PenelitianDocument12 pagesJurnal PenelitianYanto FransiscusNo ratings yet

- Envi ComplaintDocument6 pagesEnvi ComplaintJustin LoredoNo ratings yet

- Air Handling UnitDocument11 pagesAir Handling UnitRoland CepedaNo ratings yet

- Aqua - CELDocument2 pagesAqua - CELfajry_uhNo ratings yet

- Pandora Brilliance CFPDocument28 pagesPandora Brilliance CFPAbdulrahman JradiNo ratings yet

- Leed Canada-Ncv1.0 EqDocument104 pagesLeed Canada-Ncv1.0 EqbethsaidaNo ratings yet

- Solid Waste ManagementDocument6 pagesSolid Waste ManagementJ. ROHININo ratings yet

- Avaliação de Risco USEPA 2009 IIDocument68 pagesAvaliação de Risco USEPA 2009 IINayaraFeitosaNo ratings yet

- EnvironmentDocument14 pagesEnvironmentDiorVelasquezNo ratings yet

- Cat Supplemental Coolant Additive (SCA)Document15 pagesCat Supplemental Coolant Additive (SCA)Maider de la FuenteNo ratings yet

- Cement Industry EIADocument19 pagesCement Industry EIASourav Suman100% (1)

- MSDS Colamate Opa-30Document3 pagesMSDS Colamate Opa-30mndmatt100% (2)

- Using Recycled Waste Tyres in Concrete Paving BlocksDocument1 pageUsing Recycled Waste Tyres in Concrete Paving BlocksTung-Chai LingNo ratings yet

- Environmental Pollution Research Paper PDFDocument6 pagesEnvironmental Pollution Research Paper PDFfvgj0kvd100% (1)

- The Increasing Sustainability of Conventional Energy, Cato Policy Analysis No. 341Document51 pagesThe Increasing Sustainability of Conventional Energy, Cato Policy Analysis No. 341Cato Institute100% (2)

- Safety Data Sheet-Super Yellow-SB155Document6 pagesSafety Data Sheet-Super Yellow-SB155zubair1951No ratings yet

- DJP80 QFNdocumnetof EIAReportDocument285 pagesDJP80 QFNdocumnetof EIAReportvivek1280No ratings yet

- Water Based Inks For Flexographic PrintingDocument7 pagesWater Based Inks For Flexographic PrintingNur Anis HidayahNo ratings yet

- Sequence/Chronological Order & Problem and SolutionDocument11 pagesSequence/Chronological Order & Problem and SolutionMarife Waje0% (1)

- Should The International Community Try and Influence Brazil's Environmental Policies?Document2 pagesShould The International Community Try and Influence Brazil's Environmental Policies?Dombele JoaoNo ratings yet

- Portland Cement: Safety Data SheetDocument11 pagesPortland Cement: Safety Data Sheetanon_381289007No ratings yet

- Burning GenerationDocument4 pagesBurning GenerationEdafeNo ratings yet

- Waste Card SW307 1Document3 pagesWaste Card SW307 1mesess nasir100% (1)

- Green Supply Chains and Reverse Logistics in PeruDocument7 pagesGreen Supply Chains and Reverse Logistics in PeruDiego Arturo GONE RAMOSNo ratings yet

- Environmental Engineering For Civil Engineering StudentsDocument249 pagesEnvironmental Engineering For Civil Engineering StudentsAbebawNo ratings yet

- Bangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistDocument23 pagesBangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistMohammad Shafiqul Islam RoneeNo ratings yet

- 08 07 2016 Tamhini RainfallDocument1 page08 07 2016 Tamhini RainfallVikram DeshmukhNo ratings yet