Professional Documents

Culture Documents

Hobart Maxal 1100

Hobart Maxal 1100

Uploaded by

jclenerCopyright:

Available Formats

You might also like

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyra100% (1)

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Hobart Maxal 5556Document2 pagesHobart Maxal 5556dayseanedNo ratings yet

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- Chroma Weld 309 LT1Document2 pagesChroma Weld 309 LT1Gianfranco CopelloNo ratings yet

- Alia AMF600 Sanitary FlowmeterDocument3 pagesAlia AMF600 Sanitary FlowmeterRexCrazyMindNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- Er 70s2 PDFDocument1 pageEr 70s2 PDFtaravindnagarajNo ratings yet

- Kawat Las Carbon Steel ER 70S-3Document2 pagesKawat Las Carbon Steel ER 70S-3Nyoman RakaNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- WSTSB April 2013Document2 pagesWSTSB April 2013Anas OUDADDANo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Ficha Tecnica ER-316LDocument1 pageFicha Tecnica ER-316LOscar ZavaletaNo ratings yet

- AMF900 V1.2.1.A4.enDocument4 pagesAMF900 V1.2.1.A4.engilangNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- FabCO Excel Arc71Document2 pagesFabCO Excel Arc71Yousab CreatorNo ratings yet

- Ficha Tecnica EXCEL ARC 71 0.062Document2 pagesFicha Tecnica EXCEL ARC 71 0.062gizaloNo ratings yet

- Uniflow Copper Tubes TDSDocument7 pagesUniflow Copper Tubes TDSFilorNo ratings yet

- Quantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Document2 pagesQuantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Gabor VatoNo ratings yet

- Astm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Document1 pageAstm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Federico RevelloNo ratings yet

- HOB FC86R045X33 SpecSheetDocument2 pagesHOB FC86R045X33 SpecSheetJohn AltasNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Document2 pagesHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNo ratings yet

- Innershield Welding GuideDocument11 pagesInnershield Welding GuideAndi Baso Temalala STNo ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- Er70S-2 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-2 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Desiccant Dehumidifier Price List-Conloon-MayDocument2 pagesDesiccant Dehumidifier Price List-Conloon-MaySufiyan KhanNo ratings yet

- AUT 1076 en US FactSheet Main 01Document2 pagesAUT 1076 en US FactSheet Main 01Victor Solis BrevisNo ratings yet

- SuperArc L 50NDocument1 pageSuperArc L 50NH_DEBIANENo ratings yet

- Labfacility LimitedDocument2 pagesLabfacility LimitedliusfelipebNo ratings yet

- ASTM A554 Ek SyfDocument1 pageASTM A554 Ek SyfALİ YİĞİTNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- sl502 EngDocument2 pagessl502 EngArsalan QutbiNo ratings yet

- Delta E8018-B2L Aws A5.5Document1 pageDelta E8018-B2L Aws A5.5Ehab AhmedNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- Fabshield X80Document2 pagesFabshield X80marco hernandezNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- Export Copper Acr Tube Asnzs 1571 Astm b280 Bsen 12735 E67 19 LR RemovedDocument4 pagesExport Copper Acr Tube Asnzs 1571 Astm b280 Bsen 12735 E67 19 LR Removedbinkei.bdxNo ratings yet

- Datasheet Resistencias SMDDocument3 pagesDatasheet Resistencias SMDjeisonpantoja0% (1)

- Filettature Tiranti ASTM-A193Document25 pagesFilettature Tiranti ASTM-A193markoredsNo ratings yet

- Pinnacle ER316L Tig Welding Wire DATA SHEETDocument2 pagesPinnacle ER316L Tig Welding Wire DATA SHEEThsuyan2000No ratings yet

- SCR 1 70 Amperes DatasheetDocument12 pagesSCR 1 70 Amperes DatasheetJose Antonio Guadiana SánchezNo ratings yet

- RBBW Battery Ultrasonic Water Meter - DN15 To 600 - 2016Document6 pagesRBBW Battery Ultrasonic Water Meter - DN15 To 600 - 2016rbflowmeterNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- 1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesDocument2 pages1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 Amperesjsalinas78No ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- L001E HTM Leaflet enDocument8 pagesL001E HTM Leaflet enMohd HassanudinNo ratings yet

- Innershield NS-3M: Welding Positions Conformances Key FeaturesDocument1 pageInnershield NS-3M: Welding Positions Conformances Key FeaturesH_DEBIANENo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- AOX-Q Instruction BookDocument17 pagesAOX-Q Instruction Booktgg44981No ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- AMF900V1 2 3 r1 A4 en PDFDocument4 pagesAMF900V1 2 3 r1 A4 en PDFMohamed OkkaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Datasheet MTS SeriesDocument6 pagesDatasheet MTS SeriesjclenerNo ratings yet

- Holzmann Hbs470profi-230v DatasheetDocument2 pagesHolzmann Hbs470profi-230v DatasheetjclenerNo ratings yet

- HOLZMANN Autumn Promo 2018Document2 pagesHOLZMANN Autumn Promo 2018jclenerNo ratings yet

- Holzmann Combinada 5 OperacionesDocument3 pagesHolzmann Combinada 5 OperacionesjclenerNo ratings yet

- Cat Okuma 2014 EuropaDocument41 pagesCat Okuma 2014 EuropajclenerNo ratings yet

- Work Book Questions ISO - 45001Document61 pagesWork Book Questions ISO - 45001Sadia RahmanNo ratings yet

- Fcaw Welding Guide PDFDocument2 pagesFcaw Welding Guide PDFElizabethNo ratings yet

- Esab Cab 300SDocument2 pagesEsab Cab 300SSadashiva sahooNo ratings yet

- Welding SymbolsDocument49 pagesWelding SymbolsManiNo ratings yet

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Yanbu Industrial College Department of Mechanical Engineering TechnologyDocument6 pagesYanbu Industrial College Department of Mechanical Engineering Technologyumar_farooq1614No ratings yet

- Shielded Metal Arc Welding: What's The Difference Between GMAW, GTAW and Smaw?Document10 pagesShielded Metal Arc Welding: What's The Difference Between GMAW, GTAW and Smaw?Krizzie Jade CailingNo ratings yet

- Bobcat 3 Phase: Quick SpecsDocument4 pagesBobcat 3 Phase: Quick SpecsAnonymous SDeSP1No ratings yet

- Comparision of Three & Four Tandem Wire SystemDocument15 pagesComparision of Three & Four Tandem Wire SystemKumawat PrakashNo ratings yet

- The Role of Shielding GasDocument13 pagesThe Role of Shielding Gasdev-nullNo ratings yet

- RaildogsDocument34 pagesRaildogsJerônimo RafaelNo ratings yet

- Welding For Sour ServiceDocument20 pagesWelding For Sour Serviceأحمد حسن100% (4)

- Company Introduction: Megmeet Welding Technology Co., LTDDocument52 pagesCompany Introduction: Megmeet Welding Technology Co., LTDBhumikaNo ratings yet

- TSH5603G - 8 - P - 1 Arc WeldingDocument14 pagesTSH5603G - 8 - P - 1 Arc Weldinggüray bağdatlı100% (1)

- Duplex ESAB WayDocument8 pagesDuplex ESAB WayTaufikWibowoNo ratings yet

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pages3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarNo ratings yet

- Advance Welding PDFDocument2 pagesAdvance Welding PDFRajeevNo ratings yet

- Welding ReportDocument3 pagesWelding ReportMr-Mk MughalNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Handbook - Weld Defects 1Document1 pageHandbook - Weld Defects 1Danilova SonjaNo ratings yet

- Table J2.1 & J2.2 - Effective Throat of PJP Groove WeldsDocument1 pageTable J2.1 & J2.2 - Effective Throat of PJP Groove WeldsUpadrasta HarishNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- LNG WeldingDocument12 pagesLNG Weldingrodofgod100% (1)

- Aws d1.5 2020 ChangesDocument40 pagesAws d1.5 2020 ChangesA Aquino MinerosNo ratings yet

- SVM116ADocument112 pagesSVM116Ajrga19No ratings yet

- Chapter 4. Welding Welding Safety HazardsDocument52 pagesChapter 4. Welding Welding Safety HazardsKefene GurmessaNo ratings yet

- PRIMO Chemicals CatalogDocument29 pagesPRIMO Chemicals CatalogPrimo Talk100% (1)

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)

Hobart Maxal 1100

Hobart Maxal 1100

Uploaded by

jclenerOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hobart Maxal 1100

Hobart Maxal 1100

Uploaded by

jclenerCopyright:

Available Formats

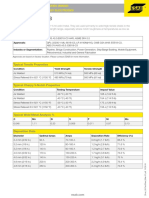

Hobart MAXAL 1100

AWS A5.10: ER1100, R1100 WELDING POSITIONS:

FEATURES: BENEFITS:

• Highest ductility/formability • Excellent corrosion resistance

• Highest electrical and thermal conductivity • Moderate shrinkage rate

• Good hot cracking sensitivity in most applications

• Low welding smut and discoloration

APPLICATIONS:

• Electrical conductors • Piping and tubing for chemicals • Food handling equipment

• Chemical storage tanks • Refrigeration • Heat exchangers

SHIELDING GAS: 100% Argon (Ar) or Argon/Helium mixtures, typical: GMAW - 35-50 cfh (14-24 l/min),

GTAW 20-30 cfh (10-14 l/min).

TYPE OF CURRENT: Direct Current Electrode Positive (DCEP) for GMAW, AC for GTAW

STANDARD DIAMETERS: 0.035” (0.9 mm), 3/64” (1.2 mm), 1/16” (1.6 mm), 3/32” (2.4 mm), 1/8” (3.2 mm)

STORAGE: Product should be stored in a dry, enclosed environment, and in its original intact packaging

TYPICAL CHEMICAL VALUES*:

Weld Metal Analysis (%) ER & R 1100

Silicon (Si) (a)

Iron (Fe) (a)

Copper (Cu) 0.05-0.20

Manganese (Mn) 0.05

Magnesium (Mg) —

Zinc (Zn) 0.10

Titanium (Ti) —

Beryllium (Be) <0.0003

Others Each 0.05

Others Total 0.15

Aluminum (Al) 99.0

(a) Si + Fe shall not exceed 0.95%

NOTE: *Single values are maximums.

TYPICAL PROPERTIES:

Electrical/Thermal As Welded Anodized Elevated Temp.

Melting Range Density Conductivity UTS Typical Color Applications +150°F

1190-1215°F 0.098 lbs/in3 58% IACS/1625 EU 13.5 ksi Yellow YES

*The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and Hobart Brothers Company

expressly disclaims any liability incurred from any reliance thereon. Typical data are those obtained when welded and tested in accordance with AWS

A5.10 specification. Other tests and procedures may produce different results. No data is to be construed as a recommendation for any welding condi-

tion or technique not controlled by Hobart Brothers Company.

Hobart Brothers Company 101 Trade Square East Troy, OH 45373

PH: (800) 424-1543 FX: 800-541-6607 www.hobartbrothers.com

Hobart MAXAL 1100

Base Material Wire-Feed

Diameter Thickness Amps Volts Speed (ipm)

Inches (mm) Inches (mm) 4xxx 5xxx 4xxx 5xxx 4xxx 5xxx

0.030 (0.8) 1/16 (1.6) 90 100 20 18 260 300

0.030 (0.8) 3/32 (2.4) 110 120 22 21 350 400

0.030 (0.8) 1/8 (3.2) 130 140 23 21 450 500

0.030 (0.8) 3/16 (4.8) 150 160 24 22 550 600

0.035 (0.9) 1/16 (1.6) 90 100 23 21 300 350

0.035 (0.9) 1/8 (3.2) 130 140 24 22 400 450

3/64 (1.2) 3/32 (2.4) 110 120 25 24 170 220

3/64 (1.2) 1/8 (3.2) 150 160 26 25 270 330

3/64 (1.2) 1/4 (6.4) 190 220 26 25 320 370

3/64 (1.2) 3/8 (9.5) 220 230 27 25 390 450

1/16 (1.6) 1/4 (6.4) 200 210 26 24 170 200

1/16 (1.6) 3/8 (9.5) 230 240 27 25 200 230

1/16 (1.6) 1/2 (12.7) 260 270 28 26 240 270

1/16 (1.6) 3/4 (19.1) 280 290 29 27 260 300

1/16 (1.6) 1 (25.4) 300 310 30 28 280 320

See Above: This information was determined by welding using 100%Argon shielding gas with a flow rate between

35-50 cfh (14-24 l/min).

AVAILABLE DIAMETERS AND PACKAGES: For a complete list of diameters and packaging, please contact Hobart

Brothers at (800) 424-1543, or (937) 332-5188 for International Customer Service.

Diameter 16-lb. 22-lb. 100-lb. 300-lb. 36-In Cut Length

Inches (mm) Reel Plastic Mini-Drum Drum (10-lb)

0.035 (0.9) 110003512

3/64 (1.2) 110004712 110004723L 110004723

1/16 (1.6) 110006212 110006223L 110006223 110006270

3/32 (2.4) 110009412P22 110009470

1/8 (3.2) 110012570

300 lb drum dimensions: diameter = 23-1/2”; height = 36”

100 lb drum dimensions: diameter = 23-1/2”; height = 18”

CONFORMANCES AND APPROVALS:

• AWS A5.10, ER1100, R1100

• ASME SFA 5.10, ER1100, R1100

• AWS A5.01 Class S1, Schedule F

• CWB

CAUTION:

Consumers should be thoroughly familiar with the safety precautions on the warning label posted in each shipment and in the American National Standard

Z49.1, “Safety in Welding and Cutting,” published by the American Welding Society, 550 NW LeJune Road, Miami, FL 33126; OSHA Safety and Health

Standards 29 CFR 1910 is available from the U.S. Department of Labor, Washington, D.C. 20210

Material Safety Data Sheets on any Hobart Brothers Company product may be obtained from Hobart Customer Service or at www.hobartbrothers.com.

Because Hobart Brothers Company is constantly improving products, Hobart reserves

the right to change design and/or specifications without notice.

Hobart is a registered trademark of Hobart Brothers Company, Troy, Ohio.

Revision Date: 130801 (Replaces 110613)

624-A, INDEX

You might also like

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyra100% (1)

- Hobart Maxal 4943Document2 pagesHobart Maxal 4943brunizzaNo ratings yet

- Hobart Maxal 5556Document2 pagesHobart Maxal 5556dayseanedNo ratings yet

- AMF601NTV1 1 9 A4 en PDFDocument4 pagesAMF601NTV1 1 9 A4 en PDFtruongNo ratings yet

- Chroma Weld 309 LT1Document2 pagesChroma Weld 309 LT1Gianfranco CopelloNo ratings yet

- Alia AMF600 Sanitary FlowmeterDocument3 pagesAlia AMF600 Sanitary FlowmeterRexCrazyMindNo ratings yet

- Quantum Arc 3Document2 pagesQuantum Arc 3nateNo ratings yet

- Er 70s2 PDFDocument1 pageEr 70s2 PDFtaravindnagarajNo ratings yet

- Kawat Las Carbon Steel ER 70S-3Document2 pagesKawat Las Carbon Steel ER 70S-3Nyoman RakaNo ratings yet

- Er70S-6 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-6 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- WSTSB April 2013Document2 pagesWSTSB April 2013Anas OUDADDANo ratings yet

- Er70S-3 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-3 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Ficha Tecnica ER-316LDocument1 pageFicha Tecnica ER-316LOscar ZavaletaNo ratings yet

- AMF900 V1.2.1.A4.enDocument4 pagesAMF900 V1.2.1.A4.engilangNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- Typical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Document20 pagesTypical Mechanical Properties (As Welded) : Do Not Breathe Fumes!Samuel LatumahinaNo ratings yet

- Alia AMF601 Electromagnetic FlowmeterDocument4 pagesAlia AMF601 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- ALIA AMF900 Electromagnetic FlowmeterDocument4 pagesALIA AMF900 Electromagnetic FlowmeterRexCrazyMindNo ratings yet

- FabCO Excel Arc71Document2 pagesFabCO Excel Arc71Yousab CreatorNo ratings yet

- Ficha Tecnica EXCEL ARC 71 0.062Document2 pagesFicha Tecnica EXCEL ARC 71 0.062gizaloNo ratings yet

- Uniflow Copper Tubes TDSDocument7 pagesUniflow Copper Tubes TDSFilorNo ratings yet

- Quantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Document2 pagesQuantum Arc 6: Hobart Brothers LLC 101 Trade Square East Troy, OH 45373Gabor VatoNo ratings yet

- Astm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Document1 pageAstm A270-03 S2 / Asme Bpe and Ui: Not For Production Use (For Reference Only)Federico RevelloNo ratings yet

- HOB FC86R045X33 SpecSheetDocument2 pagesHOB FC86R045X33 SpecSheetJohn AltasNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Document2 pagesHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoNo ratings yet

- Innershield Welding GuideDocument11 pagesInnershield Welding GuideAndi Baso Temalala STNo ratings yet

- Pinnacle Alloys ER2594Document2 pagesPinnacle Alloys ER2594Federico Quintana100% (1)

- Atom Arc 8018: Features Typical Mechanical PropertiesDocument2 pagesAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónNo ratings yet

- Er70S-2 Carbon Steel Welding Wire: Technical Specification SheetDocument2 pagesEr70S-2 Carbon Steel Welding Wire: Technical Specification Sheetrizviabbas2012No ratings yet

- Desiccant Dehumidifier Price List-Conloon-MayDocument2 pagesDesiccant Dehumidifier Price List-Conloon-MaySufiyan KhanNo ratings yet

- AUT 1076 en US FactSheet Main 01Document2 pagesAUT 1076 en US FactSheet Main 01Victor Solis BrevisNo ratings yet

- SuperArc L 50NDocument1 pageSuperArc L 50NH_DEBIANENo ratings yet

- Labfacility LimitedDocument2 pagesLabfacility LimitedliusfelipebNo ratings yet

- ASTM A554 Ek SyfDocument1 pageASTM A554 Ek SyfALİ YİĞİTNo ratings yet

- 410 Welding Wire and RodDocument1 page410 Welding Wire and RodJenderalKancilNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDocument3 pagesDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoNo ratings yet

- sl502 EngDocument2 pagessl502 EngArsalan QutbiNo ratings yet

- Delta E8018-B2L Aws A5.5Document1 pageDelta E8018-B2L Aws A5.5Ehab AhmedNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- Fabshield X80Document2 pagesFabshield X80marco hernandezNo ratings yet

- Unibraze ER316L PDFDocument1 pageUnibraze ER316L PDFsmpoe017No ratings yet

- Export Copper Acr Tube Asnzs 1571 Astm b280 Bsen 12735 E67 19 LR RemovedDocument4 pagesExport Copper Acr Tube Asnzs 1571 Astm b280 Bsen 12735 E67 19 LR Removedbinkei.bdxNo ratings yet

- Datasheet Resistencias SMDDocument3 pagesDatasheet Resistencias SMDjeisonpantoja0% (1)

- Filettature Tiranti ASTM-A193Document25 pagesFilettature Tiranti ASTM-A193markoredsNo ratings yet

- Pinnacle ER316L Tig Welding Wire DATA SHEETDocument2 pagesPinnacle ER316L Tig Welding Wire DATA SHEEThsuyan2000No ratings yet

- SCR 1 70 Amperes DatasheetDocument12 pagesSCR 1 70 Amperes DatasheetJose Antonio Guadiana SánchezNo ratings yet

- RBBW Battery Ultrasonic Water Meter - DN15 To 600 - 2016Document6 pagesRBBW Battery Ultrasonic Water Meter - DN15 To 600 - 2016rbflowmeterNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- 1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesDocument2 pages1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 Amperesjsalinas78No ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- L001E HTM Leaflet enDocument8 pagesL001E HTM Leaflet enMohd HassanudinNo ratings yet

- Innershield NS-3M: Welding Positions Conformances Key FeaturesDocument1 pageInnershield NS-3M: Welding Positions Conformances Key FeaturesH_DEBIANENo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- AOX-Q Instruction BookDocument17 pagesAOX-Q Instruction Booktgg44981No ratings yet

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- AMF900V1 2 3 r1 A4 en PDFDocument4 pagesAMF900V1 2 3 r1 A4 en PDFMohamed OkkaNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Datasheet MTS SeriesDocument6 pagesDatasheet MTS SeriesjclenerNo ratings yet

- Holzmann Hbs470profi-230v DatasheetDocument2 pagesHolzmann Hbs470profi-230v DatasheetjclenerNo ratings yet

- HOLZMANN Autumn Promo 2018Document2 pagesHOLZMANN Autumn Promo 2018jclenerNo ratings yet

- Holzmann Combinada 5 OperacionesDocument3 pagesHolzmann Combinada 5 OperacionesjclenerNo ratings yet

- Cat Okuma 2014 EuropaDocument41 pagesCat Okuma 2014 EuropajclenerNo ratings yet

- Work Book Questions ISO - 45001Document61 pagesWork Book Questions ISO - 45001Sadia RahmanNo ratings yet

- Fcaw Welding Guide PDFDocument2 pagesFcaw Welding Guide PDFElizabethNo ratings yet

- Esab Cab 300SDocument2 pagesEsab Cab 300SSadashiva sahooNo ratings yet

- Welding SymbolsDocument49 pagesWelding SymbolsManiNo ratings yet

- Copper AlloysDocument4 pagesCopper AlloysMuhammed SulfeekNo ratings yet

- Yanbu Industrial College Department of Mechanical Engineering TechnologyDocument6 pagesYanbu Industrial College Department of Mechanical Engineering Technologyumar_farooq1614No ratings yet

- Shielded Metal Arc Welding: What's The Difference Between GMAW, GTAW and Smaw?Document10 pagesShielded Metal Arc Welding: What's The Difference Between GMAW, GTAW and Smaw?Krizzie Jade CailingNo ratings yet

- Bobcat 3 Phase: Quick SpecsDocument4 pagesBobcat 3 Phase: Quick SpecsAnonymous SDeSP1No ratings yet

- Comparision of Three & Four Tandem Wire SystemDocument15 pagesComparision of Three & Four Tandem Wire SystemKumawat PrakashNo ratings yet

- The Role of Shielding GasDocument13 pagesThe Role of Shielding Gasdev-nullNo ratings yet

- RaildogsDocument34 pagesRaildogsJerônimo RafaelNo ratings yet

- Welding For Sour ServiceDocument20 pagesWelding For Sour Serviceأحمد حسن100% (4)

- Company Introduction: Megmeet Welding Technology Co., LTDDocument52 pagesCompany Introduction: Megmeet Welding Technology Co., LTDBhumikaNo ratings yet

- TSH5603G - 8 - P - 1 Arc WeldingDocument14 pagesTSH5603G - 8 - P - 1 Arc Weldinggüray bağdatlı100% (1)

- Duplex ESAB WayDocument8 pagesDuplex ESAB WayTaufikWibowoNo ratings yet

- 3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingDocument96 pages3 Unit 2 - Arc, Gas, Plastic Welding, LBW, EBW and Thermit WeldingAditya KumarNo ratings yet

- Advance Welding PDFDocument2 pagesAdvance Welding PDFRajeevNo ratings yet

- Welding ReportDocument3 pagesWelding ReportMr-Mk MughalNo ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Handbook - Weld Defects 1Document1 pageHandbook - Weld Defects 1Danilova SonjaNo ratings yet

- Table J2.1 & J2.2 - Effective Throat of PJP Groove WeldsDocument1 pageTable J2.1 & J2.2 - Effective Throat of PJP Groove WeldsUpadrasta HarishNo ratings yet

- Duplex SSDocument12 pagesDuplex SSTushar PatilNo ratings yet

- LNG WeldingDocument12 pagesLNG Weldingrodofgod100% (1)

- Aws d1.5 2020 ChangesDocument40 pagesAws d1.5 2020 ChangesA Aquino MinerosNo ratings yet

- SVM116ADocument112 pagesSVM116Ajrga19No ratings yet

- Chapter 4. Welding Welding Safety HazardsDocument52 pagesChapter 4. Welding Welding Safety HazardsKefene GurmessaNo ratings yet

- PRIMO Chemicals CatalogDocument29 pagesPRIMO Chemicals CatalogPrimo Talk100% (1)

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)